A Modified Bio-Ecological Process for Rural Wastewater Treatment

Abstract

:1. Introduction

2. Materials and Methods

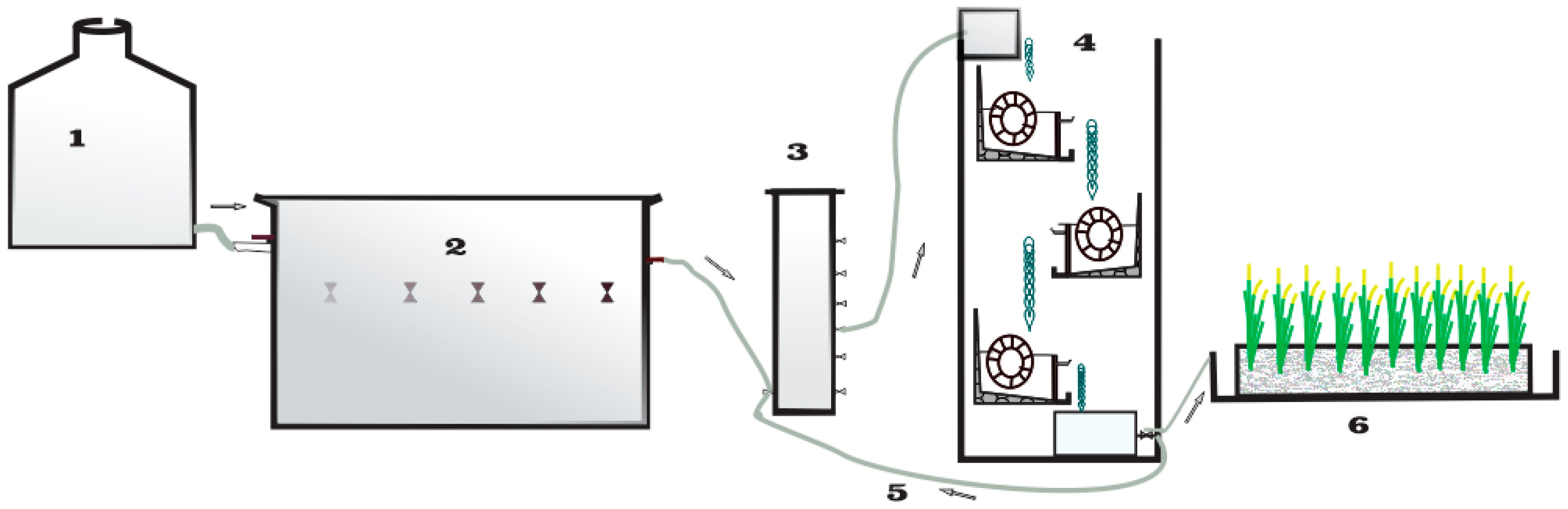

2.1. Reactor Setup

2.1.1. Anaerobic Baffled Reactor

2.1.2. Anoxic Tank

2.1.3. Oxic Unit

2.1.4. Constructed Wetland

2.2. Experimental Procedure

2.3. Sewage Characteristics

2.4. Analytical Methods

2.5. Data Analysis

2.6. Start-Up Conditions

3. Results and Discussion

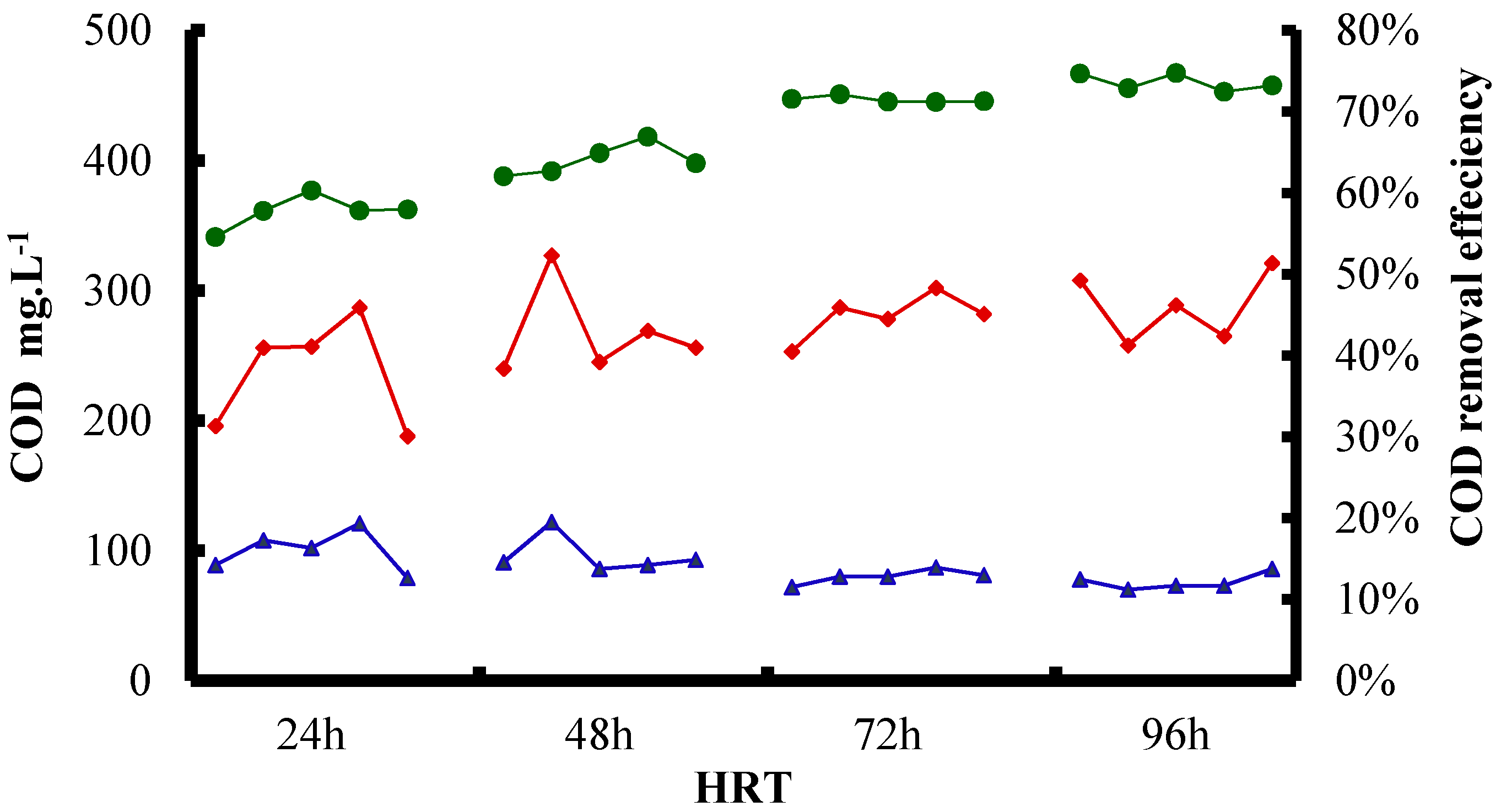

3.1. Performance Evaluation of ABR

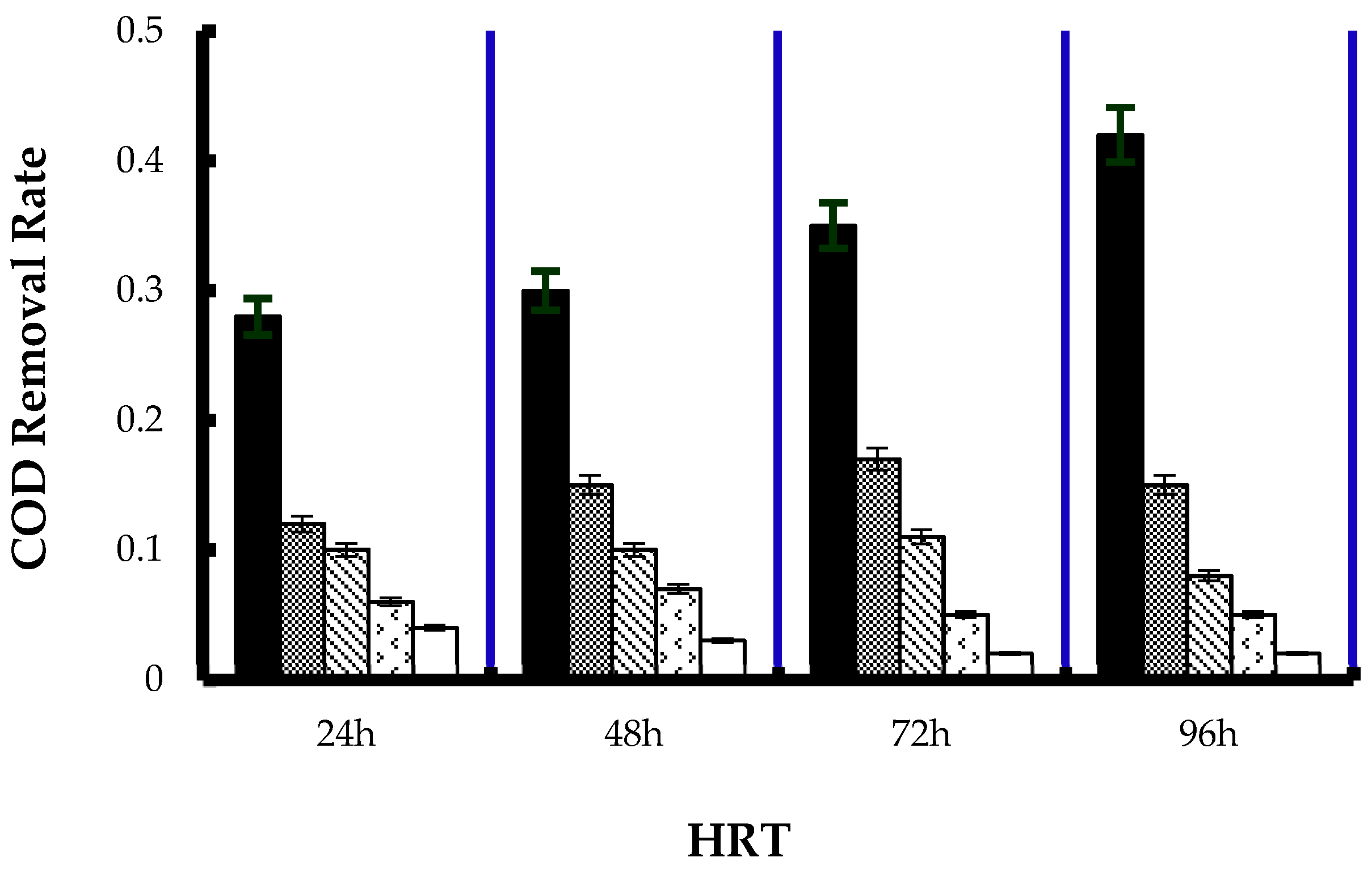

3.2. Optimization of the Anoxic Tank Configuration

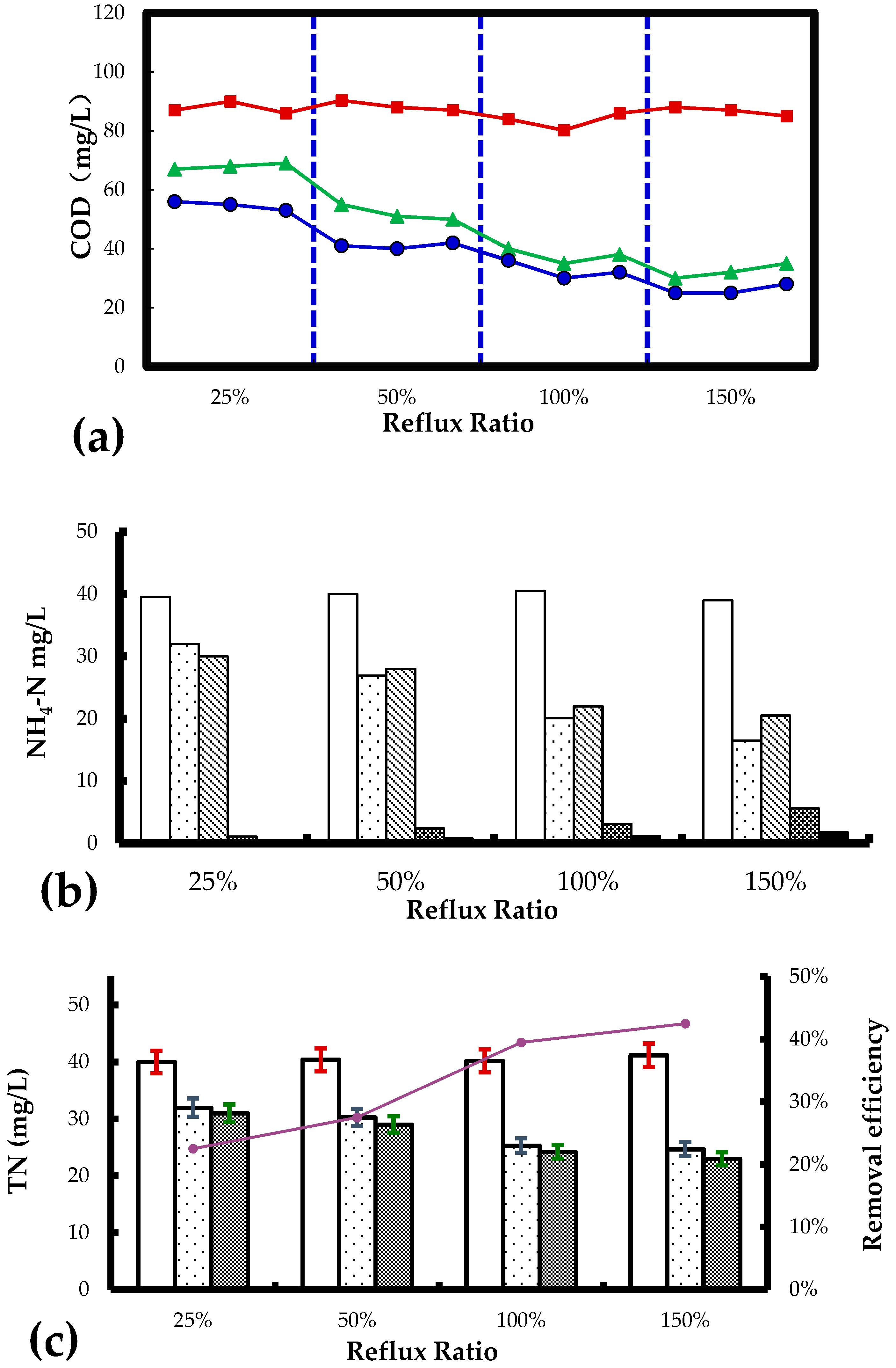

3.3. Overall Reactor Performance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ali, R.; McFarlane, D.; Varma, S.; Dawes, W.; Emelyanova, I.; Hodgson, G.; Charles, S. Potential climate change impacts on groundwater resources of south-western australia. J. Hydrol. 2012, 475, 456–472. [Google Scholar] [CrossRef]

- Flörke, M.; Kynast, E.; Bärlund, I.; Eisner, S.; Wimmer, F.; Alcamo, J. Domestic and industrial water uses of the past 60 years as a mirror of socio-economic development: A global simulation study. Glob. Environ. Chang. 2013, 23, 144–156. [Google Scholar] [CrossRef]

- Powley, H.R.; Dürr, H.H.; Lima, A.T.; Krom, M.D.; Van Cappellen, P. Direct discharges of domestic wastewater are a major source of phosphorus and nitrogen to the mediterranean sea. Environ. Sci. Technol. 2016, 50, 8722–8730. [Google Scholar] [CrossRef] [PubMed]

- Affam, A.C.; Chaudhuri, M.; Kutty, S.R.M.; Muda, K. Combination of FeGAC/H2O2 advanced oxidation process and sequencing batch reactor for treatment pesticide wastewater. Environ. Earth Sci. 2016, 75, 1–9. [Google Scholar] [CrossRef]

- Naidoo, S.; Olaniran, A.O. Treated wastewater effluent as a source of microbial pollution of surface water resources. Int. J. Environ. Res. Public Health 2013, 11, 249–270. [Google Scholar] [CrossRef] [PubMed]

- Gunady, M.; Shishkina, N.; Tan, H.; Rodriguez, C. A review of on-site wastewater treatment systems in western australia from 1997 to 2011. J. Environ. Public Health 2015, 2015, 716957. [Google Scholar] [CrossRef] [PubMed]

- Odjadjare, E.C.; Olaniran, A.O. Prevalence of antimicrobial resistant and virulent Salmonella spp. In treated effluent and receiving aquatic milieu of wastewater treatment plants in durban, south africa. Int. J. Environ. Res. Public Health 2015, 12, 9692–9713. [Google Scholar] [CrossRef] [PubMed]

- Molinos-Senante, M.; Gómez, T.; Garrido-Baserba, M.; Caballero, R.; Sala-Garrido, R. Assessing the sustainability of small wastewater treatment systems: A composite indicator approach. Sci. Total Environ. 2014, 497, 607–617. [Google Scholar] [CrossRef] [PubMed]

- Supply, W.U.J.W.; Programme, S.M.; Organization, W.H. Progress on Drinking Water and Sanitation: 2014 Update; World Health Organization: Geneva, Switzerland, 2014. [Google Scholar]

- Gordon, B.A.; Mackay, R.; Rehfuess, E. Inheriting the World: The Atlas of Children's Health and the Environment; World Health Organization: Geneva, Switzerland, 2004. [Google Scholar]

- Gleick, P.H. Global freshwater resources: Soft-path solutions for the 21st century. Science 2003, 302, 1524–1528. [Google Scholar] [CrossRef] [PubMed]

- Lens, P.; Lens, P.N.; Zeeman, G.; Lettinga, G. Decentralised Sanitation and Reuse: Concepts, Systems and Implementation; IWA Publishing: London, UK, 2001. [Google Scholar]

- Massoud, M.A.; Tarhini, A.; Nasr, J.A. Decentralized approaches to wastewater treatment and management: Applicability in developing countries. J. Environ. Manag. 2009, 90, 652–659. [Google Scholar] [CrossRef] [PubMed]

- Maurer, M.; Rothenberger, D.; Larsen, T. Decentralised wastewater treatment technologies from a national perspective: At what cost are they competitive? Water Science Technol. Water Supply 2005, 5, 145–154. [Google Scholar]

- Li, W.-S.; Wang, H.-Y.; Pan, S.-J. Present status on decentralized domestic sewage in rural areas of china and its treatment technology. Tianjin Agric. Sci. 2008, 6, 025. [Google Scholar]

- Li, H.; Zhou, B.; Tian, Z.; Song, Y.; Xiang, L.; Wang, S.; Sun, C. Efficient biological nitrogen removal by johannesburg-sulfur autotrophic denitrification from low COD/TN ratio municipal wastewater at low temperature. Environ. Earth Sci. 2015, 73, 5027–5035. [Google Scholar] [CrossRef]

- Rabalais, N.N. Nitrogen in aquatic ecosystems. AMBIO: J. Hum. Environ. 2002, 31, 102–112. [Google Scholar] [CrossRef]

- Wu, Y.; Zhu, W.; Lu, X. Identifying key parameters in a novel multistep bio-ecological wastewater treatment process for rural areas. Ecol. Eng. 2013, 61, 166–173. [Google Scholar] [CrossRef]

- Chen, Y.; Peng, C.; Wang, J.; Ye, L.; Zhang, L.; Peng, Y. Effect of nitrate recycling ratio on simultaneous biological nutrient removal in a novel anaerobic/anoxic/oxic (A2/O)-biological aerated filter (BAF) system. Bioresour. Technol. 2011, 102, 5722–5727. [Google Scholar] [CrossRef] [PubMed]

- Abualhai, S.; Naseer, R.; Xiwu, L. Biological nutrient removal using a novel five-step continuous flow activated sludge process technology. Environ. Prot. Eng. 2013, 39, 165–184. [Google Scholar]

- Zhou, Q.; He, S.; He, X.; Huang, X.; Picot, B.; Li, X.; Chen, G. Nutrients removal mechanisms in high rate algal pond treating rural domestic sewage in east china. Water Sci. Technol. Water Supply 2006, 6, 43–50. [Google Scholar] [CrossRef]

- Haruta, S.; Sakurai, Y. Reclaimed wastewater quality in combined household wastewater treatment facilities for individual houses in rural area. J. Rural Plan. 2007, 12, 215–220. [Google Scholar] [CrossRef]

- Molinos-Senante, M.; Gómez, T.; Caballero, R.; Hernández-Sancho, F.; Sala-Garrido, R. Assessment of wastewater treatment alternatives for small communities: An analytic network process approach. Sci. Total Environ. 2015, 532, 676–687. [Google Scholar] [CrossRef] [PubMed]

- Otterpohl, R.; Braun, U.; Oldenburg, M. Innovative technologies for decentralised water-, wastewater and biowaste management in urban and peri-urban areas. Water Sci. Technol. 2004, 48, 23–32. [Google Scholar]

- Cameron, K.; Madramootoo, C.; Crolla, A.; Kinsley, C. Pollutant removal from municipal sewage lagoon effluents with a free-surface wetland. Water Res. 2003, 37, 2803–2812. [Google Scholar] [CrossRef]

- Federation WE. Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Barber, W.P.; Stuckey, D.C. The use of the anaerobic baffled reactor (ABR) for wastewater treatment: A review. Water Res. 1999, 33, 1559–1578. [Google Scholar] [CrossRef]

- Hassan, S.R.; Zaman, N.Q.; Dahlan, I. Effect of organic loading rate on anaerobic digestion: Case study on recycled paper mill effluent using modified anaerobic hybrid baffled (MAHB) reactor. KSCE J. Civ. Eng. 2015, 19, 1271–1276. [Google Scholar] [CrossRef]

- Liu, R.; Tian, Q.; Yang, B.; Chen, J. Hybrid anaerobic baffled reactor for treatment of desizing wastewater. Int. J. Environ. Sci. Technol. 2010, 7, 111–118. [Google Scholar] [CrossRef]

- Skiadas, I.; Lyberatos, G. The periodic anaerobic baffled reactor. Water Sci. Technol. 1998, 38, 401–408. [Google Scholar] [CrossRef]

- Jiao, T.; Wang, H.-Z.; Zhang, W.-B.; Huang, J. Study on rural scattered sewage treatment in contact oxidation reactor. Environ. Sci. Technol. 2011, S2, 25–30. [Google Scholar]

- El-Mashad, H.M.; Zeeman, G.; Van Loon, W.K.; Bot, G.P.; Lettinga, G. Effect of temperature and temperature fluctuation on thermophilic anaerobic digestion of cattle manure. Bioresour. Technol. 2004, 95, 191–201. [Google Scholar] [CrossRef] [PubMed]

- Xing, J.; Tilche, A. The effect of hydraulic retention time on the hybrid anaerobic baffled reactor performance at constant loading. Biomass Bioenergy 1992, 3, 25–29. [Google Scholar] [CrossRef]

- Abdelgadir, A.; Chen, X.; Liu, J.; Xie, X.; Zhang, J.; Zhang, K.; Wang, H.; Liu, N. Characteristics, process parameters, and inner components of anaerobic bioreactors. BioMed Res. Int. 2014, 2014, 841573. [Google Scholar] [CrossRef] [PubMed]

- Zhu, G.-F.; Li, J.-Z.; Wu, P.; Jin, H.-Z.; Wang, Z. The performance and phase separated characteristics of an anaerobic baffled reactor treating soybean protein processing wastewater. Bioresour. Technol. 2008, 99, 8027–8033. [Google Scholar] [CrossRef] [PubMed]

- Movahedyan, H.; Assadi, A.; Parvaresh, A. Performance evaluation of an anaerobic baffled reactor treating wheat flour starch industry wastewater. Iran. J. Environ. Health. Sci. Eng. 2007, 4, 77–84. [Google Scholar]

- Babaee, A.; Shayegan, J. Effects of Organic Loading Rates (OLR) on Production of Methane from Anaerobic Digestion of Vegetable Waste. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011.

- Kanimozhi, R.; Vasudevan, N. Effect of organic loading rate on the performance of aerobic sbr treating anaerobically digested distillery wastewater. Clean Technol. Environ. Policy 2014, 16, 467–476. [Google Scholar] [CrossRef]

- Chelliapan, S.; Wilby, T.; Yuzir, A.; Sallis, P.J. Influence of organic loading on the performance and microbial community structure of an anaerobic stage reactor treating pharmaceutical wastewater. Desalination 2011, 271, 257–264. [Google Scholar] [CrossRef]

- Wang, S.-Y. Effect of carbon source and nitrate concentration on denitrifying phosphorus removal by dpb sludge. J. Environ. Sci. 2004, 16, 548–552. [Google Scholar]

- Rajagopal, R.; Rousseau, P.; Bernet, N.; Béline, F. Combined anaerobic and activated sludge anoxic/oxic treatment for piggery wastewater. Bioresour. Technol. 2011, 102, 2185–2192. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.-C.; Zhang, Q.-L.; Liu, Y.; Liu, Z.-P. Simultaneous removal of organic matter and nitrogen by a heterotrophic nitrifying–aerobic denitrifying bacterial strain in a membrane bioreactor. Bioresour. Technol. 2013, 143, 83–87. [Google Scholar] [CrossRef] [PubMed]

- Brix, H. Wastewater treatment in constructed wetlands: System design, removal processes, and treatment performance. In Constructed Wetland and Water Quality Improvement; Moshiri, G.A., Ed.; Lewis Publisher: Lewis, NY, USA, 1993; pp. 9–22. [Google Scholar]

- Shelef, O.; Gross, A.; Rachmilevitch, S. Role of plants in a constructed wetland: Current and new perspectives. Water 2013, 5, 405–419. [Google Scholar] [CrossRef]

- Sharma, S.B.; Sayyed, R.Z.; Trivedi, M.H.; Gobi, T.A. Phosphate solubilizing microbes: Sustainable approach for managing phosphorus deficiency in agricultural soils. Springer Plus 2013, 2, 587. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, X.; Guo, F. Paradigms of mangroves in treatment of anthropogenic wastewater pollution. Sci. Total Environ. 2016, 544, 971–979. [Google Scholar] [CrossRef] [PubMed]

- Luostarinen, S.A.; Rintala, J.A. Anaerobic on-site treatment of black water and dairy parlour wastewater in uasb-septic tanks at low temperatures. Water Res. 2005, 39, 436–448. [Google Scholar] [CrossRef] [PubMed]

- Gill, L.; Doran, C.; Misstear, D.; Sheahan, B. The use of recycled glass as a filter media for on-site wastewater treatment. Desalin. Water Treat. 2009, 4, 198–205. [Google Scholar] [CrossRef]

- Liang, H.; Gao, M.; Liu, J.; Wei, Y.; Guo, X. A novel integrated step-feed biofilm process for the treatment of decentralized domestic wastewater in rural areas of china. J. Environ. Sci. 2010, 22, 321–327. [Google Scholar] [CrossRef]

- Hong, S.-W.; Choi, Y.-S.; Kim, S.-J.; Kwon, G. Pilot-testing an alternative on-site wastewater treatment system for small communities and its automatic control. Water Sci. Technol. 2005, 51, 101–108. [Google Scholar] [PubMed]

- Davison, L.; Headley, T.; Edmonds, M. On-site domestic wastewater treatment by reed bed in the moist subtropics. Water Sci. Technol. 2001, 44, 353–360. [Google Scholar] [PubMed]

- Gong, L.; Jun, L.; Yang, Q.; Wang, S.; Ma, B.; Peng, Y. Biomass characteristics and simultaneous nitrification–denitrification under long sludge retention time in an integrated reactor treating rural domestic sewage. Bioresour. Technol. 2012, 119, 277–284. [Google Scholar] [CrossRef] [PubMed]

- Wakeel, M.; Chen, B.; Hayat, T.; Alsaedi, A.; Ahmad, B. Energy consumption for water use cycles in different countries: A review. Appl. Energy 2016, 178, 868–885. [Google Scholar] [CrossRef]

- Jusufranić, I.; Milešević, T.; Biočanin, R. Water facilities in the system of urban sustainable development. In Proceedings of the 3rd International Conference on New Functional Materials and High Technology, NFMaHT-2015, Tivat, Montenegro, 29–30 June 2015.

Influent water;

Influent water;  Effluent water;

Effluent water;  COD removal efficiency.

COD removal efficiency.

Influent water;

Influent water;  Effluent water;

Effluent water;  COD removal efficiency.

COD removal efficiency.

Compartment I;

Compartment I;  Compartment II;

Compartment II;  Compartment III;

Compartment III;  Compartment IV;

Compartment IV;  Compartment V.

Compartment V.

Compartment I;

Compartment I;  Compartment II;

Compartment II;  Compartment III;

Compartment III;  Compartment IV;

Compartment IV;  Compartment V.

Compartment V.

anaerobic inflow;

anaerobic inflow;  anoxic effluent water;

anoxic effluent water;  oxic inflow; (b) Reflux ratio effect on NH4–N removal in anoxic tank.

oxic inflow; (b) Reflux ratio effect on NH4–N removal in anoxic tank.  anaerobic ammonia;

anaerobic ammonia;  anoxic ammonia;

anoxic ammonia;  anaerobic nitrate;

anaerobic nitrate;  anoxic nitrate;

anoxic nitrate;  oxic nitrate; (c) Reflux ratio effect on TN removal in anoxic tank.

oxic nitrate; (c) Reflux ratio effect on TN removal in anoxic tank.  anaerobic flow;

anaerobic flow;  anoxic effluent;

anoxic effluent;  oxic flow;

oxic flow;  TN removal.

TN removal.

anaerobic inflow;

anaerobic inflow;  anoxic effluent water;

anoxic effluent water;  oxic inflow; (b) Reflux ratio effect on NH4–N removal in anoxic tank.

oxic inflow; (b) Reflux ratio effect on NH4–N removal in anoxic tank.  anaerobic ammonia;

anaerobic ammonia;  anoxic ammonia;

anoxic ammonia;  anaerobic nitrate;

anaerobic nitrate;  anoxic nitrate;

anoxic nitrate;  oxic nitrate; (c) Reflux ratio effect on TN removal in anoxic tank.

oxic nitrate; (c) Reflux ratio effect on TN removal in anoxic tank.  anaerobic flow;

anaerobic flow;  anoxic effluent;

anoxic effluent;  oxic flow;

oxic flow;  TN removal.

TN removal.

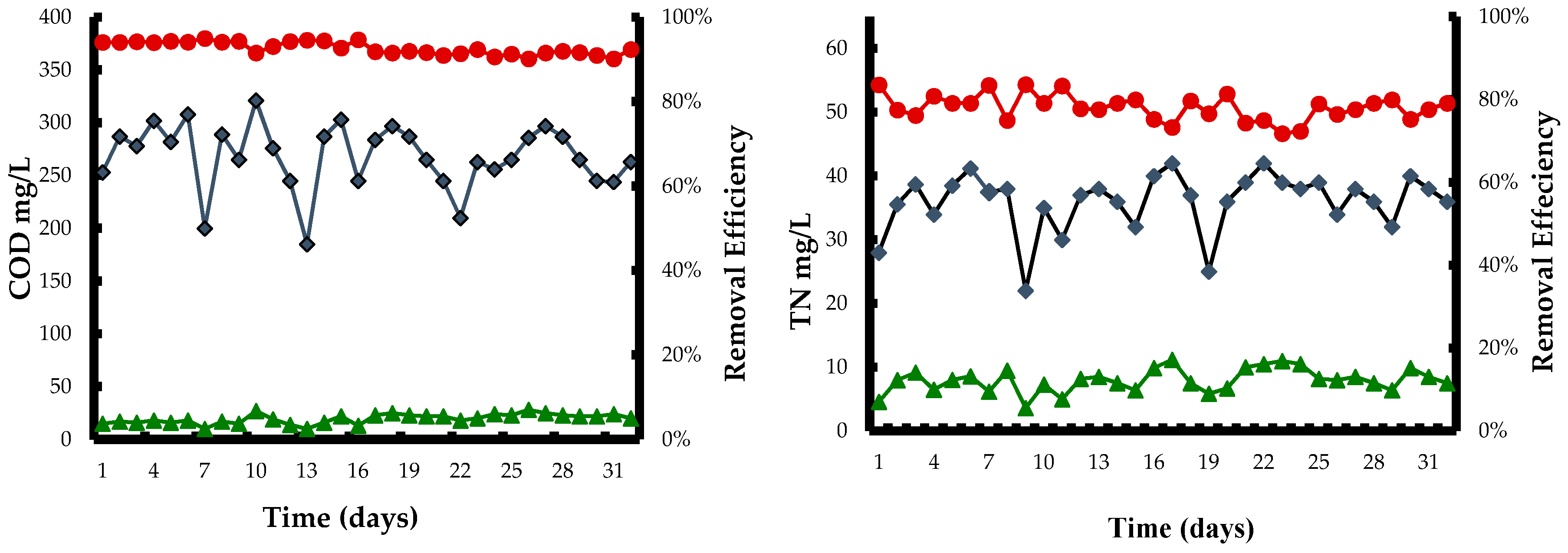

Influent water;

Influent water;  Effluent water;

Effluent water;  COD removal efficiency.

COD removal efficiency.

Influent water;

Influent water;  Effluent water;

Effluent water;  COD removal efficiency.

COD removal efficiency.

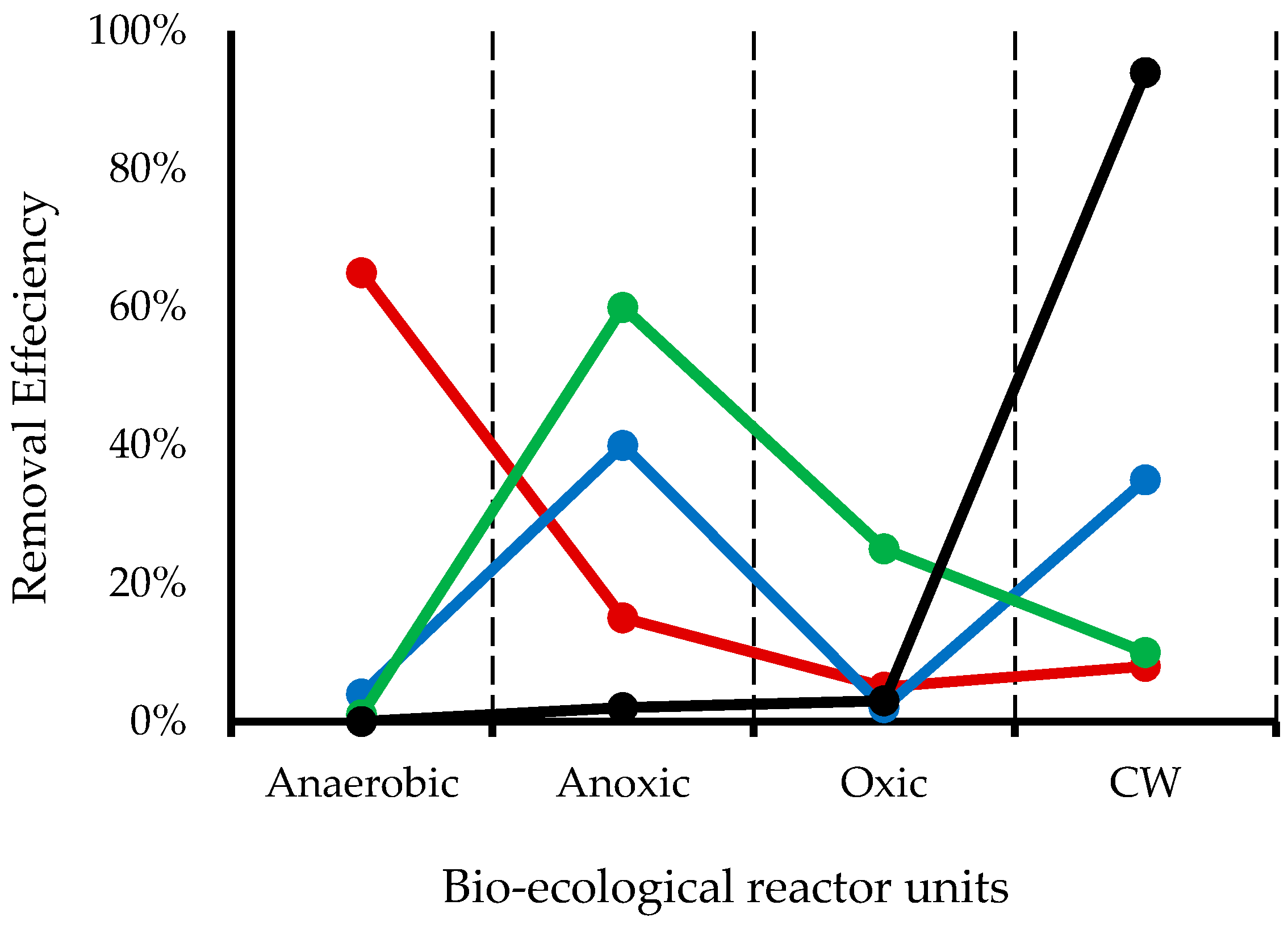

COD;

COD;  TN;

TN;  NH4–N;

NH4–N;  TP.

TP.

COD;

COD;  TN;

TN;  NH4–N;

NH4–N;  TP.

TP.

| Parameters | pH | COD | TN | NH4–N | TP | TSS |

|---|---|---|---|---|---|---|

| mg/L−1 | ||||||

| Range | 6.89–7.23 | 183.0–324.5 | 22.4–43.5 | 15.4–35.7 | 3.4–5.1 | 172–364 |

| Mean | 7.06 | 258.4 | 33.8 | 25.6 | 4.3 | 276 |

| No. | Parameters | Test Methods |

|---|---|---|

| 1 | COD | Closed reflux |

| 2 | TN | Potassium persulfate spectrophotometry |

| 3 | Ammonium | Salicylic acid spectrophotometry |

| 4 | TP | Molybdenum antimony anti points spectrophotometry |

| 5 | TSS | Gravimetric analysis |

| Phase | Time (Days) | Temperature (°C) | HRT (Hours) | Volume Load (kg COD/m3·day) | COD Removal Rate % |

|---|---|---|---|---|---|

| I | 20 | 16–23 | 72 | 0.67–1.06 | 51 |

| II | 15 | 18–28 | 48 | 0.92–1.61 | 60 |

| III | 15 | 20–31 | 24 | 1.76–3.24 | 61 |

| Parameters | Influent | Effluent | Efficiency | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Mean ± SD ** | Min | Max | Mean ± SD ** | Min | Max | Mean | |

| mg/L−1 | % | ||||||||

| COD | 185.3 | 321.2 | 268.2 ± 30.75 | 10.4 | 28.7 | 19.6 ± 4.6 | 0.87 | 0.95 | 0.91 |

| TN | 22.4 | 42.1 | 36.01 ± 4.59 | 3.6 | 11.5 | 7.96 ± 1.84 | 0.75 | 0.85 | 0.78 |

| NH4–N | 17 | 36 | 29.9 ± 4.42 | 0.5 | 4.6 | 2.35 ± 0.99 | 0.81 | 0.94 | 0.85 |

| TP | 3.2 | 5.7 | 4.7 ± 0.59 | 0.2 | 0.58 | 0.36 ± 0.10 | 0.87 | 0.95 | 0.92 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbasi, H.N.; Xu, F.; Lu, X. A Modified Bio-Ecological Process for Rural Wastewater Treatment. Appl. Sci. 2017, 7, 66. https://doi.org/10.3390/app7010066

Abbasi HN, Xu F, Lu X. A Modified Bio-Ecological Process for Rural Wastewater Treatment. Applied Sciences. 2017; 7(1):66. https://doi.org/10.3390/app7010066

Chicago/Turabian StyleAbbasi, Haq Nawaz, Feng Xu, and Xiwu Lu. 2017. "A Modified Bio-Ecological Process for Rural Wastewater Treatment" Applied Sciences 7, no. 1: 66. https://doi.org/10.3390/app7010066