Effect of Dangling Bonds on De-Poling Time for Polymeric Electric Field Optical Sensors

Abstract

:1. Introduction

2. Experimental Investigation

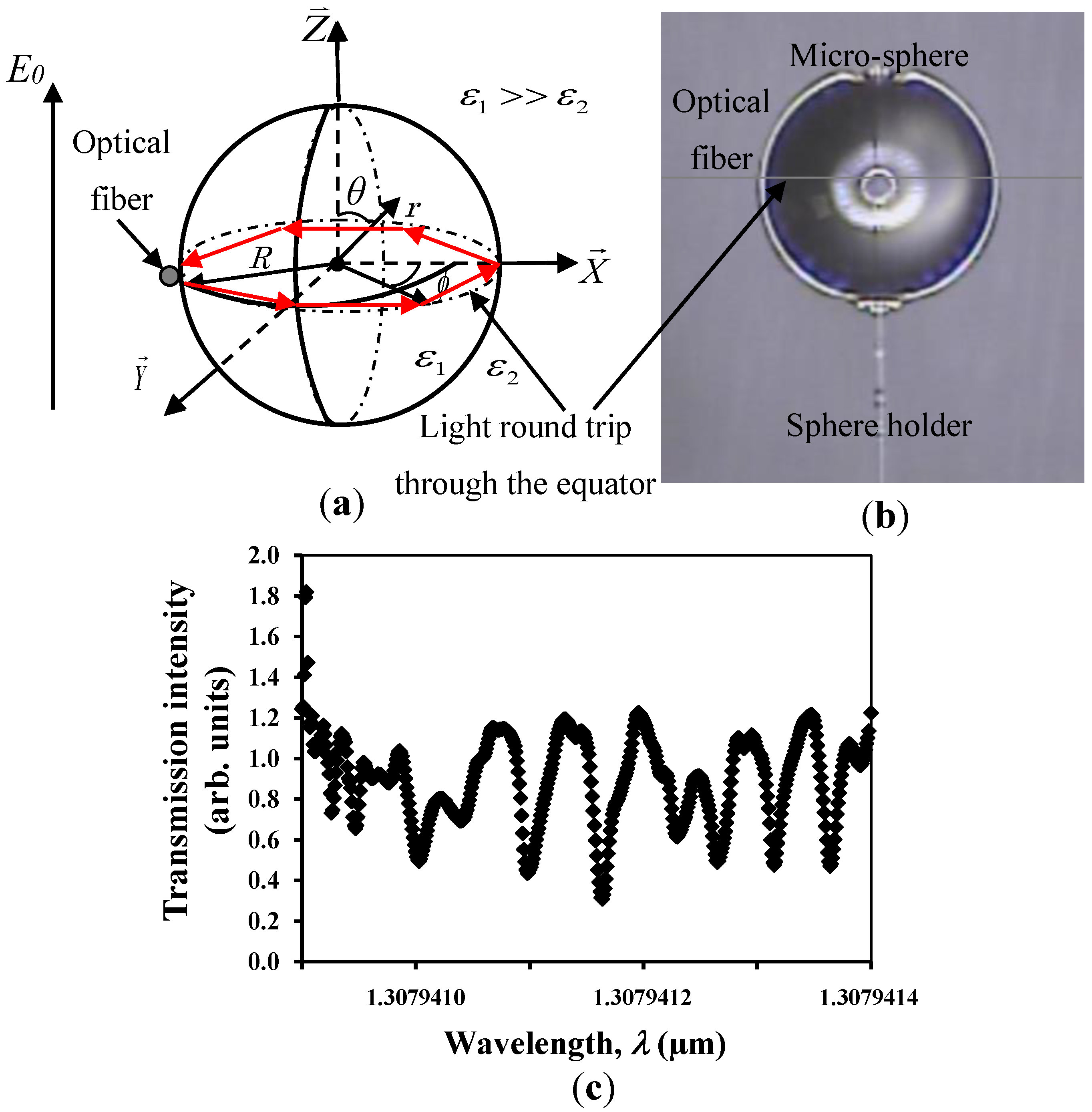

2.1. Measurement Approach

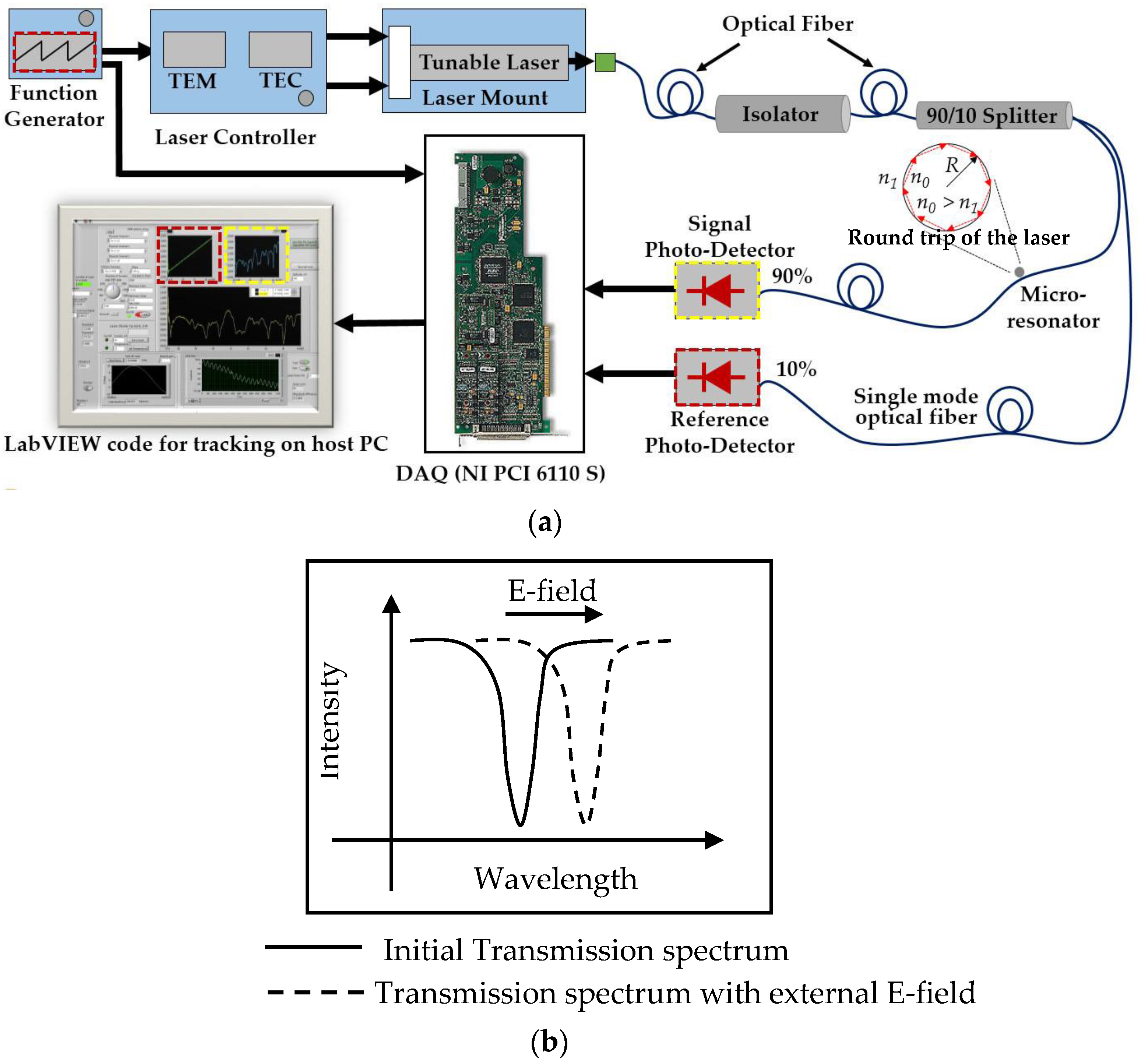

2.2. Experimental Opto-Electronics Setup

2.3. Fabrication of Sensing Elements

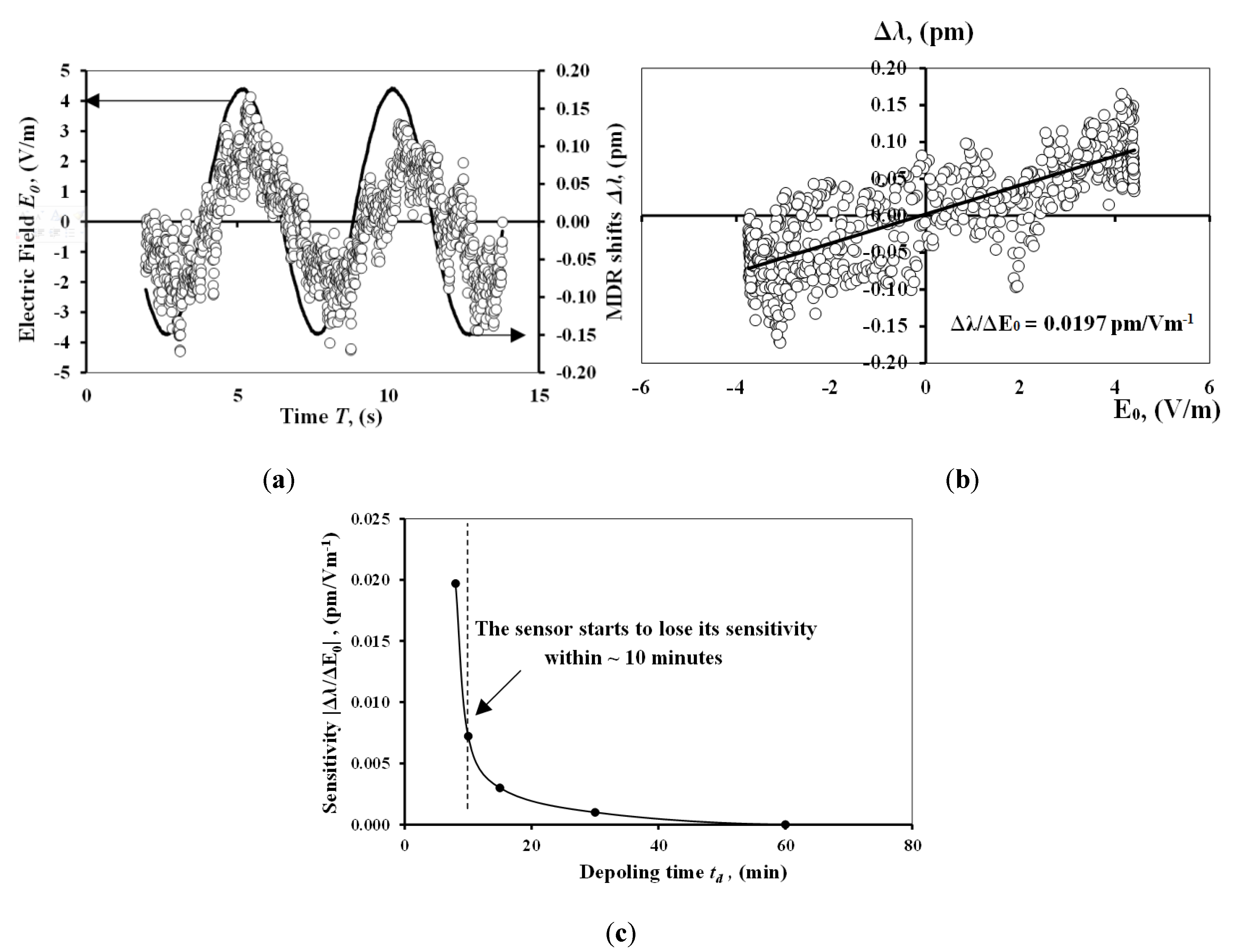

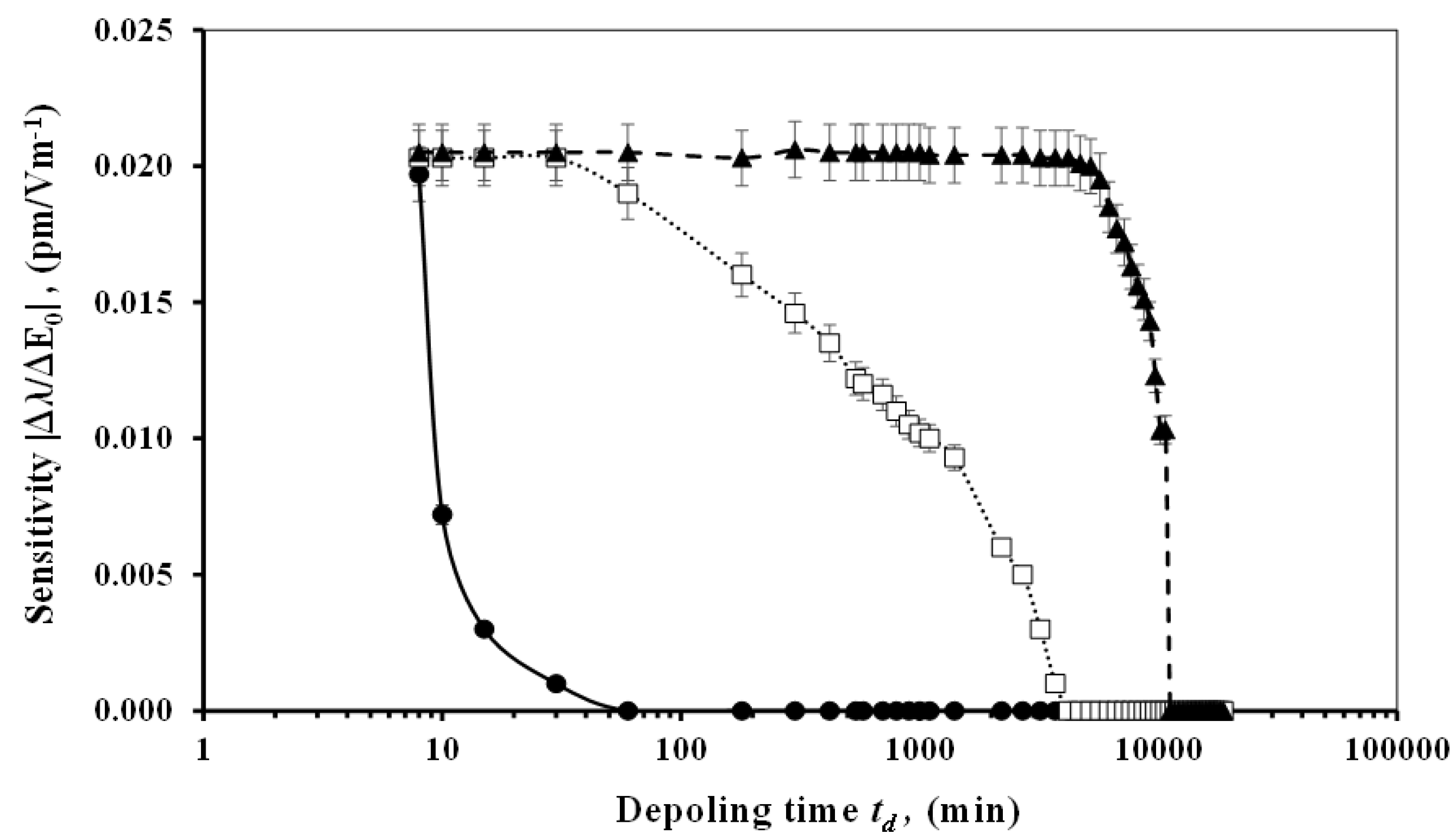

3. Experimental Results

4. Analysis and Discussion

5. Conclusions

Author Contributions

Conflicts of Interest

References

- Serpengüzel, A.; Arnold, S.; Griffel, G. Excitation of resonances of microspheres on an optical fiber. Opt. Lett. 1995, 20, 654–656. [Google Scholar] [CrossRef] [PubMed]

- Rosenberger, A.T.; Rezac, J.P. Whispering-gallerymode evanescent-wave microsensor for trace-gas detection. Proc. SPIE 2001, 4265, 102–112. [Google Scholar]

- Das, N.; Ioppolo, T.; Ötügen, V. Investigation of a micro-optical concentration sensor concept based on whispering gallery mode resonators. In Proceedings of the 45th AIAA Aerospace Sciences Meeting and Exhibition, Reno, NV, USA, 8–11 January 2007. [Google Scholar]

- Guan, G.; Arnold, S.; Ötügen, M.V. Temperature Measurements Using a Micro-Optical Sensor Based on Whispering Gallery Modes. AIAA J. 2006, 44, 2385–2389. [Google Scholar] [CrossRef]

- Roll, G.; Schweiger, G. Geometrical optics model of Mie resonances. J. Opt. Soc. Am. A. 2000, 17, 1301–1311. [Google Scholar] [CrossRef]

- Roll, G.; Kaiser, T.; Lange, S.; Schweiger, G. Ray interpretation of multipole fields in spherical dielectric cavities. J. Opt. Soc. Am. A. 1998, 15, 2879–2891. [Google Scholar] [CrossRef]

- Gorodetsky, M.L.; Savchenkov, A.A.; Ilchenko, V.S. Ultimate Q of optical microsphere resonators. Opt. Lett. 1996, 21, 453–455. [Google Scholar] [CrossRef] [PubMed]

- Griffel, G.; Arnold, S.; Taskent, D.; Serpengüzel, A.; Connolly, J.; Morris, N. Morphology-dependent resonances of a microsphere–optical fiber system. Opt. Lett. 1996, 21, 695–697. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.R.; Kamel, M.A. Mathematical model for electric field sensor based on whispering gallery modes using Navier’s equation for linear elasticity. J. Math. Probl. Eng. 2017, 2017, 9649524. [Google Scholar] [CrossRef]

- Ali, A.R.; Kamel, M.A. Novel techniques for optical sensor using single core multilayer structures for electric field detection. In Proceedings of the SPIE Optics & Optoelectronics, Prague, Czech Republic, 24–27 April 2017. [Google Scholar]

- Ali, A.R.; Ioppolo, T.; Ötügen, V.; Christensen, M.; MacFarlane, D. Photonic electric field sensor based on polymeric microspheres. J. Polym. Sci. Part B Polym. Phys. 2014, 52, 276–279. [Google Scholar] [CrossRef]

- Ioppolo, T.; Ötügen, M.V.; Ayaz, U.K. Development of whispering gallery mode polymeric micro-optical electric field sensors. J. Vis. Exp. 2013, e50199. [Google Scholar] [CrossRef] [PubMed]

- Ioppolo, T.; Stubblefield, J.; Ötügen, M.V. Electric field-induced deformation of polydimethylsiloxane polymers. J. Appl. Phys. 2012, 112, 044906. [Google Scholar] [CrossRef]

- Gluckman, B.J.; Nguyen, H.; Weinstein, S.L.; Schiff, S.J. Adaptive Electric Field Control of Epileptic Seizures. J. Neurosci. 2001, 21, 590–600. [Google Scholar] [CrossRef] [PubMed]

- Ioppolo, T.; Ayaz, U.K.; Ötügen, M.V. High-resolution force sensor based on morphology dependent optical resonances of polymeric spheres. J. Appl. Phys. 2009, 105, 013535. [Google Scholar] [CrossRef]

- Ali, A.R.; Ioppolo, T.; Ötügen, M.V. High-resolution electric field sensor based on whispering gallery modes of a beam-coupled dielectric resonator. In Proceedings of the 2012 International Conference on Engineering and Technology (ICET), Cairo, Egypt, 10–11 October 2012. [Google Scholar]

- Ayaz, U.; Ioppolo, T.; Ötügen, M.V. Wall shear stress sensor based on the optical resonances of dielectric microspheres. Meas. Sci. Technol. 2011, 22, 075203. [Google Scholar] [CrossRef]

- Serpengüzel, A.; Arnold, S.; Griffel, G.; Lock, J.A. Enhanced coupling to microsphere resonances with optical fibers. J. Opt. Soc. Am. B 1997, 14, 790–795. [Google Scholar] [CrossRef]

- Foreman, M.R. Single-particle Spectroscopy: Whispers of absorption. Nat. Photonics 2016, 10, 755–757. [Google Scholar] [CrossRef]

- Klitzing, W.V. Tunable whispering modes for spectroscopy and CQED Experiments. New J. Phys. 2001, 3, 14:1–14:14. [Google Scholar] [CrossRef]

- Cai, M.; Painter, O.; Vahala, K.J.; Sercel, P.C. Fiber-coupled microsphere laser. Opt. Lett. 2000, 25, 1430–1432. [Google Scholar] [CrossRef] [PubMed]

- Tapalian, H.C.; Laine, J.P.; Lane, P.A. Thermooptical switches using coated microsphere resonators. IEEE Photonics Technol. Lett. 2002, 14, 1118–1120. [Google Scholar] [CrossRef]

- Little, B.E.; Chu, S.T.; Haus, H.A.; Foresi, J.; Laine, J.P. Microring resonator channel dropping filters. J. Lightwave Technol. 1997, 15, 998–1005. [Google Scholar] [CrossRef]

- Offrein, B.J.; Germann, R.; Horst, F.; Salemink, H.W.M.; Beyerl, R.; Bona, G.L. Resonant coupler-based tunable add-after-drop filter in silicon-oxynitride technology for WDM networks. IEEE J. Sel. Top. Quantum Electron. 1999, 5, 1400–1406. [Google Scholar] [CrossRef]

- Ali, A.R.; Elias, C.M. Ultra-sensitive optical resonator for organic solvents detection based on whispering gallery modes. Chemosensors 2017, 5, 19. [Google Scholar] [CrossRef]

- Ali, A.R. Development of Whispering Gallery Mode Polymeric Micro-optical Sensors to Detect Chemical Impurities in Water Environment. Sci. Pages Photonics Opt. 2017, 1, 7–15. [Google Scholar]

- Ali, A.R.; Massoud, Y.M. Bio-optical sensor for brain activity measurement based on whispering gallery modes. In Proceedings of the SPIE Micro Technologies, Barcelona, Spain, 8–10 May 2017. [Google Scholar]

- Ali, A.R.; Afifi, A.N.; Taha, H. Optical signal processing and tracking of whispering gallery modes in real time for sensing applications. In Proceedings of the SPIE Micro Technologies, Barcelona, Spain, 8–10 May 2017. [Google Scholar]

- Ali, A.R.; Erian, A.; Shokry, K. Computational model and simulation for the whispering gallery modes inside micro-optical cavity. In Proceedings of the SPIE Micro Technologies, Barcelona, Spain, 8–10 May 2017. [Google Scholar]

- Ali, A.R.; Elias, C. Direct measurement for organic solvents diffusion using ultra-sensitive optical resonator. In Proceedings of the SPIE Micro Technologies, Barcelona, Spain, 8–10 May 2017. [Google Scholar]

- Ali, A.R.; Gatherer, A.; Ibrahim, M.S. Spinning optical resonator sensor for torsional vibrational applications measurements. In Proceedings of the SPIE LASE International Society for Optics and Photonics, San-Francisco, CA, USA, 22 April 2016. [Google Scholar]

- Matsko, A.B.; Savchenkov, A.A.; Strekalov, D.; Ilchenko, V.S.; Maleki, L. Review of application of whispring-gallery mode resonators in photonics and nonlinear optics. IPN Prog. Rep. 2005, 42–162, 1–51. [Google Scholar]

- Huston, A.L.; Eversole, J.D. Strain-sensitive elastic scattering from cylinders. Opt. Lett. 1993, 18, 1104–1106. [Google Scholar] [CrossRef] [PubMed]

- Knight, J.C.; Cheung, G.; Jacques, F.; Birks, T.A. Phase-matched excitation of whispering-gallery-mode resonances by a fiber taper. Opt. Lett. 1997, 22, 1129–1131. [Google Scholar] [CrossRef] [PubMed]

- Lemke, B.P.; Haneman, D. Dangling bonds on silicon. Phys. Rev. B 1978, 17, 1893. [Google Scholar] [CrossRef]

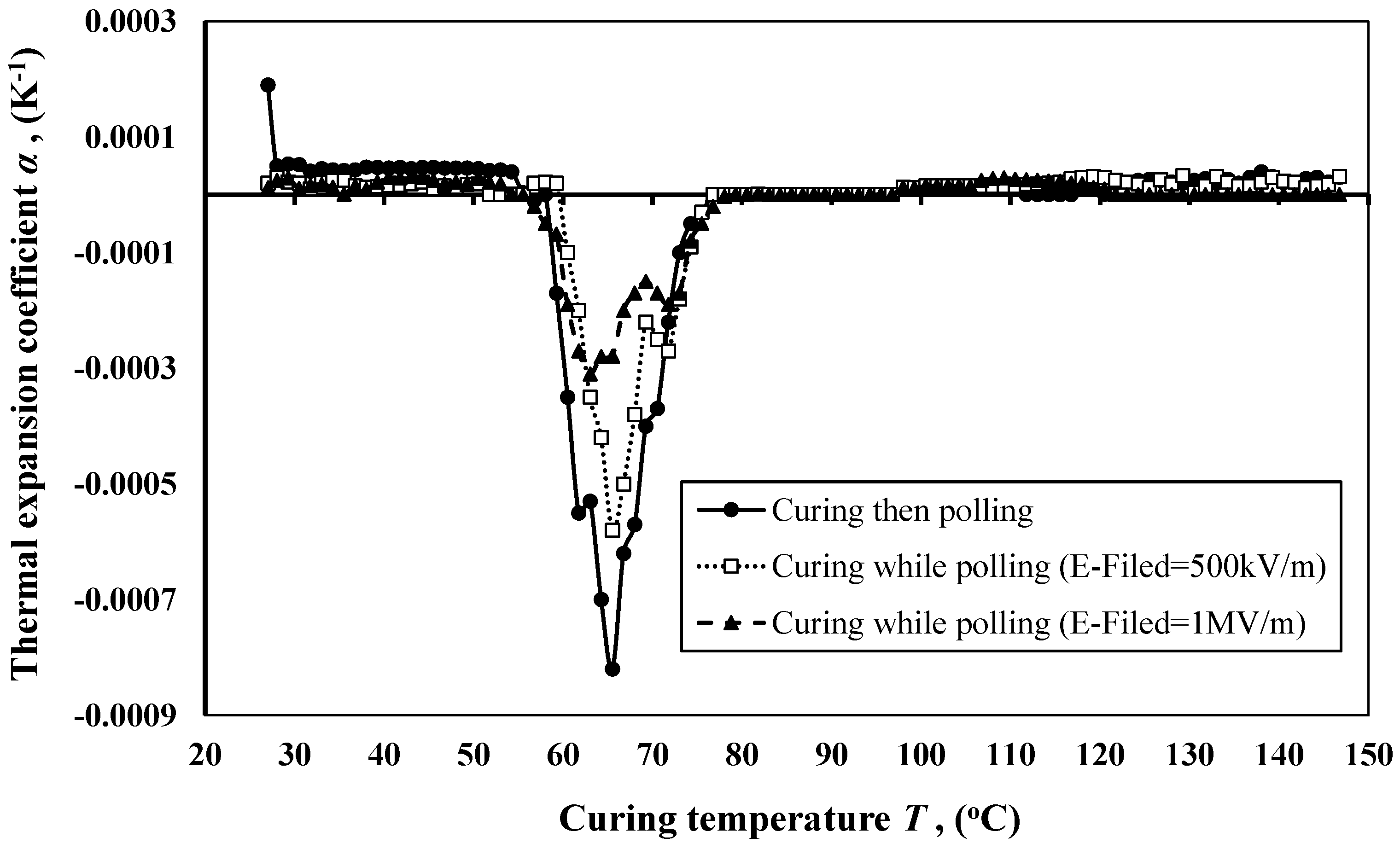

is the curing then poling,

is the curing then poling,  is the curing while poling in an electric field = 500 kV/m, and

is the curing while poling in an electric field = 500 kV/m, and  is the curing while poling in an electric field = 1 MV/m.

is the curing while poling in an electric field = 1 MV/m.

is the curing then poling,

is the curing then poling,  is the curing while poling in an electric field = 500 kV/m, and

is the curing while poling in an electric field = 500 kV/m, and  is the curing while poling in an electric field = 1 MV/m.

is the curing while poling in an electric field = 1 MV/m.

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.R.; Tourky, A.S.; Ali, R.A. Effect of Dangling Bonds on De-Poling Time for Polymeric Electric Field Optical Sensors. Chemosensors 2018, 6, 3. https://doi.org/10.3390/chemosensors6010003

Ali AR, Tourky AS, Ali RA. Effect of Dangling Bonds on De-Poling Time for Polymeric Electric Field Optical Sensors. Chemosensors. 2018; 6(1):3. https://doi.org/10.3390/chemosensors6010003

Chicago/Turabian StyleAli, Amir R., Amal S. Tourky, and Roushdy A. Ali. 2018. "Effect of Dangling Bonds on De-Poling Time for Polymeric Electric Field Optical Sensors" Chemosensors 6, no. 1: 3. https://doi.org/10.3390/chemosensors6010003