Non-Destructive Evaluation for Corrosion Monitoring in Concrete: A Review and Capability of Acoustic Emission Technique

Abstract

:1. Introduction

2. NDT Methods for Corrosion Monitoring

2.1. Visual Inspection

2.2. Electrochemical Methods

| Corrosion Activity | Potential Level (mV) [53] | Resistivity (Ω·m) [51] | Corrosion Rate | |

|---|---|---|---|---|

| LPR (Icorr (A/cm2)) [39] | GPM (Rct (kΩ·cm2)) [39] | |||

| Very High | - | - | 10–100 | 0.25–2.5 |

| High | <−350 | <100 | 1.0–10 | 2.5–25 |

| Moderate/Middle | −200 to −350 | 100–500 | - | - |

| Low | >−200 | 500–1000 | 0.1–1 | 25–250 |

| Negligible/passive | - | >1000 | <0.1 | >250 |

2.3. Electromagnetic (EM) Waves

2.4. Infrared Thermography (IRT)

2.5. Optical Sensing Methods

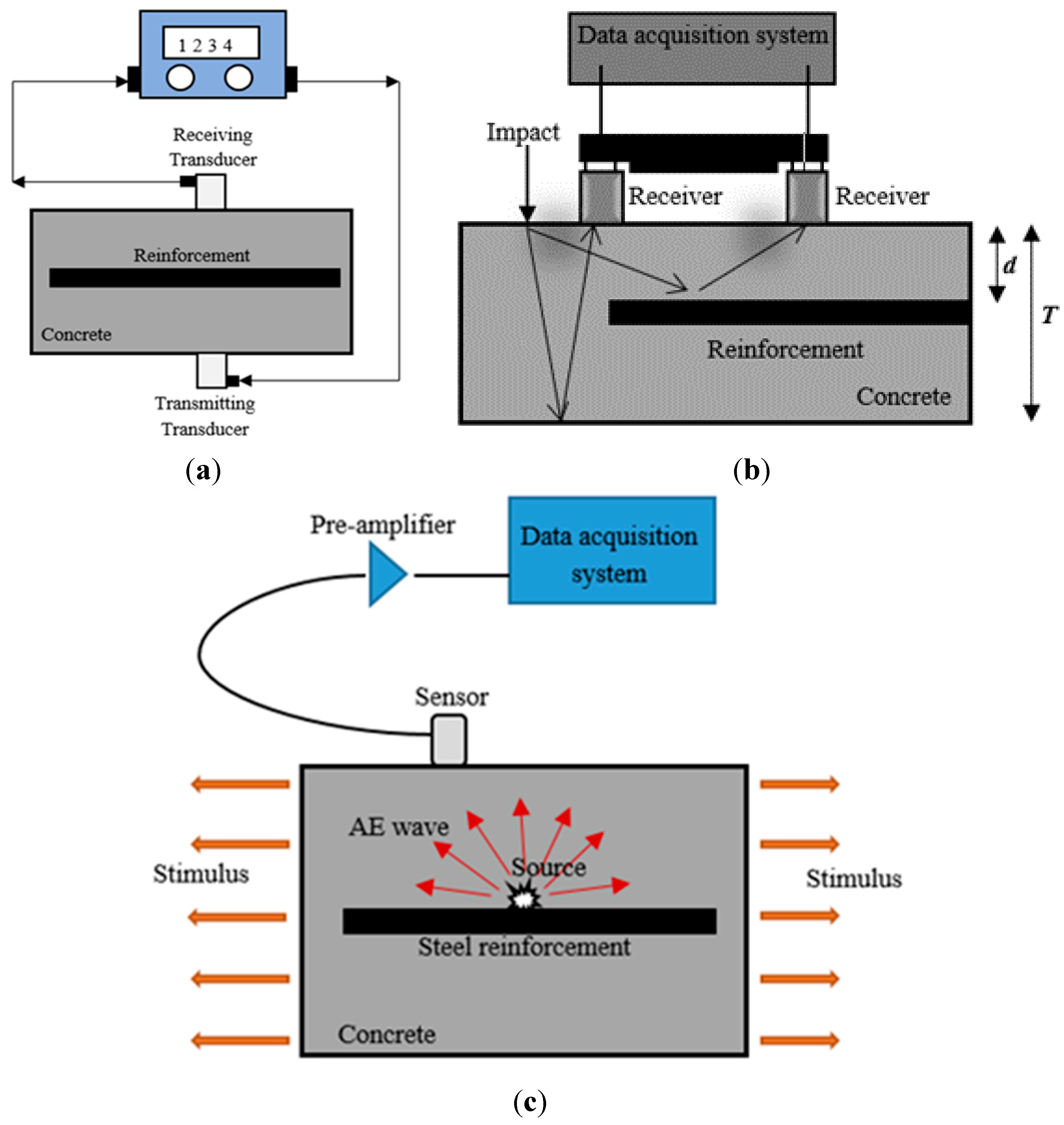

2.6. Elastic Wave Methods

| No | NDT Methods | Principles | Advantages | Disadvantages | Corrosion Evaluation | Specific Equipment |

|---|---|---|---|---|---|---|

| 1 | Electrochemical Method | |||||

| Open circuit potential (OCP) monitoring | Electrical potential value (in mV or V) is measured between steel reinforcement of RC and reference electrode (indicates corrosion potential of the steel inside RC). | The results are not in the form of equipotential contours, rather a single value that gives an indication of the steel condition. | Time consuming and need to be closed several hours during the inspection. | Potential level (mV or V) | Potential electrode, Voltmeter, and connecting wire (working electrode). | |

| Resistivity method | Resistivity (ρ) of RC, which the current can easily pass between anode and cathode areas of the concrete. | An easy, fast, portable, and inexpensive technique, which can be used for routine inspection. | Reinforcement in the test region can provide a “short-circuit” path and cause erroneous reduction in the measurement. | Resistivity (Ω·cm) | Current and potential electrodes, Voltmeter or resistivity unit, and insulated wire (working electrode). | |

| Polarization resistance | The change in potential during reactions (polarization) is recorded using an electrode plate on the concrete surface. | Short time for measurement and applies small perturbations that do not interfere with the existing electrochemical processes. | It takes time to obtain a full response because of the electrical capacitance across the steel and concrete interface. The voltage error introduced by IR drop in the concrete between working (steel rebars) and reference electrode. | Corrosion current (Icorr (A/cm2)) | Reference electrode, counter electrode, Voltmeter, Ammeter, and connecting wire (working electrode). | |

| Galvanostatic pulse method (GPM) | The anodic current pulse is applied galvanostatically on the steel reinforcement from counter electrode placed on the concrete surface. | A rapid device for determining the corrosion rate of steel reinforcement in RC, it enables display of corrosion rate, electrical resistance and potential value simultaneously. | Unstable reading due to parallel or crossing of the steel reinforcement, also cracks and delamination are often the reason for wrong readings. | Potential resistance (Rct (kΩ·cm2)) | Reference electrode, counter electrode, guard ring, and connecting wire (working electrode). | |

| Electrochemical noise (EN) | EN describe the fluctuations of current and potential spontaneously generated by corrosion reactions. | Simple to use, no interference to the system, and measured signals can be analyzed by mathematical analysis. | The complicated kinds of noise (i.e., physical origin) due to corrosion of steel reinforcement make mathematical analysis unsuccessful. | Noise resistance (Rn (kΩ·cm2)) | Electrodes (reference, counter, and working), Voltmeter, Ammeter, amplifier, and data acquisitions board. | |

| 2 | Elastic Wave Method | |||||

| Ultrasonic pulse velocity (UPV) | Mechanical energy propagates through the concrete as stress waves and is converted into electrical energy by a second transducer. | A large penetration depth and it is easy to use for estimating the size, shape and nature of the concrete damage. | The evaluation of UPV data is a highly specialized task, which requires careful data collection and expert analysis. | Pulse velocity (V) | Transducers (transmitter and receiver), amplifier, and oscillator. | |

| Acoustic emission (AE) | Elastic waves are generated due to rapid release of energy from a localized source within an RC structure. | A cost-effective and sensitive technique that can detect and locate the active defects. | Passive defects cannot be effectively detected. | AE parameters | Transducer, preamplifier, filter, amplifier, and storage equipment. | |

| Impact echo (IE) | Stress wave are propagated within the RC structure through vibrations and impact load. | A simple, fast, reliable method for inspecting the concrete is to impact the surface with a hammer and listen to the results. | The reliability of the IE method decreases with an increase in thickness. | Wave velocity (Vp) | Mechanical impactors, high-fidelity receiver, and data acquisition-signal analysis system. | |

| 3 | Electromagnetic Method | |||||

| Ground penetrating radar (GPR) | Transmission of electromagnetic (EM) waves into the RC structure under investigation. | Equipment portable and effective for investigating one large area from one surface. | Difficult interpretation of the results and needs post-processing analysis. | EM wave velocity (V) | Antennas (transmitter and receiver), a control unit, and computer. | |

| 4 | Optical Sensing Method | |||||

| Fiber Bragg grating (FBG) | The shift of FBG wavelength measures the increase in fiber strains with an increase in the cross section of steel reinforcement of corroded RC structures. | Small physical dimensions and suitable for embedding into structures. | The equipment has a high cost and there is no standardization of the procedure. | Bragg wavelength (λB) | Optical fiber sensor, Bragg meter, and computer. | |

| 5 | Infrared Thermography Method | |||||

| Infrared thermography (IRT) | IR radiation emitted by a concrete material is converted into an electrical signal and processed to create maps of the surface temperature. | Easy interpretation of the results and no radiation, rapid set-up, portable, and cost-effective technique. | There is no quantitative information on corrosion damage (i.e., size or depth). | Radiation power (E) | Multi spectrum camera. | |

3. Acoustic Emission (AE) for Corrosion Monitoring

3.1. AE Parameters for Corrosion Monitoring

| Variables | Parameter | Description | Variables | Parameter |

|---|---|---|---|---|

| Time domain | Hit | Detection of an AE signal | Hit | Detection of an AE signal |

| Event | Local material change, an event is a number of hits | Event | Local material change, an event is a number of hits | |

| Amplitude | Largest voltage peak in the waveforms | Amplitude | Largest voltage peak in the waveforms | |

| Rise time | Time elapsed from signal start and peak amplitude | Rise time | Time elapsed from signal start and peak amplitude | |

| Duration | Time between signal start and signal end | Duration | Time between signal start and signal end | |

| Threshold | Electronic compactor such that signals with amplitude larger than this level will be recorded | Threshold | Electronic compactor such that signals with amplitude larger than this level will be recorded | |

| Counts | Number of times AE signal crosses threshold | Counts | Number of times AE signal crosses threshold | |

| Signal Strength | Area under the positive and negative envelope of linear voltage signal | Signal Strength | Area under the positive and negative envelope of linear voltage signal | |

| Frequency domain | Frequency spectrum | Nature of source event | Frequency domain | Frequency spectrum |

| Time-frequency domain | Spectrogram | Energy distribution of source event through time | Time-frequency domain | Spectrogram |

3.1.1. AE Hits

3.1.2. Signal Strength (SS) and Cumulative Signal Strength (CSS)

3.1.3. Absolute (ABS) Energy

3.1.4. RA Values and Average Frequency

3.1.5. b-Value and Ib-Value

3.1.6. Intensity Analysis

3.1.7. Relaxation Ratio

3.2. Signal-Based AE for Corrosion Monitoring

3.2.1. AE Source Location

3.2.2. SiGMA

3.2.3. Noise Filtering

4. Conclusions

- The early number of cumulative AE hits can detect the corrosion at early stage. If there is significant increase of cumulative AE hits, it corresponds to onset of corrosion.

- Other AE parameters, like the sudden rise in cumulative signal strength (CSS) and absolute energy (ABS) might indicate crack initiation due to steel corrosion.

- The distribution of RA value and average frequency (AF) are also proposed as a means of classifying the onset of corrosion and nucleation of cracks. The onset of corrosion is identified by a drastic increase in RA value and a decrease in average frequency. In addition, the nucleation of cracks is implied by an increase in RA value and a decrease in average frequency at the next stage. Based on the above parameters, the steel corrosion of RC structures can be analyzed according to two stages, i.e., the onset of corrosion and the nucleation of crack due to corrosion product.

- In addition, b-value, Ib-value, and intensity analysis are developed to characterize damage in RC structures. Previous studies have indicated that a b-value below 1.0 indicates the transition from microcracking to macrocracking. The large fluctuations in Ib-value imply that these cracks are generally repeated due to expansion of corrosion product. On the other hand, intensity analysis uses several criteria to identify the condition of the RC structure (i.e., no corrosion, early corrosion, and cracking).

Acknowledgments

Conflicts of Interest

References

- Badawi, M.; Soudki, K. Control of corrosion-induced damage in reinforced concrete beams using carbon fiber-reinforced polymer laminates. J. Compos. Constr. 2005, 9, 195–201. [Google Scholar] [CrossRef]

- Ahmad, S. Reinforcement corrosion in concrete structures, its monitoring and service life prediction—A review. Cem. Concr. Compos. 2003, 25, 459–471. [Google Scholar] [CrossRef]

- Yuan, Y.; Ji, Y.; Shah, S.P. Comparison of two accelerated corrosion techniques for concrete structures. ACI Struct. J. 2007, 104, 344–347. [Google Scholar]

- Song, G.; Shayan, A. Corrosion of Steel in Concrete: Causes, Detection and Prediction; Australian Road Research Board: Vermont South, Australia, 1999. [Google Scholar]

- Almusallam, A.A. Effect of degree of corrosion on the properties of reinforcing steel bars. Constr. Build. Mater. 2001, 15, 361–368. [Google Scholar] [CrossRef]

- Büyüköztürk, O. Imaging of concrete structures. NDT&E Int. 1998, 31, 233–243. [Google Scholar]

- Elsener, B.; Andrade, C.; Gulikers, J.; Polder, R.; Raupach, M. Half-cell potential measurements—Potential mapping on reinforced concrete structures. Mater. Struct. 2003, 36, 461–471. [Google Scholar] [CrossRef]

- Wiggenhauser, H.; Reinhardt, H.W. NDT in civil engineering: Experience and results of the for 384 research group. In Proceedings of the AIP Conference, Melbourne, Australia, 15–18 Febraury 2010.

- Arndt, R.; Jalinoos, F. NDE for corrosion detection in reinforced concrete structures-benchmark approach. In Proceedings of the Non-Destructive Testing In Civil Engineering (NDTCE'09), Nantes, France, 30 June–3 July 2009.

- Rhazi, J.; Dous, O.; Laurens, S. A new application of the GPR technique to reinforced concrete bridge decks. In Proceeding of the 4th Middle East NDT conference and Exhibition, Manama, Kingdom of Bahrain, 2–5 December 2007.

- Rodriguez, P.; Ramirez, E.; Gonzalez, J.A. Methods for studying corrosion in reinforced concrete. Mag. Concr. Res. 1994, 46, 81–90. [Google Scholar] [CrossRef]

- Carino, N.J. Nondestructive techniques to investigate corrosion status in concrete structures. J. Perform. Constr. Facil 1999, 13, 96–106. [Google Scholar] [CrossRef]

- Vedalakshmi, R.; Balamurugan, L.; Saraswathy, V.; Kim, S.H.; Ann, K.Y. Reliability of galvanostatic pulse technique in assessing the corrosion rate of rebar in concrete structures: Laboratory vs field studies. KSCE J. Civ. Eng. 2010, 14, 867–877. [Google Scholar] [CrossRef]

- Holloway, L.; Karajayli, P.; Birbilis, N. Galvanostatic pulse corrosion rate monitoring for steel in concrete. In Proceeding of the 49th Annual Conference of the Australasian Corrosion Association: Corrosion and Prevention, Charleston, SC, USA, 13 January 2009.

- Law, D.W.; Millard, S.G.; Bungey, J.H. Use of galvanostatic pulse measurements on active reinforcing steel in concrete to assess corrosion rates. Br. Corros. J. 2001, 36, 75–80. [Google Scholar] [CrossRef]

- Lu, C.; Peiyu, Y. An algorithm of galvanostatic pulse method to determine the corrosion status of reinforcement in concrete. Corros. Sci. 2000, 42, 675–686. [Google Scholar] [CrossRef]

- Xu, J.; Yao, W. Corrosion detection of steel in concrete by use of galvanostatic pulse technique. J. Chin. Soc. Corros. Prot. 2010, 30, 181–186. [Google Scholar]

- Shi, J.J.; Sun, W.; Geng, G.Q. Steel corrosion in simulated concrete pore solutions using a galvanostatic pulse method. J. Univ. Sci. Technol. Beijing 2011, 33, 727–733. [Google Scholar]

- Poursaee, A.; Hansson, C.M. Galvanostatic pulse technique with the current confinement guard ring: The laboratory and finite element analysis. Corros. Sci. 2008, 50, 2739–2746. [Google Scholar] [CrossRef]

- Holloway, L.; Birbilis, N.; Forsyth, M. Long term monitoring of a reinforced concrete remediation method in a marine environment. In Proceeding of the European Corrosion Conference: Long Term Prediction and Modelling of Corrosion (EUROCORR), Nice, France, 12–16 September 2004.

- Gonzalez, J.A.; Miranda, J.M.; Birbilis, N.; Feliu, S. Electrochemical techniques for studying corrosion of reinforcing steel: Limitations and advantages. Corrosion 2005, 61, 37–50. [Google Scholar] [CrossRef]

- Koleva, D.A.; de Wit, J.H.W.; van Breugel, K.; Lodhi, Z.F.; van Westing, E. Investigation of corrosion and cathodic protection in reinforced concrete: I. Application of electrochemical techniques. J. Electrochem. Soc. 2007, 154, P52–P61. [Google Scholar] [CrossRef]

- Song, H.W.; Saraswathy, V. Corrosion monitoring of reinforced concrete structures—A review. Int. J. Electrochem. Sci. 2007, 2, 1–28. [Google Scholar]

- Andrade, C.; Gonzalez, J.A. Quantitative measurements of corrosion rate of reinforcing steels embedded in concrete using polarization resistance measurements. Werkst. Korros. 1978, 29, 515–519. [Google Scholar] [CrossRef]

- Baronio, G.; Berra, M.; Bertolini, L.; Pastore, T. Steel corrosion monitoring in normal and total-lightweight concretes exposed to chloride and sulphate solutions Part I: Potential measurements. Cem. Concr. Res. 1996, 26, 683–689. [Google Scholar] [CrossRef]

- Andrade, C.; Keddam, M.; Novoa, X.R.; Perez, M.C.; Rangel, C.M.; Takenouti, H. Electrochemical behaviour of steel rebars in concrete: Influence of environmental factors and cement chemistry. Electrochim. Acta 2001, 46, 3905–3912. [Google Scholar] [CrossRef]

- Fang, X.; Chen, L.; Pan, J. Comparative study of on-site corrosion monitoring for concrete by different methods. Adv. Mater. Res. 2014, 838–841, 2066–2070. [Google Scholar] [CrossRef]

- Swarup, J.; Sharma, P.C. Electrochemical techniques for the monitoring of corrosion of reinforcement in concrete structures. Bull. Electrochem. 1996, 12, 103–108. [Google Scholar]

- Ohtsu, M.; Yamamoto, T. Compensation procedure for half-cell potential measurement. Constr. Build. Mater. 1997, 11, 395–402. [Google Scholar] [CrossRef]

- Assouli, B.; Ballivy, G.; Rivard, P. Influence of environmental parameters on application of standard ASTM C876–91: Half cell potential measurements. Corros. Eng. Sci. Technol. 2008, 43, 93–96. [Google Scholar] [CrossRef]

- Yeih, W.; Huang, R. Detection of the corrosion damage in reinforced concrete members by ultrasonic testing. Cem. Concr. Res. 1998, 28, 1071–1083. [Google Scholar] [CrossRef]

- Sadowski, L. Methodology for assessing the probability of corrosion in concrete structures on the basis of half-cell potential and concrete resistivity measurements. Sci. World J. 2013, 2013. [Google Scholar] [CrossRef] [PubMed]

- Ismail, M.A.; Soleymani, H.; Ohtsu, M. Early detection of corrosion activity in reinforced concrete slab by AE technique. In Proceeding of the 6th Asia-Pasific Structural Engineering and Construction Conference (APSEC 2006), Kuala Lumpur, Malaysia, 5–6 September 2006.

- Andrade, C.; Alonso, M.C.; Gonzalez, J.A. An initial effort to use corrosion rate measurements for estimating rebar durability corrosion rates of steel in concrete. Corros. Rat. Steel Concr. ASTM STP 1990, 1065, 29–37. [Google Scholar]

- Clear, K.C. Measuring rate of corrosion of steel in field concrete structures. Trans. Res. Rec. 1989, 1211, 28–37. [Google Scholar]

- Broomfield, J.P. Field measurement of the corrosion rate of steel in concrete using a microprocessor controlled unit with a monitored guard ring for signal confinement. ASTM Spec. Tech. Publ. 1996, 1276, 91–106. [Google Scholar]

- Reichling, K.; Raupach, M.; Broomfield, J.; Gulikers, J.; Nygaard, P.V.; Schneck, U.; Sergi, G. Local detailed inspection methods regarding reinforcement corrosion of concrete structures. Mater. Corros. 2013, 64, 128–134. [Google Scholar] [CrossRef]

- Fukuyama, T.; Nagai, H.; Noguchi, T. Corrosion monitoring of reinforcing bars by electrochemical noise measurement. In Proceeding of the 4th International Conference on Structural Health Monitoring of Intelligent Infrastructure (SHMII-4), Zurich, Switzerland, 22–24 July 2009.

- Newton, C.J.; Sykes, J.M. A galvanostatic pulse technique for investigation of steel corrosion in concrete. Corros. Sci. 1988, 28, 1051–1074. [Google Scholar] [CrossRef]

- Elsener, B.; Wojtas, H.; Bohni, H. Inspection and monitoring of reinforced concrete structures—Electrochemical methods to detect corrosion. Insight 1994, 36, 502–506. [Google Scholar]

- Sathiyanarayanan, S.; Natarajan, P.; Saravanan, K.; Srinivasan, S.; Venkatachari, G. Corrosion monitoring of steel in concrete by galvanostatic pulse technique. Cem. Concr. Compos. 2006, 28, 630–637. [Google Scholar] [CrossRef]

- Vedalakshmi, R.; Thangavel, K. Reliability of electrochemical techniques to predict the corrosion rate of steel in concrete structures. Arab. J. Sci. Eng. 2011, 36, 769–783. [Google Scholar] [CrossRef]

- Wojtas, H. Determination of corrosion rate of reinforcement with a modulated guard ring electrode: Analysis of errors due to lateral current distribution. Corros. Sci. 2004, 46, 1621–1632. [Google Scholar] [CrossRef]

- Bungey, J.H.; Millard, S.G. Testing of Concrete in Structures, 3rd ed.; Blackie Academic & Professional: New York, NY, USA, 1996. [Google Scholar]

- Sadowski, L. New non-destructive method for linear polarisation resistance corrosion rate measurement. Arch. Civ. Mech. Eng. 2010, 10, 109–116. [Google Scholar] [CrossRef]

- Cavalier, P.G.; Vassie, P.R. Investigation and repair of reinforcement corrosion in a bridge deck. In Proceedings of the Institution of Civil Engineers (London) Part 1—Design & Construction, Birmingham, UK, 15–16 September 1981; pp. 461–480.

- Clear, K.C. Time to Corrosion of Reinforcing Steel in Concrete Slabs; Federal Highway Administration: Washington, DC, USA, 1982.

- Polder, R.B. Test methods for on site measurement of resistivity of concrete—A RILEM TC-154 technical recommendation. Constr. Build. Mater. 2001, 15, 125–131. [Google Scholar] [CrossRef]

- Polder, R.; Andrade, C.; Elsener, B.; Vennesland, O.; Gulikers, J.; Weidert, R.; Raupach, M. Test methods for on site measurement of resistivity of concrete. Mater. Struct. 2000, 33, 603–611. [Google Scholar] [CrossRef]

- Reichling, K.; Raupach, M.; Broomfield, J.; Gulikers, J.; L’Hostis, V.; Kessler, S.; Osterminski, K.; Pepenar, I.; Schneck, U.; Sergi, G.; et al. Full surface inspection methods regarding reinforcement corrosion of concrete structures. Mater. Corros. 2013, 64, 116–127. [Google Scholar] [CrossRef]

- Legat, A. Monitoring of steel corrosion in concrete by electrode arrays and electrical resistance probes. Electrochim. Acta 2007, 52, 7590–7598. [Google Scholar] [CrossRef]

- Legat, A.; Govekar, E. Detection of corrosion by analysis of electrochemical noise. Fractals 1994, 2, 241–244. [Google Scholar] [CrossRef]

- Inoue, H.; Moriya, R.; Nishimura, R. Extreme-value distribution of the metastable-pit depth estimated by potential noise method. J. Soc. Mater. Sci. Jpn 2008, 57, 1097–1100. [Google Scholar] [CrossRef]

- Bertocci, U.; Huet, F. Noise analysis applied to electrochemical systems. Corrosion 1995, 51, 131–144. [Google Scholar] [CrossRef]

- Xiao, H.; Mansfeld, F. Evaluation of coating degradation with electrochemical impedance spectroscopy and electrochemical noise analysis. J. Electrochem. Soc. 1994, 141, 2332–2337. [Google Scholar] [CrossRef]

- Mansfeld, F.; Xiao, H. Electrochemical noise analysis of iron exposed to NaCl solutions of different corrosivity. J. Electrochem. Soc. 1993, 140, 2205–2209. [Google Scholar] [CrossRef]

- Yu, J.G.; Luo, J.L.; Norton, P.R. Investigation of hydrogen induced pitting active sites. Electrochim. Acta 2002, 47, 4019–4025. [Google Scholar] [CrossRef]

- Mansfeld, F.; Sun, Z.; Hsu, C.H. Electrochemical noise analysis (ENA) for active and passive systems in chloride media. Electrochim. Acta 2001, 46, 3651–3664. [Google Scholar] [CrossRef]

- Hashimoto, M.; Miyajima, S.; Murata, T. An experimental study of potential fluctuation during passive film breakdown and repair on iron. Corros. Sci. 1992, 33, 905–915. [Google Scholar] [CrossRef]

- Mariaca, L.; Bautista, A.; Rodríguez, P.; González, J.A. Use of electrochemical noise for studying the rate of corrosion of reinforcements embedded in concrete. Mater. Struct. 1997, 30, 613–617. [Google Scholar] [CrossRef]

- Legat, A.; Leban, M.; Bajt, Ž. Corrosion processes of steel in concrete characterized by means of electrochemical noise. Electrochim. Acta 2004, 49, 2741–2751. [Google Scholar] [CrossRef]

- Zhao, B.; Li, J.H.; Hu, R.G.; Du, R.G.; Lin, C.J. Study on the corrosion behavior of reinforcing steel in cement mortar by electrochemical noise measurements. Electrochim. Acta 2007, 52, 3976–3984. [Google Scholar] [CrossRef]

- Aballe, A.; Bethencourt, M.; Botana, F.J.; Marcos, M.; Sánchez-Amaya, J.M. Influence of the degree of polishing of alloy AA 5083 on its behaviour against localised alkaline corrosion. Corros. Sci. 2004, 46, 1909–1920. [Google Scholar] [CrossRef]

- Mills, D.; Mabbutt, S.; Bierwagen, G. Investigation into mechanism of protection of pigmented alkyd coatings using electrochemical and other methods. Prog. Org. Coat. 2003, 46, 176–181. [Google Scholar] [CrossRef]

- Nagiub, A.; Mansfeld, F. Evaluation of corrosion inhibition of brass in chloride media using EIS and ENA. Corros. Sci. 2001, 43, 2147–2171. [Google Scholar] [CrossRef]

- Hong, S.; Lai, W.L.; Helmerich, R. Experimental monitoring of chloride-induced reinforcement corrosion and chloride contamination in concrete with ground-penetrating radar. Struct. Infrastruct. Eng. 2014, 15–26. [Google Scholar] [CrossRef]

- Patil, S.; Karkare, B.; Goyal, S. Acoustic emission vis-Ã-vis electrochemical techniques for corrosion monitoring of reinforced concrete element. Constr. Build. Mater. 2014, 68, 326–332. [Google Scholar] [CrossRef]

- Kabir, S.; Zaki, A. Detection and quantification of corrosion damage using ground penetrating radar (GPR). In Proceeding of the Progress in Electromagnetic Research Symposium (PIERS), Marrakesh, Marocco, 20–23 March 2011.

- Halabe, U.B. Condition Assessment of Reinforced Concrete Structures Using Electromagnetic Waves. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1990. [Google Scholar]

- Sbartai, Z.M.; Laurens, S.; Rhazi, J.; Balayssac, J.P.; Arliguie, G. Using radar direct wave for concrete condition assessment: Correlation with electrical resistivity. J. Appl. Geophys. 2007, 62, 361–374. [Google Scholar] [CrossRef]

- Lai, W.L.; Kind, T.; Wiggenhauser, H. Frequency-dependent dispersion of high-frequency ground penetrating radar wave in concrete. NDT&E Int. 2011, 44, 267–273. [Google Scholar]

- Robert, A. Dielectric permittivity of concrete between 50 MHz and 1 GHz and GPR measurements for building materials evaluation. J. Appl. Geophys. 1998, 40, 89–94. [Google Scholar] [CrossRef]

- Soutsos, M.N.; Bungey, J.H.; Millard, S.G.; Shaw, M.R.; Patterson, A. Dielectric properties of concrete and their influence on radar testing. NDT&E Int. 2001, 34, 419–425. [Google Scholar]

- Sbartai, Z.M.; Laurens, S.; Balayssac, J.P.; Ballivy, G.; Arliguie, G. Effect of concrete moisture on radar signal amplitude. ACI Mater. J. 2006, 103, 419–426. [Google Scholar]

- Maierhofer, C. Nondestructive evaluation of concrete infrastructure with ground penetrating radar. J. Mater. Civ. Eng. 2003, 15, 287–297. [Google Scholar] [CrossRef]

- Kim, W. Ground Penetrating Radar Application for Non-Destructive Testing: Bridge Deck Inspection and Dowel Bar Detection. Ph.D, Thesis, University of Missouri–Rolla, Rolla, MO, USA, 2003. [Google Scholar]

- Klysz, G.; Balayssac, J.P.; Laurens, S. Spectral analysis of radar surface waves for non-destructive evaluation of cover concrete. NDT&E Int. 2004, 37, 221–227. [Google Scholar]

- Lai, W.L.; Kou, S.C.; Tsang, W.F.; Poon, C.S. Characterization of concrete properties from dielectric properties using ground penetrating radar. Cem. Concr. Res. 2009, 39, 687–695. [Google Scholar] [CrossRef]

- Sbartai, Z.M.; Laurens, S.; Balayssac, J.P.; Arliguie, G.; Ballivy, G. Ability of the direct wave of radar ground-coupled antenna for NDT of concrete structures. NDT&E Int. 2006, 39, 400–407. [Google Scholar]

- Barnes, C.L.; Trottier, J.F.; Forgeron, D. Improved concrete bridge deck evaluation using GPR by accounting for signal depth-amplitude effects. NDT&E Int. 2008, 41, 427–433. [Google Scholar]

- Kim, W.; Ismail, A.; Anderson, N.L.; Atekwana, E.A.; Buccellato, A. Non-destructive testing (NDT) for corrosion in bridge decks using GPR. In Proceedings of the 3rd International Conference on the Application of Geophysical Methodologies and NDT to Transportation Facilities and Infrastructure, Geophysics 2003, Orlando, FL, USA, 8–12 December 2003.

- Lai, W.L.; Kind, T.; Wiggenhauser, H. Detection of accelerated reinforcement corrosion in concrete by ground penetrating radar. In Proceeding of the 13th International Conference on Ground Penetrating Radar (GPR), Lecce, Italy, 21–25 June 2010.

- Hong, S.X.; Lai, W.L.; Helmerich, R. Monitoring accelerated corrosion in chloride contaminated concrete with ground penetrating radar. In Proceeding of the 14th International Conference on Ground Penetrating Radar, Shanghai, China, 4–8 June 2012.

- Manning, D.G.; Holt, F.B. Detecting delamination in concrete bridge decks. Concr. Int. 1980, 2, 34–41. [Google Scholar]

- Kordatos, E.Z.; Strantza, M.; Soulioti, D.V.; Matikas, T.E.; Aggelis, D.G. Combined NDT methods for characterization of subsurface cracks in concrete. In Proceeding of the SPIE—The International Society for Optical Engineering, San Diego, CA, USA, 6 March 2011.

- Bagavathiappan, S.; Lahiri, B.B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Washer, G.; Bolleni, N.; Fenwick, R. Thermographic imaging of subsurface deterioration in concrete bridges. Trans. Res. Rec. 2010, 2201, 27–33. [Google Scholar] [CrossRef]

- Pieper, D.; Donnell, K.M.; Ghasr, M.T.; Kinzel, E.C. Integration of microwave and thermographic NDT methods for corrosion detection. In Proceeding of AIP Conference, Canberra, Australia, 7–12 December 2014.

- Kobayashi, K.; Banthia, N. Detection of reinforcement corrosion with a new non-destructive test method using induction heating. In Proceeding of the 6th International Conference on Concrete under Severe Conditions (CONSEC’10), Merida, Mexico, 7–9 June 2010.

- Clark, M.R.; McCann, D.M.; Forde, M.C. Application of infrared thermography to the non-destructive testing of concrete and masonry bridges. NDT&E Int. 2003, 36, 265–275. [Google Scholar]

- Chung, L.; Paik, I.K.; Roh, Y.S. Non-destructive evaluation techniques of reinforcing steel corrosion using infrared thermography. Key Eng. Mater. 2004, 270, 1592–1597. [Google Scholar] [CrossRef]

- Chung, L.; Paik, I.K.; Cho, S.H.; Roh, Y.S. Infrared thermographic technique to measure corrosion in reinforcing bar. Key Eng. Mater. 2006, 321, 821–824. [Google Scholar] [CrossRef]

- Washer, G. Advances in the use of thermographic imaging for the condition assessment of bridges. Bridg. Struct. Assess. Des. Constr. 2012, 8, 81–90. [Google Scholar]

- Kobayashi, K.; Banthia, N. Corrosion detection in reinforced concrete using induction heating and infrared thermography. J. Civ. Struct. Health Monit. 2011, 1, 25–35. [Google Scholar] [CrossRef]

- Kwon, S.J.; Xue, H.; Feng, M.Q.; Baek, S. Nondestructive corrosion detection in concrete through integrated heat induction and IR thermography. In Proceeding of the SPIE—The International Society for Optical Engineering, San Diego, CA, USA, 6 March 2011.

- Baek, S.; Xue, W.; Feng, M.Q.; Kwon, S. Nondestructive corrosion detection in RC through integrated heat induction and IR thermography. J. Nondestr. Eval. 2012, 31, 181–190. [Google Scholar] [CrossRef]

- Vallee, R.; Fredrick, S.; Asatryan, K.; Fischer, M.; Galstian, T. Real-time observation of Bragg grating formation in As2S3 chalcogenide ridge waveguides. Opt. Commun. 2004, 230, 301–307. [Google Scholar] [CrossRef]

- Hassan, M.R.A.; Bakar, M.H.A.; Dambul, K.; Adikan, F.R.M. Optical-based sensors for monitoring corrosion of reinforcement rebar via an etched Cladding Bragg grating. Sensors 2012, 12, 15820–15826. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.; Dong, X. Modification of the wavelength-strain coefficient of FBG for the prediction of steel bar corrosion embedded in concrete. Opt. Fiber Technol. 2012, 18, 47–50. [Google Scholar] [CrossRef]

- Zheng, Z.; Sun, X.; Lei, Y. Monitoring corrosion of reinforcement in concrete structures via fiber Bragg grating sensors. Front. Mech. Eng. Chin. 2009, 4, 316–319. [Google Scholar] [CrossRef]

- Lee, J.R.; Yun, C.Y.; Yoon, D.J. A structural corrosion-monitoring sensor based on a pair of prestrained fiber Bragg gratings. Meas. Sci. Technol. 2010, 21. [Google Scholar] [CrossRef]

- Gao, J.; Wu, J.; Li, J.; Zhao, X. Monitoring of corrosion in reinforced concrete structure using Bragg grating sensing. NDT&E Int. 2011, 44, 202–205. [Google Scholar]

- Lau, K.T. Fibre-optic sensors and smart composites for concrete applications. Mag. Concr. Res. 2003, 55, 19–34. [Google Scholar] [CrossRef]

- Geng, J.; Wu, J.; Zhao, X. Simulation of fiber Bragg grating sensor for rebar corrosion. In Proceeding of SPIE—The International Society for Optical Engineering, Weihai, China, 8 July 2009.

- Lei, Y.; Zheng, Z.P. Review of physical based monitoring techniques for condition assessment of corrosion in reinforced concrete. Math. Probl. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Sohn, H.; Park, G.; Wait, J.R.; Limback, N.P.; Farrar, C.R. Wavelet-based active sensing for delamination detection in composite structures. Smart Mater. Struct. 2004, 13, 153–160. [Google Scholar] [CrossRef]

- ASTM. ASTM C-597–83: Standard Test Method for Pulse Velocity Through Concrete. Available online: http://www.astm.org/DATABASE.CART/HISTORICAL/C597-97.htm (accessed on 6 May 2015).

- Bungey, J.H. Ultrasonic testing to identify alkali-silica reaction in concrete. Br. J. Non-Destr. Test. 1991, 33, 227–231. [Google Scholar]

- John, G.; Hladky, K.; Gaydecki, P.; Dawson, J. Recent developments in inspection techniques for corrosion damaged concrete structures. Corros. Forms Control Infrastruct. 1992, 1137, 246–257. [Google Scholar]

- Raad, J.; Aktan, H.; Usmen, M. Laboratory for non destructive evaluation of civil structures. In Proceeding of ASEE Annual Conference, Milwaukee, WI, USA, 15–18 June 1997.

- Ervin, B.; Kuchma, D.; Bernhard, J.; Reis, H. Monitoring corrosion of rebar embedded in mortar using high-frequency guided ultrasonic waves. J. Eng. Mech. 2009, 135, 9–19. [Google Scholar] [CrossRef]

- Sharma, S.; Mukherjee, A. Longitudinal guided waves for monitoring chloride corrosion in reinforcing bars in concrete. Struct. Health Monit. 2010, 9, 555–567. [Google Scholar] [CrossRef]

- Jung, Y.-C.; Na, W.-B.; Kundu, T.; Ehsani, M. Damage detection in concrete using Lamb waves. In Proceeding of SPIE—The International Society for Optical Engineering, Newport Beach, CA, USA, 6 March 2000; pp. 448–458.

- Sharma, S.; Mukherjee, A. Monitoring corrosion in oxide and chloride environments using ultrasonic guided waves. J. Mater. Civ. Eng. 2011, 23, 207–211. [Google Scholar] [CrossRef]

- Sharma, S.; Mukherjee, A. Nondestructive evaluation of corrosion in varying environments using guided waves. Res. Nondestr. Eval. 2013, 24, 63–88. [Google Scholar] [CrossRef]

- Miller, T.H.; Yanagita, T.; Kundua, T.; Grill, J.; Grill, W. Nondestructive inspection of reinforced concrete structures. In Proceeding of the SPIE—The International Society for Optical Engineering, San Diego, CA, USA, 8 March 2009.

- Goueygou, M.; Piwakowski, B.; Fnine, A.; Kaczmarek, M.; Buyle-Bodin, F. NDE of two-layered mortar samples using high-frequency Rayleigh waves. Ultrasonics 2004, 42, 889–895. [Google Scholar] [CrossRef] [PubMed]

- Aggelis, D.G.; Kordatos, E.Z.; Soulioti, D.V.; Matikas, T.E. Combined use of thermography and ultrasound for the characterization of subsurface cracks in concrete. Constr. Build. Mater. 2010, 24, 1888–1897. [Google Scholar] [CrossRef]

- Li, D.; Zhang, S.; Yang, W.; Zhang, W. Corrosion monitoring and evaluation of reinforced concrete structures utilizing the ultrasonic guided wave technique. Int. J. Distrib. Sens. Netw. 2014, 2014. [Google Scholar] [CrossRef]

- Komlos, K.; Popovics, S.; NÃrnbergerovÃ, T.; BabÃl, B.; Popovics, J.S. Ultrasonic pulse velocity test of concrete properties as specified in various standards. Cem. Concr. Compos. 1996, 18, 357–364. [Google Scholar] [CrossRef]

- Sansalone, M.J.; Streett, W.B. Impact-echo. Nondestructive Evaluation of Concrete & Masonry; Bullbrier Press: Jersey Shore, PA, USA, 1997. [Google Scholar]

- Carino, N.J.; Sansalone, M.; Hsu, N.N. Flaw detection in concrete by frequency spectrum analysis of impact-echo waveforms. Int. Adv. Nondestruct. Test. 1986, 12, 117–146. [Google Scholar]

- Liang, M.T.; Su, P.J. Detection of the corrosion damage of rebar in concrete using impact-echo method. Cem. Concr. Res. 2001, 31, 1427–1436. [Google Scholar] [CrossRef]

- Samarkova, K.; Chobola, Z.; Stefkova, D. The corrosion status of reinforced concrete structure monitoring by impact echo method. Adv. Mater. Res. 2014, 875–877, 445–449. [Google Scholar] [CrossRef]

- Samarkova, K.; Chobola, Z.; Stefkova, D. Using of impact-echo methods to assessment of reinforced concrete structures corrosion. Appl. Mech. Mater. 2014, 446–447, 1400–1404. [Google Scholar]

- Samarkova, K.; Chobola, Z.; Stefkova, D.; Kusak, I. Impact-echo methods to assessment corrosion of reinforced concrete structures. Appl. Mech. Mater. 2014, 627, 268–271. [Google Scholar] [CrossRef]

- Samarkova, K.; Stefkova, D.; Chobola, Z. Monitoring of reinforced concrete structure corrosion by using impact-echo method. Adv. Mater. Res. 2014, 1000, 239–242. [Google Scholar] [CrossRef]

- Miller, R.K.; Mc Intire, P. Acoustic emission testing. In Encyclopedic Dictionary of Polymers; Springer New York: New York, NY, USA, 1987; pp. 12–154. [Google Scholar]

- Beattie, A.G. Acoustic emission, principles and instrumentation. J. Acoust. Emission 1983, 2, 95–128. [Google Scholar]

- Shiotani, T. Evaluation of long-term stability for rock slope by means of acoustic emission technique. NDT&E Int. 2006, 39, 217–228. [Google Scholar]

- Alvarez, M.G.; Lapitz, P.; Ruzzante, J. Analysis of acoustic emission signals generated from SCC propagation. Corros. Sci. 2012, 55, 5–9. [Google Scholar] [CrossRef]

- Lapitz, P.; Ruzzante, J.; Alvarez, M.G. AE response of α-brass during stress corrosion crack propagation. Corros. Sci. 2007, 49, 3812–3825. [Google Scholar] [CrossRef]

- Wells, D. An acoustic apparatus to record emissions from concrete under strain. Nucl. Eng. Des. 1970, 12, 80–88. [Google Scholar] [CrossRef]

- Luo, X.; Haya, H.; Inaba, T.; Shiotani, T.; Nakanishi, Y. Experimental study on evaluation of breakage in foundations using train-induced acoustic emission. In Proceeding of the Structural Engineering World Congress, Tokyo, Japan, 13–14 December 2002.

- ASTM. ASTM C-610–98A: Definitions of Terms Relating to Acoustic Emission. Available online: http://www.astm.org/DATABASE.CART/WITHDRAWN/E610.htm (accessed on 6 May 2015).

- Malhotra, V.M.; Carino, N.J. CRC Handbook on Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 1991. [Google Scholar]

- Ohtsu, M.; Yuyama, S. Recommended practice for in-situ monitoring of concrete structures by acoustic emission. In Proceedings of the 15th International Acoustic Emission Symposium, Tokyo, Japan, 11–14 September 2000; pp. 263–268.

- Carpinteri, A.; Lacidogna, G.; Niccolini, G. Damage analysis of reinforced concrete buildings by the acoustic emission technique. Struct. Control Health Monit. 2011, 18, 660–673. [Google Scholar] [CrossRef]

- Ohtsu, M. Mathematical theory of acustic emission and moment tensor solution. J. Soc. Mater. Sci. 1987, 36, 1025–1031. [Google Scholar] [CrossRef]

- Colombo, S.; Main, I.G.; Forde, M.C. Assessing damage of reinforced concrete beam using “b-value” analysis of acoustic emission signals. J. Mater. Civ. Eng. 2003, 15, 280–286. [Google Scholar] [CrossRef]

- Grosse, C.U.; Reinhardt, H.W.; Finck, F. Signal-based acoustic emission techniques in civil engineering. J. Mater. Civ. Eng. 2003, 15, 274–279. [Google Scholar] [CrossRef]

- Ohno, K.; Ohtsu, M. Crack classification in concrete based on acoustic emission. Constr. Build. Mater. 2010, 24, 2339–2346. [Google Scholar] [CrossRef]

- Dunn, S.E.; Young, J.D.; Hartt, W.H.; Brown, R.P. Acoustic emission characterization of corrosion induced damage in reinforced concrete. Corrosion 1984, 40, 339–343. [Google Scholar] [CrossRef]

- Shiotani, T.; Ohtsu, M.; Ikeda, K. Detection and evaluation of AE waves due to rock deformation. Constr. Build. Mater. 2001, 15, 235–246. [Google Scholar] [CrossRef]

- Titus, T.N.K.; Reddy, D.V.; Dunn, S.E.; Hartt, W.H. Acoustic emission crack monitoring and prediction of remaining life of corroding reinforced concrete beams. In Proceeding of the 4th European Conference Non-destructive Testing, London, UK, 13–17 September 1988.

- Ohtsu, M. The history and development of acoustic emission in concrete engineering. Mag. Concr. Res. 1996, 48, 321–330. [Google Scholar] [CrossRef]

- Ohtsu, M. Recommendation of RILEM TC 212-ACD: Acoustic emission and related NDE techniques for crack detection and damage evaluation in concrete. Mater. Struct. 2010, 43, 1187–1189. [Google Scholar]

- Ismail, M.E.; Ismail, M.; Ohtsu, M. Non-destructive evaluation of corrosion activity in reinforced concrete slab. In Proceeding of the 4th International Structural Engineering and Construction Conference (ISEC-4)—Innovations in Structural Engineering and Construction, Melbourne, Australia, 26–28 September 2008.

- Calabrese, L.; Campanella, G.; Proverbio, E. Identification of corrosion mechanisms by univariate and multivariate statistical analysis during long term acoustic emission monitoring on a pre-stressed concrete beam. Corros. Sci. 2013, 73, 161–171. [Google Scholar] [CrossRef]

- Yu, A.; Zhao, Y.; Wang, L. Acoustic emission (AE) online monitoring test on corrosion in reinforced concrete. J. Build. Mater. 2014, 17, 291–297. [Google Scholar]

- Ohtsu, M.; Tomoda, Y. Corrosion process in reinforced concrete identified by acoustic emission. Mater. Trans. 2007, 48, 1184–1189. [Google Scholar] [CrossRef]

- Yoon, D.J.; Weiss, W.J.; Shah, S.P. Assessing damage in corroded reinforced concrete using acoustic emission. J. Eng. Mech. 2000, 126, 273–283. [Google Scholar] [CrossRef]

- Kawasaki, Y.; Wakuda, T.; Kobarai, T.; Ohtsu, M. Corrosion mechanisms in reinforced concrete by acoustic emission. Constr. Build. Mater. 2013, 48, 1240–1247. [Google Scholar] [CrossRef]

- Kawasaki, Y.; Tomoda, Y.; Ohtsu, M. AE monitoring of corrosion process in cyclic wet–dry test. Constr. Build. Mater. 2010, 24, 2353–2357. [Google Scholar] [CrossRef]

- Ohtsu, M.; Tomoda, Y. Acoustic emission techniques for rebar corrosion in reinforced concrete. In Advances in Construction Materials 2007; Springer-Verlag: Berlin, Germany, 2007. [Google Scholar]

- Ohtsu, M.; Tomoda, Y. Phenomenological model of corrosion process in reinforced concrete identified by acoustic emission. ACI Mater. J. 2008, 105, 194–199. [Google Scholar]

- Elfergani, H.A.; Pullin, R.; Holford, K.M. Damage assessment of corrosion in prestressed concrete by acoustic emission. Constr. Build. Mater. 2013, 40, 925–933. [Google Scholar] [CrossRef]

- Behnia, A.; Chai, H.K.; Shiotani, T. Advanced structural health monitoring of concrete structures with the aid of acoustic emission. Constr. Build. Mater. 2014, 65, 282–302. [Google Scholar] [CrossRef]

- ElBatanouny, M.K.; Ziehl, P.H.; Larosche, A.; Mangual, J.; Matta, F.; Nanni, A. Acoustic emission monitoring for assessment of prestressed concrete beams. Constr. Build. Mater. 2014, 58, 46–53. [Google Scholar] [CrossRef]

- Melchers, R.E.; Li, C.Q. Phenomenological modeling of reinforcement corrosion in marine environments. ACI Mater. J. 2006, 103, 25–32. [Google Scholar]

- Velez, W.; Matta, F.; Ziehl, P. Acoustic emission intensity analysis of corrosion in prestressed concrete piles. In Proceeding of the 10th International Conference on Barkhausen Noise and Micromagnetic Noise and Micromagnetic Testing, Melville, NY, USA, 26–28 August 2014.

- Velez, W.; Matta, F.; Ziehl, P. Acoustic emission characterization of early corrosion in prestressed concrete exposed to salt water. In Proceeding of the 11th International Conference on Structural Safety and Reliability (ICOSSAR), New York, NY, USA, 16–20 June 2013.

- Ing, M.; Austin, S.; Lyons, R. Cover zone properties influencing acoustic emission due to corrosion. Cem. Concr. Res. 2005, 35, 284–295. [Google Scholar] [CrossRef] [Green Version]

- JCMS-IIIB5706. Monitoring Method for Active Cracks in Concrete by Acoustic Emission. Available online: http://framcos.org/FraMCoS-7/09-01.pdf (accessed on 6 May 2015).

- Rao, M.V.M.S.; Prasanna Lakshmi, K.J. Analysis of b-value and improved b-value of acoustic emissions accompanying rock fracture. Curr. Sci. 2005, 89, 1577–1582. [Google Scholar]

- Gutenberg, B.; Richter, C.F. Seismicity of the Earth and Associated Phenomena; Princeton University Press: Princeton, NJ, USA, 1954. [Google Scholar]

- Shiotani, T.; Ohtsu, M. Prediction of Slope Failure Based on AE Activity; ASTM Special Technical Publication: West Conshohocken, PA, USA, 1999; pp. 156–172. [Google Scholar]

- ElBatanouny, M.K.; Larosche, A.; Mazzoleni, P.; Ziehl, P.H.; Matta, F.; Zappa, E. Identification of cracking mechanisms in scaled FRP reinforced concrete beams using acoustic emission. Exp. Mech. 2012, 54, 69–82. [Google Scholar] [CrossRef]

- Ono, K. Application of acoustic emission for structure diagnosis. Konf. Naukowa 2010, 2, 317–341. [Google Scholar]

- Yuyama, S.; Yokoyama, K.; Niitani, K.; Ohtsu, M.; Uomoto, T. Detection and evaluation of failures in high-strength tendon of prestressed concrete bridges by acoustic emission. Constr. Build. Mater. 2007, 21, 491–500. [Google Scholar] [CrossRef]

- ElBatanouny, M.K.; Mangual, J.; Velez, W.; Ziehl, P.H.; Matta, F.; Gonzalez, M. Monitoring corrosion in prestressed concrete beams using acoustic emission technique. In Proceeding of the SPIE—The International Society for Optical Engineering, San Diego, CA, USA, 11 March 2012.

- Mangual, J.; ElBatanouny, M.K.; Velez, W.; Ziehl, P.; Matta, F.; Gonzalez, M. Characterization of corrosion damage in prestressed concrete using acoustic emission. In Proceeding of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, Parts 1 and 2, San Diego, CA, USA, 12–15 March 2012.

- ElBatanouny, M.K.; Mangual, J.; Ziehl, P.H.; Matta, F. Early corrosion detection in prestressed concrete girders using acoustic emission. J. Mater. Civ. Eng. 2014, 26, 504–511. [Google Scholar] [CrossRef]

- Fowler, T.J.; Blessing, J.A.; Strauser, F.E. Intensity analysis. In Proceedinds of the 4 International Symposia Acoustic Emission from Composite Materials, Columbus, OH, USA, 27–31 July 1992; pp. 16–27.

- Gostautas, R.S.; Ramirez, G.; Peterman, R.J.; Meggers, D. Acoustic emission monitoring and analysis of glass fiber-reinforced composites bridge decks. J. Bridg. Eng. 2005, 10, 713–721. [Google Scholar] [CrossRef]

- Mangual, J.; ElBatanouny, M.K.; Ziehl, P.; Matta, F. Acoustic emission-based characterization of corrosion damage in cracked concrete with prestressing strand. ACI Mater. J. 2013, 110, 89–98. [Google Scholar]

- Colombo, S.; Forde, M.C.; Main, I.G.; Shigeishi, M. Predicting the ultimate bending capacity of concrete beams from the “relaxation ratio” analysis of AE signals. Constr. Build. Mater. 2005, 19, 746–754. [Google Scholar] [CrossRef]

- Yun, H.D.; Choi, W.C.; Seo, S.Y. Acoustic emission activities and damage evaluation of reinforced concrete beams strengthened with CFRP sheets. NDT&E Int. 2010, 43, 615–628. [Google Scholar]

- Ohtsu, M.; Okamoto, T.; Yuyama, S. Moment tensor analysis of acoustic emission for cracking mechanisms in concrete. ACI Struct. J. 1998, 95, 87–95. [Google Scholar]

- Shigeishi, M.; Ohtsu, M. Acoustic emission moment tensor analysis: Development for crack identification in concrete materials. Constr. Build. Mater. 2001, 15, 311–319. [Google Scholar] [CrossRef]

- Farid Uddin, A.K.M.; Ohtsu, M. Micromechanics of corrosion cracking in concrete by AE-SIGMA. J. Acoustic Emission. 2005, 23, 136–141. [Google Scholar]

- Baranov, V.M.; Kapralov, E.Y.; Karasevich, V.A. Acoustic and electrochemical noise methods in extreme-condition fatigue tests. Meas. Tech. 2003, 46, 994–999. [Google Scholar] [CrossRef]

- Kouroussis, D.A.; Anastassopoulos, A.A.; Lenain, J.C.; Proust, A. Advances in Classification of Acoustic Emission Sources. Les Journées COFREND Reims 2001. Available online: http://www.epandt.com/Biblio/EA2001-06A.pdf (accessed on 5 May 2015).

- Calabrese, L.; Campanella, G.; Proverbio, E. Noise removal by cluster analysis after long time AE corrosion monitoring of steel reinforcement in concrete. Constr. Build. Mater. 2012, 34, 362–371. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaki, A.; Chai, H.K.; Aggelis, D.G.; Alver, N. Non-Destructive Evaluation for Corrosion Monitoring in Concrete: A Review and Capability of Acoustic Emission Technique. Sensors 2015, 15, 19069-19101. https://doi.org/10.3390/s150819069

Zaki A, Chai HK, Aggelis DG, Alver N. Non-Destructive Evaluation for Corrosion Monitoring in Concrete: A Review and Capability of Acoustic Emission Technique. Sensors. 2015; 15(8):19069-19101. https://doi.org/10.3390/s150819069

Chicago/Turabian StyleZaki, Ahmad, Hwa Kian Chai, Dimitrios G. Aggelis, and Ninel Alver. 2015. "Non-Destructive Evaluation for Corrosion Monitoring in Concrete: A Review and Capability of Acoustic Emission Technique" Sensors 15, no. 8: 19069-19101. https://doi.org/10.3390/s150819069

APA StyleZaki, A., Chai, H. K., Aggelis, D. G., & Alver, N. (2015). Non-Destructive Evaluation for Corrosion Monitoring in Concrete: A Review and Capability of Acoustic Emission Technique. Sensors, 15(8), 19069-19101. https://doi.org/10.3390/s150819069