1. Introduction

Traditional interaction research emphasizes visual and auditory display, but pay little attention to haptic display. Visual and auditory interactions use vision and voices to transmit information. These interactions are non-contact interaction approaches, and they have some limitations. For example, vision mainly dominates visual percepts like size, shape and position [

1], but kinematic feelings such as velocity, acceleration or inertia cannot be reflected, even though vision has a higher spatial resolution than touch. Haptic refers to touching or interacting with real, virtual and remote environments, such as exploring and distinguishing material properties [

2,

3] and tele-operating a robot. Different from visual and auditory display, haptic is a unique bilateral sensory modality with energy and information flowing both from and to the user. This bi-directionality is often referred to as the single most important feature of the haptic interaction modality [

4]. As a medium between environments and human users, haptic interfaces transmit and display haptic stimuli [

5]. With precisely controlled forces and torques exerted on the manipulator’s fingertips, hand or arm, subtle sensations are able to be perceived, thus a high level of immersion is constructed. With the development of computer science, haptic has manifested great superiorities in fields, ranging from robotics and tele-operation to computational geometry and computer graphics, and to psychophysics, cognitive science and the neurosciences [

4]. Nowadays, haptic interfaces have been widely applied in many areas such as education [

6], entertainment [

7], surgical simulation and training [

8], and scientific visualization [

9].

The past decade has shown an increasing interest in the science of haptics. A number of haptic devices with different structures have been developed, some of which are commercially available devices and some are experimental prototypes. The PHANToM haptic device (SensAble Technologies, Woburn, MA, USA) designed by Massie and Salisbury [

10,

11] is a convenient desktop device with 3 or 6 actuated DOF. Due to characteristics of low inertia, low friction and high position precision, it has been widely used in a multitude of applications. Although it shows great success, there are still some weaknesses, such as limited strength, low stiffness and small workspace,

etc. A critical study of the mechanical and electrical properties of the PHANToM is presented in [

12]. After the research of the kinematics, dynamics, high frequency dynamic response, and velocity estimation of the PHANToM system, some modifications are made to compensate for the deficiencies that impede high performance. The Novint Falcon is a relatively inexpensive 3 DOF haptic device made by Novint for the gaming industry [

13]. It has features of low inertia, high stiffness, high operating rate and better position repeatability due to the adoption of the DELTA mechanism [

14]. Nevertheless, it still has some shortages. Firstly, its workspace is small, and output forces are relatively small and inaccurate. Secondly, complexity of kinematic modelling increases significantly compared to its serial counterparts. In fact, some of the same advantages and disadvantages exist in haptic devices such as the DELTA Haptic Device (Force Dimension, Nyon, Switzerland) [

15], OMEGA Haptic Devices (Force Dimension, Nyon, Switzerland), haptic prototypes designed by Jumpei Arata

et al. [

16] and Minh Hung Vu

et al. [

17]. The VISHARD6 [

18] and VISHARD10 [

19] are both haptic devices with a serial kinematic design. The VISHARD6 is a 6 DOF device designed towards a comparatively large workspace and high force capability. However, it suffers from low mechanical stiffness. Singularities exist in its workspace as well. The VISHARD10 with 10 DOF introduces actuated kinematic redundancies to realize a larger workspace free of singularities while simultaneously reduce the device size. However, serial structure may lead to large occupation in space and loss in portability. On these issues, both devices do not have any breakthroughs. The same disadvantages are reflected in haptic devices such as HapticMaster [

20].

Traditionally, structure of haptic devices can be divided into serial and parallel structures. The serial structure is an open kinematic structure, which usually provides a large workspace, but shows lack of strength. Furthermore, singularities may exist in the workspace, whereas the parallel structure has a higher level of stiffness and better position repeatability. However, applications have been limited by its small workspace and complex kinematic modelling. Consequently, a hybrid structure that combines advantages of both structures is proposed. This form has proven itself as an excellent platform of large workspace, high output ability and high stiffness. The compact 6 DOF haptic interface designed by Y.Tsumaki

et al. [

21] is such a hybrid structure device.

With the diversification of haptic applications, many tasks need to simulate arbitrary object-object interactions. A 6 DOF haptic device that provides torque feedback in addition to force feedback is very useful. In 6 DOF haptic scenes, the virtual avatar is usually a wrench, a screwdriver or something like a teapot [

22]. It gives operators enough dexterity to feel and explore virtual objects. Additionally, in some special tasks, it is necessary to simulate grabbing actions. Although a press button can solve parts of the problem sometimes, a grasping interface like CyberForce or CyberGrasp that can represent multi-finger joints is much more desirable.

Force feedback and sensing is a key technology in a virtual training system. It guarantees the authenticity of the training in many contact operations such as load transmission and component assembly. The absence of forces destructs immersions when touching and moving objects. It is necessary to have a haptic device to integrate operators into the virtual training system. Contact operations mainly relay on human upper extremity. Currently, commercially available haptic devices provide limited kinds of force feedback for upper limbs and hands. CyberTouch only provides senses of touch through vibration. CyberGrasp only represents forces of fingers. PHANTOM, HAPTION and CyberForce only provide forces on hand. The combination of CyberForce and CyberGrasp can exert forces on finger and hand, but CyberGrasp is hard to equip, and its motor-pull transfer method has electromagnetic interference problems. So it is essential to design a haptic device that combines finger and hand together, that is easy to equip, and that can realize various operations such as grasping, pushing-and-pulling and twisting in a virtual training system. Based on these motivations, a new 6 DOF haptic device with a grasping interface is designed and fabricated. This device differs from previous haptic devices on several important points. First, the integration of finger and hand increases dexterity of this device. Second, it is a new hybrid structure device designed towards a comparatively large workspace and high force output ability. Lastly, with an adjustable base, it allows operators to change different postures without interrupting haptic tasks.

The rest of this paper is organized as follows.

Section 2 proposes the mechanical design of this 6 DOF haptic device. Motion measurement and tracking, as well as realization of force feedback, are introduced in

Section 3 and

Section 4 respectively.

Section 5 describes the control scheme of this device. Specific calibration and evaluation experiments are shown in

Section 6. Experimental results and error analysis are also given in this section. Finally, conclusions are made in

Section 7.

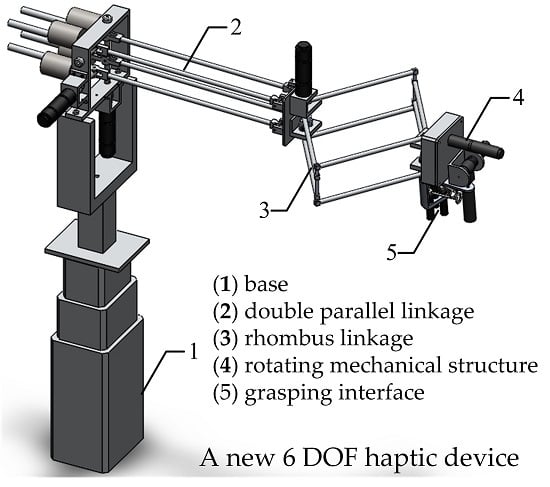

2. Mechanical Design

Generally, an ideal haptic device is designed towards low inertial mass, low friction, low backlash, high structural stiffness, high force bandwidth and dynamic range, large workspace, and freedom of mechanical singularity [

23]. However, these demands are conflicting and difficult to achieve entirely. Careful considerations should be given by designers to the selection of a variety of requirements that a desirable haptic device needs to meet. Additionally, human perceptual thresholds can be used to establish general design guidelines [

24]. The main design objectives of our device are to obtain a large workspace and high output capability, and, at the same time, provide force feedback for three fingers. A hybrid structure haptic device with a grasping interface was designed. The general assembly drawing and overview of this device are presented in

Figure 1 and

Figure 2 individually. It is mainly composed of an adjustable base, a double parallel linkage, a rhombus linkage, a rotating mechanical structure and a grasping interface.

Figure 1.

General assembly drawing (1) Base; (2) Double parallel linkage; (3) Rhombus linkage; (4) Rotating mechanical structure; (5) Grasping interface.

Figure 1.

General assembly drawing (1) Base; (2) Double parallel linkage; (3) Rhombus linkage; (4) Rotating mechanical structure; (5) Grasping interface.

Figure 2.

Overview of the haptic device.

Figure 2.

Overview of the haptic device.

The principle of the double parallel linkage is described in

Figure 3. When a single linking bar rotates around a fixed point, there will be an inclination of the end-plane (see

Figure 3a). Once two parallel linking bars are employed, the inclination disappears. The end-plane always keeps parallel to the initial location (see

Figure 3b).

Figure 3.

Double parallel linkage. (a) Single linking bar; (b) Two parallel linking bars; (c) Double parallel linkage.

Figure 3.

Double parallel linkage. (a) Single linking bar; (b) Two parallel linking bars; (c) Double parallel linkage.

The double parallel linkage utilizes this principle. As shown in

Figure 3c, there are four identical linking bars in this structure. The linking bar A1 A2, B1 B2, C1 C2 and D1 D2 are fixed on the base plane A1 B1 C1 D1 and the movable plane A2 B2 C2 D2 with universal joints at their extremities. The inclination and orientation in space of the movable plane remain unchanged, whatever motions of linking bars may be. The trajectory of the plane A2 B2 C2 D2 is a part of the spherical surface. There is only a small displacement along the Z-axis. A new structure that can realize a large independent linear motion in Z direction was designed.

The rhombus linkage (shown in

Figure 4) is a symmetrical structure. The linking bar E1 E2 and E2 E3 are connected by an axial joint. The same connection is applied to the bar E1 E4 and E4 E3. The four linking bars constitute a deformable space-rhombus. If this structure is stretched to the dotted position, the point E3 will have a large movement along the Z-axis (see

Figure 4a). But if rotation rates of the bar E1 E2 and E1 E4 are different, there will be a deflection (displayed in

Figure 4b). To ensure synchronous motions, gear mesh constraints are added at the points E1 and E3 (see

Figure 4c).

Figure 4.

Rhombus linkage. (a) A large movement along the Z-axis ; (b) Deflection without gear mesh constraint; (c) Synchronous motion with gear mesh constraint.

Figure 4.

Rhombus linkage. (a) A large movement along the Z-axis ; (b) Deflection without gear mesh constraint; (c) Synchronous motion with gear mesh constraint.

The rotating mechanical structure is shown in

Figure 5. There are three motors numbered as NO. 4~NO. 6 in this structure. Each motor is perpendicular to the other two in space, so there is no coupling interference among torques. The torque τ6 generated by motor NO. 6 is transmitted to the handle through pulley block. The other two torques are transmitted through mechanisms.

Figure 5.

Rotating mechanical structure.

Figure 5.

Rotating mechanical structure.

The grasping interface (shown in

Figure 6) is designed to provide three independent forces to the thumb, forefinger and middle finger respectively. It is equipped with three motors and three finger rings. During operation, users are asked to hold the handle with three fingers inserted into the rings to feel grasping forces. Dynamic compensations that are based on rotation angles have been integrated to counteract the effect of gravity so that operators can feel more comfortable when grasping objects.

Figure 6.

Grasping interface.

Figure 6.

Grasping interface.

In addition, an adjustable base that can provide 400 mm of free adjusting space along the vertical direction is introduced to meet the requirement of different postures.

There are mainly two kinds of haptic actuators: DC motors and MR (Magneto-Rheological) actuators. Since haptic actuator is constantly working at a locked-rotor condition, it must have a high level of static performance and good cooling performance. Choosing a proper haptic actuator can enhance the haptic feedback performance dramatically, and hence provide better user experience. In this paper, the actuators chosen are Maxon DC motors, produced in Switzerland. This type of motor uses high-performance permanent magnetic steel as a magnetic component. It is a tight and efficient driving device. Because of its small polar moment of inertia, it has a short response time, which is about 2~3 ms. At the same time, Maxon also provides each motor with a supporting decelerator to reduce output rotating speed, and increases output torque and load capability. This motor is highly suitable for a haptic feedback device which has low rotating rate and large torque. The position sensor is mainly used to measure angular displacement at moveable joints. Common angular sensors include the Hall sensor, the DC tachometer, rotating transformers, and encoders. Out of these sensors, the encoder is the most commonly used angular sensor. It has many advantages, such as high accuracy, small volume, and light weight. Considering the integration level and capability of the device, we choose the supporting encoder for the selected Maxon motor as the angular sensor.

In addition, to improve the performance of this device, we have made some modifications. First, to reduce the overall mass, all linking bars are hollowed to proper thickness, and steel components are replaced by aluminum counterparts in light loading areas. Next, for a workspace free of singularities, arresting pins are applied to constrain extreme motions of the rhombus linkage. Balance weight blocks are added to eliminate the influence of gravity.

3. Motion Measurement and Tracking

Motion measurement and tracking is one of the most fundamental tasks of a haptic control system. It is expected to generate real-time data that dynamically represents the pose changes of a human body (or a part of it) based on motion-sensing technologies. It needs kinematic data of motion sequences. As a result, positions of the end-effector and joint angles must be acquired. In the device, we use nine encoders to measure and track motions of the operator’s hand and fingers. The motion measurement model of the translational structure is shown in

Figure 7.

Figure 7.

Motion measurement model of translational structure.

Figure 7.

Motion measurement model of translational structure.

For convenience of description, rotation angles of the double parallel linkage around axises 1 and 2 are defined as

β and

α. The angle between the linking bar E1 E2 and the centre line O1 O2 is set as

γ. Lengths of the bar A1 A2 and E1 E2 are L1 and L2, respectively. The height between the point O0 and O is

. In the

coordinate system, the coordinate of point O0, O1 and O2 are

,

and

, respectively. Therefore, the following equations are established.

The vector

is always perpendicular to the plane A2 B2 C2 D2, regardless of the location of the translational structure. Hence, the vector

can be represented as:

is the length of the vector

.

Thus, the vector can be rewritten as:

The trajectory of the plane A2 B2 C2 D2 is a part of the spherical surface. Using the conversion between the spherical coordinate system and the Cartesian coordinate system, the vector

is expressed as:

Thus, the coordinate of the point O2 is acquired.

According to pervious equations, the coordinate of O1 is:

The trajectory of the point O1 is a spherical arc. Therefore:

Thus, three angles can be calculated:

4. Realization of Force Feedback

Haptic-rendering algorithms compute interaction forces between avatars and objects when collisions are detected. Assume that outputs of three actuators along axises 1–3 are

,

and

respectively.

,

and

are components of force along three axes of the

coordinate system. The model of translational force feedback is illustrated in

Figure 8.

Figure 8.

Model of translational force feedback.

Figure 8.

Model of translational force feedback.

and

can easily be acquired.

is the arm of force:

The rhombus linkage has its own characteristics. The principle of virtual work [

25,

26] is adopted in the computation of

. The principle of virtual work states that the sum of the works of the internal and external forces done by virtual displacements is zero.

Virtual displacements are infinitesimal changed in the position coordinates of a system such that the constraints remain satisfied. The model of virtual work is displayed in

Figure 9.

Figure 9.

Model of virtual work.

Figure 9.

Model of virtual work.

is the infinitesimal change of the point E3.

is the tiny rotation angle of the linking bar E1-E2.

represents the component of external force in the Z-axis. Therefore, the virtual work of the user’s hand

and the actuator

are computed as follows:

Since

is small enough, the displacement E2 E2‘ can be treated as a vertical line of the linking bar E1 E2 (see

Figure 10). Approximate equations are established:

Figure 10.

Approximation model.

Figure 10.

Approximation model.

Based on Equations (15) and (16), the force

is calculated as:

So

,

and

can be expressed as below:

Shafts of the rotating mechanical structure are mutually perpendicular.

,

and

are independent torques in pitch, yaw and roll respectively.

Forces exerted on the three fingers are also independent. They are only relevant to the corresponding torques and arms. The motors in the grasping interface are numbered as NO. 7~NO. 9. Three grasping forces are shown as below:

Thses forces are desired to be as close as possible to the forces that would arise during real-object contact. With accurate force feedback, operators were able to acquire an intuitive feeling about what they had touched.

5. Control Scheme of the 6 DOF Haptic Device

Haptic interactions require both motion collection and actuator control. The control scheme of this haptic device is illustrated in

Figure 11. Motions of the operators’ hand and fingers are collected by encoders. Through the smooth function, the data is transmitted to forward kinematic equations for position and orientation calculation. Position information is compensated before sent to the haptic rendering engine for collision detection. Interaction forces are computed by modeling a spring between the avatar and the device.

represents the object’s stiffness. Force commands are transferred back to generate corresponding forces under the condition that the current of all motors are less than the peak values. In the diagram, P(t) and F(t) are continuous-time position and force signals exchanged between the human user and the haptic device. P(K) and F(K) are discrete-time position and force signals exchanged between haptic device and virtual environment.

Figure 11.

Control scheme diagram.

Figure 11.

Control scheme diagram.

To ensure the accuracy of computed positions and orientations at a high level, a smoothing function is used to filter peak values that may cause disturbances. It acts as follows. First, three successive frames of position data are received and saved. Let be the position data of motor i received at the previous frame, let be the position data at the current frame, and let be the position data at the next frame. and represent the maximum positive position error and negative position error, respectively. Without loss of generality, we assume that the three frames of data all meet the communication protocols and there is no data loss. Three frames of data is subsequently checked. The smoothing function is described in Algorithm 1.

| Algorithm 1 Peak Values Filter of Current Frame of Data |

| |

| |

| |

| |

| |

| |

| |

| |

| |

|

There are nine motors and encoders in the haptic device. In order to maintain a stable system while displaying smooth and realistic forces and torques, the force control rate must be as high as possible. As described above, the actuator chosen was the Maxon DC motor, which has a short response time of about 2~3 ms. Force commands were controlled at the frequency of 300 HZ.