A Review of 4IR/5IR Enabling Technologies and Their Linkage to Manufacturing Supply Chain

Abstract

:1. Introduction

- What is the present state of the supply chain for the manufacturing sectors?

- What approaches have researchers employed in describing the manufacturing supply chain?

- What does the literature suggest will be the proposed impact of the enablers of the manufacturing supply chain?

- What does the literature indicate as the gaps and the shortfalls of the fourth industrial revolution concerning the manufacturing supply chain?

2. Research Methodology

3. Industrial Revolutions and the Enablers of Industry 4.0

3.1. Physical Technology Drivers

3.1.1. Autonomous Vehicles

Autonomous Vehicles and MSC

3.1.2. Additive Manufacturing

Additive Manufacturing and MSC

3.1.3. Advanced Robotics and Collaborating Robots

Advanced Robotics and Collaborating Robots and MSC

3.2. Digital Technology Drivers

3.2.1. IoT

IoT and MSC

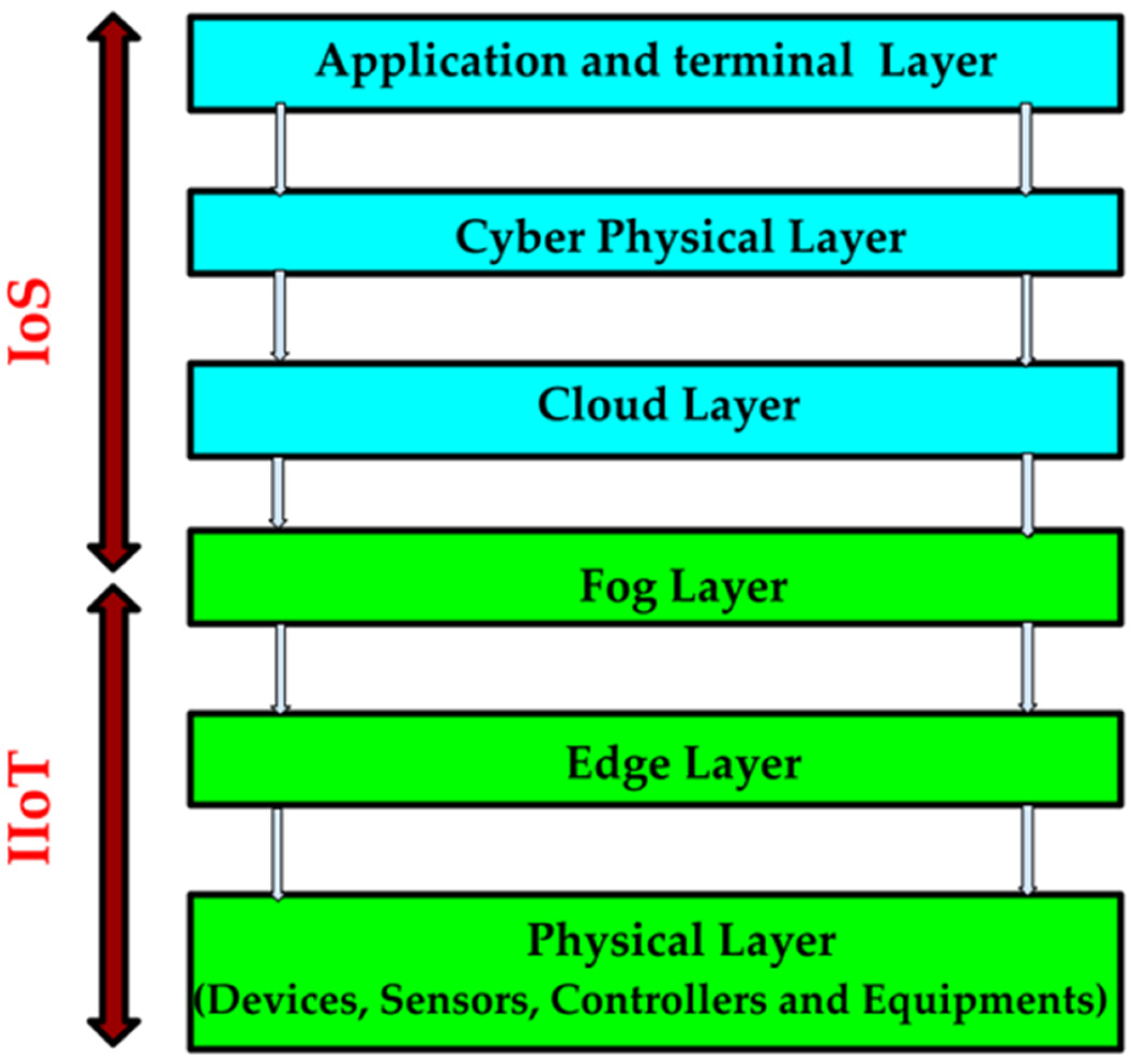

3.2.2. IIoT

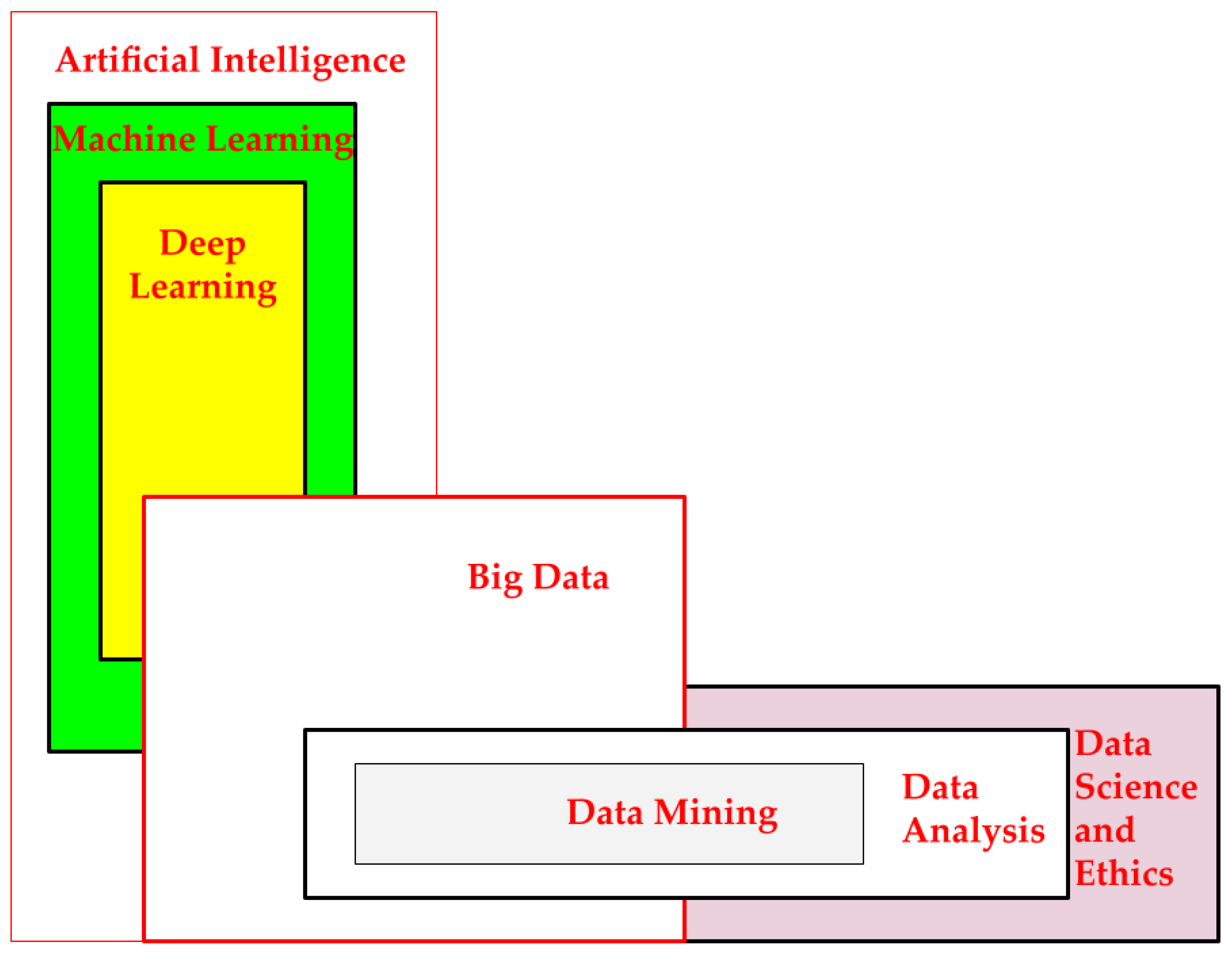

3.2.3. Artificial Intelligence

- AI design must benefit humanity;

- Increasing the effectiveness of AI must not jeopardize human dignity; and

- It must be possible for a human to reverse the unintended consequences of the AI design algorithm.

AI and MSC

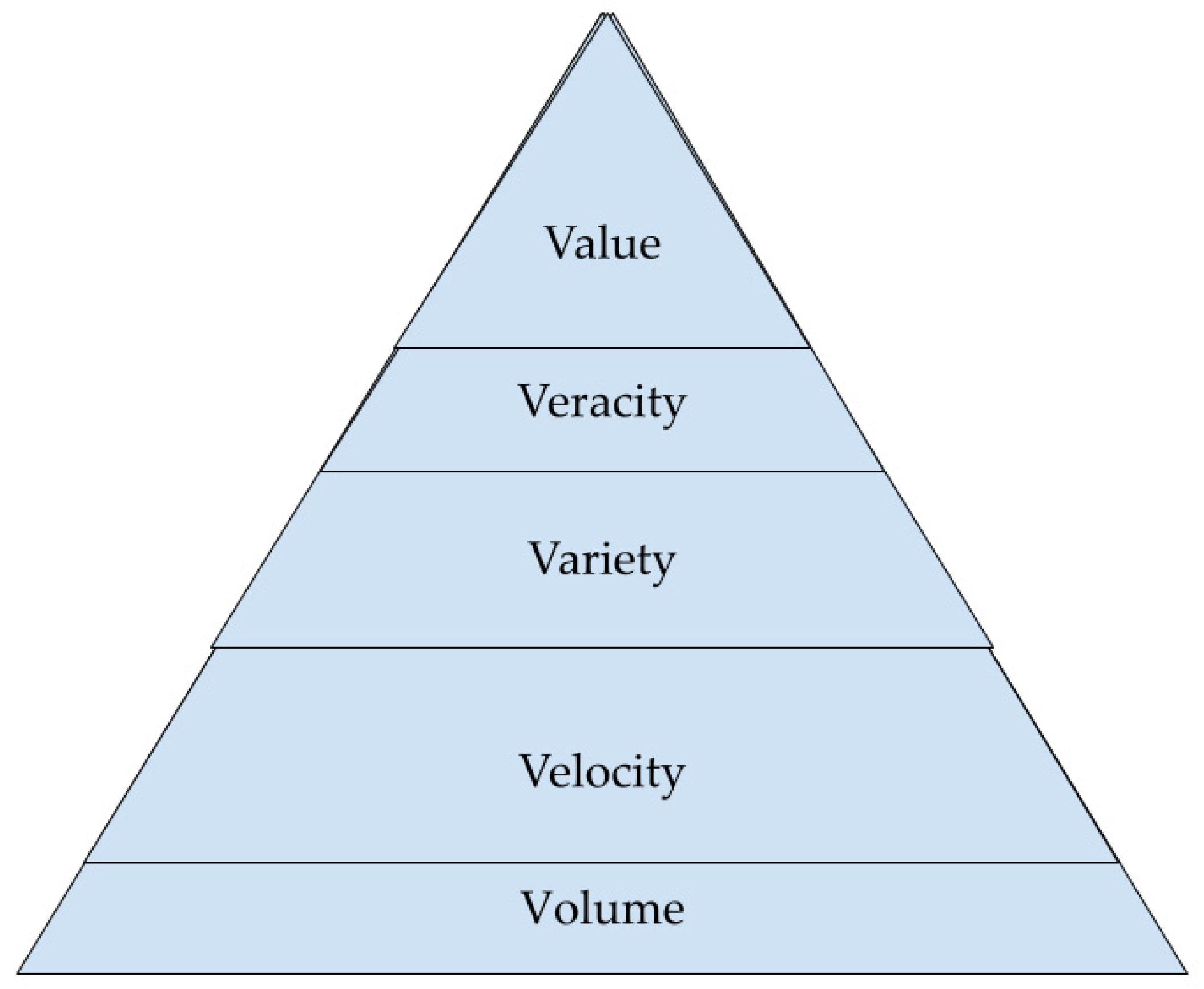

3.2.4. Big Data and Cloud Computing

Cloud Computing, Big Data and MSC

3.2.5. Blockchain-Powered Digital Platforms

Blockchain and MSC

3.2.6. Machine and Deep Learning

Machine/Deep Learning and MSC

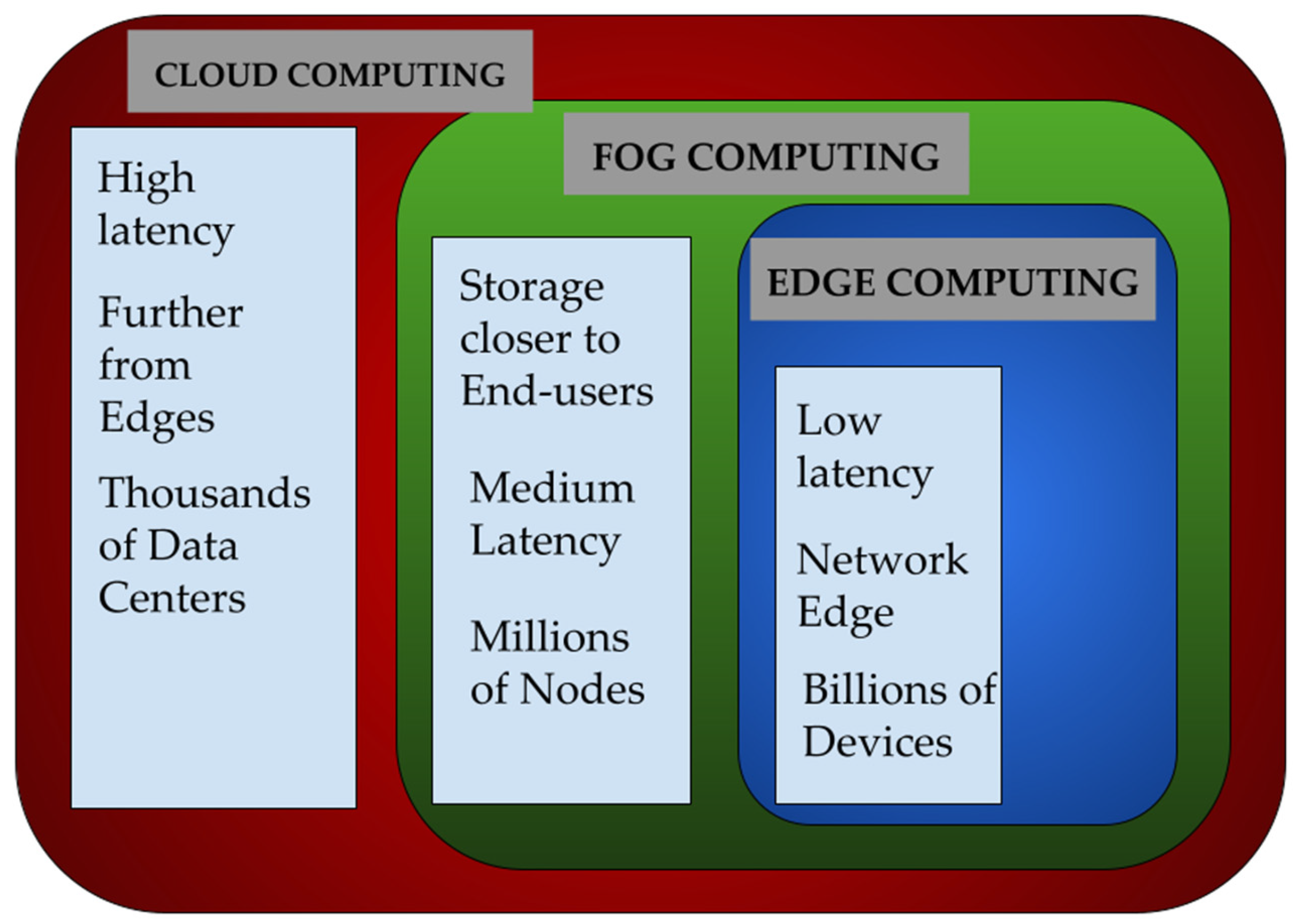

3.2.7. Edge Analytics and Fog Computing

Edge Analytics and Fog Computing and MSC

4. Approaches to Manufacturing Technologies

4.1. Intelligent Manufacturing

4.2. IoT-Enabled Manufacturing

4.3. Cloud-Based Smart Manufacturing

4.4. Flexible Manufacturing Systems

4.5. Reconfigurable Manufacturing Systems

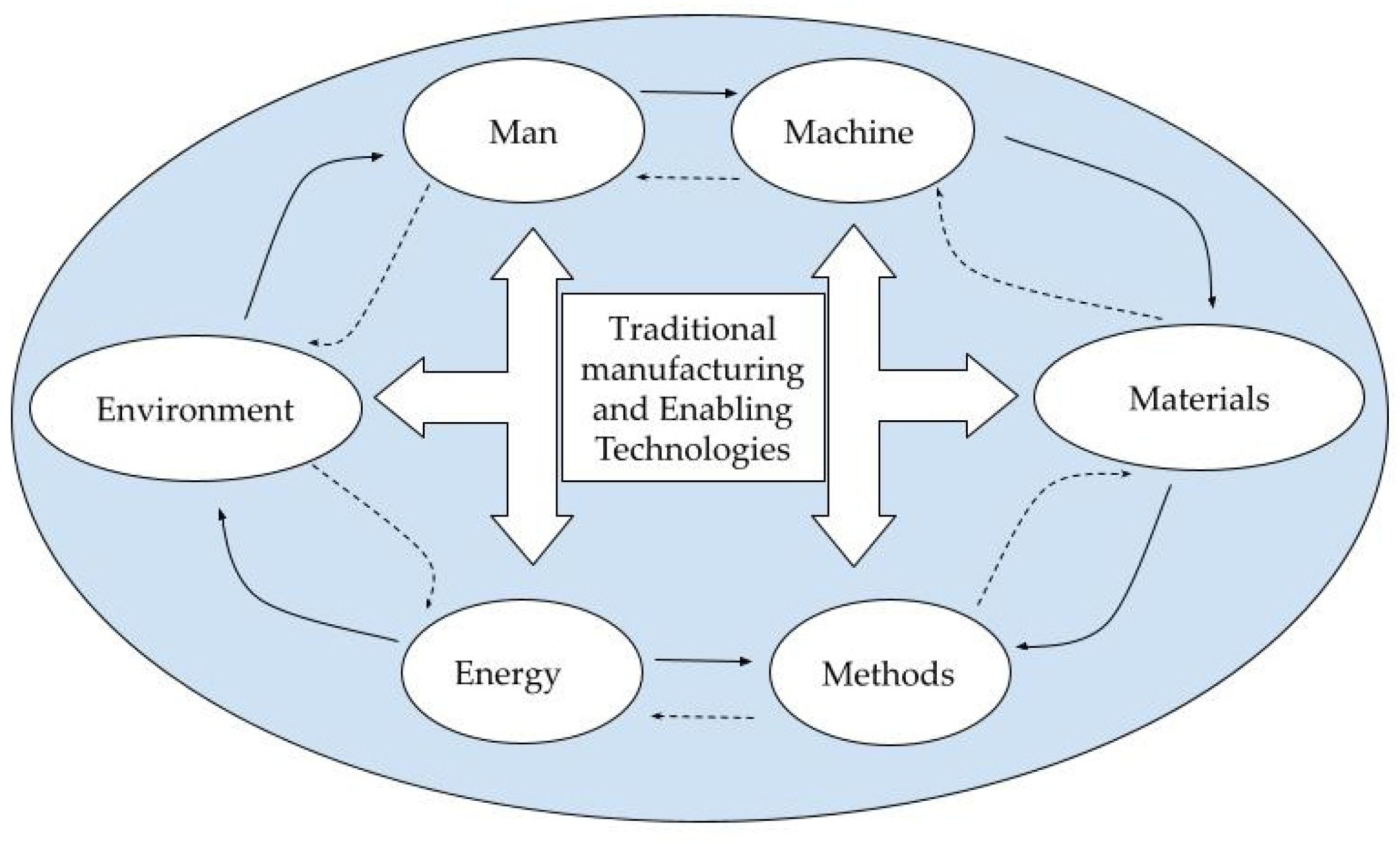

4.6. Traditional Manufacturing

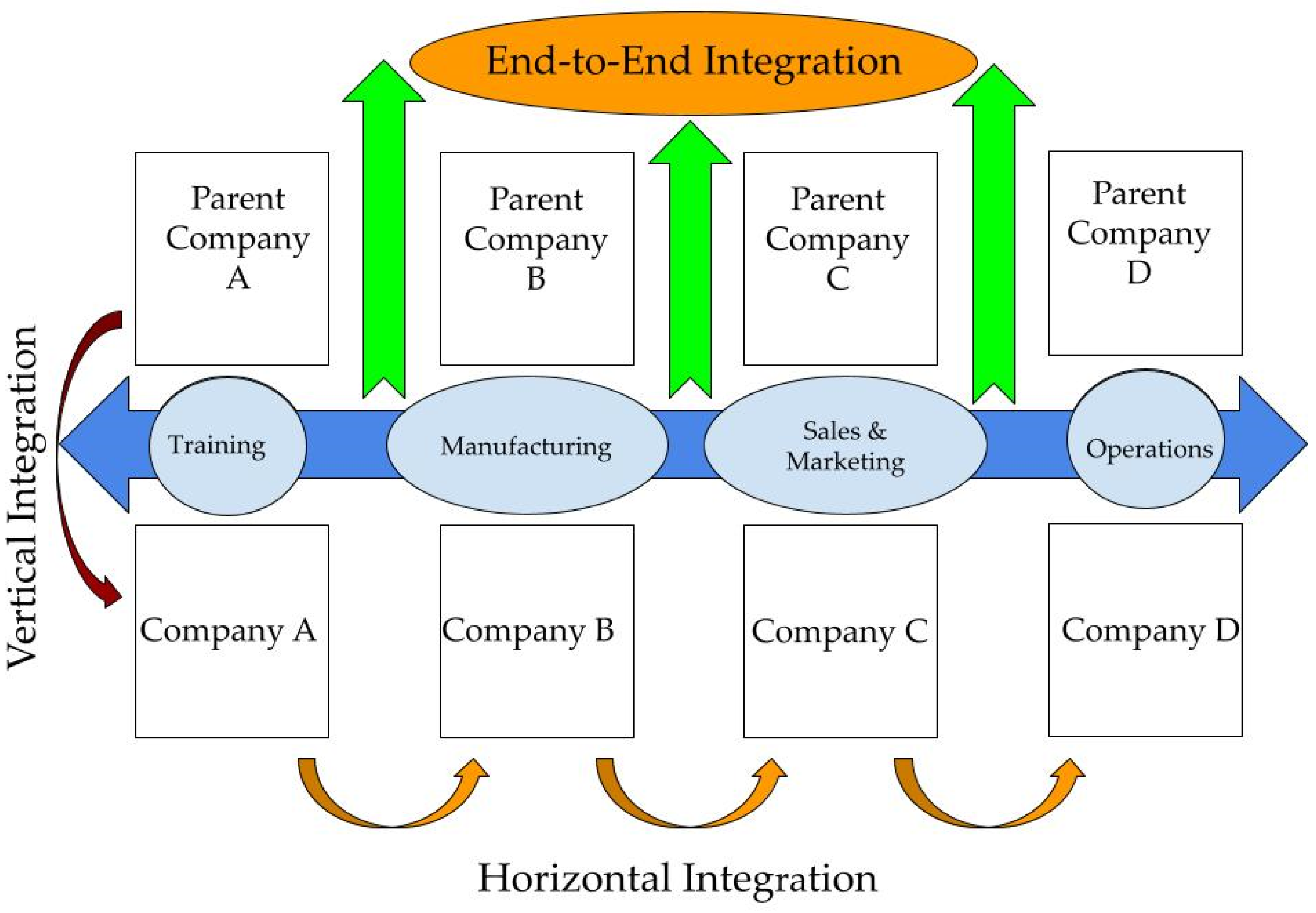

5. Integration for Innovative Industries

5.1. Horizontal Integration

5.2. Vertical Integration

5.3. End-to-End Digital Integration

6. Impact of Smart Manufacturing

6.1. Productivity and Efficiency

6.2. Revenue Growth (Profitability)

6.3. Employment

6.4. Sustainability and Energy Efficiency (Energy Saving)

6.5. Quality Management

6.6. Supply Chain Management

7. Justifying the Advancement from Industry 4.0 to Industry 5.0

7.1. Symmetrical Innovations Systems and “Extreme Integration without a Safe Exit Strategy from Networks”

7.2. Filter Bubbles, Technology, and Society

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, L.; Zhu, B.; Zhang, Y. A runtime intelligent iterative manufacturing system (RIIMS) for hot stamping. In Proceedings of the Advanced High Strength Steel and Press Hardening: Proceedings of the 2nd International Conference (ICHSU2015), Changsha, China, 15–18 October 2015; pp. 647–654. [Google Scholar]

- Tolio, T.; Magnanini, M.C. The Paradigm of Pit—Stop Manufacturing. In Proceedings of the International Conference on the Industry 4.0 Model for Advanced Manufacturing, Belgrade, Serbia, 3–6 June 2019; pp. 35–47. [Google Scholar]

- Szulewski, P. The concepts and components of the smart factory. Mechanik 2017, 90, 98–102. [Google Scholar] [CrossRef] [Green Version]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Illa, P.K.; Padhi, N. Practical guide to smart factory transition using Iot, big data and edge analytics. IEEE Access 2018, 6, 55162–55170. [Google Scholar] [CrossRef]

- Chen, G.; Wang, P.; Feng, B.; Li, Y.; Liu, D. The framework design of smart factory in discrete manufacturing industry based on cyber-physical system. Int. J. Comput. Integr. Manuf. 2019, 33, 79–101. [Google Scholar] [CrossRef]

- Tuptuk, N.; Hailes, S. Security of smart manufacturing systems. J. Manuf. Syst. 2018, 47, 93–106. [Google Scholar] [CrossRef]

- Kalsoom, T.; Ramzan, N.; Ahmed, S.; Ur-Rehman, M. Advances in Sensor Technologies in the Era of Smart Factory and Industry 4.0. Sensors 2020, 20, 6783. [Google Scholar] [CrossRef] [PubMed]

- Benotsmane, R.; Kovács, G.; Dudás, L. Economic, Social Impacts and Operation of Smart Factories in Industry 4.0 Focusing on Simulation and Artificial Intelligence of Collaborating Robots. Soc. Sci. 2019, 8, 143. [Google Scholar] [CrossRef] [Green Version]

- Lucke, D.; Constantinescu, C.; Westkämper, E. Smart factory-a step towards the next generation of manufacturing. In Manufacturing Systems and Technologies for the New Frontier; Springer: London, UK, 2008; pp. 115–118. [Google Scholar] [CrossRef]

- Lu, Y.; Ju, F. Smart manufacturing systems based on cyber-physical manufacturing services (CPMS). IFAC-Pap. 2017, 50, 15883–15889. [Google Scholar] [CrossRef]

- Hozdić, E. Smart factory for industry 4.0: A review. Int. J. Mod. Manuf. Technol. 2015, 7, 28–35. [Google Scholar]

- Cha, S.K.; Yoon, J.Y.; Hong, J.K.; Kang, H.G.; Cho, H.C. The system architecture and standardization of production IT convergence for Smart Factory. J. Korean Soc. Precis. Eng. 2015, 32, 17–24. [Google Scholar] [CrossRef]

- Raut, R.D.; Gotmare, A.; Narkhede, B.E.; Govindarajan, U.H.; Bokade, S.U. Enabling technologies for Industry 4.0 manufacturing and supply chain: Concepts, current status, and adoption challenges. IEEE Eng. Manag. Rev. 2020, 48, 83–102. [Google Scholar] [CrossRef]

- Mohajan, H. The first industrial revolution: Creation of a new global human era. Soc. Sci. Humanit. 2019, 5, 377–387. [Google Scholar]

- Morrar, R.; Arman, H.; Mousa, S. The fourth industrial revolution (Industry 4.0): A social innovation perspective. Technol. Innov. Manag. Rev. 2017, 7, 12–20. [Google Scholar] [CrossRef] [Green Version]

- McDonough, W.; Braungart, M. The next industrial revolution. In Sustainable Solutions; Charter, M.U.T., Ed.; Routledge: London, UK, 2017; pp. 139–150. [Google Scholar]

- Haleem, A.; Javaid, M. Additive Manufacturing Applications in Industry 4.0: A Review. J. Ind. Integr. Manag. 2019, 4, 1930001. [Google Scholar] [CrossRef]

- Almaghrabi, F.; Yang, S.; Allmendinger, R.; Sachan, S. Comments from young scholars: Can machines completely replace humans in manufacturing processes? Front. Eng. Manag. 2018, 5, 131–137. [Google Scholar] [CrossRef] [Green Version]

- Chui, M.; Manyika, J.; Miremadi, M. Where Machines Could Replace Humans-and Where They Can’t (Yet); McKinsey: Rosemont, IL, USA, 2016; pp. 1–12. [Google Scholar]

- Demira, K.A.; Döven, G.; Sezen, B. Industry 5.0 and human-robot co-working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Ajoudani, A.; Zanchettin, A.M.; Ivaldi, S.; Albu-Schäffer, A.; Kosuge, K.; Khatib, O. Progress and prospects of the human–robot collaboration. Auton. Robot. 2018, 42, 957–975. [Google Scholar] [CrossRef] [Green Version]

- Liu, Q.; Liu, Z.; Xu, W.; Tang, Q.; Zhou, Z.; Pham, D.T. Human-robot collaboration in disassembly for sustainable manufacturing. Int. J. Prod. Res. 2019, 57, 4027–4044. [Google Scholar] [CrossRef]

- George, A.S.; George, A.H. Industrial revolution 5.0: The transformation of the modern manufacturing process to enable man and machine to work hand in hand. J. Seybold Rep. 2020, 15, 214–234. [Google Scholar]

- Arai, T.; Kato, R.; Fujita, M. Assessment of operator stress induced by robot collaboration in assembly. CIRP Ann. 2010, 59, 5–8. [Google Scholar] [CrossRef]

- Buerkle, A.; Eaton, W.; Lohse, N.; Bamber, T.; Ferreira, P. EEG based arm movement intention recognition towards enhanced safety in symbiotic Human-Robot Collaboration. Robot. Comput.-Integr. Manuf. 2021, 70, 102137. [Google Scholar] [CrossRef]

- Burns, T.; Cosgrove, J.; Doyle, F. A Review of Interoperability Standards for Industry 4.0. Procedia Manuf. 2019, 38, 646–653. [Google Scholar] [CrossRef]

- Liserre, M.; Sauter, T.; Hung, J.Y. Future energy systems: Integrating renewable energy sources into the smart power grid through industrial electronics. IEEE Ind. Electron. Mag. 2010, 4, 18–37. [Google Scholar] [CrossRef]

- Stern, D.I.; Kander, A. The role of energy in the industrial revolution and modern economic growth. Energy J. 2012, 33, 125–152. [Google Scholar] [CrossRef] [Green Version]

- Zou, C.; Zhao, Q.; Zhang, G.; Xiong, B. Energy revolution: From a fossil energy era to a new energy era. Nat. Gas Ind. B 2016, 3, 1500476. [Google Scholar] [CrossRef] [Green Version]

- Roser, C. Faster, Better, Cheaper in the History of Manufacturing: From the Stone Age to Lean Manufacturing and Beyond, 1st ed.; Productivity Press: New York, NY, USA, 2016; p. 439. [Google Scholar]

- Dogaru, L. The Main Goals of the Fourth Industrial Revolution. Renewable Energy Perspectives. Procedia Manuf. 2020, 46, 397–401. [Google Scholar] [CrossRef]

- Xu, M.; David, J.M.; Kim, S.H. The fourth industrial revolution: Opportunities and challenges. Int. J. Financ. Res. 2018, 9, 90–95. [Google Scholar] [CrossRef] [Green Version]

- Skilton, M.; Hovsepian, F. The 4th Industrial Revolution Impact. In The 4th Industrial Revolution: Responding to the Impact of Artificial Intelligence on Business; Springer: Cham, Switzerland, 2018; pp. 3–28. [Google Scholar]

- Troxler, P. Making the 3rd industrial revolution. In FabLabs: Of Machines, Makers and Inventors, Transcript; FabLab: Bielefeld, Germany, 2013. [Google Scholar]

- Janicke, M.; Jacob, K. A Third Industrial Revolution? 1st ed.; Routledge: London, UK, 2013; pp. 47–71. [Google Scholar]

- Bigliardi, B.; Bottani, E.; Casella, G. Enabling technologies, application areas and impact of industry 4.0: A bibliographic analysis. Procedia Manuf. 2020, 42, 322–326. [Google Scholar] [CrossRef]

- Taalbi, J. Origins and pathways of innovation in the third industrial revolution. Ind. Corp. Chang. 2019, 28, 1125–1148. [Google Scholar] [CrossRef]

- Demir, K.A.; Cicibas, H. Industry 5.0 and a Critique of Industry 4.0. In Proceedings of the International Management Information Systems Conference, Istanbul, Turkey, 17–20 October 2017; pp. 17–20. [Google Scholar]

- Nahavandi, S. Industry 5.0—A human-centric solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef] [Green Version]

- Prisecaru, P. Challenges of the fourth industrial revolution. Knowl. Horiz. Econ. 2016, 8, 57–62. [Google Scholar]

- Li, G.; Hou, Y.; Wu, A. Fourth Industrial Revolution: Technological drivers, impacts and coping methods. Chin. Geogr. Sci. 2017, 27, 626–637. [Google Scholar] [CrossRef] [Green Version]

- Matthyssens, P. Reconceptualizing value innovation for Industry 4.0 and the Industrial Internet of Things. J. Bus. Ind. Mark. 2019, 34, 1203–1209. [Google Scholar] [CrossRef]

- Popović, A. Implications of the Fourth Industrial Revolution on sustainable development. Econ. Sustain. Dev. 2020, 4, 45–60. [Google Scholar] [CrossRef]

- Martinelli, A.; Mina, A.; Moggi, M. The enabling technologies of industry 4.0: Examining the seeds of the fourth industrial revolution. Ind. Corp. Chang. 2020, 30, 161–188. [Google Scholar] [CrossRef]

- Faisal, A.; Yigitcanlar, T.; Kamruzzaman, M.; Currie, G. Understanding autonomous vehicles: A systematic literature review on capability, impact, planning and policy. J. Transp. Land Use 2019, 12, 45–72. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.; Hu, J.; Shi, Y.; Peng, Y.; Fang, J.; Zhao, R.; Zhao, L. Vehicle-to-everything (V2X) services supported by LTE-based systems and 5G. IEEE Commun. Stand. Mag. 2017, 1, 70–76. [Google Scholar] [CrossRef]

- Rasouli, A.; Tsotsos, J.K. Autonomous vehicles that interact with pedestrians: A survey of theory and practice. IEEE Trans. Intell. Transp. Syst. 2020, 21, 900–918. [Google Scholar] [CrossRef] [Green Version]

- Rosique, F.; Navarro, P.J.; Fernandez, C.; Padilla, A. A Systematic Review of Perception System and Simulators for Autonomous Vehicles Research. Sensors 2019, 19, 648. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Raviteja, T. An introduction of autonomous vehicles and a brief survey. J. Crit. Rev. 2020, 7, 196–202. [Google Scholar] [CrossRef]

- Zhou, C.; Li, F.; Cao, W. Architecture design and implementation of image based autonomous car: THUNDER-1. Multimed. Tools Appl. 2019, 78, 28557–28573. [Google Scholar] [CrossRef]

- Betz, J.; Wischnewski, A.; Heilmeier, A.; Nobis, F.; Stahl, T.; Hermansdorfer, L.; Lohmann, B.; Lienkamp, M. What can we learn from autonomous level-5 motorsport? In International Munich Chassis Symposium, 9th ed.; Pfeffer, P.D.P., Ed.; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2019; pp. 123–146. [Google Scholar]

- Perussi, J.B.; Gressler, F.; Seleme, R. Supply chain 4.0: Autonomous vehicles and equipment to meet demand. Int. J. Supply Chain. Manag. 2019, 8, 33–41. [Google Scholar]

- Shah, S.; Logiotatopouloh, I.; Menon, S. Industry 4.0 and autonomous transportation: The impacts on supply chain management. Int. J. Transp. Syst. 2019, 4, 45–50. [Google Scholar]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Srai, J.S. Intelligent autonomous vehicles in digital supply chains: A framework for integrating innovations towards sustainable value networks. J. Clean. Prod. 2018, 181, 60–71. [Google Scholar] [CrossRef]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Iakovou, E. Sustainable supply chain management in the digitalisation era: The impact of Automated Guided Vehicles. J. Clean. Prod. 2017, 142, 3970–3984. [Google Scholar] [CrossRef] [Green Version]

- Okwu, M.; Tartibu, L.; Machesa, M. Fourth industrial revolution and sustainable impact in autonomous fleets for effective supply chain network in manufacturing systems. In Proceedings of the 31th Annual Conference of Southern African Institute for Industrial Engineering, Virtual, 5–7 October 2020; pp. 742–752. [Google Scholar]

- Ramakrishna, S.; Khong, T.C.; Leong, T.K. Smart Manufacturing. Procedia Manuf. 2017, 12, 128–131. [Google Scholar] [CrossRef]

- Khanpara, P.; Tanwar, S. Additive Manufacturing: Concepts and Technologies. In A Roadmap to Industry 4.0: Smart Production, Sharp Business and Sustainable Development (IEREK Interdisciplinary Series for Sustainable Development); Nayyar, A., Kumar, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 171–185. [Google Scholar]

- Attaran, M. The rise of 3-D printing: The advantages of additive manufacturing over traditional manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Revilla-Leon, M.; Ozcan, M. Additive Manufacturing Technologies Used for Processing Polymers: Current Status and Potential Application in Prosthetic Dentistry. J. Prosthodont. 2019, 28, 146–158. [Google Scholar] [CrossRef] [Green Version]

- Müller, S.; Westkämper, E. Modelling of production processes: A theoretical approach to additive manufacturing. Procedia CIRP 2018, 72, 1524–1529. [Google Scholar] [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A comparison of traditional manufacturing vs additive manufacturing, the best method for the job. In Proceedings of the 14th Global Congress on Manufacturing and Management (GCMM-2018), Brisbane, Australia, 5–7 December 2019; pp. 11–18. [Google Scholar]

- Liu, Z.; Jiang, Q.; Cong, W.; Li, T.; Zhang, H.-C. Comparative study for environmental performances of traditional manufacturing and directed energy deposition processes. Int. J. Environ. Sci. Technol. 2018, 15, 2273–2282. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Biamino, S.; Lombardi, M.; Atzeni, E.; Salmi, A.; Minetola, P.; Iuliano, L.; Fino, P. Overview on Additive Manufacturing Technologies. Proc. IEEE 2017, 105, 593–612. [Google Scholar] [CrossRef]

- Jiménez, M.; Romero, L.; Domínguez, I.A.; Espinosa, M.d.M.; Domínguez, M. Additive Manufacturing Technologies: An Overview about 3D Printing Methods and Future Prospects. Complexity 2019, 2019, 9656938. [Google Scholar] [CrossRef] [Green Version]

- Strong, D.; Kay, M.; Conner, B.; Wakefield, T.; Manogharan, G. Hybrid manufacturing–integrating traditional manufacturers with additive manufacturing (AM) supply chain. Addit. Manuf. 2018, 21, 159–173. [Google Scholar] [CrossRef]

- Long, J.; Gholizadeh, H.; Lu, J.; Bunt, C.; Seyfoddin, A. Application of Fused Deposition Modelling (FDM) Method of 3D Printing in Drug Delivery. Curr. Pharm. Des. 2017, 23, 433–439. [Google Scholar] [CrossRef]

- Alogla, A.A.; Baumers, M.; Tuck, C.; Elmadih, W. The Impact of Additive Manufacturing on the Flexibility of a Manufacturing Supply Chain. Appl. Sci. 2021, 11, 3707. [Google Scholar] [CrossRef]

- Delic, M.; Eyers, D.R.; Mikulic, J. Additive manufacturing: Empirical evidence for supply chain integration and performance from the automotive industry. Supply Chain Manag. 2019, 24, 604–621. [Google Scholar] [CrossRef]

- Mashhadi, A.R.; Esmaeilian, B.; Behdad, S. Impact of additive manufacturing adoption on future of supply chains. In Proceedings of the International Manufacturing Science and Engineering Conference, Charlotte, NC, USA, 8–12 June 2015; p. V001T002A064. [Google Scholar]

- Evjemo, L.D.; Gjerstad, T.; Grøtli, E.I.; Sziebig, G. Trends in Smart Manufacturing: Role of Humans and Industrial Robots in Smart Factories. Curr. Robot. Rep. 2020, 1, 35–41. [Google Scholar] [CrossRef] [Green Version]

- Zanchettin, A.M.; Croft, E.; Ding, H.; Li, M. Collaborative robots in the workplace [from the guest editors]. IEEE Robot. Autom. Mag. 2018, 25, 16–17. [Google Scholar] [CrossRef]

- Hentout, A.; Aouache, M.; Maoudj, A.; Akli, I. Human–robot interaction in industrial collaborative robotics: A literature review of the decade 2008–2017. Adv. Robot. 2019, 33, 764–799. [Google Scholar] [CrossRef]

- Ajaykumar, G.; Stiber, M.; Huang, C.-M. Designing user-centric programming aids for kinesthetic teaching of collaborative robots. Robot. Auton. Syst. 2021, 145, 103845. [Google Scholar] [CrossRef]

- Müller, D.; Veil, C.; Seidel, M.; Sawodny, O. One-Shot kinesthetic programming by demonstration for soft collaborative robots. Mechatronics 2020, 70, 102418. [Google Scholar] [CrossRef]

- Heo, Y.J.; Kim, D.; Lee, W.; Kim, H.; Park, J.; Chung, W.K. Collision Detection for Industrial Collaborative Robots: A Deep Learning Approach. IEEE Robot. Autom. Lett. 2019, 4, 740–746. [Google Scholar] [CrossRef]

- Attaran, M. Digital technology enablers and their implications for supply chain management. Supply Chain Forum Int. J. 2020, 21, 158–172. [Google Scholar] [CrossRef]

- Jain, V.N. Robotics for Supply Chain and Manufacturing Industries and Future It Holds! Int. J. Eng. Res. Technol. 2019, 8, 66–79. [Google Scholar] [CrossRef]

- Wollschlaeger, M.; Sauter, T.; Jasperneite, J. The future of industrial communication: Automation networks in the era of the internet of things and industry 4.0. IEEE Ind. Electron. Mag. 2017, 11, 17–27. [Google Scholar] [CrossRef]

- Kobusińska, A.; Leung, C.; Hsu, C.-H.; Raghavendra, S.; Chang, V. Emerging trends, issues and challenges in Internet of Things, Big Data and cloud computing. Future Gener. Comput. Syst. 2018, 87, 416–419. [Google Scholar] [CrossRef]

- ITU. Overview of the internet of Things. In Information Security and Communications Privacy; International Telecommunication Union: Geneva, Switzerland, 2012. [Google Scholar]

- Falcone, R.; Sapienza, A. On the Users’ Acceptance of IoT Systems: A Theoretical Approach. Information 2018, 9, 53. [Google Scholar] [CrossRef] [Green Version]

- Božanić, M.; Sinha, S. Visible Light Communications for 6G. In Mobile Communication Networks: 5G and a Vision of 6G; Springer International Publishing: Cham, Switzerland, 2021; Volume 751, pp. 155–188. [Google Scholar] [CrossRef]

- Stupar, S.; Ćar, M.B.; Kurtović, E.; Vico, G. Theoretical and Practical Aspects of Internet of Things (IoT) Technology. In Proceedings of the International Conference “New Technologies, Development and Applications”, Sarajevo, Bosnia and Herzegovina, 25–27 June 2020; pp. 422–431. [Google Scholar]

- Kafle, V.P.; Fukushima, Y.; Harai, H. Internet of things standardization in ITU and prospective networking technologies. IEEE Commun. Mag. 2016, 54, 43–49. [Google Scholar] [CrossRef]

- Gupta, B.B.; Quamara, M. An overview of Internet of Things (IoT): Architectural aspects, challenges, and protocols. Concurr. Comput. Pract. Exp. 2020, 32, e4946. [Google Scholar] [CrossRef]

- Sobin, C.C. A survey on architecture, protocols and challenges in IoT. Wirel. Pers. Commun. 2020, 112, 1383–1429. [Google Scholar] [CrossRef]

- Čolaković, A.; Hadžialić, M. Internet of Things (IoT): A review of enabling technologies, challenges, and open research issues. Comput. Netw. 2018, 144, 17–39. [Google Scholar] [CrossRef]

- Milić, S.D.; Babić, B.M. Toward the Future—Upgrading Existing Remote Monitoring Concepts to IIoT Concepts. IEEE Internet Things J. 2020, 7, 11693–11700. [Google Scholar] [CrossRef]

- Kiel, D.; Arnold, C.; Voigt, K.-I. The influence of the Industrial Internet of Things on business models of established manufacturing companies—A business level perspective. Technovation 2017, 68, 4–19. [Google Scholar] [CrossRef]

- Wan, J.; Tang, S.; Shu, Z.; Li, D.; Wang, S.; Imran, M.; Vasilakos, A.V. Software-Defined Industrial Internet of Things in the Context of Industry 4.0. IEEE Sens. J. 2016, 16, 7373–7380. [Google Scholar] [CrossRef]

- Munirathinam, S. Industry 4.0: Industrial Internet of Things (IIOT). In The Digital Twin Paradigm for Smarter Systems and Environments: The Industry Use Cases, 1st ed.; Pethuru, R., Preetha, E., Eds.; Advances in Computers; Academic Press: Cambridge, MA, USA, 2020; Volume 117, pp. 129–164. [Google Scholar]

- Juhas, P.; Frunyo, J.; Mlynka, T. Possibilities of using Industrial Internet of Things (IIOT) in industrial communication. Industry 2020, 5, 206–209. [Google Scholar]

- Chalapathi, G.S.S.; Chamola, V.; Vaish, A.; Buyya, R. Industrial internet of things (iiot) applications of edge and fog computing: A review and future directions. Fog/Edge Comput. Secur. Priv. Appl. 2021, 83, 293–325. [Google Scholar] [CrossRef]

- Salehi, H.; Burgueño, R. Emerging artificial intelligence methods in structural engineering. Eng. Struct. 2018, 171, 170–189. [Google Scholar] [CrossRef]

- He, J.; Baxter, S.L.; Xu, J.; Xu, J.; Zhou, X.; Zhang, K. The practical implementation of artificial intelligence technologies in medicine. Nat. Med. 2019, 25, 30–36. [Google Scholar] [CrossRef]

- Martin, S.M.; Casey, J.R.; Kane, S. History of Artificial Intelligence and Personalized Learning. In Serious Games in Personalized Learning; Routledge: London, UK, 2021; pp. 27–47. [Google Scholar]

- Kaul, V.; Enslin, S.; Gross, S.A. History of artificial intelligence in medicine. Gastrointest. Endosc. 2020, 92, 807–812. [Google Scholar] [CrossRef] [PubMed]

- González García, C.; Núñez-Valdez, E.; García-Díaz, V.; Pelayo G-Bustelo, C.; Cueva-Lovelle, J.M. A Review of Artificial Intelligence in the Internet of Things. Int. J. Interact. Multimed. Artif. Intell. 2019, 5, 9–20. [Google Scholar] [CrossRef]

- Strandhagen, J.W.; Alfnes, E.; Strandhagen, J.O.; Vallandingham, L.R. The fit of Industry 4.0 applications in manufacturing logistics: A multiple case study. Adv. Manuf. 2017, 5, 344–358. [Google Scholar] [CrossRef] [Green Version]

- Woschank, M.; Rauch, E.; Zsifkovits, H. A review of further directions for artificial intelligence, machine learning, and deep learning in smart logistics. Sustainability 2020, 12, 3760. [Google Scholar] [CrossRef]

- Oh, A.-S. Development of a smart supply-chain management solution based on logistics standards utilizing artificial intelligence and the internet of things. J. Inf. Commun. Converg. Eng. 2019, 17, 198–204. [Google Scholar] [CrossRef]

- Gandomi, A.; Haider, M. Beyond the hype: Big data concepts, methods, and analytics. Int. J. Inf. Manag. 2015, 35, 137–144. [Google Scholar] [CrossRef] [Green Version]

- Lee, I. Big data: Dimensions, evolution, impacts, and challenges. Bus. Horiz. 2017, 60, 293–303. [Google Scholar] [CrossRef]

- Yang, C.; Huang, Q.; Li, Z.; Liu, K.; Hu, F. Big Data and cloud computing: Innovation opportunities and challenges. Int. J. Digit. Earth 2017, 10, 13–53. [Google Scholar] [CrossRef] [Green Version]

- El-Seoud, S.A.; El-Sofany, H.F.; Abdelfattah, M.A.F.; Mohamed, R. Big Data and Cloud Computing: Trends and Challenges. Int. J. Interact. Mob. Technol. 2017, 11, 34. [Google Scholar] [CrossRef]

- Hazen, B.T.; Skipper, J.B.; Ezell, J.D.; Boone, C.A. Big data and predictive analytics for supply chain sustainability: A theory-driven research agenda. Comput. Ind. Eng. 2016, 101, 592–598. [Google Scholar] [CrossRef]

- Jain, A.D.S.; Mehta, I.; Mitra, J.; Agrawal, S. Application of big data in supply chain management. Mater. Today Proc. 2017, 4, 1106–1115. [Google Scholar] [CrossRef]

- Zanoon, N.; Al-Haj, A.; Khwaldeh, S.M. Cloud computing and big data is there a relation between the two: A study. Int. J. Appl. Eng. Res. 2017, 12, 6970–6982. [Google Scholar]

- Hammoud, A.; Mourad, A.; Otrok, H.; Wahab, O.A.; Harmanani, H. Cloud federation formation using genetic and evolutionary game theoretical models. Future Gener. Comput. Syst. 2020, 104, 92–104. [Google Scholar] [CrossRef]

- Teng, F.; Magoulès, F. A new game theoretical resource allocation algorithm for cloud computing. In Proceedings of the International Conference on Grid and Pervasive Computing, Hualien, Taiwan, 10–13 May 2010; pp. 321–330. [Google Scholar]

- Künsemöller, J.; Karl, H. A game-theoretical approach to the benefits of cloud computing. In International Workshop on Grid Economics and Business Models; Springer: Berlin/Heidelberg, Germany, 2011; pp. 148–160. [Google Scholar]

- Tian, L.-Q.; Lin, C.; Ni, Y. Evaluation of user behavior trust in cloud computing. In Proceedings of the International Conference on Computer Application and System Modeling (ICCASM 2010), Taiyuan, China, 22–24 October 2010; p. V7-567. [Google Scholar]

- Wu, Y.; Cegielski, C.G.; Hazen, B.T.; Hall, D.J. Cloud computing in support of supply chain information system infrastructure: Understanding when to go to the cloud. J. Supply Chain Manag. 2013, 49, 25–41. [Google Scholar] [CrossRef]

- Moustafa, N.; Creech, G.; Sitnikova, E.; Keshk, M. Collaborative anomaly detection framework for handling big data of cloud computing. In Proceedings of the Military Communications and Information Systems Conference (MilCIS), Canberra, Australia, 14–16 November 2017; pp. 1–6. [Google Scholar]

- Dai, H.-N.; Wang, H.; Xu, G.; Wan, J.; Imran, M. Big data analytics for manufacturing internet of things: Opportunities, challenges and enabling technologies. Enterp. Inf. Syst. 2020, 14, 1279–1303. [Google Scholar] [CrossRef] [Green Version]

- Jassbi, J.; Di Orio, G.; Barata, D.; Barata, J. The impact of cloud manufacturing on supply chain agility. In Proceedings of the International Conference on Industrial Informatics (INDIN), Porto Alegre, Brazil, 27–30 July 2014; pp. 495–500. [Google Scholar]

- Zhong, R.Y.; Newman, S.T.; Huang, G.Q.; Lan, S. Big Data for supply chain management in the service and manufacturing sectors: Challenges, opportunities, and future perspectives. Comput. Ind. Eng. 2016, 101, 572–591. [Google Scholar] [CrossRef]

- Sanders, N.R. How to use big data to drive your supply chain. Calif. Manag. Rev. 2016, 58, 26–48. [Google Scholar] [CrossRef]

- Moktadir, M.A.; Ali, S.M.; Paul, S.K.; Shukla, N. Barriers to big data analytics in manufacturing supply chains: A case study from Bangladesh. Comput. Ind. Eng. 2019, 128, 1063–1075. [Google Scholar] [CrossRef]

- Kim, K.; Lee, G.; Kim, S. A Study on the Application of Blockchain Technology in the Construction Industry. KSCE J. Civ. Eng. 2020, 24, 2561–2571. [Google Scholar] [CrossRef]

- Tschorsch, F.; Scheuermann, B. Bitcoin and Beyond: A Technical Survey on Decentralized Digital Currencies. IEEE Commun. Surv. Tutor. 2016, 18, 2084–2123. [Google Scholar] [CrossRef]

- Mazur, M. Blockchain-Powered New Generation of Global B2B Platforms: A Conceptual Approach. 2020. Available online: https://ssrn.com/abstract=3678563 (accessed on 21 August 2021).

- Fernandez-Carames, T.M.; Fraga-Lamas, P. A Review on the Application of Blockchain to the Next Generation of Cybersecure Industry 4.0 Smart Factories. IEEE Access 2019, 7, 45201–45218. [Google Scholar] [CrossRef]

- Yu, C.; Zhang, L.; Zhao, W.; Zhang, S. A blockchain-based service composition architecture in cloud manufacturing. Int. J. Comput. Integr. Manuf. 2020, 33, 701–715. [Google Scholar] [CrossRef]

- Al-Jaroodi, J.; Mohamed, N.; Jawhar, I. A service-oriented middleware framework for manufacturing industry 4.0. ACM SIGBED Rev. 2018, 15, 29–36. [Google Scholar] [CrossRef]

- Bahga, A.; Madisetti, V.K. Blockchain platform for industrial internet of things. J. Softw. Eng. Appl. 2016, 9, 533–546. [Google Scholar] [CrossRef] [Green Version]

- Ozyilmaz, K.R.; Yurdakul, A. Designing a Blockchain-based IoT with Ethereum, swarm, and LoRa: The software solution to create high availability with minimal security risks. IEEE Consum. Electron. Mag. 2019, 8, 28–34. [Google Scholar] [CrossRef] [Green Version]

- Vo, H.T.; Mohania, M.; Verma, D.; Mehedy, L. Blockchain-powered big data analytics platform. In Proceedings of the International Conference on Big Data Analytics, Warangal, India, 18–21 December 2018; pp. 15–32. [Google Scholar]

- Mendi, A.F.; Çabuk, A. Blockchain Applications in Geographical Information Systems. Photogramm. Eng. Remote Sens. 2020, 86, 5–10. [Google Scholar] [CrossRef]

- Höhne, S.; Tiberius, V. Powered by blockchain: Forecasting blockchain use in the electricity market. Int. J. Energy Sect. Manag. 2020, 14, 1221–1238. [Google Scholar] [CrossRef]

- Jeong, W.-Y.; Choi, M. Design of recruitment management platform using digital certificate on blockchain. J. Inf. Process. Syst. 2019, 15, 707–716. [Google Scholar] [CrossRef]

- Kranz, J.; Nagel, E.; Yoo, Y. Blockchain token sale. Bus. Inf. Syst. Eng. 2019, 61, 745–753. [Google Scholar] [CrossRef]

- Liu, D.; Huang, C.; Ni, J.; Lin, X.; Shen, X.S. Blockchain-based smart advertising network with privacy-preserving accountability. IEEE Trans. Netw. Sci. Eng. 2020, 8, 2118–2130. [Google Scholar] [CrossRef]

- Huckle, S.; Bhattacharya, R.; White, M.; Beloff, N. Internet of Things, Blockchain and Shared Economy Applications. Procedia Comput. Sci. 2016, 98, 461–466. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, N.; Al-Jaroodi, J. Applying blockchain in industry 4.0 applications. In Proceedings of the Annual Computing and Communication Workshop and Conference (CCWC), Las Vegas, NV, USA, 30 October 2019; pp. 852–858. [Google Scholar]

- Oranburg, S.; Palagashvili, L. The gig economy, smart contracts, and disruption of traditional work arrangements. Smart Contracts Disrupt. Tradit. Work Arrange. 2018. [Google Scholar] [CrossRef]

- Li, J.; Maiti, A.; Springer, M.; Gray, T. Blockchain for supply chain quality management: Challenges and opportunities in context of open manufacturing and industrial internet of things. Int. J. Comput. Integr. Manuf. 2020, 33, 1321–1355. [Google Scholar] [CrossRef]

- Chanson, M.; Bogner, A.; Bilgeri, D.; Fleisch, E.; Wortmann, F. Privacy-preserving data certification in the Internet of things: Leveraging blockchain technology to protect sensor data. J. Assoc. Inf. Syst. 2019, 20. [Google Scholar] [CrossRef]

- Dietrich, F.; Ge, Y.; Turgut, A.; Louw, L.; Palm, D. Review and analysis of blockchain projects in supply chain management. Procedia Comput. Sci. 2021, 180, 724–733. [Google Scholar] [CrossRef]

- Abeyratne, S.A.; Monfared, R.P. Blockchain ready manufacturing supply chain using distributed ledger. Int. J. Res. Eng. Technol. 2016, 5, 1–10. [Google Scholar]

- Bose, S.; Raikwar, M.; Mukhopadhyay, D.; Chattopadhyay, A.; Lam, K. BLIC: A Blockchain Protocol for Manufacturing and Supply Chain Management of ICS. In Proceedings of the International Conference on Internet of Things (iThings) and IEEE Green Computing and Communications (GreenCom) and IEEE Cyber, Physical and Social Computing (CPSCom) and IEEE Smart Data (SmartData), Halifax, NS, Canada, 30 July–3 August 2018; pp. 1326–1335. [Google Scholar]

- Khanfar, A.A.; Iranmanesh, M.; Ghobakhloo, M.; Senali, M.G.; Fathi, M. Applications of Blockchain Technology in Sustainable Manufacturing and Supply Chain Management: A Systematic Review. Sustainability 2021, 13, 7870. [Google Scholar] [CrossRef]

- Vafadarnikjoo, A.; Ahmadi, H.B.; Liou, J.J.; Botelho, T.; Chalvatzis, K. Analyzing blockchain adoption barriers in manufacturing supply chains by the neutrosophic analytic hierarchy process. Ann. Oper. Res. 2021, 1–28. [Google Scholar] [CrossRef]

- Xu, Z.; Liu, Y.; Zhang, J.; Song, Z.; Li, J.; Zhou, J. Manufacturing industry supply chain management based on the ethereum blockchain. In Proceedings of the 2019 IEEE International Conferences on Ubiquitous Computing & Communications (IUCC) and Data Science and Computational Intelligence (DSCI) and Smart Computing, Networking and Services (SmartCNS), Shenyang, China, 21–23 October 2019; pp. 592–596. [Google Scholar]

- Mondragon, A.E.C.; Mondragon, C.E.C.; Coronado, E.S. Exploring the applicability of blockchain technology to enhance manufacturing supply chains in the composite materials industry. In Proceedings of the 2018 IEEE International Conference on Applied System Invention (ICASI), Chiba, Tokyo, Japan, 13–17 April 2018; pp. 1300–1303. [Google Scholar]

- Dargan, S.; Kumar, M.; Ayyagari, M.R.; Kumar, G. A Survey of Deep Learning and Its Applications: A New Paradigm to Machine Learning. Arch. Comput. Methods Eng. 2019, 27, 1071–1092. [Google Scholar] [CrossRef]

- de Oliveira, M.B.; Zucchi, G.; Lippi, M.; Cordeiro, D.F.; da Silva, N.R.; Iori, M. Lead Time Forecasting with Machine Learning Techniques for a Pharmaceutical Supply Chain. In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS), Virtual, 26–28 April 2021. [Google Scholar]

- Manasas, V. Supply Chain Optimization Using Machine Learning Methods. A Manufacturing Case Study; International Hellenic University: Thessaloniki, Greece, 2020. [Google Scholar]

- Li, X.; Li, D.; Wan, J.; Liu, C.; Imran, M. Adaptive Transmission Optimization in SDN-Based Industrial Internet of Things with Edge Computing. IEEE Internet Things J. 2018, 5, 1351–1360. [Google Scholar] [CrossRef]

- Jin, H.; Jia, L.; Zhou, Z. Boosting Edge Intelligence with Collaborative Cross-Edge Analytics. IEEE Internet Things J. 2020, 8, 2444–2458. [Google Scholar] [CrossRef]

- Xu, X.; Huang, S.; Feagan, L.; Chen, Y.; Qiu, Y.; Wang, Y. Eaaas: Edge analytics as a service. In Proceedings of the 2017 IEEE International Conference on Web Services (ICWS), Honolulu, HI, USA, 25–30 June 2017; pp. 349–356. [Google Scholar]

- Trinks, S.; Felden, C. Edge computing architecture to support real time analytic applications: A state-of-the-art within the application area of smart factory and industry 4.0. In Proceedings of the 2018 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 2930–2939. [Google Scholar]

- Hu, P.; Chen, W.; He, C.; Li, Y.; Ning, H. Software-defined edge computing (SDEC): Principle, open IoT system architecture, applications, and challenges. IEEE Internet Things J. 2019, 7, 5934–5945. [Google Scholar] [CrossRef]

- Harth, N.; Anagnostopoulos, C. Quality-aware aggregation & predictive analytics at the edge. In Proceedings of the 2017 IEEE International Conference on Big Data (Big Data), Seattle, WA, USA, 10–13 December 2018; pp. 17–26. [Google Scholar]

- Anawar, M.R.; Wang, S.; Azam Zia, M.; Jadoon, A.K.; Akram, U.; Raza, S. Fog Computing: An Overview of Big IoT Data Analytics. Wirel. Commun. Mob. Comput. 2018, 2018, 7157192. [Google Scholar] [CrossRef]

- Atlam, H.; Walters, R.; Wills, G. Fog Computing and the Internet of Things: A Review. Big Data Cogn. Comput. 2018, 2, 10. [Google Scholar] [CrossRef] [Green Version]

- Musa, Z.; Vidyasankar, K. A fog computing framework for blackberry supply chain management. Procedia Comput. Sci. 2017, 113, 178–185. [Google Scholar] [CrossRef]

- Aljawarneh, N.; Taamneh, M.; Alhndawi, N.; Alomari, K.; Masad, F. Fog computing-based logistic supply chain management and organizational agility: The mediating role of user satisfaction. Uncertain Supply Chain Manag. 2021, 9, 767–778. [Google Scholar] [CrossRef]

- Dastjerdi, A.V.; Buyya, R. Fog computing: Helping the Internet of Things realize its potential. Computer 2016, 49, 112–116. [Google Scholar] [CrossRef]

- Gania, I.; Stachowiak, A.; Oleśków-Szłapka, J. Flexible manufacturing systems: Industry 4.0 solution. In Proceedings of the 24th International Conference on Production Research (ICPR 2017), Poznań, Poland, 30 July–3 August 2017. [Google Scholar]

- Florescu, A.; Barabas, S.A. Modeling and simulation of a flexible manufacturing system—A basic component of industry 4.0. Appl. Sci. 2020, 10, 8300. [Google Scholar] [CrossRef]

- Bihi, T.; Luwes, N.; Kusakana, K. Innovative quality management system for flexible manufacturing systems. In Proceedings of the 2018 Open Innovations Conference (OI), Limpopo, South Africa, 3–5 October 2018; pp. 40–46. [Google Scholar]

- Koren, Y.; Gu, X.; Guo, W. Reconfigurable manufacturing systems: Principles, design, and future trends. Front. Mech. Eng. 2017, 13, 121–136. [Google Scholar] [CrossRef] [Green Version]

- Bortolini, M.; Galizia, F.G.; Mora, C. Reconfigurable manufacturing systems: Literature review and research trend. J. Manuf. Syst. 2018, 49, 93–106. [Google Scholar] [CrossRef]

- Sawangsri, W.; Suppasasawat, P.; Thamphanchark, V.; Pandey, S. Novel Approach of an Intelligent and Flexible Manufacturing System: A Contribution to the Concept and Development of Smart Factory. In Proceedings of the 2018 International Conference on System Science and Engineering (ICSSE), New Taipei City, Taiwan, 28–30 June 2018; pp. 1–4. [Google Scholar]

- Li, X.; Nassehi, A.; Epureanu, B.I. Degradation-aware decision making in reconfigurable manufacturing systems. CIRP Ann. 2019, 68, 431–434. [Google Scholar] [CrossRef]

- Mehrabi, M.G.; Ulsoy, A.G.; Koren, Y. Reconfigurable manufacturing systems: Key to future manufacturing. J. Intell. Manuf. 2000, 11, 403–419. [Google Scholar] [CrossRef]

- Koren, Y.; Gu, X.; Badurdeen, F.; Jawahir, I.S. Sustainable living factories for next generation manufacturing. Procedia Manuf. 2018, 21, 26–36. [Google Scholar] [CrossRef]

- Andersen, A.-L.; Brunoe, T.D.; Nielsen, K.; Rösiö, C. Towards a generic design method for reconfigurable manufacturing systems: Analysis and synthesis of current design methods and evaluation of supportive tools. J. Manuf. Syst. 2017, 42, 179–195. [Google Scholar] [CrossRef]

- Bell, J.; Crick, D.; Young, S. Small firm internationalization and business strategy: An exploratory study of ‘knowledge-intensive’and ‘traditional’manufacturing firms in the UK. Int. Small Bus. J. 2004, 22, 23–56. [Google Scholar] [CrossRef]

- Chukalov, K. Horizontal and vertical integration, as a requirement for cyber-physical systems in the context of industry 4.0. Industry 2017, 2, 155–157. [Google Scholar]

- De Paula Ferreira, W.; Armellini, F.; De Santa-Eulalia, L.A. Simulation in industry 4.0: A state-of-the-art review. Comput. Ind. Eng. 2020, 149, 106868. [Google Scholar] [CrossRef]

- Park, S. Development of Innovative Strategies for the Korean Manufacturing Industry by Use of the Connected Smart Factory (CSF). Procedia Comput. Sci. 2016, 91, 744–750. [Google Scholar] [CrossRef] [Green Version]

- Görçün, Ö.F. The Rise of Smart Factories in the Fourth Industrial Revolution and Its Impacts on the Textile Industry. Int. J. Mater. Mech. Manuf. 2018, 6, 136–141. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Fettig, K.; Gačić, T.; Köskal, A.; Kühn, A.; Stuber, F. Impact of industry 4.0 on organizational structures. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Stuttgart, Germany, 17–20 June 2018; pp. 1–8. [Google Scholar]

- García-Muiña, F.E.; Medina-Salgado, M.S.; Ferrari, A.M.; Cucchi, M. Sustainability transition in industry 4.0 and smart manufacturing with the triple-layered business model canvas. Sustainability 2020, 12, 2364. [Google Scholar] [CrossRef] [Green Version]

- Agolla, J.E. Human Capital in the Smart Manufacturing and Industry 4.0 Revolution. In Digital Transformation in Smart Manufacturing; IntechOpen Book Series; IntechOpen: London, UK, 2018; Chapter 3; pp. 42–58. [Google Scholar]

- Cimini, C.; Pezzotta, G.; Pinto, R.; Cavalieri, S. Industry 4.0 Technologies Impacts in the Manufacturing and Supply Chain Landscape: An Overview. In 2018 Service Orientation in Holonic and Multi-Agent Manufacturing; Studies in Computational Intelligence; Springer Nature: Cham, Switzerland, 2019; pp. 109–120. [Google Scholar]

- Kuhlman, T.; Farrington, J. What is Sustainability? Sustainability 2010, 2, 3436–3448. [Google Scholar] [CrossRef] [Green Version]

- Meng, Y.; Yang, Y.; Chung, H.; Lee, P.-H.; Shao, C. Enhancing Sustainability and Energy Efficiency in Smart Factories: A Review. Sustainability 2018, 10, 4779. [Google Scholar] [CrossRef] [Green Version]

- Sartal, A.; Bellas, R.; Mejías, A.M.; García-Collado, A. The sustainable manufacturing concept, evolution and opportunities within Industry 4.0: A literature review. Adv. Mech. Eng. 2020, 12, 1687814020925232. [Google Scholar] [CrossRef]

- Caiado, R.G.G.; Quelhas, O.L.G. Factories for the Future: Toward Sustainable Smart Manufacturing. In Responsible Consumption and Production; Leal Filho, W., Azul, A.M., Brandli, L., Özuyar, P.G., Wall, T., Eds.; Encyclopedia of the UN Sustainable Development Goals; Springer International Publishing: Cham, Switzerland, 2020; pp. 239–250. [Google Scholar]

- Wieland, A. Dancing the supply chain: Toward transformative supply chain management. J. Supply Chain Manag. 2021, 57, 58–73. [Google Scholar] [CrossRef]

- Wu, L.; Yue, X.; Jin, A.; Yen, D.C. Smart supply chain management: A review and implications for future research. Int. J. Logist. Manag. 2016, 27, 395–417. [Google Scholar] [CrossRef]

- Kiran, D.; Sharma, I.; Garg, I. Industry 5.0 And Smart Cities: A Futuristic Approach. Eur. J. Mol. Clin. Med. 2020, 7, 2750–2756. [Google Scholar]

- Steen, M.; Sand, M.; Poel, I. Virtue Ethics for Responsible Innovation. Bus. Prof. Ethics J. 2021. [Google Scholar] [CrossRef]

- Ozdemir, V. Industry 5.0: The Power of Symmetrical Innovation for Agri-Food Industry. Available online: https://millingandgrain.com/industry-50-the-power-of-symmetrical-innovation-for-agri-food-industry-19724 (accessed on 9 August 2021).

- Özdemir, V. The dark side of the moon: The internet of things, industry 4.0, and the quantified planet. Omics J. Integr. Biol. 2018, 22, 637–641. [Google Scholar] [CrossRef] [PubMed]

- Özdemir, V.; Hekim, N. Birth of industry 5.0: Making sense of big data with artificial intelligence,“the internet of things” and next-generation technology policy. Omics J. Integr. Biol. 2018, 22, 65–76. [Google Scholar] [CrossRef] [PubMed]

| IR | Energy Sources | Inventions | Final Objective |

|---|---|---|---|

| 1st | Coal and steam [28,29,30]. | Steam engines [31]. | Mechanization and centralized manufacturing. |

| 2nd | Electricity, natural gas, and oil [28,30,32]. | Lighting, telegraph, telephone, long-distance wireless communications, and steel production. | Industrialization [33]. |

| 3rd | Among others, a mix of energy sources: natural gas, nuclear power (energy) [30,32,34,35,36], coal and others. There is also a move towards renewable sources | Solid-state electronics [37], robotics, automated process; and programmable logic control. | Factory automation and computerization [38]. |

| 4th | A mix of previous and existing energy sources and a greater focus towards sustainable sources. | Cloud computing, IoT, IIoT and blockchain. | Digitalization. |

| 5th | Most likely sustainable energy [39]. | Massive IoT, Autonomous cars, Augmented reality, and virtual reality. | Customization and personalization [40]. |

| Technological Drivers | Fields |

|---|---|

| Physical | Autonomous cars Additive manufacturing Advanced Robotics and Collaborating Robots |

| Digital | IoT IIoT Artificial Intelligence and machine/deep learning Big Data and (Cloud, Edge, and Fog) Computing Blockchain-powered digital platforms |

| Biotechnological | Genetic engineering Neurotechnology |

| Layer | Sublayer | Functions |

|---|---|---|

| Transport and Security | Transport layer Security layer | Pre-processing data to the cloud. Check against a security threat. Encryption/decryption functions. |

| Network | Temporary storage Pre-processing Monitoring | Connection point to transport and security. Storage of data temporarily (Microdata centre) Re-ordering of data. Activity monitoring, i.e., resource and service allocation. Resources provisioning. |

| Physical/Virtualization | Physical layer | Capturing and forwarding of data for upward processing generation and collection of data. |

| Traditional Manufacturing | Smart Manufacturing |

|---|---|

| A stand-alone, manual, isolated process with separate systems that are not capable of automated monitoring and control. | A dependent, strongly related, and closely linked system that continually communicates and collaborates is backed by automation, monitoring, and control capabilities. |

| Humans are in charge of machine operation and control. | Machines and robots interact with, without or with little human intervention. |

| There is no plan to develop an action through equipment that learns from processes; therefore, gathering, evaluating, and updating information is carried out manually. | It is possible to collect, analyze, update, and develop an action that learns from data-driven processes. |

| The manufacturing line is fixed, and the system must be shut down before any reconfiguration occurs. | The production line is dynamic and can be maintained without being disconnected from the power supply. |

| The production process is centrally managed. | Decentralized production processes. |

| A less productive, flexible, sustainable system. Enterprise competitiveness suffers as a result of wasteful resource utilization. | More competitiveness is achieved by increased productivity, flexibility, sustainability, and efficient resource usage. |

| A considerable number of inexperienced operators are engaged. As a result, the factory’s production line has increased labor costs. | At a lower cost to the manufacturing, a workforce skilled in developing and operating intelligent devices is brought on board. |

| There is a lack of self-optimization and reconfiguration production systems to learn and respond to shifting demand patterns. | Self-optimisation and reconfiguration, production systems that learn and adjust to changing demand patterns, are available. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fanoro, M.; Božanić, M.; Sinha, S. A Review of 4IR/5IR Enabling Technologies and Their Linkage to Manufacturing Supply Chain. Technologies 2021, 9, 77. https://doi.org/10.3390/technologies9040077

Fanoro M, Božanić M, Sinha S. A Review of 4IR/5IR Enabling Technologies and Their Linkage to Manufacturing Supply Chain. Technologies. 2021; 9(4):77. https://doi.org/10.3390/technologies9040077

Chicago/Turabian StyleFanoro, Mokesioluwa, Mladen Božanić, and Saurabh Sinha. 2021. "A Review of 4IR/5IR Enabling Technologies and Their Linkage to Manufacturing Supply Chain" Technologies 9, no. 4: 77. https://doi.org/10.3390/technologies9040077

APA StyleFanoro, M., Božanić, M., & Sinha, S. (2021). A Review of 4IR/5IR Enabling Technologies and Their Linkage to Manufacturing Supply Chain. Technologies, 9(4), 77. https://doi.org/10.3390/technologies9040077