Carbon Fiber Epoxy Composites for Both Strengthening and Health Monitoring of Structures

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Specimens

2.1.1. Carbon Tow

| Number of Filaments | Fineness of Tow (tex) | Tensile Strength (GPa) | Tensile Modulus (GPa) | Elongation at Break (%) | Filament Diameter (µm) | Density (g/m3) | Single Filament Resistivity (µΩm) |

|---|---|---|---|---|---|---|---|

| 50 k | 3200 | 4.0 | 253 | 1.6 | 7 | 1.80 | 15 |

| 24 k | 1600 | 5.0 | 270 | 1.9 | 7 | 1.81 | 14 |

2.1.2. Carbon Fiber Epoxy-Matrix Composite Probes for Preliminary Tests at the Dynamometer

- a first layer of epoxy-resin is spread on the top of an acrylic plate, which has a very smooth surface;

- then, carbon fibers are laid on this first layer of resin according to determined arrangements;

- further, another layer of resin is applied on the top of the fibers, embedding them very well;

- finally, the specimens are let to cure the resin for some days.

| Carbon Filament Tow in Epoxy-Resin with 3 Days of Cure, with the Dimension of 700 × 50 mm. | |

| A:Thin tow, with <50 k filaments, | B: solid thin tow, with <50 k and with eight partial cuts, |

|  |

| (R0 = 74.8 Ω) | (R0 = 100.5 Ω) |

| C: solid thin tow over thin tow, <50 k/<50 k, | D: solid thin tow, with <50 k, long length (snake design), (R0 = 347.5 Ω) |

| |

| (R0 = 84.4 Ω) | |

| E: Tow with 50 k and with six partial cuts, | |

| |

| (R0 = 8.6 Ω) | |

| Carbon Filament Tow in Epoxy-Resin with 7 Days of Cure, with the Dimensions of 902 × 50 mm. | |

| F: Tow over tow, 50 k/50 k, | G: solid thin tow over thin tow, <50 k/<50 k, |

|  |

| (R0 = 8.0 Ω) | (R0 = 63.1 Ω) |

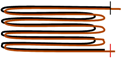

| H: solid thin tow, with <50 k and with eight partial cuts, | I: solid thin tow over thin tow, <50 k/<50 k (snake over straight), |

|  |

| (R0 = 120.1 Ω) | (R0 = 72.2 Ω) |

2.1.3. Woven Epoxy-Matrix Composite Probes for Preliminary Tests at the Dynamometer

2.2. Tensile-Strain Tests While Recording the Electrical Resistance

| Probes | Type | Thickness (cm) | Carbon Fiber Volume Fraction | Total Fiber Volume Fraction | Initial Resistance (Ω) |

|---|---|---|---|---|---|

| 1 | 24 k carbon fibers | 0.17 ± 0.048 | 0.12 | 0.32 | 31.9 ± 0.01 |

| |||||

| 2 | 24 k/24 k carbon fibers | 0.17 ± 0.036 | 0.23 | 0.42 | 11.0 ± 0.03 |

|

2.3. Flexural Loading Tests of Concrete Elements for Bending Moment Analysis

2.4. Loading Tests of Reinforced Concrete Beam Subjected to Flexure

3. Results and Discussion

3.1. Initial Electrical Resistance

3.2. Tensile-Strain Tests at the Dynamometer

3.3. Laboratory Flexural Strength Loading Tests of Concrete Slabs

3.4. Laboratory Tests of Reinforced Concrete Beams

4. Conclusions

- decreasing the number of filaments of the tow or

- increasing the length of the sensing fibers or

- introducing disruptions on the electrical pathway or

- crossing tows, defining contact zones between two sensing tows.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Azhari, F.; Banthia, N. Cement-based sensors with carbon fibers and carbon nanotubes for piezoresistive sensing. Cem. Concr. Compos. 2012, 34, 866–873. [Google Scholar] [CrossRef]

- Boller, C.; Staszewski, W. Structural Health Monitoring; DEStech Publications Inc.: Lancaster, PA, USA, 2004. [Google Scholar]

- Chang, F.K. Structural Health Monitoring; DEStech Publications Inc.: Lancaster, PA, USA, 2003. [Google Scholar]

- Balageas, D.; Fritzen, C.; Guemes, A. Structural Health Monitoring; Wiley-ISTE: London, UK; Newport Beach, CA, USA, 2006. [Google Scholar]

- Yin, G.; Hu, N.; Karube, Y.; Liu, Y.; Li, Y.; Fukunaga, H. A carbon nanotube/polymer strain sensor with linear and anti-symmetric piezoresistivity. J. Compos. Mater. 2011, 45, 1315–1323. [Google Scholar] [CrossRef]

- Hu, N.; Itoi, T.; Akagi, T.; Kojima, T.; Xue, J.; Yan, C.; Atobe, S.; Fukunaga, H.; Yuan, W.; Ning, H.; et al. Ultrasensitive strain sensors made from metal-coated carbon nanofiller/epoxy composites. Carbon 2013, 51, 202–212. [Google Scholar] [CrossRef]

- López-Higuera, J.M.; Cobo, L.R.; Incera, A.Q.; Cobo, A. Fiber Optic Sensors in Structural health monitoring. Light. Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- Chung, D.D.L. Structural Health Monitoring by Electrical Resistance Measurement. Smart Mater. Struct. 2001, 10, 624–636. [Google Scholar] [CrossRef]

- Sevkat, E.; Li, J.; Liaw, B.; Delale, F. A statistical model of electrical resistance of carbon fiber reinforced composites under tensile loading. Compos. Sci. Technol. 2008, 68, 2214–2219. [Google Scholar] [CrossRef]

- Shen, L.; Li, J.; Liaw, B.M.; Delale, F.; Chung, J.H. Modeling and analysis of the electrical resistance measurement of carbon fiber polymer–matrix composites. Compos. Sci. Technol. 2007, 67, 2513–2520. [Google Scholar] [CrossRef]

- Angelidis, N.; Wei, C.Y.; Irving, P.E. Response to discussion of paper: The electrical resistance response of continuous carbon fibre composite laminates to mechanical strain. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1495–1499. [Google Scholar] [CrossRef]

- Nishi, Y.; Hirano, M. Bending Stress Dependent Electrical Resistivity of Carbon Fiber in Polymer for Health Monitoring System. Mater. Trans. 2007, 48, 2735–2738. [Google Scholar] [CrossRef]

- Swait, T.J.; Jones, F.R.; Hayes, S.A. A practical structural health monitoring system for carbon fibre reinforced composite based on electrical resistance. Compos. Sci. Technol. 2012, 72, 1515–1523. [Google Scholar] [CrossRef]

- Huang, H.; Yang, C.; Wu, Z. Electrical sensing properties of carbon fiber reinforced plastic strips for detecting low-level strains. Smart Mater. Struct. 2012, 21, 035013. [Google Scholar] [CrossRef]

- Boschetti-de-Fierro, A.; Pardey, R.; Svino, V.; Müller, A.J. Piezoresistive Behavior of Epoxy Matrix-Carbon Fiber Composites with Different Reinforcement Arrangements. J. Appl. Polym. Sci. 2009, 111, 2851–2858. [Google Scholar] [CrossRef]

- Wang, X.; Fu, X.; Chung, D.D.L. Strain sensing using carbon fiber. J. Mater. Res. 1999, 14, 790–802. [Google Scholar] [CrossRef]

- Shoukai, W.; Chung, D.D.L. Electrical Behavior of Carbon Fiber Polymer-Matrix Composites in the Through-Thickness Direction. J. Mater. Sci. 2000, 35, 91–100. [Google Scholar] [CrossRef]

- Kupke, M.; Schulte, K.; Schüler, R. Non-destructive testing of FRP by dc and ac electrical methods. Compos. Sci. Technol. 2001, 61, 837–847. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salvado, R.; Lopes, C.; Szojda, L.; Araújo, P.; Gorski, M.; Velez, F.J.; Castro-Gomes, J.; Krzywon, R. Carbon Fiber Epoxy Composites for Both Strengthening and Health Monitoring of Structures. Sensors 2015, 15, 10753-10770. https://doi.org/10.3390/s150510753

Salvado R, Lopes C, Szojda L, Araújo P, Gorski M, Velez FJ, Castro-Gomes J, Krzywon R. Carbon Fiber Epoxy Composites for Both Strengthening and Health Monitoring of Structures. Sensors. 2015; 15(5):10753-10770. https://doi.org/10.3390/s150510753

Chicago/Turabian StyleSalvado, Rita, Catarina Lopes, Leszek Szojda, Pedro Araújo, Marcin Gorski, Fernando José Velez, João Castro-Gomes, and Rafal Krzywon. 2015. "Carbon Fiber Epoxy Composites for Both Strengthening and Health Monitoring of Structures" Sensors 15, no. 5: 10753-10770. https://doi.org/10.3390/s150510753

APA StyleSalvado, R., Lopes, C., Szojda, L., Araújo, P., Gorski, M., Velez, F. J., Castro-Gomes, J., & Krzywon, R. (2015). Carbon Fiber Epoxy Composites for Both Strengthening and Health Monitoring of Structures. Sensors, 15(5), 10753-10770. https://doi.org/10.3390/s150510753