Failure Monitoring and Condition Assessment of Steel-Concrete Adhesive Connection Using Ultrasonic Waves

Abstract

:1. Introduction

2. Materials and Methods

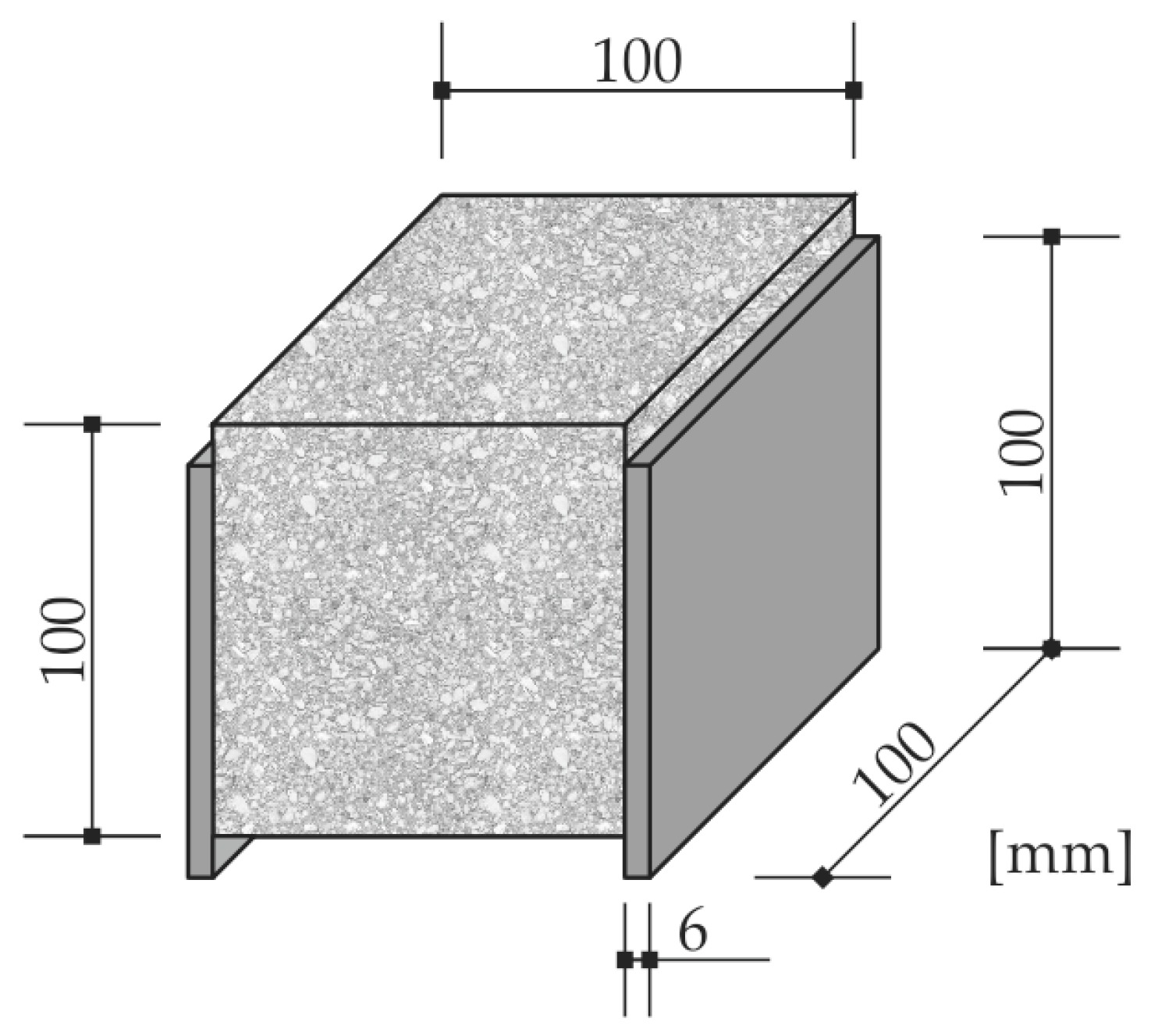

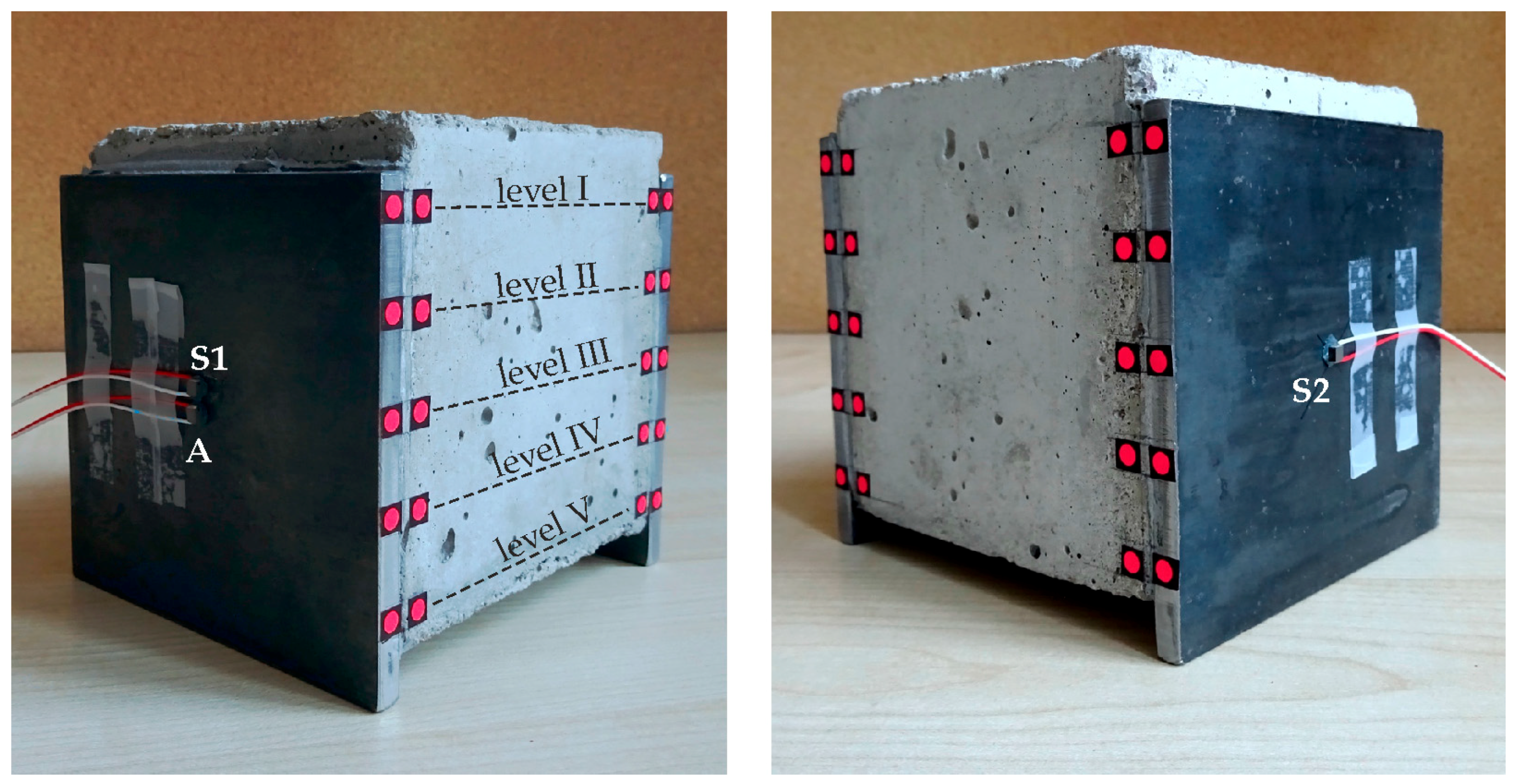

2.1. Test Specimens

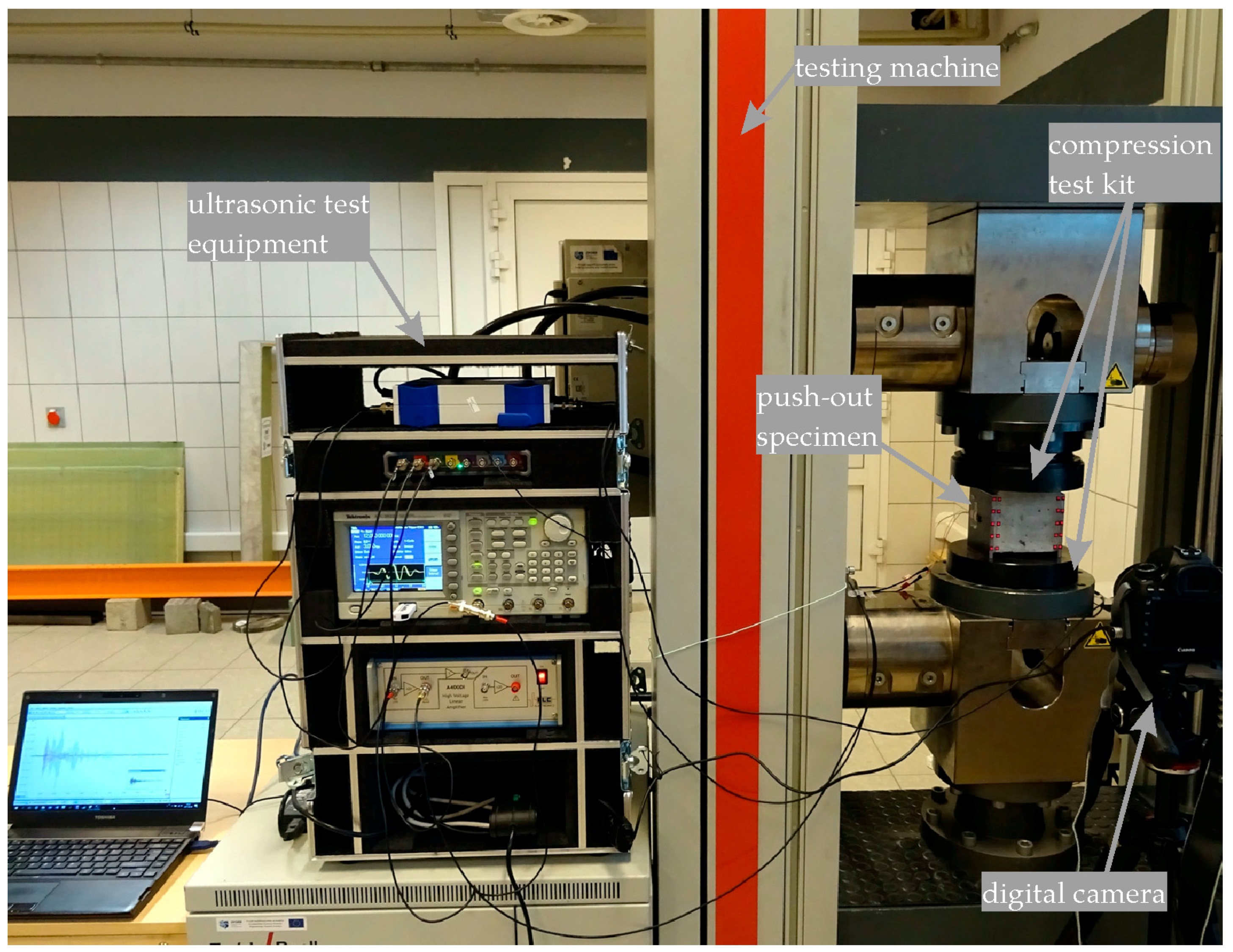

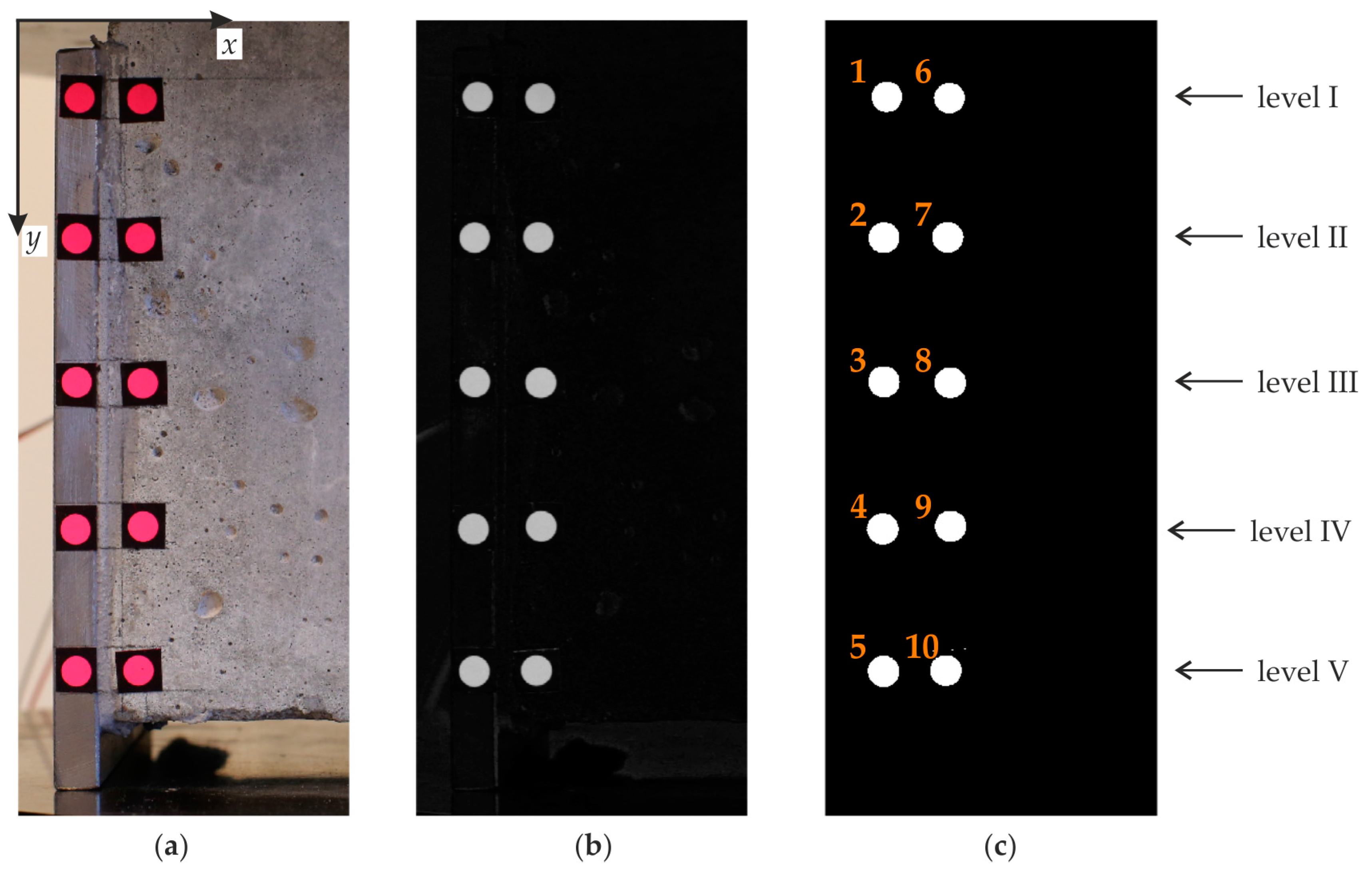

2.2. Experimental Procedure

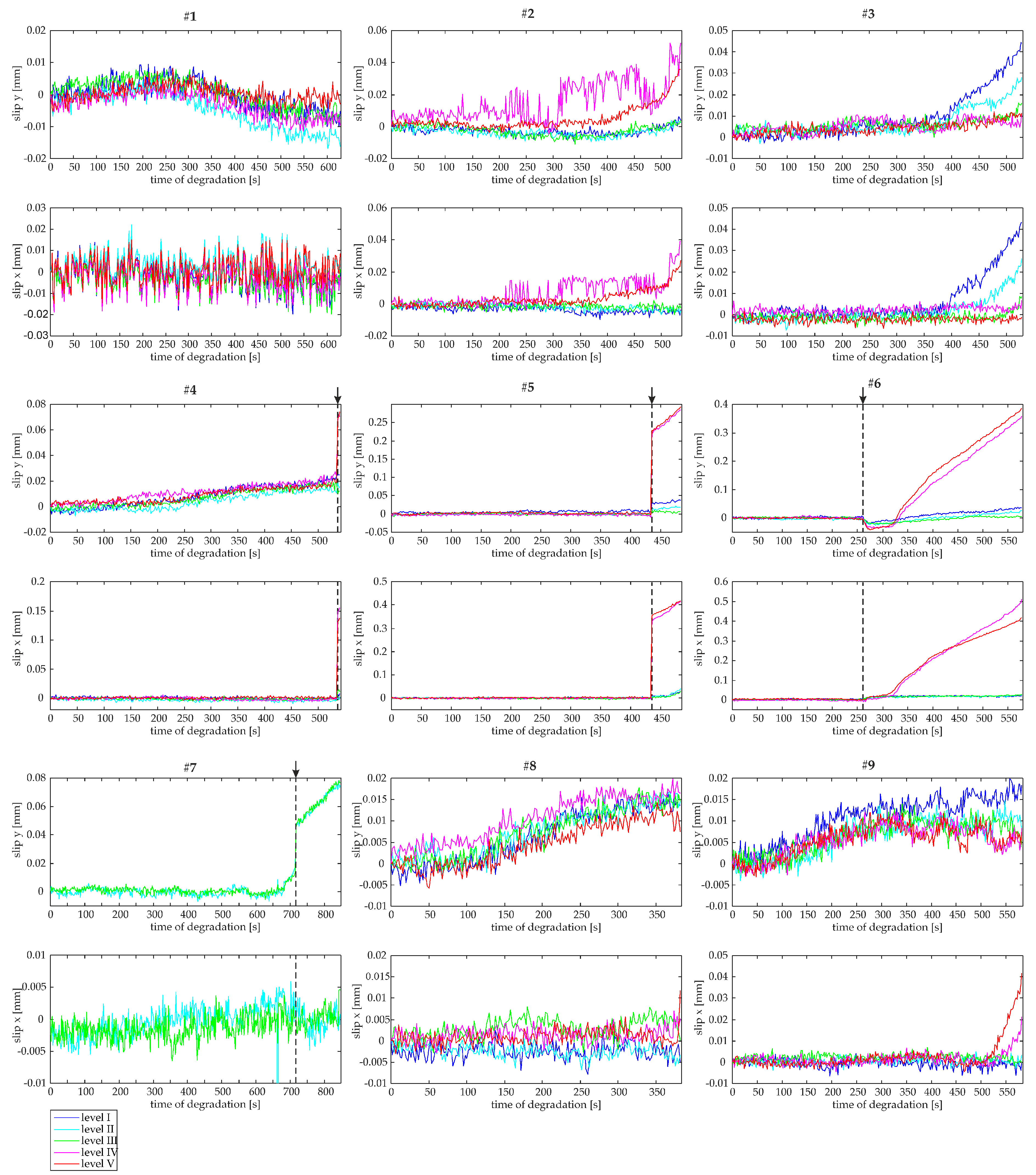

2.3. Data Processing for Slip Measurements

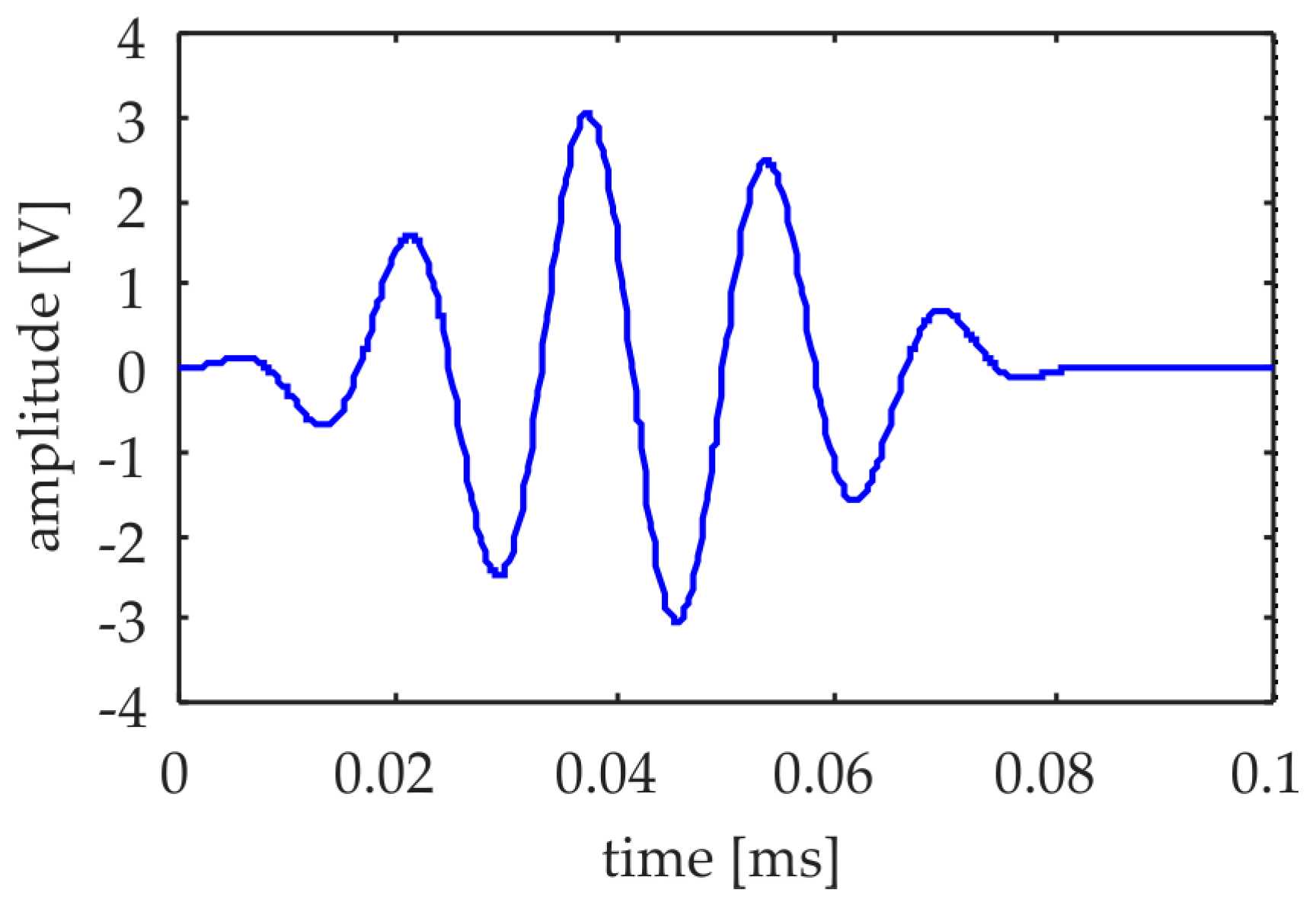

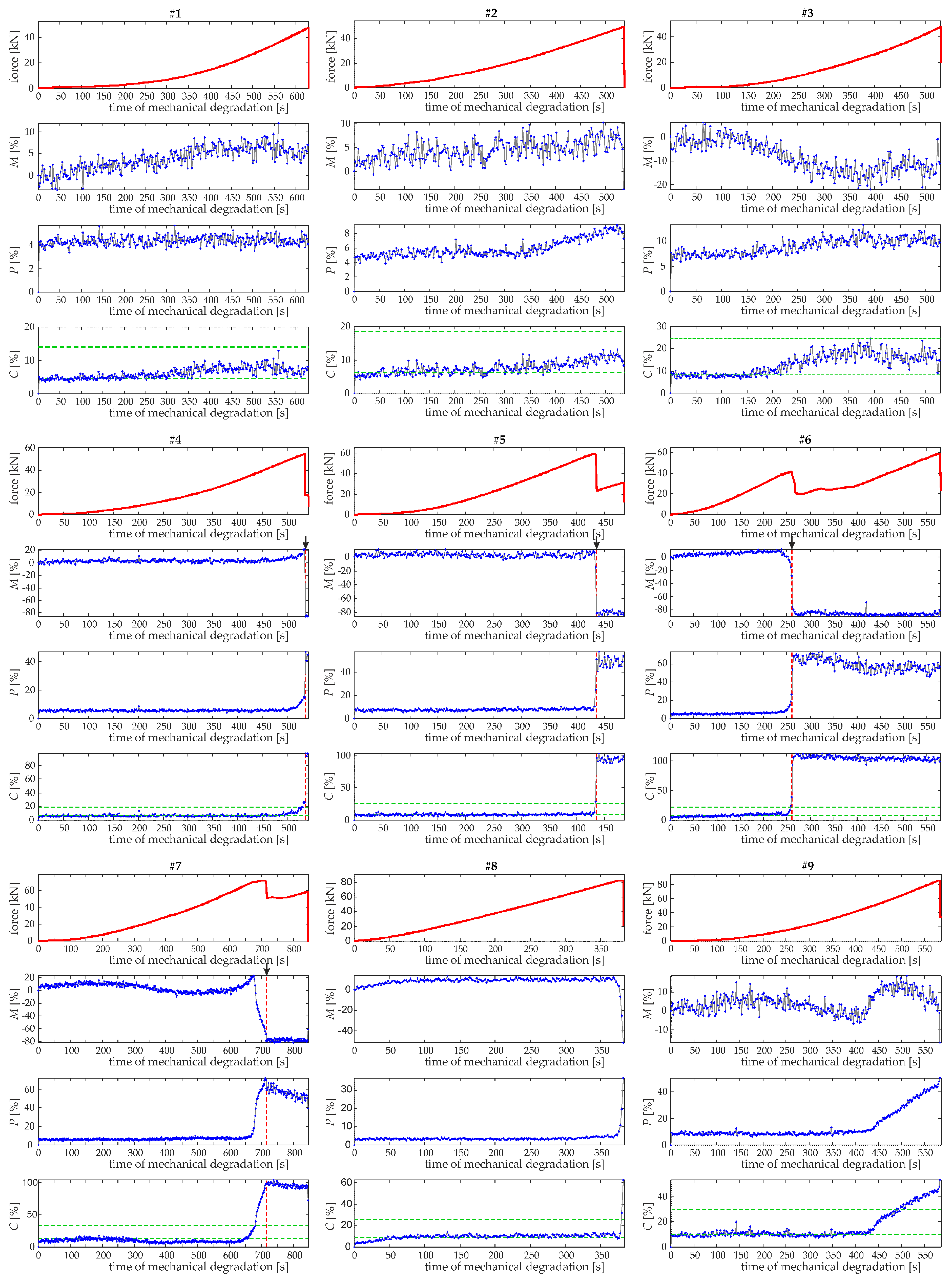

2.4. Data Processing for Damage Assessment

3. Results and Discussion

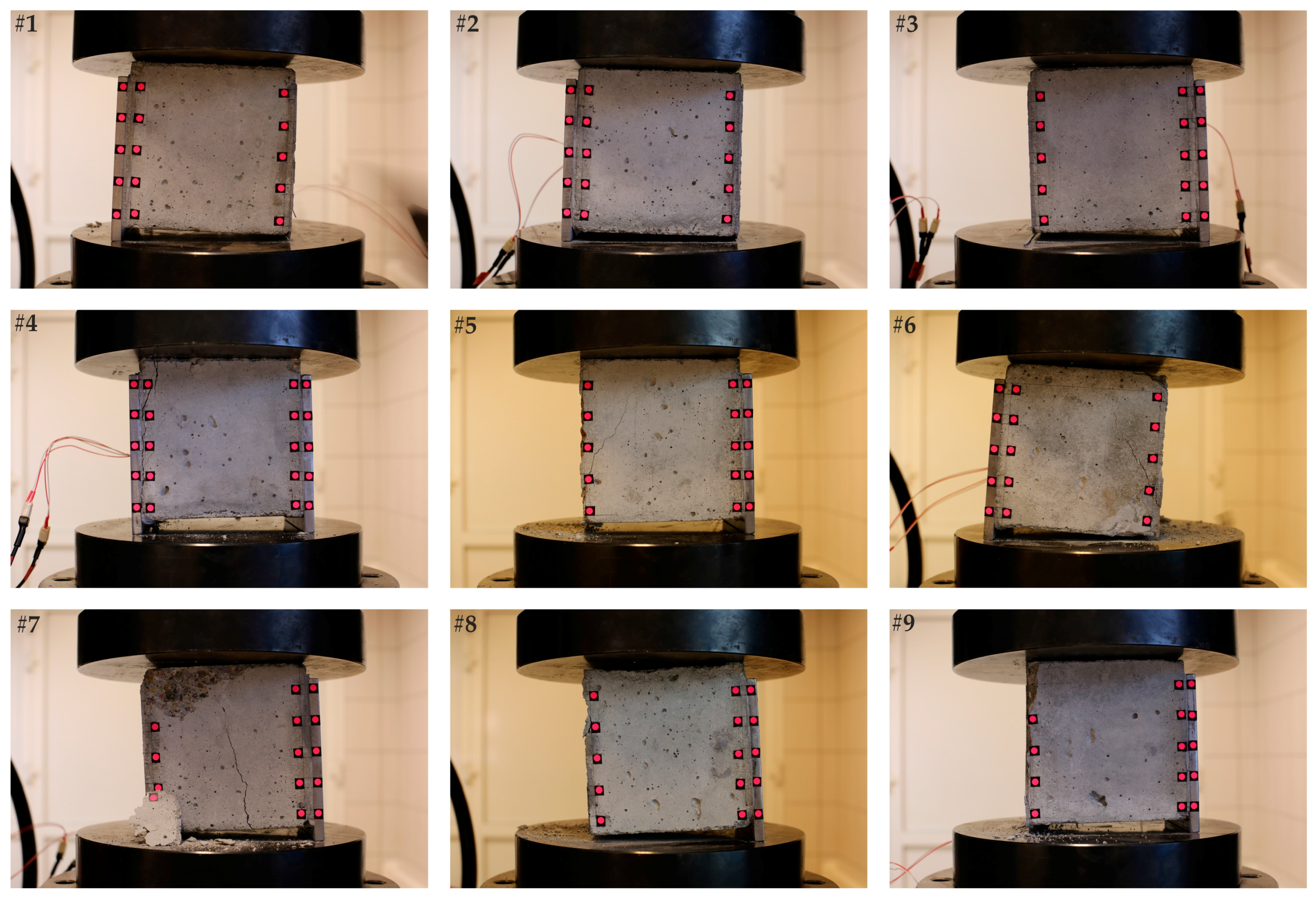

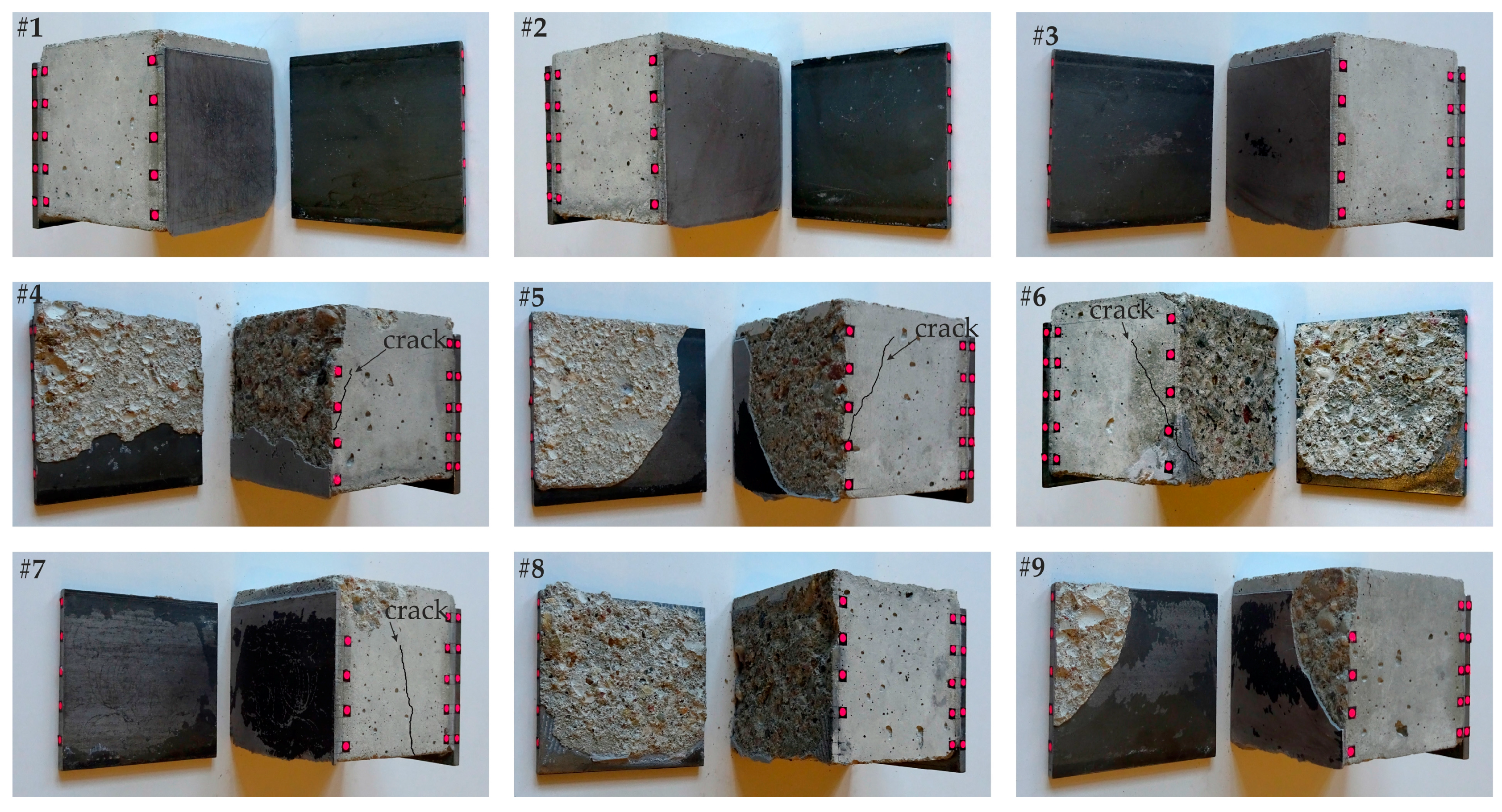

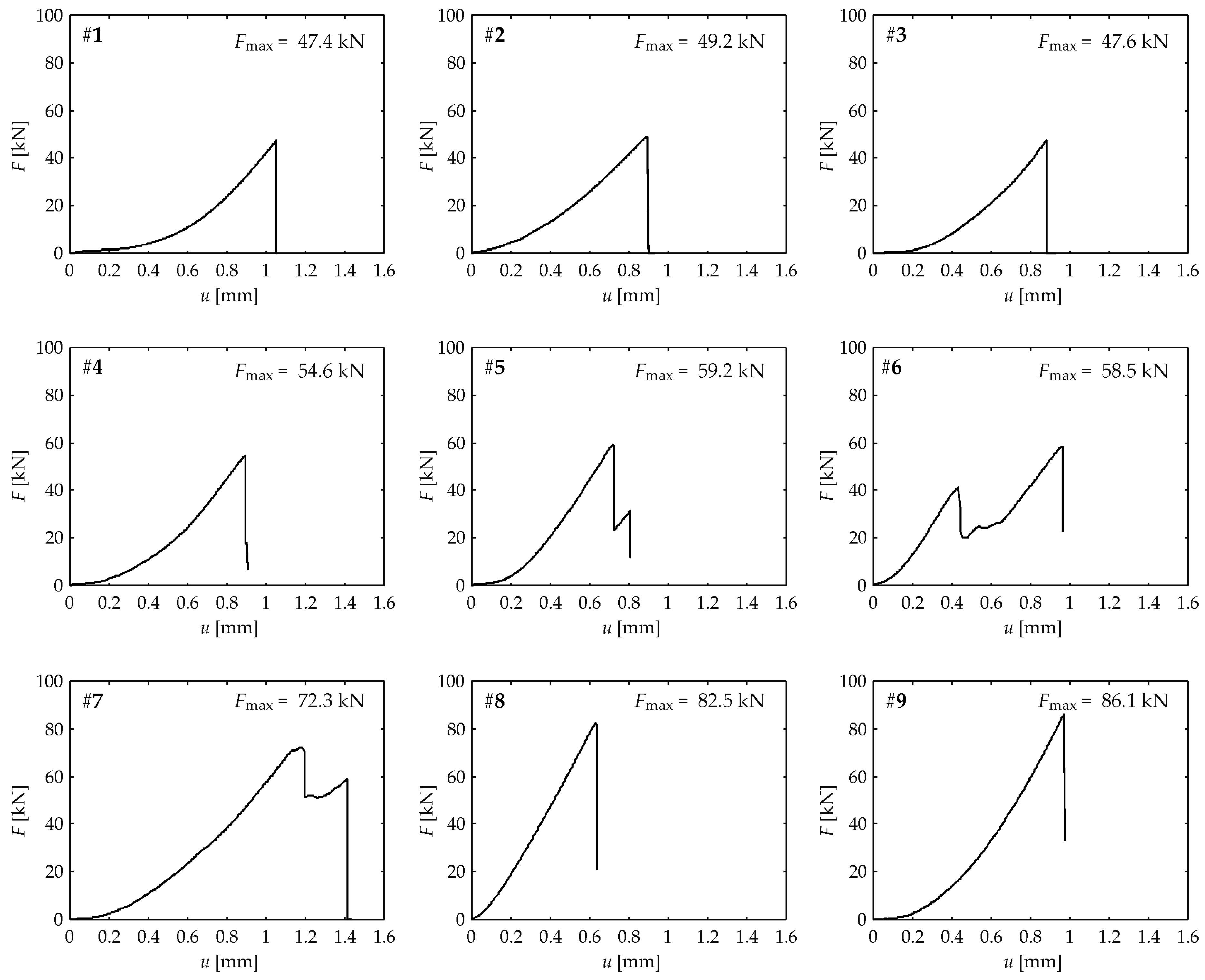

3.1. Push-out Tests and Failure Modes

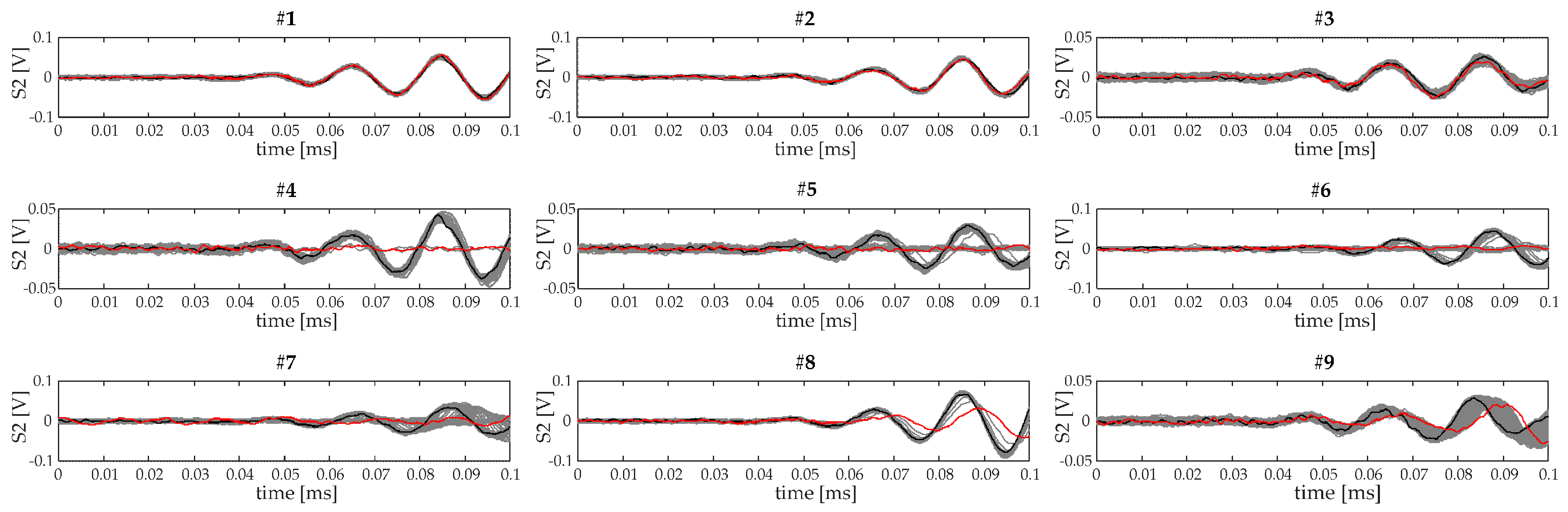

3.2. Ultrasonic Tests

4. Conclusions

Acknowledgments

Conflicts of Interest

References

- Adams, R.D.; Wake, W.C. Structural Adhesive Joints in Engineering; Elsevier Applied Science Publishers: Amsterdam, The Netherlands, 1986; ISBN 978-94-010-8977-7. [Google Scholar]

- Kumar, P.; Patnaik, A.; Chaudhary, S. A review on application of structural adhesives in concrete and steel–concrete composite and factors influencing the performance of composite connections. Int. J. Adhes. Adhes. 2017, 77, 1–14. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Lyons, J.; Petrou, M.; Laub, D.; Whitley, S. Fracture mechanics testing of the bond between composite overlays and a concrete substrate. J. Adhes. Sci. Technol. 2001, 15, 1351–1371. [Google Scholar] [CrossRef]

- Ali, M.S.M.; Oehlers, D.J.; Bradford, M.A. Debonding of steel plates adhesively bonded to the compression faces of RC beams. Constr. Build. Mater. 2005, 19, 413–422. [Google Scholar]

- Verbruggen, S.; De Sutter, S.; Iliopoulos, S.; Aggelis, D.G.; Tysmans, T. Experimental Structural Analysis of Hybrid Composite-Concrete Beams by Digital Image Correlation (DIC) and Acoustic Emission (AE). J. Nondestruct. Eval. 2016, 35, 1–10. [Google Scholar] [CrossRef]

- Marcon, M.; Vorel, J.; Ninčević, K.; Wan-Wendner, R. Modeling adhesive anchors in a discrete element framework. Materials 2017, 10, 917. [Google Scholar] [CrossRef] [PubMed]

- Bouazaoui, L.; Perrenot, G.; Delmas, Y.; Li, A. Experimental study of bonded steel concrete composite structures. J. Constr. Steel Res. 2007, 63, 1268–1278. [Google Scholar] [CrossRef]

- Bouazaoui, L.; Jurkiewiez, B.; Delmas, Y.; Li, A. Static behaviour of a full-scale steel-concrete beam with epoxy-bonding connection. Eng. Struct. 2008, 30, 1981–1990. [Google Scholar] [CrossRef]

- Jurkiewiez, B.; Meaud, C.; Michel, L. Non linear behaviour of steel-concrete epoxy bonded composite beams. J. Constr. Steel Res. 2011, 67, 389–397. [Google Scholar] [CrossRef]

- Van Gemert, D. Force transfer in epoxy bonded steel/concrete joints. Int. J. Adhes. Adhes. 1980, 1, 67–72. [Google Scholar] [CrossRef]

- Barnes, R.A.; Mays, G.C. The transfer of stress through a steel to concrete adhesive bond. Int. J. Adhes. Adhes. 2001, 21, 495–502. [Google Scholar] [CrossRef]

- Nehdi, M.; El Damatty, A.; Rahimi, R. Investigation on lap-joint behaviour of GFRP plates bonded to silica fume and rice husk ash concrete. Int. J. Adhes. Adhes. 2003, 23, 323–333. [Google Scholar] [CrossRef]

- Si Larbi, A.; Ferrier, E.; Jurkiewiez, B.; Hamelin, P. Static behaviour of steel concrete beam connected by bonding. Eng. Struct. 2007, 29, 1034–1042. [Google Scholar] [CrossRef]

- Berthet, J.F.; Yurtdas, I.; Delmas, Y.; Li, A. Evaluation of the adhesion resistance between steel and concrete by push out test. Int. J. Adhes. Adhes. 2011, 31, 75–83. [Google Scholar] [CrossRef]

- Helincks, P.; De Corte, W.; Klusák, J.; Boel, V.; De Schutter, G. Experimental Investigation of the Influence of the Bond Conditions on the Shear Bond Strength between Steel and Self-Compacting Concrete Using Push-Out Tests. Key Eng. Mater. 2012, 525–526, 205–208. [Google Scholar] [CrossRef]

- Meaud, C.; Jurkiewiez, B.; Ferrier, E. Steel-concrete bonding connection: An experimental study and non-linear finite element analysis. Int. J. Adhes. Adhes. 2014, 54, 131–142. [Google Scholar] [CrossRef]

- Zhan, Y.; Ma, Z.J.; Asce, F.; Zhao, R.; Li, G.; Xiang, T. Interface Behavior between Steel and Concrete Connected by Bonding. J. Bridge Eng. 2016, 21, 04016026. [Google Scholar] [CrossRef]

- Amerini, F.; Barbieri, E.; Meo, M.; Polimeno, U. Detecting loosening/tightening of clamped structures using nonlinear vibration. Smart Mater. Struct. 2010, 19, 85013. [Google Scholar] [CrossRef]

- Wang, T.; Song, G.; Wang, Z.; Li, Y. Proof-of-concept study of monitoring bolt connection status using a piezoelectric based active sensing method. Smart Mater. Struct. 2013, 22, 87001. [Google Scholar] [CrossRef]

- Kędra, R.; Rucka, M. Damage detection in a bolted lap joint using guided waves. Procedia Eng. 2017, 199, 2114–2119. [Google Scholar] [CrossRef]

- Rokhlin, S.I. Lamb wave interaction with lap-shear adhesive joints: Theory and experiment. J. Acoust. Soc. Am. 1991, 89, 2758–2765. [Google Scholar] [CrossRef]

- Di Scalea, F.L.; Bonomo, M.; Tuzzeo, D. Ultrasonic guided wave inspection of bonded lap joints: Noncontact method and photoelastic visualization. Res. Nondestruct. Eval. 2001, 13, 153–171. [Google Scholar] [CrossRef]

- Yonathan Sunarsa, T.; Aryan, P.; Jeon, I.; Park, B.; Liu, P.; Sohn, H. A Reference-Free and Non-Contact Method for Detecting and Imaging Damage in Adhesive-Bonded Structures Using Air-Coupled Ultrasonic Transducers. Materials 2017, 10, 1402. [Google Scholar] [CrossRef] [PubMed]

- Czarnecki, L.; Garbacz, A.; Krystosiak, M. On the ultrasonic assessment of adhesion between polymer coating and concrete substrate. Cem. Concr. Compos. 2006, 28, 360–369. [Google Scholar] [CrossRef]

- Garbacz, A. Application of stress based NDT methods for concrete repair bond quality control. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 77–85. [Google Scholar] [CrossRef]

- Garbacz, A.; Piotrowski, T.; Courard, L.; Kwaśniewski, L. On the evaluation of interface quality in concrete repair system by means of impact-echo signal analysis. Constr. Build. Mater. 2017, 134, 311–323. [Google Scholar] [CrossRef]

- Antonaci, P.; Bruno, C.L.E.; Gliozzi, A.S.; Scalerandi, M. Monitoring evolution of compressive damage in concrete with linear and nonlinear ultrasonic methods. Cem. Concr. Res. 2010, 40, 1106–1113. [Google Scholar] [CrossRef]

- Rucka, M.; Wilde, K. Experimental study on ultrasonic monitoring of splitting failure in reinforced concrete. J. Nondestruct. Eval. 2013, 32, 372–383. [Google Scholar] [CrossRef]

- Moradi-Marani, F.; Rivard, P.; Lamarche, C.P.; Kodjo, S.A. Evaluating the damage in reinforced concrete slabs under bending test with the energy of ultrasonic waves. Constr. Build. Mater. 2014, 73, 663–673. [Google Scholar] [CrossRef]

- Rucka, M.; Wilde, K. Ultrasound monitoring for evaluation of damage in reinforced concrete. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 65–75. [Google Scholar] [CrossRef]

- Shui, G.; Wang, Y.; Huang, P.; Qu, J. Nonlinear ultrasonic evaluation of the fatigue damage of adhesive joints. NDT E Int. 2015, 70, 9–15. [Google Scholar] [CrossRef]

- Zima, B.; Rucka, M. Guided wave propagation for assessment of adhesive bonding between steel and concrete. Procedia Eng. 2017, 199, 2300–2305. [Google Scholar] [CrossRef]

- Song, H.; Popovics, J.S. Characterization of steel-concrete interface bonding conditions using attenuation characteristics of guided waves. Cem. Concr. Compos. 2017, 83, 111–124. [Google Scholar] [CrossRef]

- Rucka, M.; Wilde, K. Crack identification using wavelets on experimental static deflection profiles. Eng. Struct. 2006, 28, 279–288. [Google Scholar] [CrossRef]

- Sprague, M.A.; Geers, T.L. A spectral-element method for modelling cavitation in transient fluid-structure interaction. Int. J. Numer. Methods Eng. 2004, 60, 2467–2499. [Google Scholar] [CrossRef]

- Schwer, L.E. Validation metrics for response histories: Perspectives and case studies. Eng. Comput. 2007, 23, 295–309. [Google Scholar] [CrossRef]

- Sarin, H.; Kokkolaras, M.; Hulbert, G.; Papalambros, P.; Barbat, S.; Yang, R.-J. Comparing Time Histories for Validation of Simulation Models: Error Measures and Metrics. J. Dyn. Syst. Meas. Control 2010, 132, 61401. [Google Scholar] [CrossRef]

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rucka, M. Failure Monitoring and Condition Assessment of Steel-Concrete Adhesive Connection Using Ultrasonic Waves. Appl. Sci. 2018, 8, 320. https://doi.org/10.3390/app8030320

Rucka M. Failure Monitoring and Condition Assessment of Steel-Concrete Adhesive Connection Using Ultrasonic Waves. Applied Sciences. 2018; 8(3):320. https://doi.org/10.3390/app8030320

Chicago/Turabian StyleRucka, Magdalena. 2018. "Failure Monitoring and Condition Assessment of Steel-Concrete Adhesive Connection Using Ultrasonic Waves" Applied Sciences 8, no. 3: 320. https://doi.org/10.3390/app8030320