1. Introduction

Polycrystalline diamond compact (PDC) bits have been widely used in the onshore and offshore petroleum drilling industry for many years. However, after a PDC bit has served for a long period of time, or when it encounters complicated geological formation conditions during its service life, defects may occur on its surface or inside. These defects include abrasion, wear, cutting teeth falling-off, surface cracks, stress concentration, and so on [

1,

2]. Among these defects, surface cracks are fatal defects because they may gradually expand and finally lead to the entire failure of the PDC bit. Moreover, the dimensions of the surface crack, especially the width, are usually very small, which makes it difficult to be detected by visual inspection.

The magnetic particle testing technique has been widely used for detecting surface defects on the drilling bit matrix. However, in order to avoid a situation where the remaining contamination reduces the detection sensitivity, surface cleaning is usually required, which makes the detection job much more time-consuming and complicated. Therefore, several other testing techniques have been employed to detect surface or internal defects in drilling bits in recent years. Lund et al. conducted nondestructive inspection for internal defects on a rotary drill bit using an ultrasonic technique [

3]. Sullivan et al. proposed a method based on an ultrasonic phased array to identify and characterized internal defects in a rotary drill component [

4]. Williard et al. demonstrated that a scanning acoustic microscope (C-SAM) can be used to detect defects at the PDC cutter of a drill bit [

5]. Bellin [

6] proposed a method of acoustic emissions for testing the toughness of PDC inserted in a drill bit. These testing techniques showed sound inspection capabilities for PDC bits. However, there are still disadvantages in these methods, such as the difficulties of using acoustic couplant on the irregular surface of PDC bits, low detection efficiency, or indirect detection results. Therefore, it is necessary to develop other effective and suitable methods for detecting surface cracks on PDC bits.

Combining high sensitivity of eddy current testing and visualization of IR thermography, eddy current pulsed thermography (ECPT), a kind of active thermography, has been widely applied to detect surface defects on conductive materials. Previous research has demonstrated the efficacy of ECPT to detect surface cracks on steel wires [

7], metal compressor blades [

8], and rail track due to rolling contact fatigue [

9], etc. In addition, He et al. detected steel corrosion and investigated the influence of testing parameters on detection accuracy of ECPT [

10,

11]. Xu et al. investigated the feasibility of ECPT for hidden crack detection on corroded metal surfaces [

12]. Xie et al. stated that multiple defects on ferromagnetic or non-ferromagnetic metallic surfaces can be detected using ECPT [

13]. ECPT has also been used to detect various defects in carbon fiber composites [

14,

15]. However, there has not been any report on the application of ECPT to detect surface defects on PDC bits. The main possible difficulties for using ECPT to detect surface defects on PDC bits come from its large volume and weight. Firstly, it is very difficult to excite the whole bit one time because the required power of heating excitation will be extremely high. Additionally, the size of the excitation coil needs to be large enough to generate sufficient heat for the entire surface of PDC bits. Therefore, it is not feasible to raise the temperature of the tested object with one or several heating excitations to detect surface defects on PDC bits using conventional ECPT. Hence, it is necessary to develop a new detection mode for ECPT to detect surface cracks on PDC bits. Some researchers have proposed scanning thermography techniques, such as line scanning thermography, scanning induction thermography, and so on [

16,

17,

18]. These scanning thermography techniques can achieve defect detection on a large area or cylinder. For example, Thomas et al. demonstrated that scanning induction thermography is effective for defect detection of composite components with flat surfaces [

18]. Such achievements motivate us to develop a new scanning mode for ECPT to detect surface cracks on PDC bits with more complicated geometry.

We aim to investigate the feasibility of using ECPT to detect surface cracks on the tungsten carbide matrix of PDC bits in this work. A new scanning detection mode for ECPT is proposed according to the surface features of the bit’s matrix. The influence of excitation duration on the detection result is analyzed, and principal component analysis (PCA) is then used to process the IR image sequences to further improve detection sensitivity. Finally, the whole crack is reconstructed by integrating IR images of varied crack segments. The paper is organized as follows. After the introduction of the research background in

Section 1, the mechanism of detection of surface cracks on the matrix of PDC bits using ECPT is described, and the theory of PCA for IR image processing is presented in

Section 2.

Section 3 introduces the experimental setup.

Section 4 presents experimental results and discussions.

Section 5 concludes the paper.

2. Methodology

2.1. Fundamental of ECPT

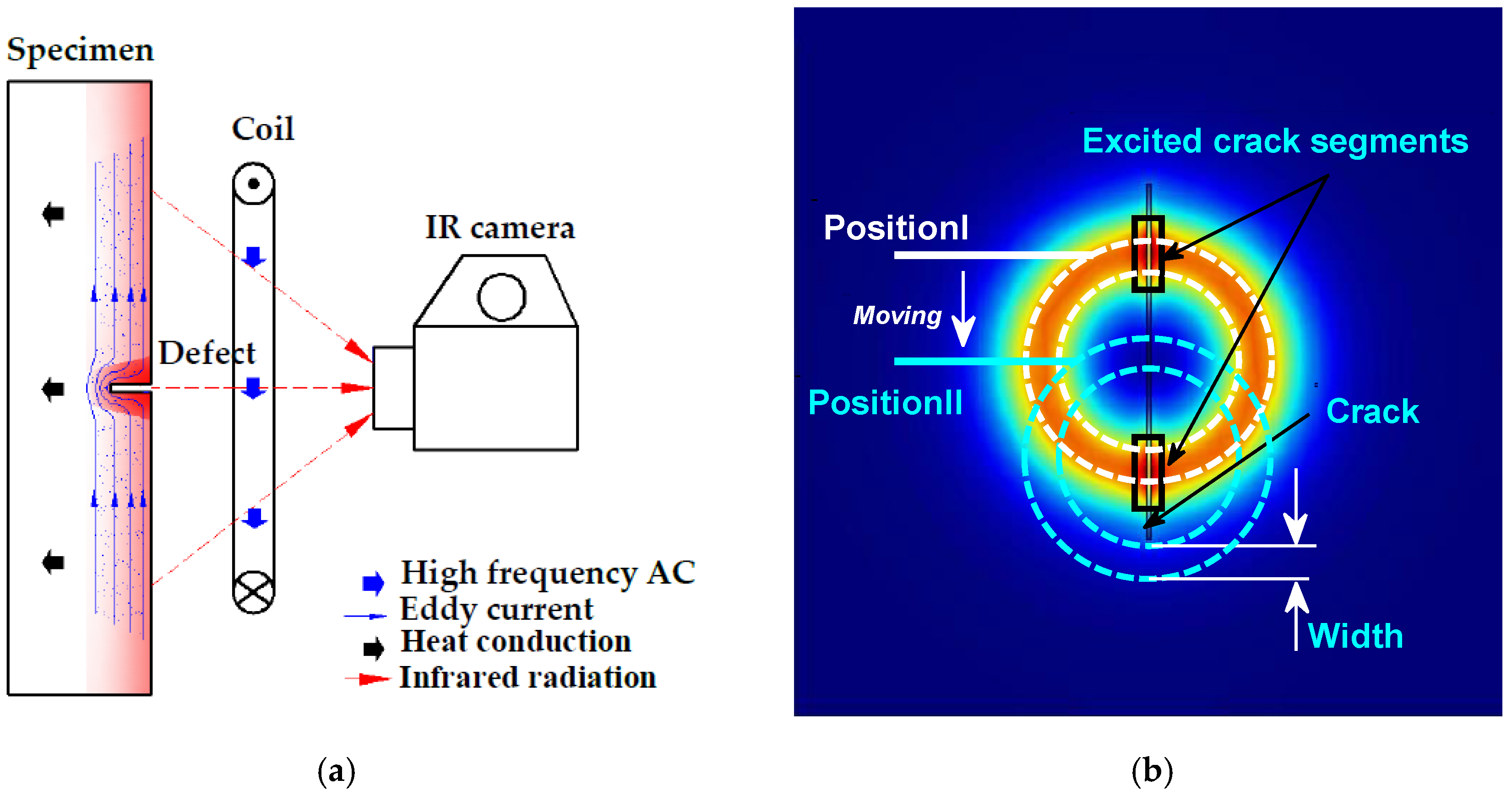

A basic schematic diagram of ECPT is shown in

Figure 1a. A coil with high frequency alternating current (AC) produces a short burst of electromagnetic excitation and thereby induces eddy currents (ECs) in the conductive material. The induced ECs concentrate in a skin depth of homogeneous material, and a local temperature rise can then be caused by the effect of Joule heating from the eddy currents. The heat will be conducted from the heated area to other places until a thermal balance is finally reached. In case there is a surface crack in a conductive material, as depicted in

Figure 1a, the presence of a crack can cause a diversion in the EC flow and heat conduction, which leads to a different temperature distribution pattern on the surface [

19]. Hence, the crack can be detected by the variation of temperature distribution between the defect and the surrounding sound areas in the IR images.

As mentioned above, due to its large volume and weight, it is difficult to thermally excite and detect the bit once using a small induction coil. In order to solve such a problem, ECPT with low excitation power and a small-size coil is proposed here to detect surface cracks on the matrix of a PDC bit in scanning mode.

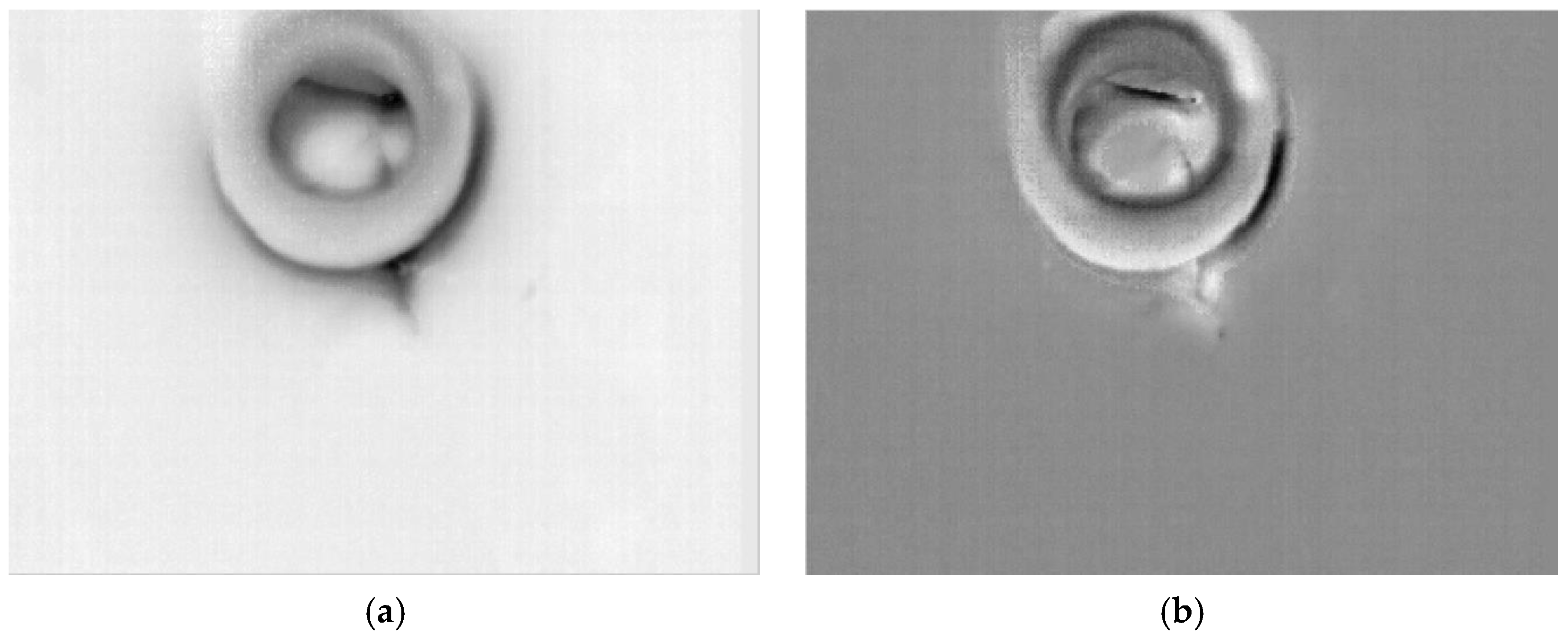

From

Figure 1b, we can see the temperature distribution of a specimen with a surface crack on the matrix excited by an annular coil with a small size, which is calculated with COMSOL. For a given position of the coil, only the annular region below the coil can be directly heated because the size of the coil is much smaller than the length of the crack. It means that only the crack segment within and around the annular coil labeled in

Figure 1b can be directly detected each time. In order to completely detect all segments of the crack, it is necessary to move the excitation coil to perform a scanning heat excitation. However, it is difficult to use continuous scanning approach presented in previous work [

18] because PDC bits have an irregular (rather than flat) surface. Therefore, a successive scanning mode is proposed for heat excitation on PDC bits. After finishing one heating excitation at the present position (Position I), as shown in

Figure 1b, the coil will be moved to the following position (Position II). The rest can be done in the same manner until all positions are detected. Then, the crack will be reconstructed by all segments in varied IR images captured in different positions. Obviously, such scanning heating mode makes it possible to ensure that all positions of a bit matrix are effectively heated because the coil can be placed in a flexible and suitable manner for each position.

2.2. PCA-Based Image Reconstruction

Different regions, such as the crack, the coil, and the surrounding sound areas, present distinctive thermal profiles in IR images. Therefore, we can take each region as an independent signal source and separately enhance the features of cracks. Here, PCA is used for source separation for IR images.

Principal component analysis (PCA) [

20,

21,

22] is a common image processing method usually used in thermography to improve the sensitivity of crack detection. A detailed algorithm of PCA can be found in a previous work [

19].

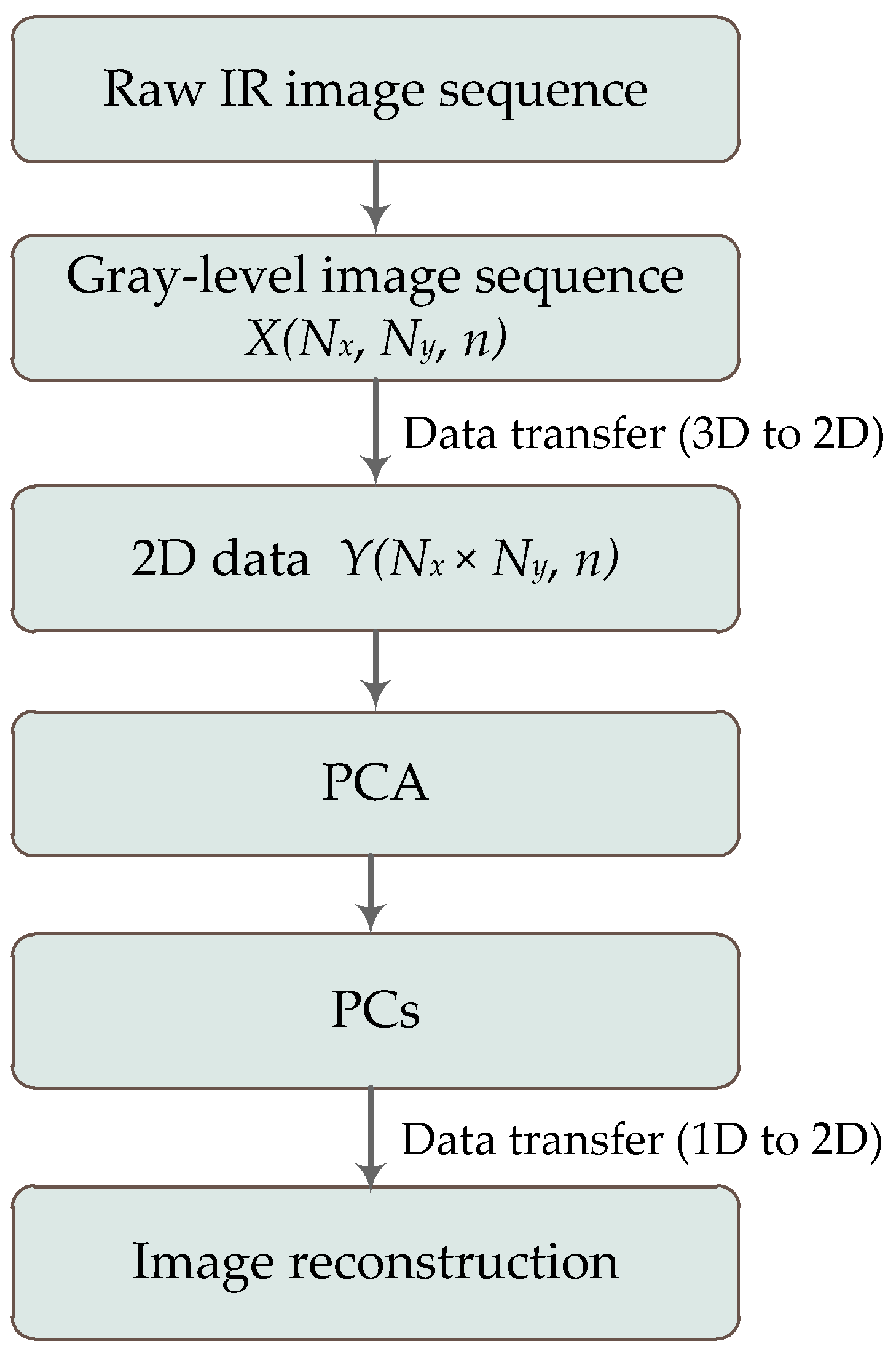

Figure 2 shows the schematic diagram of PCA-based image reconstruction method. Firstly, the IR image sequences captured by the IR camera are converted to gray-level image sequences. Here,

represents the pixel value of gray-level image sequences, which is a 3D matrix. The

means the resolution of camera, and n is the number of images. Next, the 3D matrix

X is transferred to a 2D matrix

as the input data of image processing. Then, the matrix

U is processed by PCA, generating the principal components (PCs). Finally, the appropriate PCs are transferred to 2D arrays to form new images, which can improve the detection sensitivity and increase the signal-to-noise ratio of raw IR images.

The solution of PCA is mainly based on eigenvalue decomposition of whitening matrix (EVD), as shown in the following equation.

is the orthogonal matrices of eigenvectors, represents the eigenvalue matrix, and is the eigenvalues.

Eigenvalue decomposition can be expanded as

Among them,

, so Equation (2) can be simplified as

Combining Equations (2) and (3), we can obtain the Equation (4) as follows:

Finally, the signal vector matrix (

) is separated by PCA:

Each column of the matrix is a principal component, which can be transferred to a 2D matrix and then used to conduct image reconstruction.

3. Experimental Setup

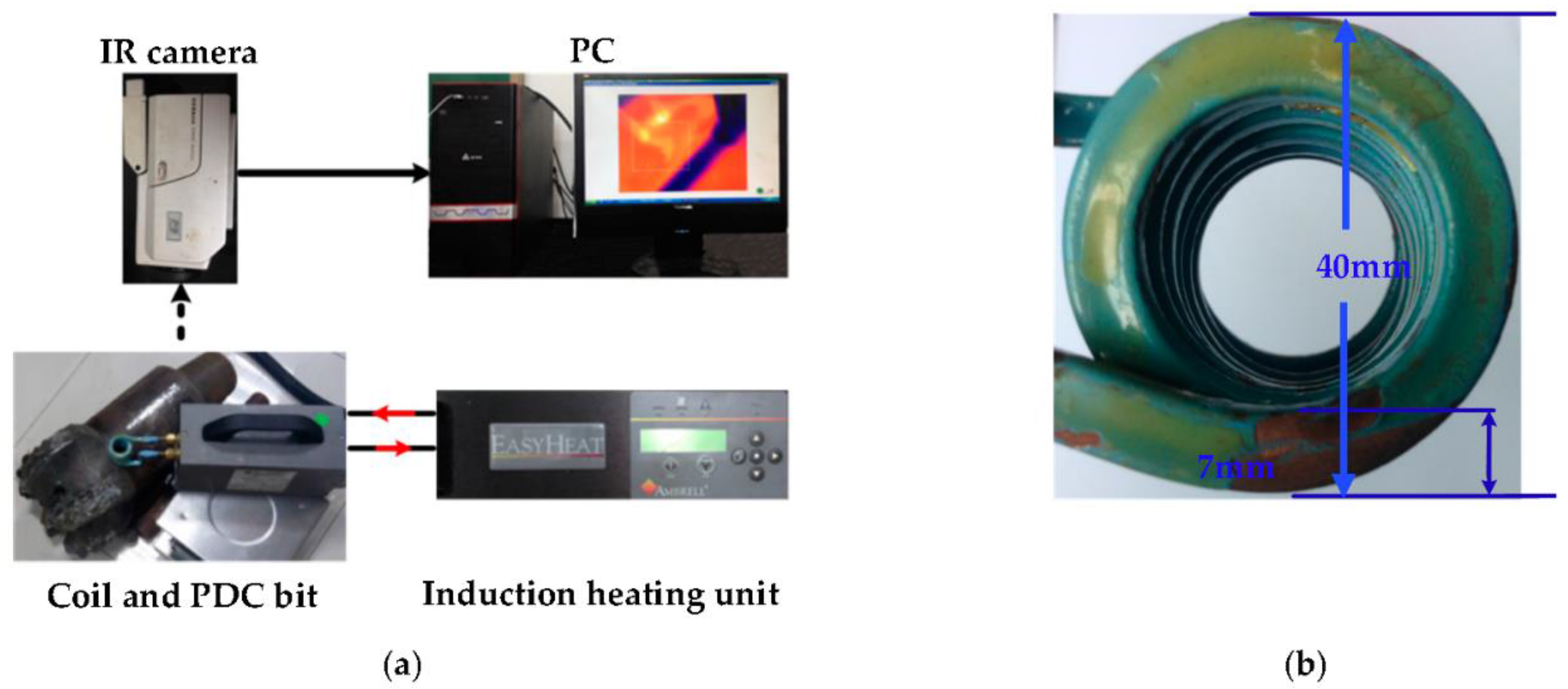

The experimental setup in this study is shown in

Figure 3a. An induction heating system (EasyHeat 0224, Ambrell, NY, USA) is used for thermal excitation. In order to fit the complex geometry of a PDC bit, the excitation coil is designed as an annular coil as shown in

Figure 3b. The induction heating system provides a maximum excitation power of 2.4 kW, a maximum output current of 380 A, and an excitation frequency range of 150~400 kHz. The temperature response of the specimen surface is recorded by an infrared camera (SAT-HY6850) with 320 × 240 pixels at a frame rate of 25 Hz and a spatial resolution of 1.3 rad. The thermal sensitivity of the camera is 80 mK and the accuracy is ±2%.

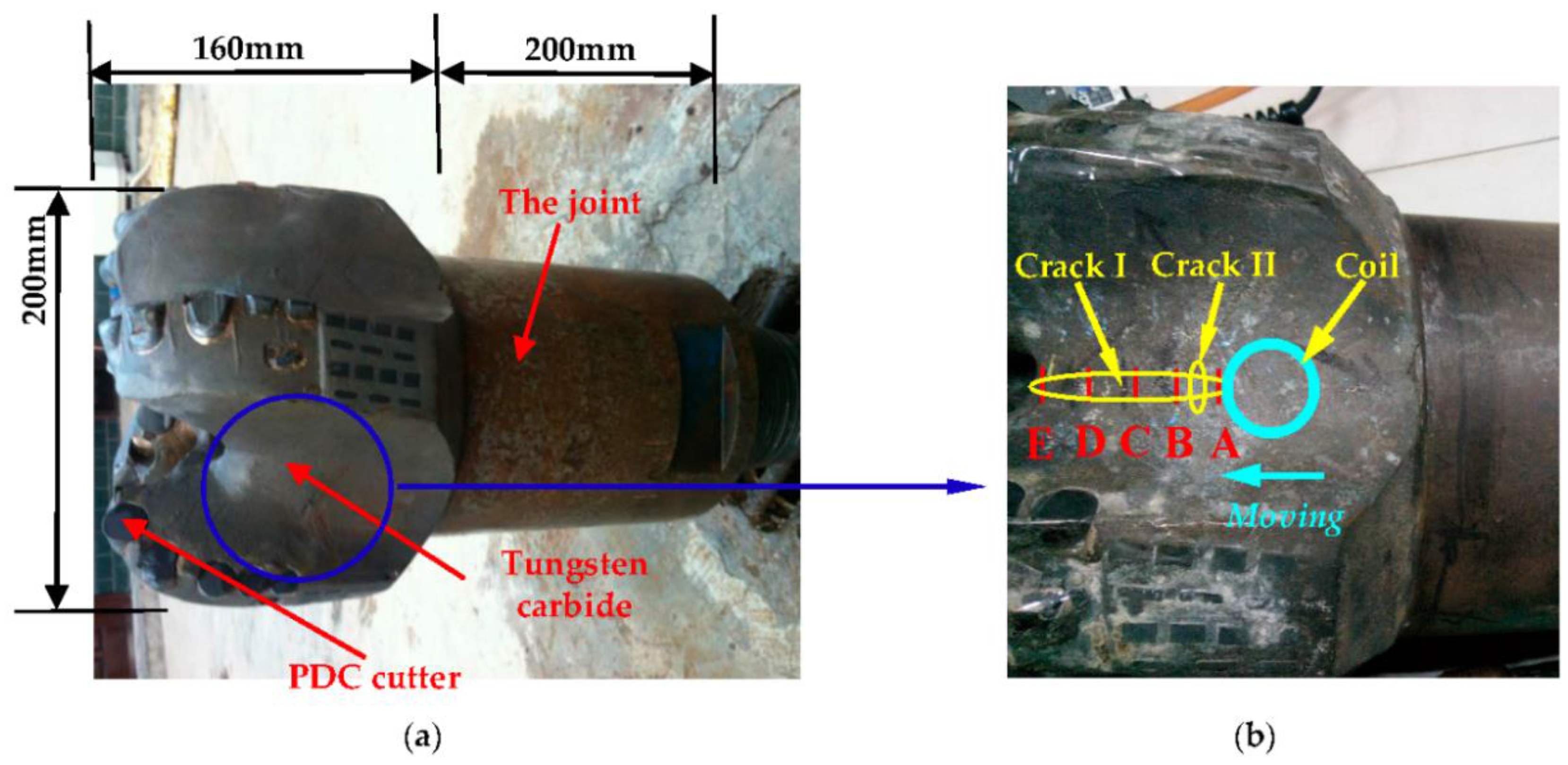

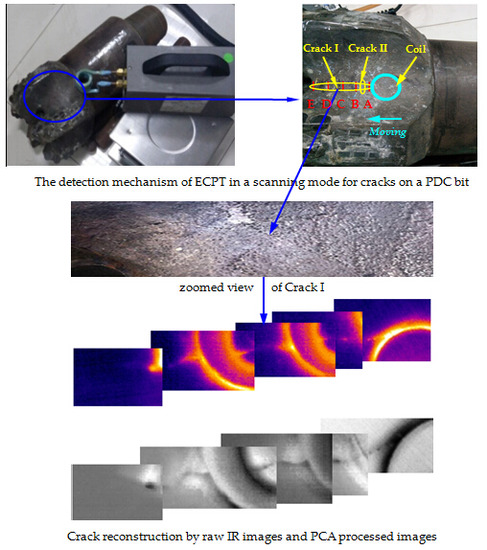

A PDC bit retired from oil drilling field is used as experimental specimen in this study, as shown in

Figure 4a. A PDC bit is comprised of three parts: a PDC cutter, a tungsten carbide matrix, and the joint. There are two crossed surface cracks on the tungsten carbide matrix, which are labeled as Crack I and Crack II, as shown in

Figure 4b. Their widths are both less than 0.2 mm, which makes it very difficult for direct visual observation. The lengths of Crack I and Crack II are 88 mm and 21 mm, respectively.

Figure 4c shows the zoomed view of Crack I. The polycrystalline diamond compact cutter comprises a thin layer of sintered polycrystalline diamond bonded to a tungsten carbide–cobalt substrate. The tungsten carbide matrix is one kind of alloy steel that mainly includes W, Fe, T.C, F.C, Si, Ni, Co, and other components. Its electrical conductivity is about

S/m and thermal conductivity is 0.42 W/(cm·K). The conductivity of tungsten carbide makes it possible to heat the PDC bit matrix by induction heating.

From

Figure 3a, we can see that the size of the annular coil is too small to detect the surface cracks on the bit matrix. Additionally, the power of the induction heating system is also limited for exciting the whole bit at one time. Therefore, as discussed in

Section 2.1, ECPT can be applied to detect the cracks in a successive scanning manner. As shown in

Figure 4b, the induction coil was successively moved from Position A to Position E in such a way: the induction coil was moved 20 mm each time and heat the PDC bit for 500 ms followed by a cooling time of 3.5 s at each position. Additionally, the recording process of the IR camera is an ongoing process during the detection for the five positions. After the excitation coil scanning the whole surface of bit matrix, each segment of each surface crack can be roughly detected in sequence.

4. Results and Discussion

4.1. Analysis of Excitation Duration on Detection Ability of ECPT for Surface Cracks on PDC Bit Matrix

Due to the principle of ECPT that the effect of current obstruction by defect can cause a different temperature distribution of the specimen surface, excitation current intensity and excitation duration are two key parameters for ECPT testing. A larger excitation current intensity generally leads to more obvious thermal contrast between the defect and the sound area. Therefore, the excitation current intensity should be set as large as possible for different inspected objects. As a result, 350 A is chosen as the excitation current intensity during the experiments. Additionally, the excitation frequency used in the experiment is set to 200 kHz, at which the calculated penetration depth of the induced eddy current is about 0.49 mm. For a specific eddy current heating system, the influence of current excitation duration on the detection result differs with varied tested objects. Hence, it is necessary to conduct an experimental investigation on determining the optimized excitation duration for detecting surface cracks on PDC bits.

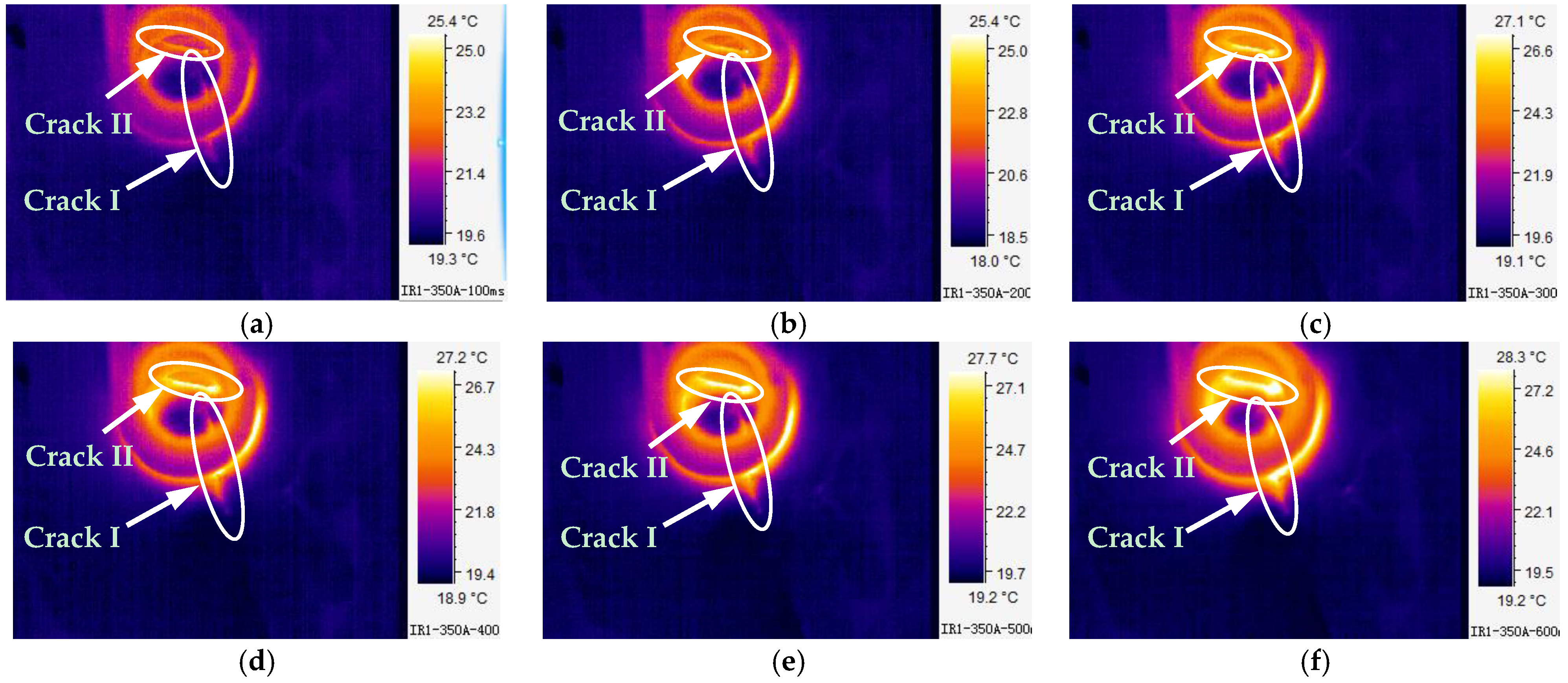

In this paper, Position D in

Figure 4b is selected as an example to optimize the excitation duration. With other detecting parameters unchanged, experiments with a series of excitation duration, including 100, 200, 300, 400, 500, and 600 ms, have been conducted respectively to detect the two cracks. Considering the infrared camera worked at the frame frequency of 25 Hz, 100 IR image frames were sequentially recorded for each position (the recording time of 4000 ms). Consequently, taking the heating duration of 500 ms as an example, each IR image sequence can be divided into three periods: frames from 1 to 10 (0~400 ms) as the stage before heating; frames from 11 to 23 (401~900 ms) as the heating stage and frames from 24 to 100 (901~4000 ms) as the cooling stage (after heating).

According to the findings in previous works [

12], the frame at the end time of heating excitation stage in each infrared sequence was chosen for IR image analysis to evaluate the influence of heat excitation duration on detection results.

Figure 5 shows IR images recorded with different excitation duration when the coil was located at Position D. We can see the segments of two cracks can be easily recognized in

Figure 5a–f despite the interference of excitation coil in visual field.

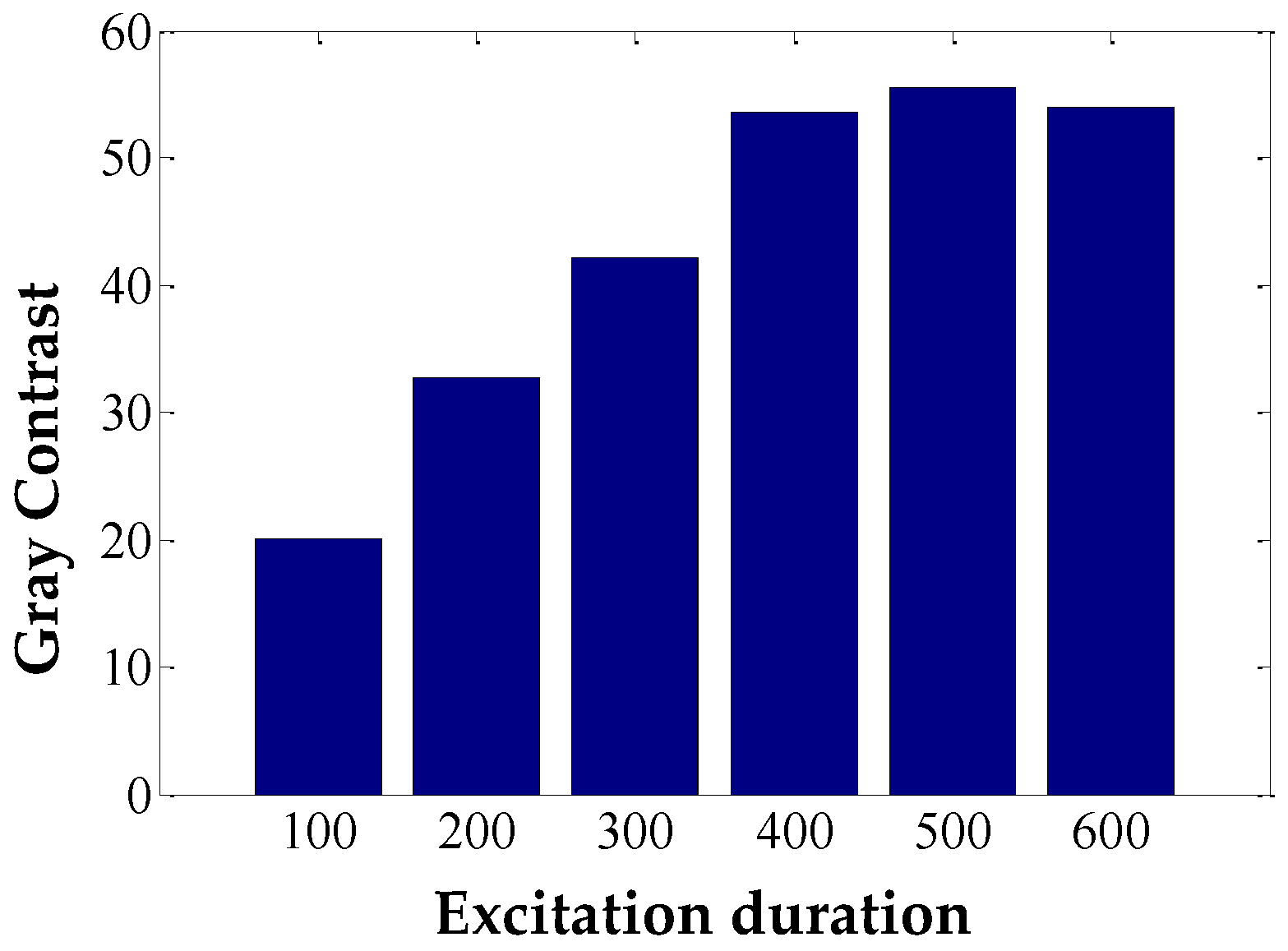

To find the optimum heating excitation duration, a criterion is necessary to find the optimum heating excitation duration. It is well known that the crack is easier to detect when the thermal contrast between the defect and the surrounding sound area is higher. Hence, such thermal contrast can be used to evaluate the effectiveness of each excitation duration setting for ECPT. The temperature response can certainly be used to calculate the thermal contrast. Additionally, there is a proportional relationship between the intensity of each pixel in the IR image and the temperature response of the corresponding position. Therefore, the intensity contrast of the IR image can be used to represent the thermal contrast. For simplified calculation, we convert the IR images to gray scale images and the gray contrast (intensity contrast gray scale-level images) between the defect and its surrounding area to represent that the thermal contrast is obtained as the criterion to assess the effectiveness of each excitation duration setting for ECPT.

Here, we take Crack I as an example and the gray contrast between the crack and sound area are calculated based on the IR images shown as

Figure 5a–f. The calculated gray contrast is shown in

Figure 6. It can be seen from

Figure 6 that the gray contrast rises with the increase of excitation duration from 100 ms to 500 ms. However, when the excitation duration exceeds 500 ms, the gray contrast decreases. The reason comes from the fact that there are two main factors affecting the contrast between the defect and the surrounding sound area: temperature rising caused by the thermal excitation and thermal balance resulted from the lateral heat conduction between the crack and its surrounding area. In the early stages of heat excitation, the thermal contrast gradually increases because the effect of temperature rising is dominant. With the increase in exciting duration, the influence of the lateral heat conduction becomes more prominent, which makes the thermal contrast begin to decreases.

Additionally, it is a waste of energy and a higher risk to damage the tested object if the excitation time is set too long. As a result, 500 ms is chosen as the optimum excitation duration for surface defect detection on the tungsten carbide matrix of the PDC bit in the presented experiments.

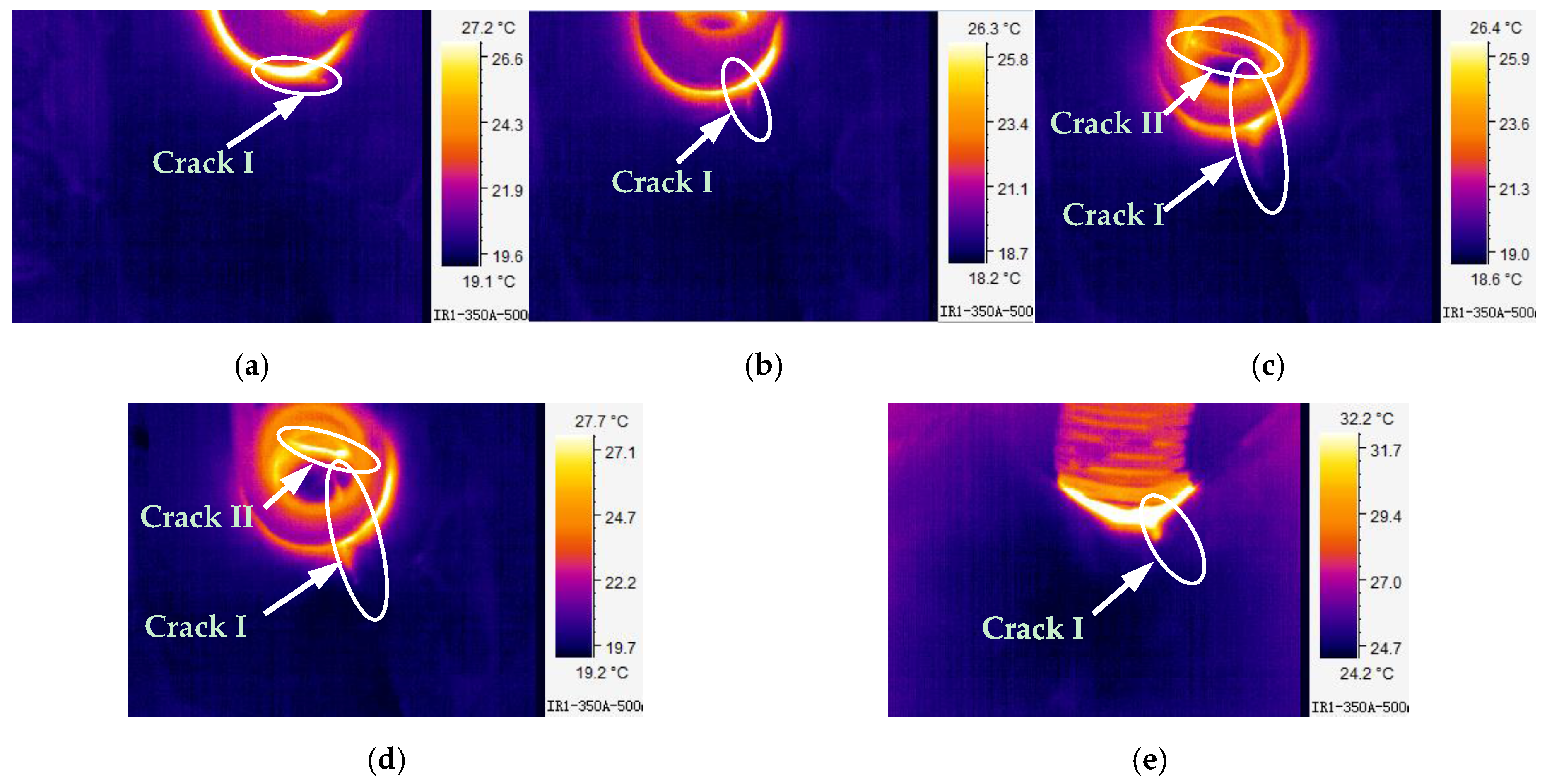

4.2. IR Image Analysis for Surface Crack Detection Using ECPT

With the optimum excitation parameter, namely the excitation current of 350 A, the frequency of 200 kHz, and the excitation duration of 500 ms, all segments of Crack I were tested by moving coil at all positions shown in

Figure 4b. The detection results are shown in

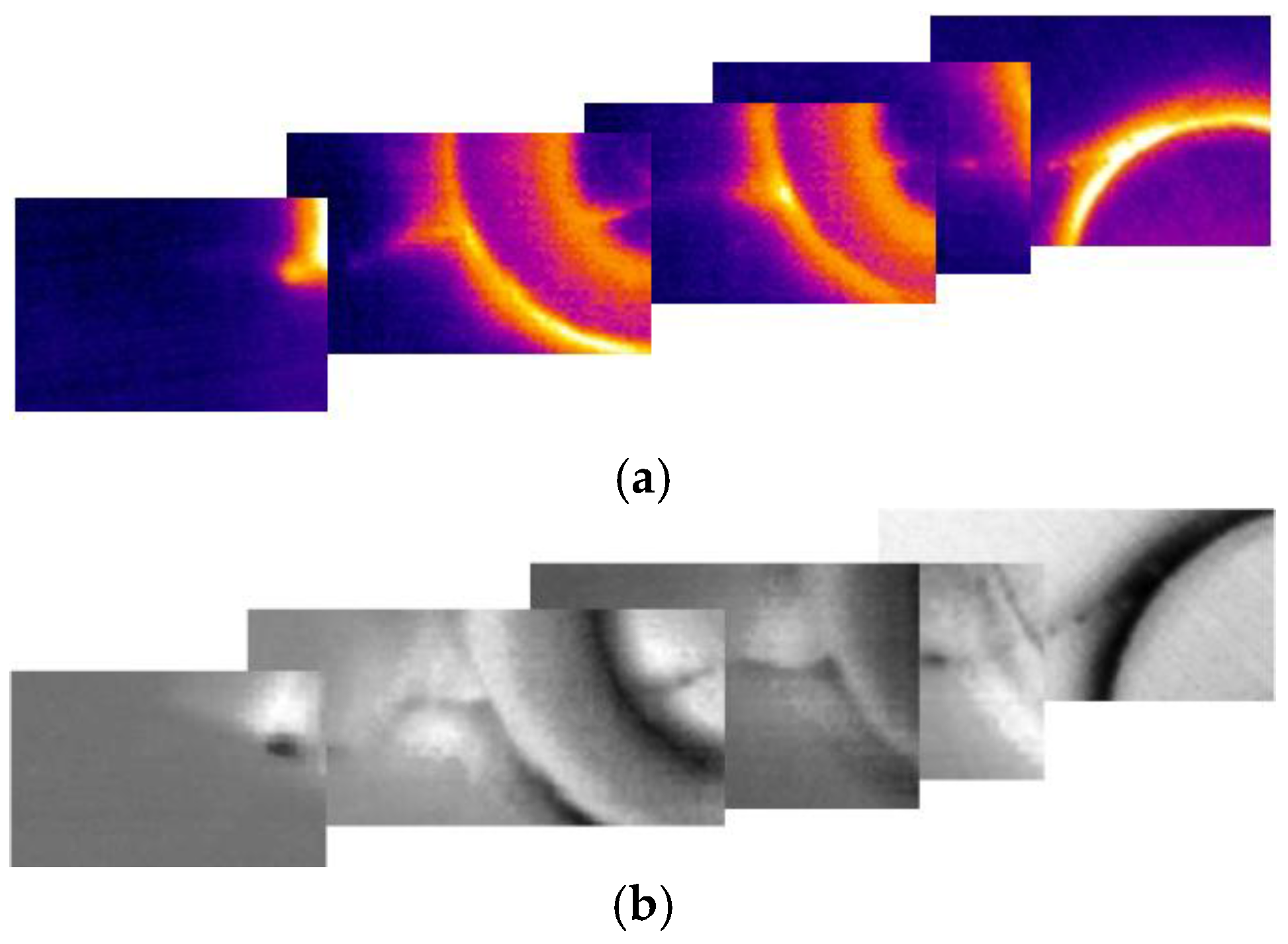

Figure 7. As mentioned before, only the crack segments within and around the annular coil can be directly detected at one heating excitation position. From

Figure 7a–e, it is found that all crack segments of Crack I are basically recognized due to the thermal contrast in each IR image. Especially, the segments at Position A and Position E are the starting tip and the end tip of Crack I, respectively. Meanwhile, Crack II with a smaller length can be clearly observed as a horizontal bright line in

Figure 7c,d. Consequently, it is demonstrated that the surface cracks on the tungsten carbide matrix of PDC bits can be detected by using ECPT in a successive scanning mode.

4.3. PCA Processing for IR Images

From the analysis of IR images above, it is obvious that ECPT can be used to detect the presence of the surface cracks on PDC bits in a successive scanning mode. However, due to the effects of a low SNR (signal-to-noise ratio) and non-uniform heating, it is difficult to make a precise characterization of the crack geometry. For example, the shape of each segment of Crack I is hard to identify in

Figure 5a–f. As discussed in

Section 2.2, PCA is effective to eliminate effects of noise and non-uniform heating in the raw IR images to enhance the features of the cracks. Hence, PCA is introduced as an image processing method to improve the detection result of ECPT for the cracks on tungsten carbide matrix of PDC bit. Here, we take the condition of the coil located at Position D as an example to illustrate the effectiveness of image processing with PCA.

There are several suggestions for selection of the IR image frames as the input of PCA method. He et al. found that the IR image sequences before the time of when the thermal responses of the defects and the intact areas appear in inversion pattern are suitable for PCA analysis [

10]. According to this finding, IR image sequences from frame 10 to 30 (400~1200 ms) were selected as the inputs for PCA processing because the cracks show higher thermal response than those of surrounding sound areas in these IR image frames. Generally, the first four principal components obtained by PCA carry most of information regarding the original data, which can be used for image reconstruction and defect feature enhancement [

21].

The reconstructed images by the first two principal components are shown in

Figure 8, which shows the enhanced features of the cracks. Compared to the original IR image in

Figure 7d, the background noise has been greatly eliminated in

Figure 8a, but the location and geometry of the segments of Crack I and Crack II are not greatly enhanced. The main reason may come from the remaining effect of non-uniform heating along the annular coil. However, from

Figure 8b, we can see that Crack I and Crack II are well separated from the surrounding areas because the effect of non-uniform heating is almost eliminated. Hence, it is easy to characterize the important features of the segments of the two cracks from

Figure 8b. Besides, with the help of the PCA method, the crack information can be automatically obtained from an IR image sequence to avoid the trouble of manually identifying defect information from a large number of IR image frames. Therefore, the PCA method is proven as one of the effective methods to improve the detectability of ECPT for surface cracks on matrix of PDC bit by greatly enhancing the features of cracks from the image reconstructed with the second principal component.

4.4. Crack Reconstruction for ECPT in Successive Scanning Mode

As mentioned above, using ECPT in a successive scanning approach, different segments of surface cracks can be detected by sequentially moving the coil to different positions. Considering that only one segment of each crack can be recognized in an IR image sequence captured at a certain coil position, it is necessary to reconstruct a crack with all segments in different IR images. Here, Crack I is taken as example to illustrate the process of crack reconstruction. In order to reconstruct the entire shape of Crack I, the original IR images obtained under five coil positions are cut into some image patches. These patches containing the distinct segments features of Crack I are then selected to put together in sequence, which finally obtains the reconstructed image of Crack I, as shown in

Figure 9a. As a comparison, the images reconstructed by using the PCA processing method are also used to reconstruct Crack I in the same approach above and the integrated image of Cracks I is shown in

Figure 9b. It is found that the whole shape of Crack I is quite rough and broken in

Figure 9a, but

Figure 9b shows more distinct features of Crack I. It demonstrates the effectiveness of the PCA method on the enhancement of detectability for ECPT. Compared with the true shape of Crack I shown in

Figure 4c, we can find that Crack I has been reconstructed in a more continuous and precise manner, as shown in

Figure 9b. Therefore, with the help of crack reconstruction, we can obtain the necessary information to characterize the whole crack based on the detailed detection results of crack segments, which further prove the feasibility of using ECPT to detect surface cracks on the matrix of PDC bit in the proposed successive scanning mode. However, there is still a shielding effect from the annular coil in

Figure 9b, which interferes with the complete shape restoration of the crack. The problem may be solved by designing a new coil with special geometry, which will be achieved in our future investigation.