High Energy-Efficient Windows with Silica Aerogel for Building Refurbishment: Experimental Characterization and Preliminary Simulations in Different Climate Conditions

Abstract

:1. Introduction

2. Materials and Methods

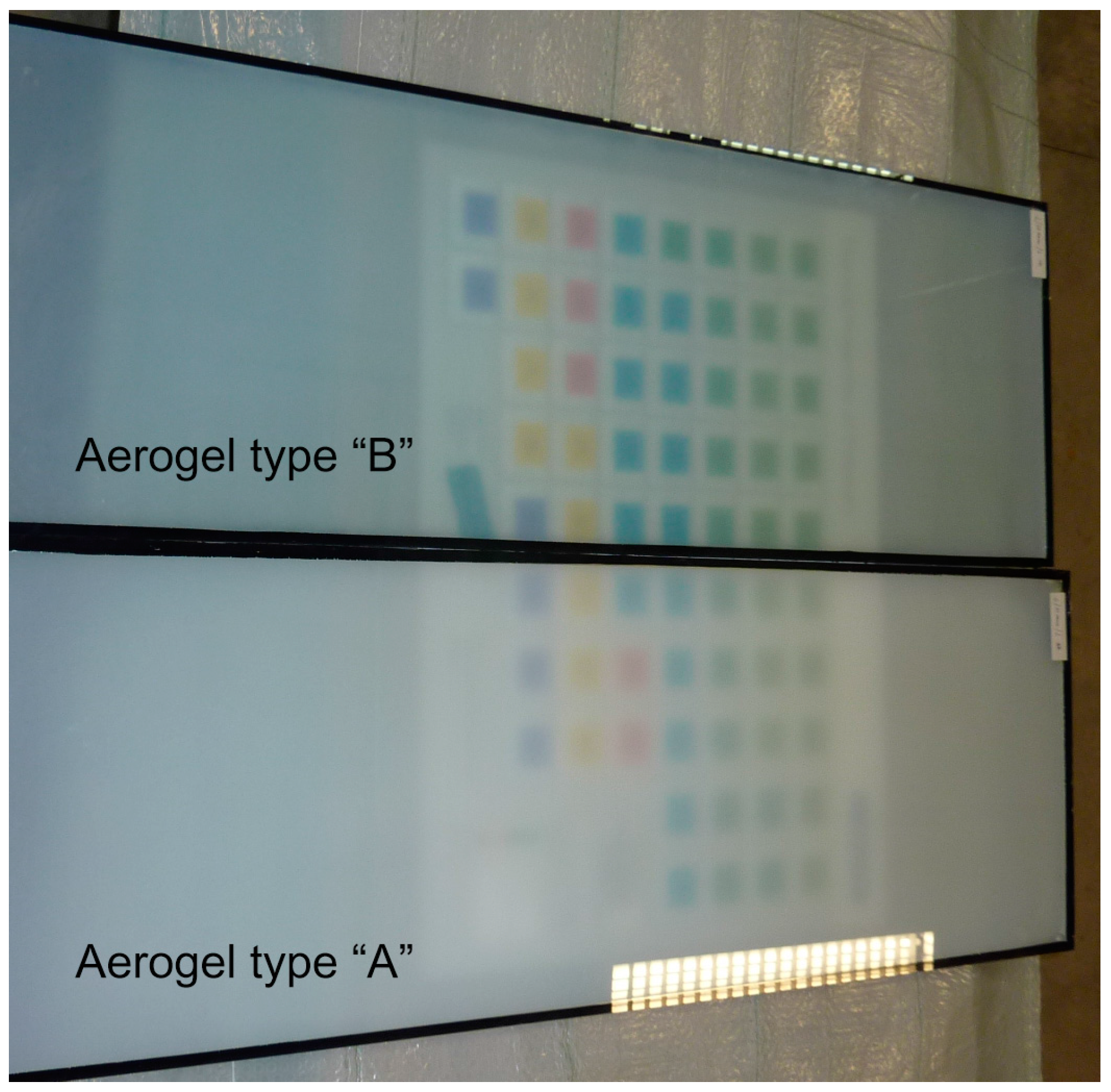

2.1. The Investigated Samples

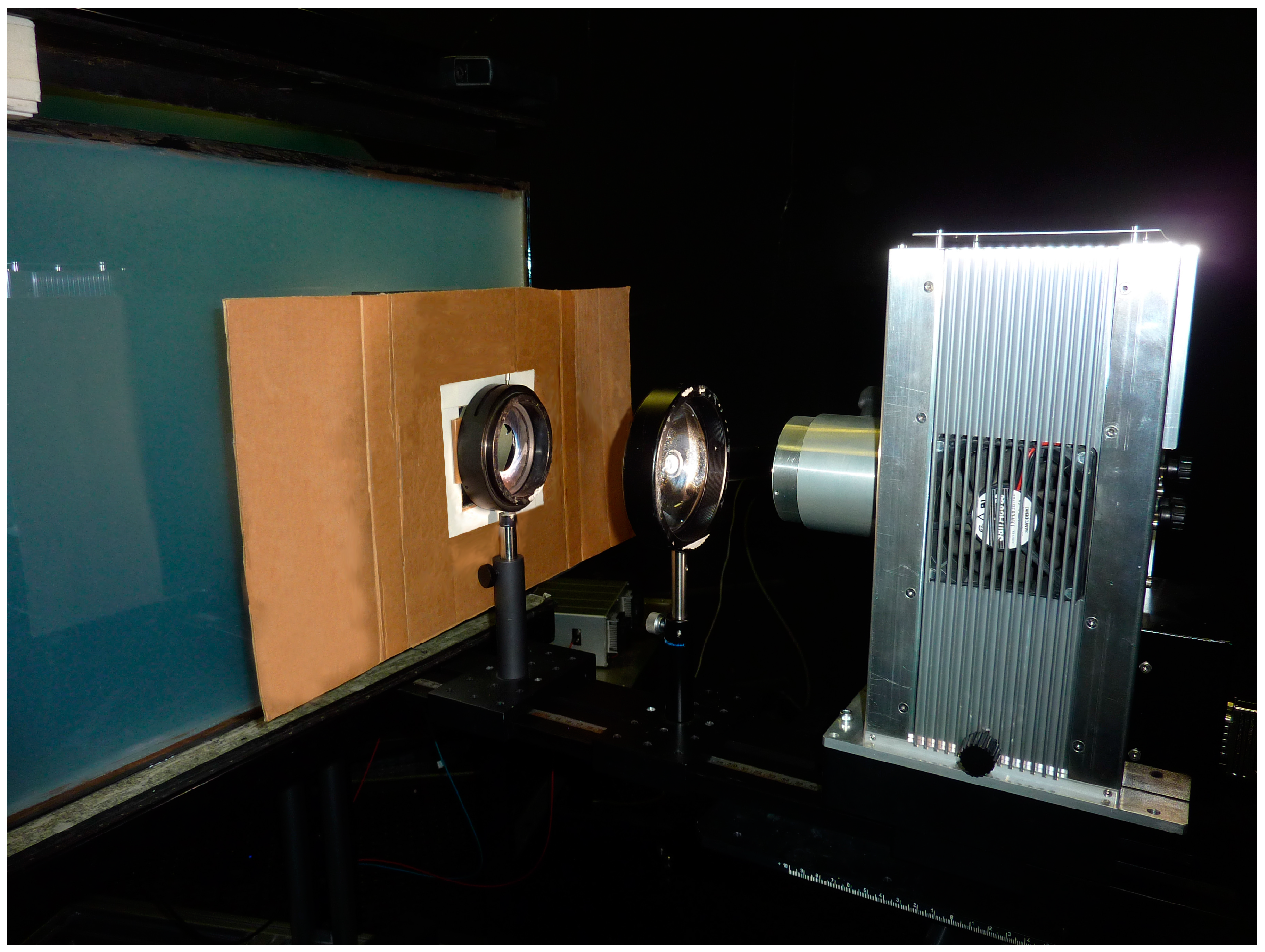

2.2. Experimental Campaign

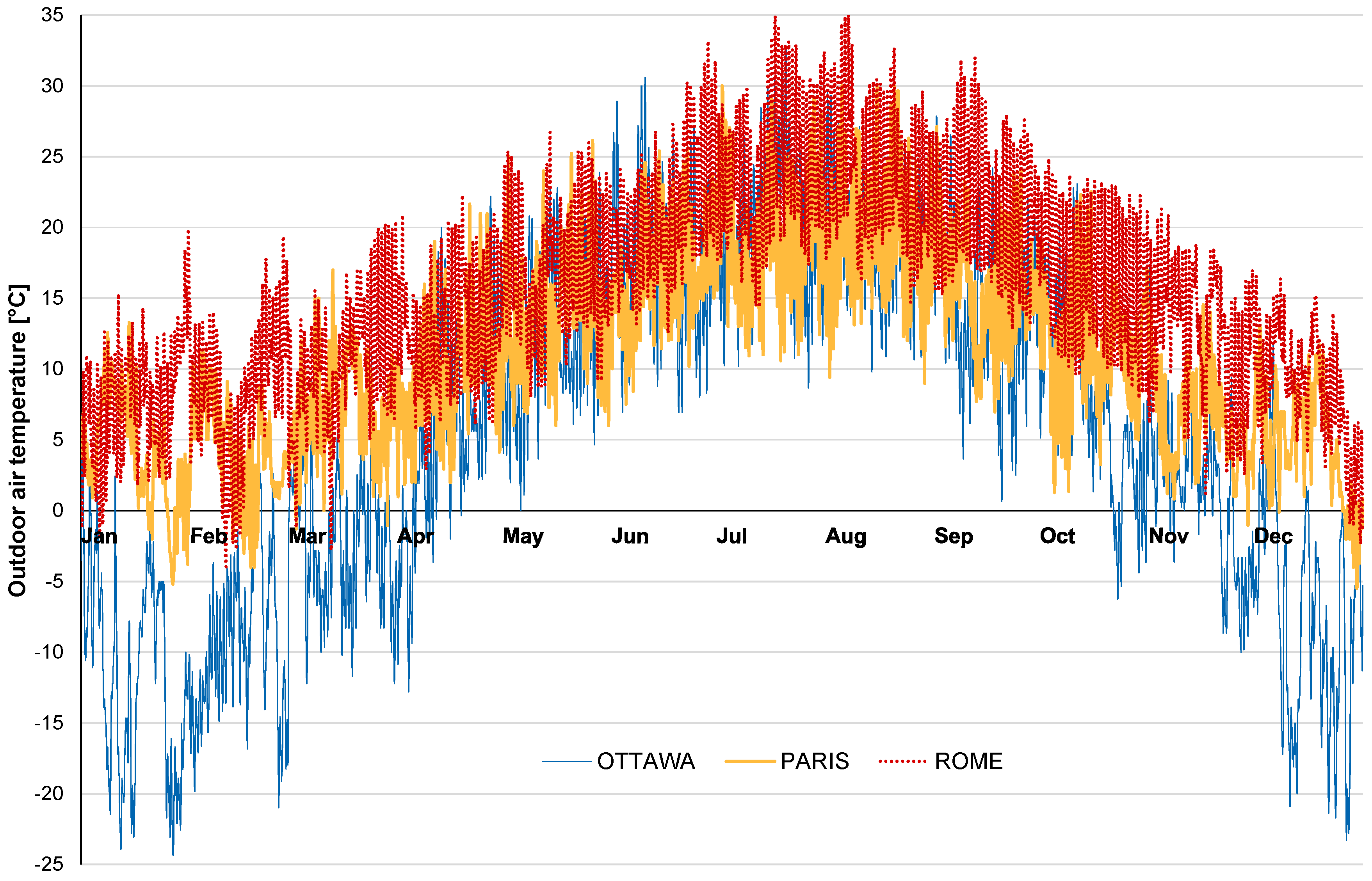

2.3. Simulations

3. Results and Discussion

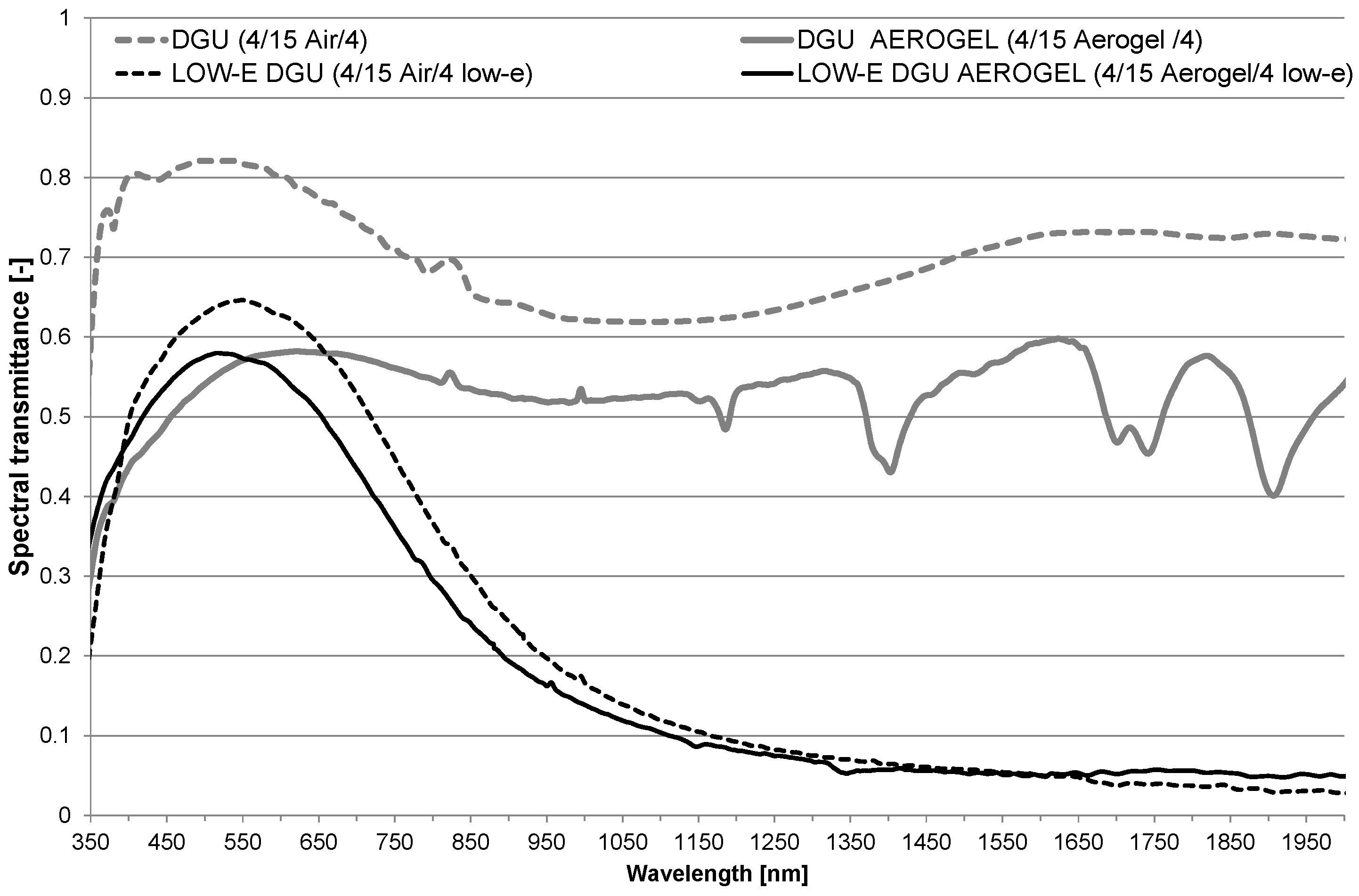

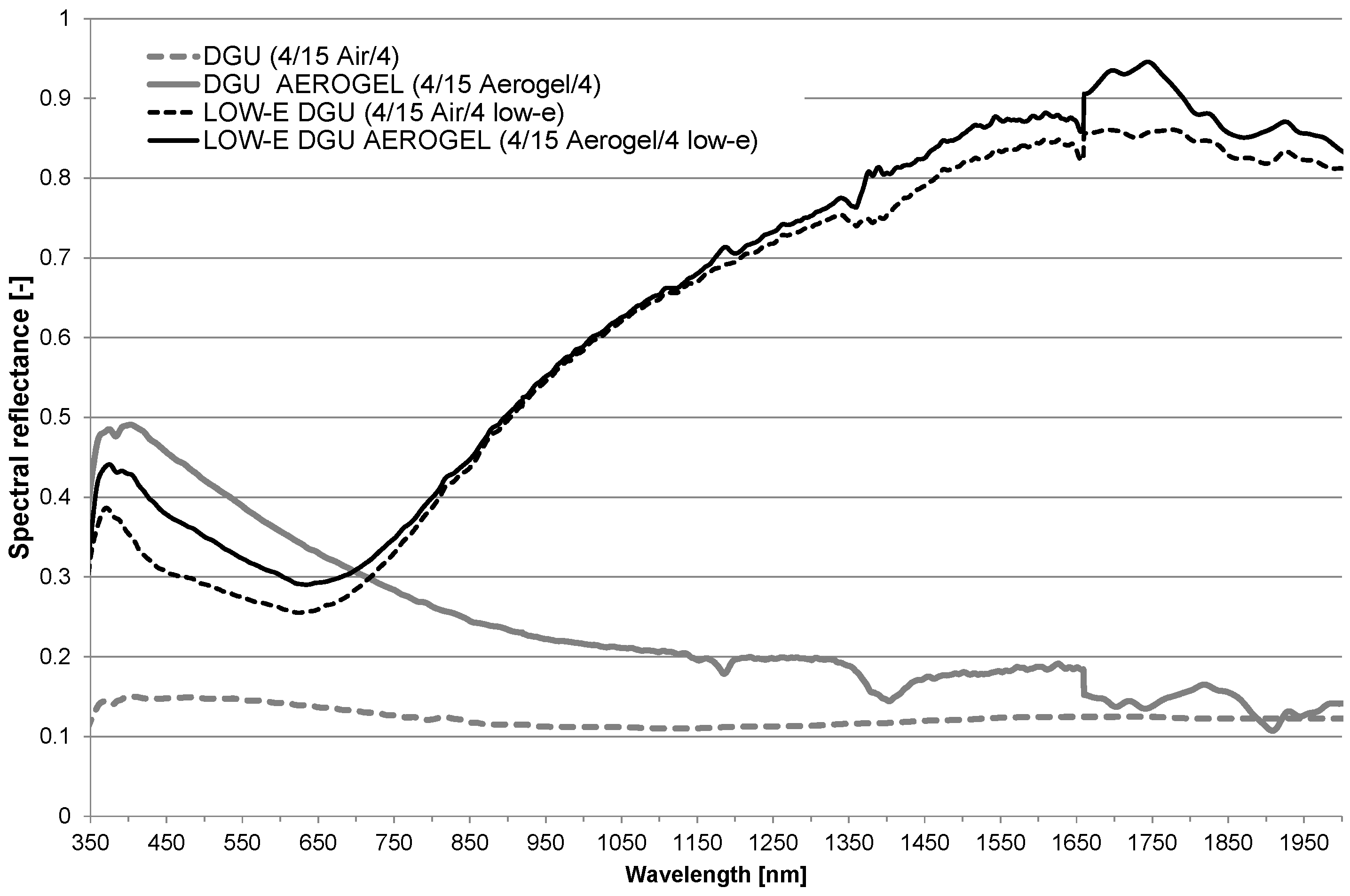

3.1. Optical and Thermal Performance

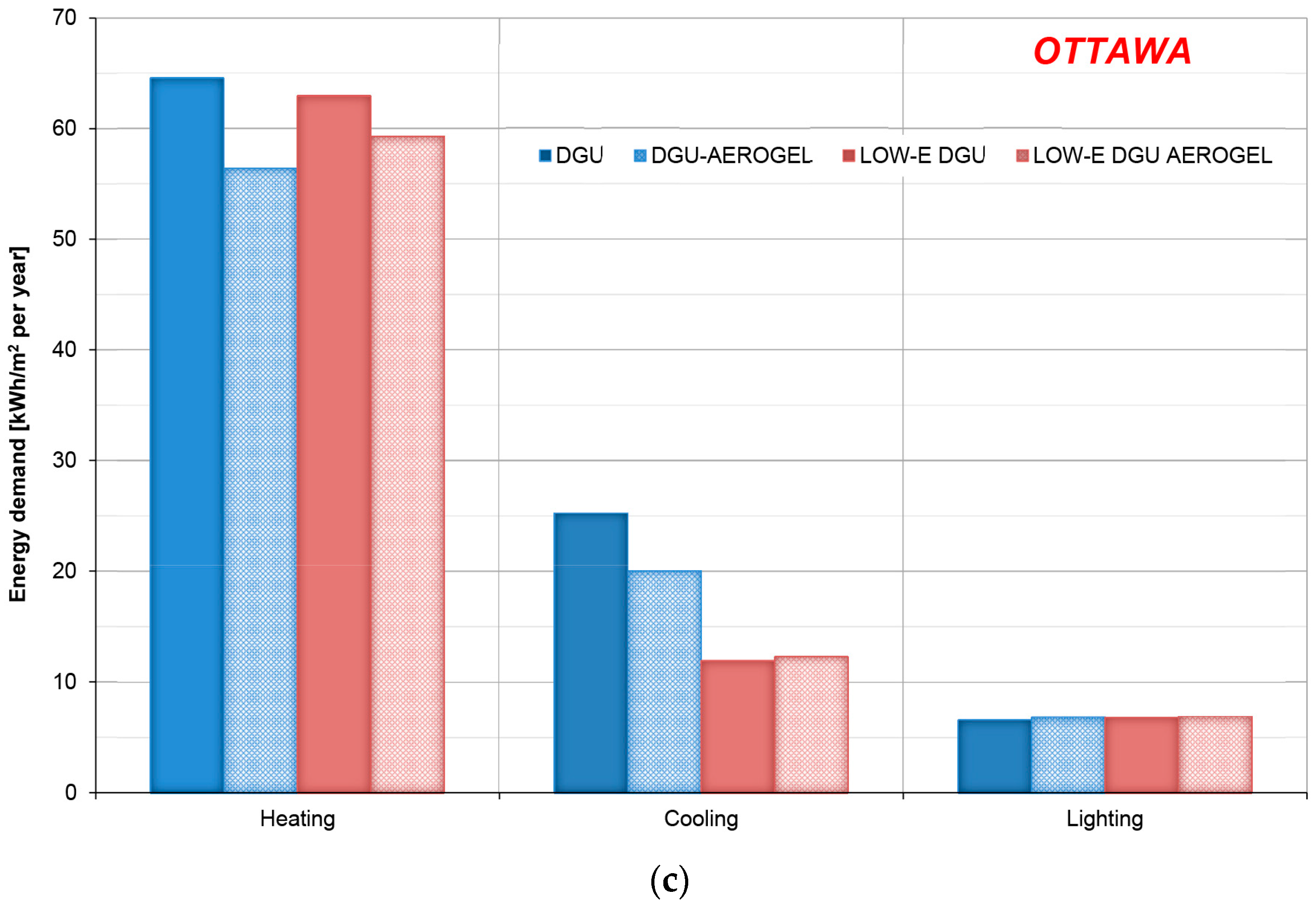

3.2. Energy Performance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jelle, B.P.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cell 2012, 96, 1–28. [Google Scholar] [CrossRef]

- Ihara, T.; Gustavsen, A.; Jelle, B.P. Effect of facade components on energy efficiency in office buildings. Appl. Energy 2015, 158, 422–432. [Google Scholar] [CrossRef]

- Mohammadpourkarbasi, H.; Sharples, S. The Eco-Refurbishment of a 19th Century Terraced House: Energy and Cost Performance for Current and Future UK Climates. Buildings 2013, 3, 220–244. [Google Scholar] [CrossRef]

- Koebel, M.; Rigacci, A.; Achard, P. Aerogel-based thermal superinsulation: An overview. J. Sol-Gel Sci. Technol. 2012, 63, 315–339. [Google Scholar] [CrossRef]

- Cuce, E.; Cuce, P.M.; Wood, C.J.; Riffat, S.B. Toward aerogel based thermal superinsulation in buildings: A comprehensive review. Renew. Sustain. Energy Rev. 2014, 34, 273–299. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Aerogel insulation for building applications: A state-of-the-art review. Energy Build. 2011, 43, 761–769. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E. Silica nanogel for energy-efficient windows. In Nanotechnology in Eco-Efficient Construction; Pacheco Torgal, F., Diamanti, M.V., Nazari, A., Granqvist, C.G., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 207–235. [Google Scholar]

- Buratti, C.; Moretti, E. Nanogel windows. In Nearly Zero Energy Building Refurbishment; Pacheco Torgal, F., Mistretta, M., Kaklauskas, A., Granqvist, C.G., Cabeza, L.F., Eds.; Springer: Londra, UK, 2013; pp. 555–582. [Google Scholar]

- Cotana, F.; Pisello, A.L.; Moretti, E.; Buratti, C. Multipurpose characterization of glazing systems with silica aerogel: In-field experimental analysis of thermal-energy, lighting and acoustic performance. Build. Environ. 2014, 81, 92–102. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E.; Agosti, F. Development of innovative aerogel based plasters: Preliminary thermal and acoustic performance evaluation. Sustainability 2014, 6, 5839–5852. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E. Aerogel plasters for energy building efficiency. In Nano and Biotech Based Materials for Energy Building Efficiency; Pacheco Torgal, F., Buratti, C., Kalaiselvam, S., Granqvist, C.G., Ivanov, V., Eds.; Springer International Publishing AG: Basel, Switzerland, 2016; pp. 17–40. [Google Scholar]

- Berardi, U. The development of a monolithic aerogel glazed window for an energy retrofitting project. Appl. Energy 2015, 154, 603–615. [Google Scholar] [CrossRef]

- Bhuiya, M.M.H.; Anderson, A.M.; Carroll, M.K.; Bruno, B.A.; Ventrella, J.L.; Silberman, B.; Keramati, B. Preparation of Monolithic Silica Aerogel for Fenestration Applications: Scaling up, Reducing Cycle Time, and Improving Performance. Ind. Eng. Chem. Res. 2016, 55, 6971–6981. [Google Scholar] [CrossRef]

- Ihara, T.; Gao, T.; Grynning, S.; Jelle, B.P.; Gustavsen, A. Aerogel granulate glazing facades and their application potential from an energy saving perspective. Appl. Energy 2015, 142, 179–191. [Google Scholar] [CrossRef]

- Gao, T.; Ihara, T.; Grynning, S.; Jelle, B.P.; Gunnarshaug Lien, A. Perspective of aerogel glazings in energy efficient buildings. Build. Environ. 2016, 95, 405–413. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.P.; Ihara, T.; Gustavsen, A. Insulating glazing units with silica aerogel granules: The impact of particle size. Appl. Energy 2014, 128, 27–34. [Google Scholar] [CrossRef]

- Garnier, C.; Muneer, T.; McCauley, L. Super insulated aerogel windows: Impact on daylighting and thermal performance. Build. Environ. 2015, 94, 231–238. [Google Scholar] [CrossRef]

- Moretti, E.; Zinzi, M.; Carnielo, E.; Merli, F. Advanced polycarbonate transparent systems with aerogel: Preliminary characterization of optical and thermal properties. Energy Procedia 2016, in press. [Google Scholar]

- Buratti, C.; Moretti, E. Lighting and energetic characteristics of transparent insulating materials: Experimental data and calculation. Indoor Built Environ. 2011, 20, 400–411. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E. Experimental performance evaluation of aerogel glazing systems. Appl. Energy 2012, 97, 430–437. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E. Glazing systems with silica aerogel for energy savings in buildings. Appl. Energy 2012, 98, 396–403. [Google Scholar] [CrossRef]

- Ihara, T.; Grynning, S.; Gao, T.; Gustavsen, A.; Jelle, B.P. Impact of convection on thermal performance of aerogel granulate glazing systems. Energy Build. 2015, 88, 165–173. [Google Scholar] [CrossRef]

- Moretti, E.; Zinzi, M.; Belloni, E. Polycarbonate panels for buildings: Experimental investigation of thermal and optical performance. Energy Build. 2014, 70, 23–35. [Google Scholar] [CrossRef]

- Maccari, A.; Montecchi, M.; Treppo, F.; Zinzi, M. CATRAM: An apparatus for the optical characterization of advanced transparent materials. Appl. Opt. 1998, 37, 5156–5161. [Google Scholar] [CrossRef] [PubMed]

- CEN. EN 12567-1. Thermal Performance of Windows and Doors. Determination of Thermal Transmittance by the Hot-Box Method. Complete Windows and Doors; International Organization for Standardization (ISO): Geneva, Switzerland, 2010. [Google Scholar]

- Moretti, E.; Belloni, E. Evaluation of energy, thermal, and daylighting performance of solar control films for a case study in moderate climate. Build. Environ. 2015, 94, 183–195. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E.; Cotana, F. Unsteady simulation of energy performance and thermal comfort in non-residential buildings. Build. Environ. 2013, 59, 482–491. [Google Scholar] [CrossRef]

- Mujeebu, M.A.; Ashraf, N.; Alsuwayigh, A. Energy performance and economic viability of nano aerogel glazing and nano vacuum insulation panel in multi-story office building. Energy 2016, 113, 949–956. [Google Scholar] [CrossRef]

- Huang, Y.; Niu, J. Energy and visual performance of the silica aerogel glazing system in commercial buildings of Hong Kong. Constr. Build. Mater. 2015, 94, 57–72. [Google Scholar] [CrossRef]

- EN 410. Glass in Building—Determination of Luminous and Solar Characteristics of Glazing; Europeen Committte for standardization (CEN): Brussels, Belgium, 2011. [Google Scholar]

- Moretti, E.; Merli, F.; Cuce, E.; Buratti, C. Thermal and acoustic properties of aerogels: Preliminary investigation of the influence of granule size. Energy Procedia 2016, in press. [Google Scholar]

- AGC Glass Europe. Available online: http://www.yourglass.com/configurator/tp/it/toolbox/configurator/main.html (accessed on 9 November 2016).

- Huang, Y.; Niu, J. Application of super-insulating translucent silica aerogel glazing system on commercial building envelope of humid subtropical climates: Impact on space cooling load. Energy 2015, 83, 316–325. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E.; Belloni, E. Nanogel windows for energy building efficiency. In Nano and Biotech Based Materials for Energy Building Efficiency; Pacheco Torgal, F., Buratti, C., Kalaiselvam, S., Granqvist, C.G., Ivanov, V., Eds.; Springer International Publishing AG: Basel, Switzerland, 2016; pp. 41–69. [Google Scholar]

| Name | External Layer | Interspace | Internal Layer | Window Frame |

|---|---|---|---|---|

| DGU | Float clear glass (4 mm) | Air (15 mm) | Float clear glass (4 mm) | Type 1 aluminum |

| DGU-AEROGEL | Float clear glass (4 mm) | Granular aerogel type “A” (15 mm) | Float clear glass (4 mm) | |

| LOW-E DGU | Solar control and low-e glass (4 mm) | Air (15 mm) | Float clear glass (4 mm) | Type 2 wood |

| LOW-E DGU-AEROGEL | Solar control and low-e glass (4 mm) | Granular aerogel type “B” (15 mm) | Float clear glass (4 mm) |

| Internal Loads | Values | Schedule | ||

| Lighting | 7 W/m2 (500 lux, fully dimmable) | 8:00–18:00 five days a week | ||

| People | 0.05 persons/m2 | |||

| Equipment | 7 W/m2 | |||

| Operating Periods of Heating and Cooling System and schedule | ||||

| City | Heating (20 °C) | Cooling (26 °C) | Schedule | |

| Rome | 1 November–15 April | 16 April–14 October | 7:00–19:00 five days a week | |

| Paris | 15 October–30 April | 1 May–14 October | ||

| Ottawa | 15 October–30 April | 1 May–14 October | ||

| Acronym | Light Transmittance τv | Light Reflectance ρv | Direct Solar Transmittance τe | Solar Reflectance ρe | Total Solar Transmittance g | U–value (W/m2·K) |

|---|---|---|---|---|---|---|

| DGU | 0.82 | 0.15 | 0.76 | 0.14 | 0.80 | 2.7 |

| DGU-AEROGEL | 0.57 | 0.38 | 0.53 | 0.31 | 0.57 | 1.0 |

| LOW-E DGU | 0.63 | 0.27 | 0.39 | 0.43 | 0.41 | 1.6 |

| LOW-E DGU-AEROGEL | 0.57 | 0.32 | 0.35 | 0.46 | 0.36 | 1.1 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buratti, C.; Moretti, E.; Zinzi, M. High Energy-Efficient Windows with Silica Aerogel for Building Refurbishment: Experimental Characterization and Preliminary Simulations in Different Climate Conditions. Buildings 2017, 7, 8. https://doi.org/10.3390/buildings7010008

Buratti C, Moretti E, Zinzi M. High Energy-Efficient Windows with Silica Aerogel for Building Refurbishment: Experimental Characterization and Preliminary Simulations in Different Climate Conditions. Buildings. 2017; 7(1):8. https://doi.org/10.3390/buildings7010008

Chicago/Turabian StyleBuratti, Cinzia, Elisa Moretti, and Michele Zinzi. 2017. "High Energy-Efficient Windows with Silica Aerogel for Building Refurbishment: Experimental Characterization and Preliminary Simulations in Different Climate Conditions" Buildings 7, no. 1: 8. https://doi.org/10.3390/buildings7010008