1. Introduction

Concrete is a representative building material and has a very important role in the construction field. Since the control of energy consumption has become a worldwide issue, many efforts have been performed to enhance energy efficiency in the field of building and concrete materials. Among the various types of concrete for special applications, lightweight concrete has been widely used due to its advantageous characteristics, such as lower density and higher insulation effect than those of conventional concrete [

1,

2]. According to EN 206, lightweight concrete is a material with density lower than 2000 kg/m

, and it contains natural or synthetic lightweight aggregates (lightweight aggregate concrete) or foam agent (foamed concrete) to reduce the weight of material; this material can be used for both structural and nonstructural purposes, i.e., insulation and concrete block [

3,

4].

To produce lightweight aggregate concrete, several types of materials have been used as lightweight aggregates. Sales et al. [

5] used sawdust and water treated sludge as lightweight aggregates and confirmed its effect to reduce the environmental impact. Chabannes et al. [

6] utilized raw rice hush for lightweight concrete and demonstrated that the material can be used as a filling material to improve the mechanical performance of concrete. Wu et al. [

7] used hollow cenospheres from fly ash as lightweight aggregates for the material and confirmed its effect on the improvement of tensile strength. Colangelo et al. [

8] used a recycled municipal solid waste incinerator (MSWI) fly ash as lightweight aggregates and showed that the material can effectively be utilized as lightweight aggregates with average performance. Lihua et al. [

9] used ferrochromium slag to improve the performance of lightweight concrete and confirmed that the material endowed a dense microstructure and high bond strength of the interfacial transition zone. Bogas and Cunha [

10] produced lightweight concrete with volcanic scoria aggregates, and the obtained material showed better mechanical behavior at high temperatures than conventional concrete. Colangelo et al. [

11] used recycled polyolefins waste and demonstrated that this material can be used as a sustainable practice in lightweight concrete manufacturing. Guneyisi et al. [

12] utilized nanosilica for lightweight concrete and showed its impact on the workability of self-compacting lightweight concrete. Youm et al. [

13] evaluated the performance of the material with silica fume for 91 days and confirmed its advanced durability against chemical deterioration. In addition, artificial lightweight aggregates, such as Poraver

(Postbauer-Heng, Germany), Leca

(Randers SV, Denmark), and Liaver

(Ilmenau, Germany), are also utilized for lightweight aggregate concrete due to their low densities and advanced properties [

14].

In general, lightweight aggregates occupy more than 50% of the volume of concrete, and the total volume of the lightweight aggregates is a significant factor to determine the properties of lightweight concrete. For example, the density of lightweight concrete, which is a factor that strongly affects both mechanical and thermal properties, varies between 800 and 1500 kg/m

depending on the volume of lightweight aggregates [

15], and when the specimen contains a large volume of lightweight aggregates, the density and thermal conductivity decrease, while the stiffness and compressive strength also tend to decrease [

16]. In addition, the physical properties of lightweight concrete, such as density, and mechanical and thermal properties, are affected significantly by the characteristics of lightweight aggregates [

17]. Therefore, a proper use of the lightweight aggregates should be carefully considered to produce lightweight concrete with acceptable performance for both mechanical and thermal responses. Among several characteristics of aggregates, the grading (or particle size distribution) of lightweight aggregates is a very important factor because it can affect the workability and cost of concrete [

18]. In particular, it is desirable for lightweight concrete to contain large volume of lightweight aggregates to reduce the density and to minimize the use of cement. For this purpose, the use of appropriate grading of aggregates is required to include large volume of lightweight aggregates in the specimen.

The main objectives of this study can be summarized as follows: (1) production of lightweight aggregate concrete (LWC) with very low density (less than 500 kg/m

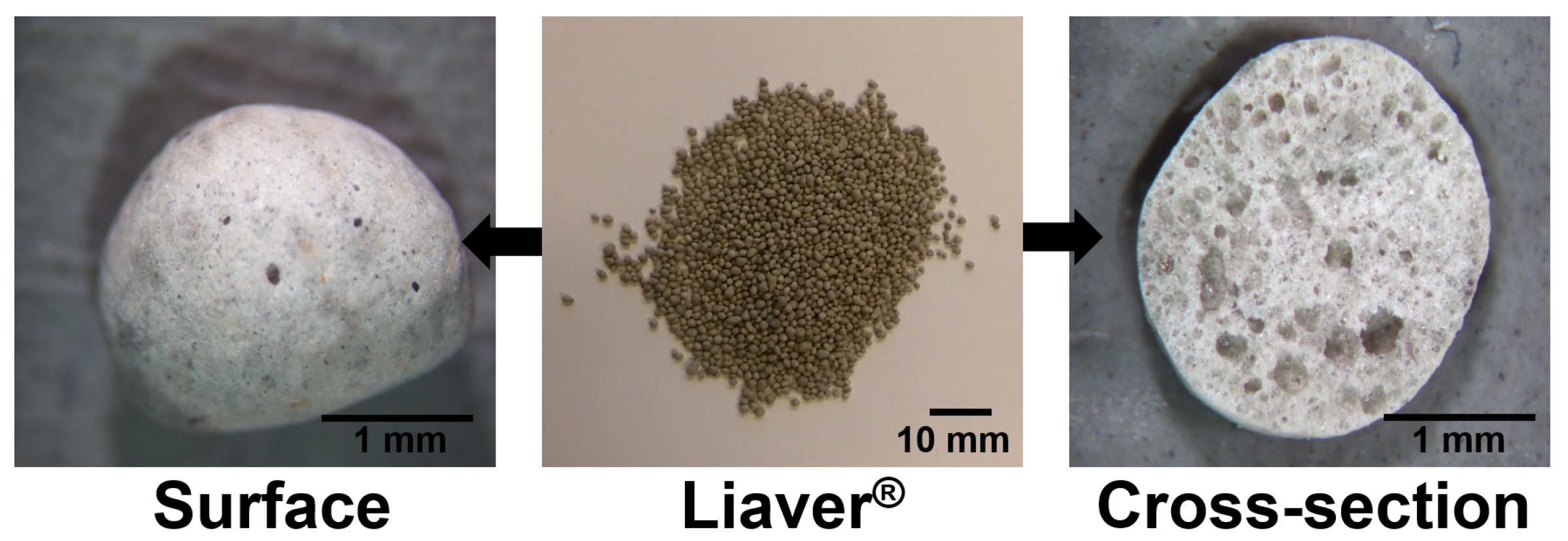

) by maximizing lightweight aggregate volume using different gradings of lightweight aggregates (LWA); (2) evaluation of the material responses using experimental and numerical approaches; and (3) investigation of the effect of different gradings on the material characteristics and properties. Here, Liaver

(Ilmenau, Germany), an expanded glass granulate, is used as lightweight aggregates for lightweight concrete specimens according to its very low density and water absorption characteristics; this material is produced by being ground, granulated, distended and vitrified in a rotary kiln at 750

C to 900

C, and this produces very light granules measuring between 100

m and 16 mm grain diameter. [

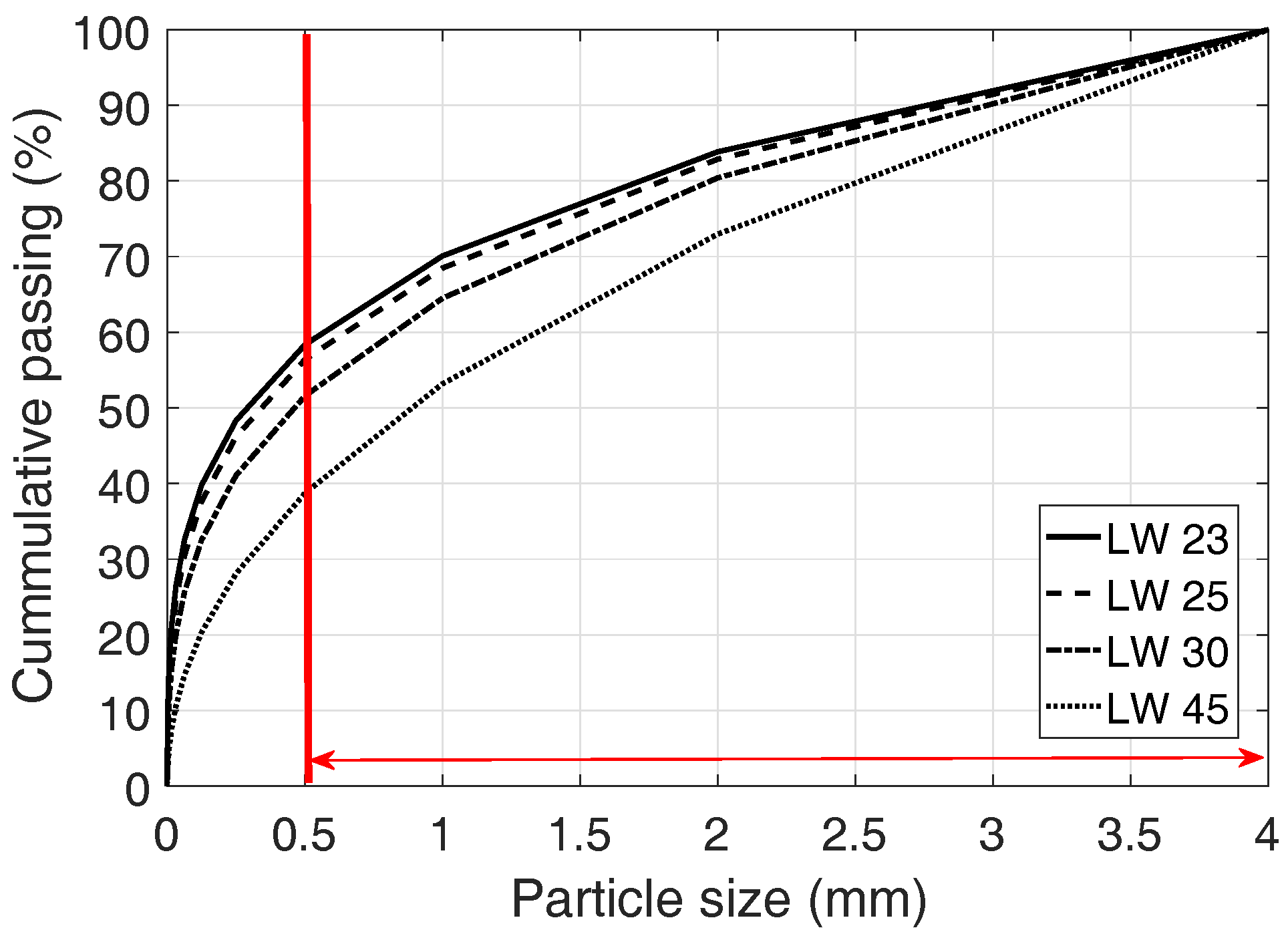

19]. Different gradings following the modified Andreasen and Andersen dense packing model [

20,

21,

22,

23] are adopted to produce the lightweight specimens with densely packed Liaver

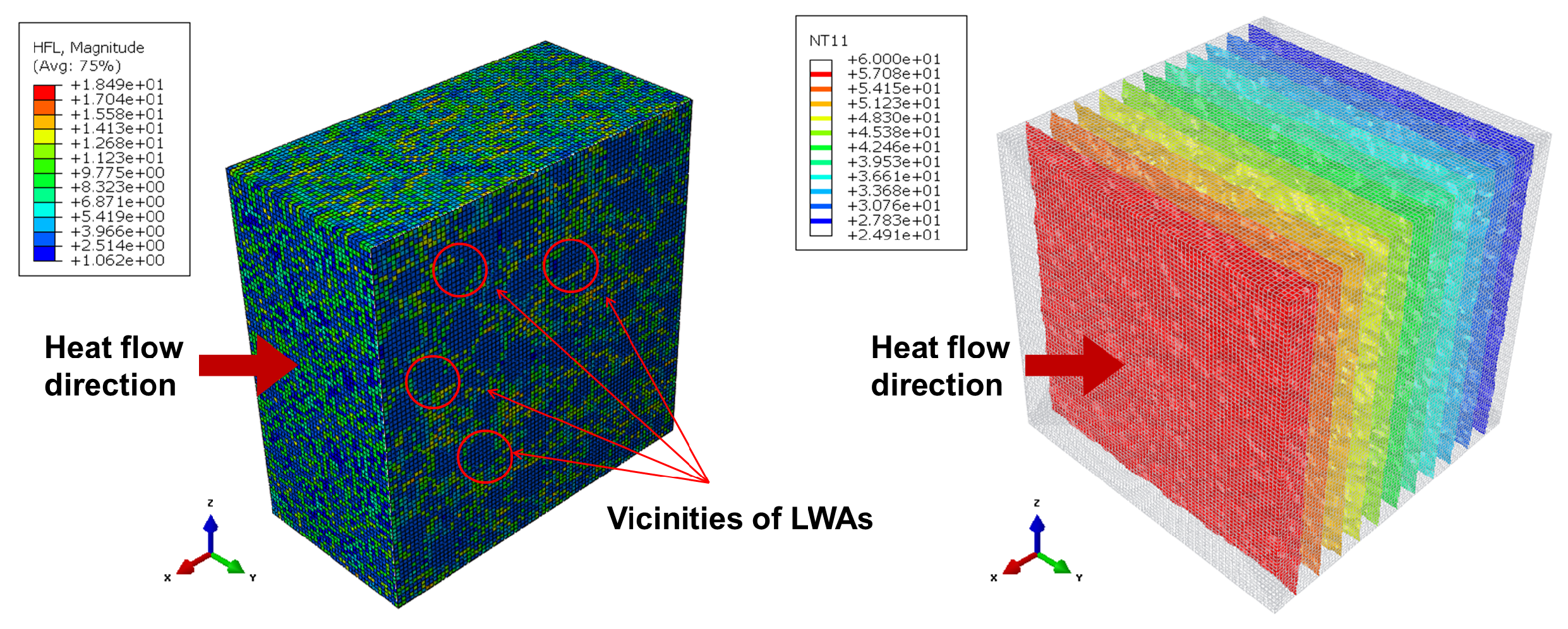

particles. Here, the target volume of lightweight aggregates is more than 70% of the concrete volume. To investigate the effect of the gradings on the material properties, elastic modulus, compressive strength, and thermal conductivity values of lightweight concrete specimens are evaluated using experimental and numerical approaches; experimental tools, such as testing compressive strength (Toni Technik, Berlin, Germany) and thermal conductivity by the transient plane source method (Hot Disk, Göteborg, Sweden), are adopted to measure the mechanical and thermal properties, respectively. For the numerical lightweight specimens, random packing models of particles with different size distributions are adopted here [

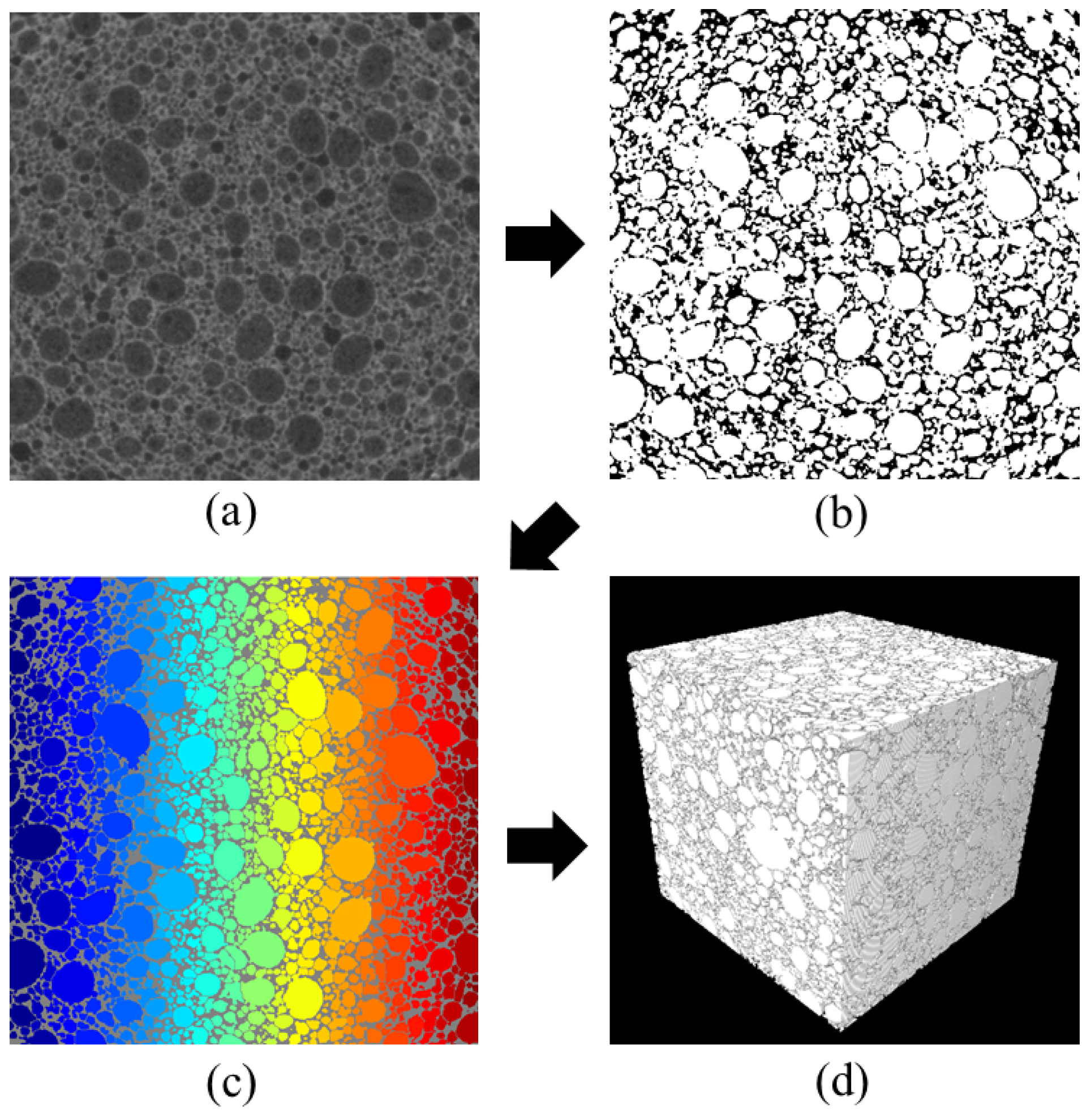

24,

25,

26], and their responses are computed using finite element (FE) analysis. In addition, X-ray computed tomography (CT) is utilized to investigate the inner structures of the lightweight concrete specimen without destruction of the samples; the aggregate structures are investigated by incorporating a probabilistic description method, the lineal-path function, to describe the size characteristics of the lightweight aggregates within the specimens. Then, the correlation of the gradings and the material properties is discussed.

5. Conclusions

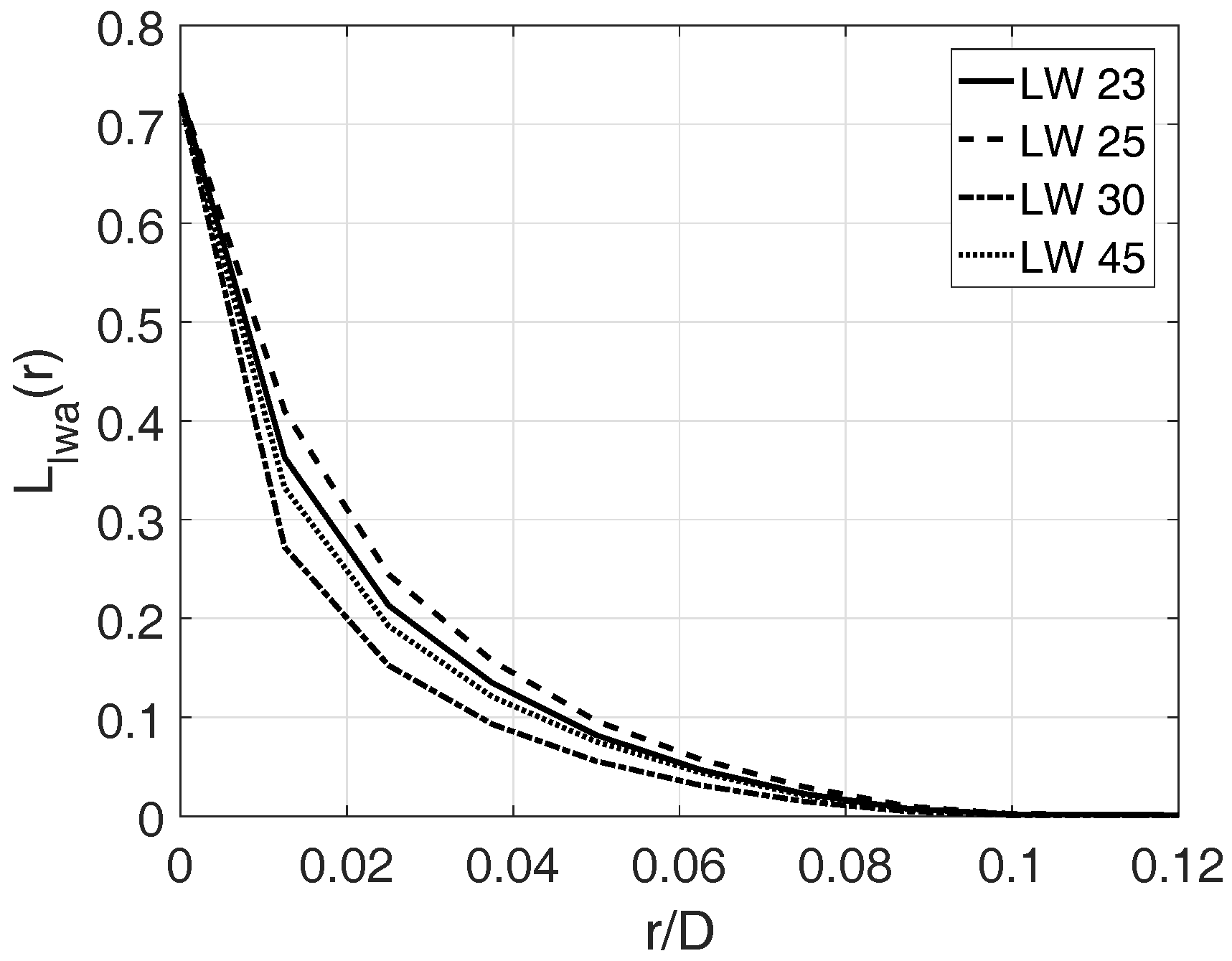

In this study, a series of ultra-lightweight concrete specimens less than 500 kg/m densities are designed and produced, and their properties and characteristics are evaluated. An expanded glass, Liaver, is used as the lightweight aggregate, and different gradings for the lightweight aggregates are adopted to maximize the aggregate contents in the specimens. The effects of gradings on the concrete characteristics and properties are investigated. For the purpose, the virtual specimens that contain more than 70% of aggregates are modeled. The qualities and the characteristics of the specimens are examined using X-ray CT and the lineal-path function, which is a probabilistic description method.

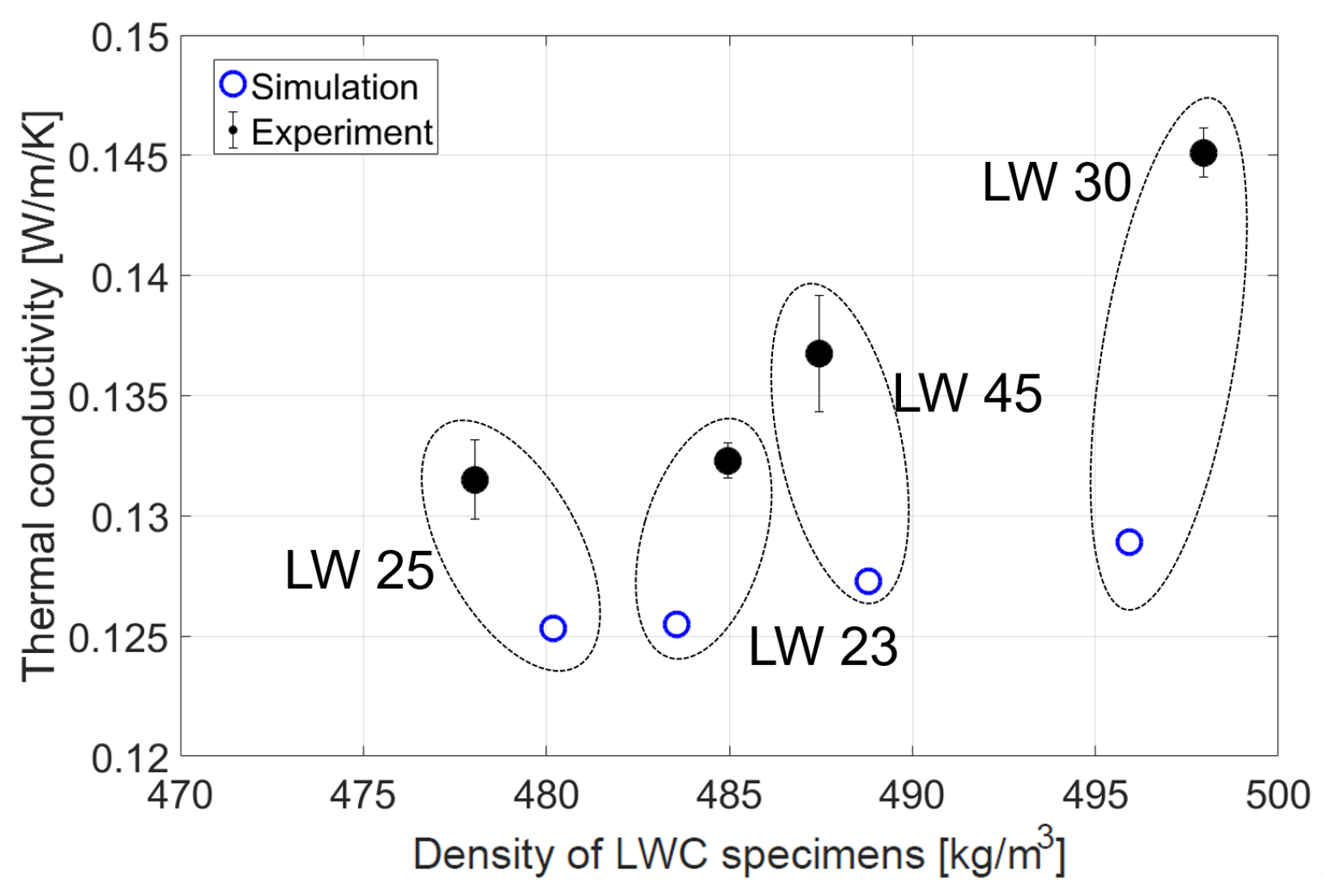

The material properties, such as elastic modulus, compressive strength, and thermal conductivity, are measured using experimental and numerical approaches. The conclusions of this study can be summarized as follows:

The obtained results show the effect of gradings and the packing algorithm on the material properties of lightweight aggregate concrete.

All the specimens produced in this study show a higher performance than conventional lightweight concrete based on efficiency factors, while the specimen densities are lower than those of conventional concretes.

When the volume content of the lightweight aggregates is the same, the lightweight concrete specimen with a larger proportion of finer aggregates shows a larger elastic modulus and compressive strength, while the thermal conductivity of the specimen is larger.

Lightweight concrete with lower thermal conductivity, while minimizing the loss of mechanical properties, can be produced by using an appropriate grading, although the density of the specimen strongly affects the material properties and becomes larger when the proportion of finer aggregates increases.

The X-ray CT imaging and the lineal-path function shows potential for examining the relative aggregate size in the concrete specimen.

With the confirmation of the effect of the grading on the material properties, a more in-depth parametric study of different gradings as well as a packing algorithm would be required for further development of ultra-lightweight concrete with higher performance.