Error Analysis and Experimental Study of a Bi-Planar Parallel Mechanism in a Pedicle Screw Robot System

Abstract

:1. Introduction

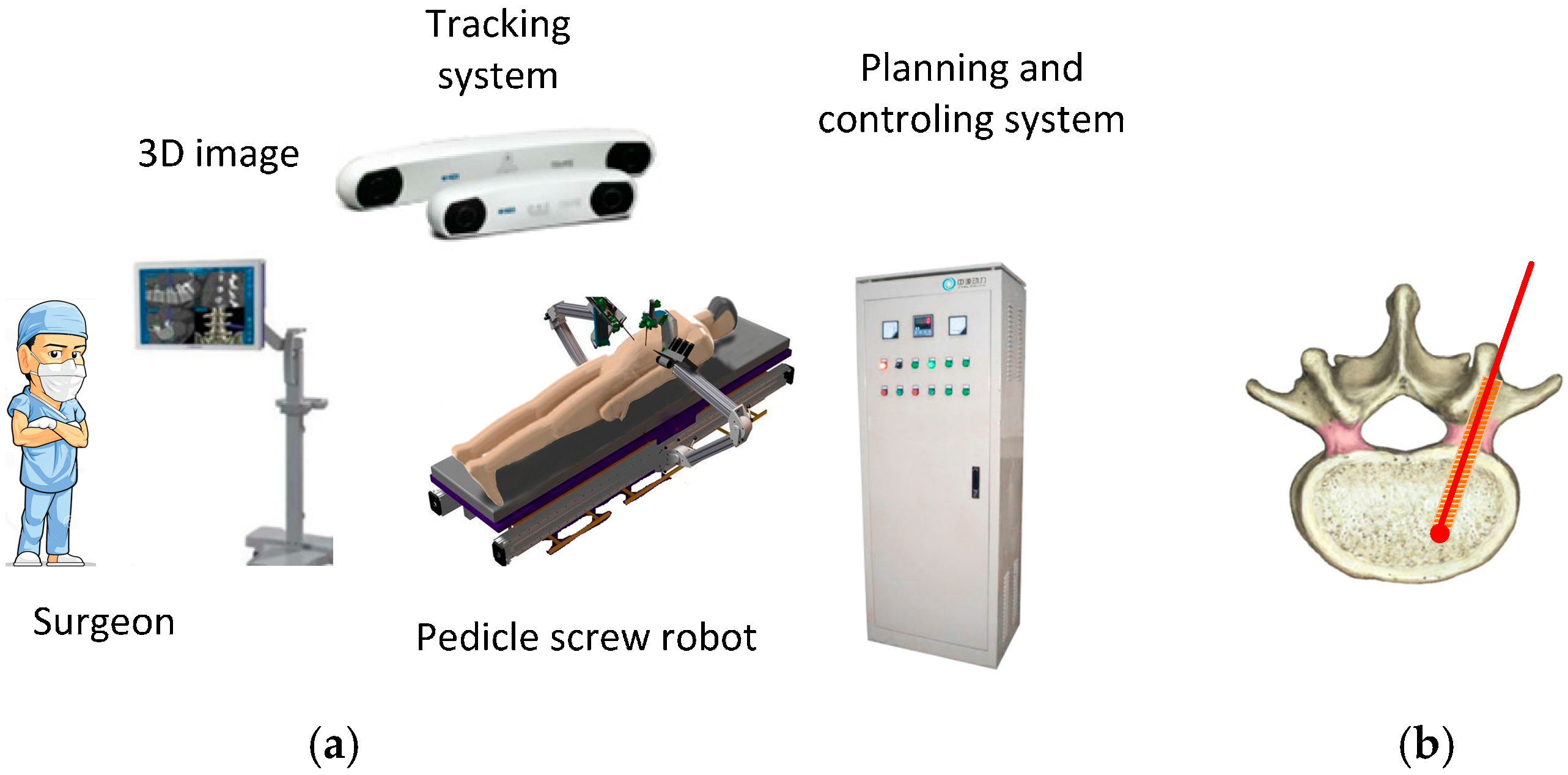

2. Structure and Working Principle of the Pedicle Screw Robot System

2.1. Structure Overview

2.2. Working Strategy

3. The Error Analysis

3.1. Error Transfer Function

3.2. Effect of Non-Parallelism of the Rotation Axis

4. Experimental Study

4.1. Positioning and Orientation Accuracy Experiment

4.2. Repetitive Positioning and Repetitive Orientation Precision Experiments

5. Conclusions

- (1)

- An error model of the mechanism has been proposed by a complete differential-coefficient theory. In addition, the relations between manufacturing errors, joint angle errors, assembly errors and the position- stance errors of the end effector have been established.

- (2)

- By analyzing the position-stance change of the end effecter, manufacturing errors and joint error have much more effect on the position-stance, so it is necessary to improve the manufacturing and assembly techniques. The trend of the position-stance changing the end effector is nonlinear.

- (3)

- The errors of the mechanism have a great effect on the position-stance of the end effector. Therefore, in the pedicle screw robot system, software and hardware compensations have been applied to correct the position-stance to improve the precision of the parallel mechanism.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kosmopoulos, V.; Schizas, C. Pedicle screw placement accuracy: A meta-analysis. Spine 2007, 32, E111–E120. [Google Scholar] [CrossRef] [PubMed]

- Rajasekaran, S.; Vidyadhara, S.; Ramesh, P.; Shetty, A.P. Randomized clinical study to compare the accuracy of navigated and non-navigated thoracic pedicle screws in deformity correction surgeries. Spine 2007, 32, E56–E64. [Google Scholar] [CrossRef] [PubMed]

- Tian, N.F.; Huang, Q.S.; Zhou, P.; Zhou, Y.; Wu, R.K.; Lou, Y.; Xu, H.Z. Pedicle screw insertion accuracy with different assisted methods: A systematic review and meta-analysis of comparative studies. Eur. Spine J. 2011, 20, 846–859. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yu, H.; Du, Z.; Dong, W. Structure optimization of a bi-planar parallel mechanism for spine surgeries. In Proceedings of the IEEE 2015 Seventh International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Nanchang, China, 13–14 June 2015; pp. 1022–1025.

- Park, M.S.; Deukmedjian, A.R.; Uribe, J.S. Minimally invasive anterolateral corpectomy for spinal tumors. Neurosurg. Clin. N. Am. 2014, 25, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Taylor, R.H.; Mittelstadt, B.D.; Paul, H.A.; Hanson, W.; Kazanzides, P.; Zuhars, J.F.; Williamson, B.; Musits, B.L.; Glassman, E.; Bargar, W.L. An image-directed robotic system for precise orthopaedic surgery. IEEE Trans. Rob. Autom. 1994, 10, 261–275. [Google Scholar] [CrossRef]

- Pechlivanis, I.; Kiriyanthan, G.; Engelhardt, M.; Scholz, M.; Lücke, S.; Harders, A.; Schmieder, K. Percutaneous placement of pedicle screws in the lumbar spine using a bone mounted miniature robotic system: First experiences and accuracy of screw placement. Spine 2009, 34, 392–398. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.; Zhang, P.; Hu, Y.; Zhang, J.; Zheng, Z. Design and kinematic analysis of a pedicle screws surgical robot. In Proceedings of the 2010 IEEE International Conference on Robotics and Biomimetics (ROBIO), Tianjin, China, 14–18 December 2010; pp. 1364–1369.

- Yu, A.; Bonev, I.A.; Zsombor-Murray, P. Geometric approach to the accuracy analysis of a class of 3-DOF planar parallel robots. Mech. Mach. Theory 2008, 43, 364–375. [Google Scholar] [CrossRef]

- Briot, S.; Bonev, I.A. Accuracy analysis of 3-DOF planar parallel robots. Mech. Mach. Theory 2008, 43, 445–458. [Google Scholar] [CrossRef]

- Briot, S.; Bonev, I.A. Accuracy analysis of 3T1R fully-parallel robots. Mech. Mach. Theory 2010, 45, 695–706. [Google Scholar] [CrossRef]

- Podhorodeski, R.P.; Pittens, K.H. A class of parallel manipulators based on kinematically simple branches. Trans. ASME J. Mech. Des. 1994, 116, 908–914. [Google Scholar] [CrossRef]

- Feng, W.L.; Yao, X.D.; Azamat, A.; Yang, J.G. Straightness error compensation for large CNC gantry type milling centers based on B-spline curves modeling. Int. J. Mach. Tools Manuf. 2015, 88, 165–174. [Google Scholar] [CrossRef]

- Cheng, G.; Ge, S.; Yong, W. Error analysis of three degree-of-freedom changeable parallel measuring mechanism. J. China Univ. Min. Technol. 2007, 17, 101–104. [Google Scholar] [CrossRef]

- Wang, Y. Research on Bi-Planar Parallel Manipulator for Minimally Invasive Spine Surgery. Master’s Thesis, Harbin Institute of Technology, Harbin, China, July 2015. [Google Scholar]

- Standard, A.S.T.M. F2554-10 Standard Practice for Measurement of Positional Accuracy of Computer Assisted Surgical Systems; ASTM International: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Puvanesarajah, V.; Liauw, J.A.; Lo, S.; Lina, I.A.; Witham, T.F. Techniques and accuracy of thoracolumbar pedicle screw placement. World J. Orthop. 2014, 5, 112. [Google Scholar] [CrossRef] [PubMed]

- Klein, S.; Whyne, C.M.; Rush, R.; Ginsberg, H.J. CT-based patient-specific simulation software for pedicle screw insertion. Clin. Spine Surg. 2009, 22, 502–506. [Google Scholar] [CrossRef] [PubMed]

- Heary, R.F.; Bono, C.M.; Black, M. Thoracic pedicle screws: Postoperative computerized tomography scanning assessment. J. Neurosurg. Spine 2004, 100, 325–331. [Google Scholar] [CrossRef]

- Yan, B. Study of Lumbar Pedicle Screws Accurate Placement Assisted by 3D Printing Navigation Modules. Master’s Thesis, Southern Medical University, Guangzhou, China, 2015. [Google Scholar]

- Gan, M.; Yang, H.; Zhou, F.; Lu, J.; Meng, B.; Mao, H.; Jiang, W.; Yang, Y.; Niu, J. Robot assisted pedicle screw placement accuracy observation nail. Chin. J. Anat. Clin. J. 2016, 21, 326–330. [Google Scholar]

- Gertzbein, S.D.; Robbins, S.E. Accuracy of pedicular screw placement in vivo. Spine 1990, 15, 11–14. [Google Scholar] [CrossRef] [PubMed]

- Pearle, A.D.; Kendoff, D.; Musahl, V. Perspectives on computer-assisted orthopaedic surgery: Movement toward quantitative orthopaedic surgery. J. Bone Joint Surg. Am. 2009, 91, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.; Wang, L.; Hu, Y.; Zhang, J.; Zheng, Z. Design and control strategy of robotic spinal surgical system. In Proceedings of the 2011 IEEE/ICME International Conference on Complex Medical Engineering (CME), Harbin, China, 22–25 May 2011; pp. 627–632.

- Khodaygan, S.; Hafezipour, M. Error reduction in spatial robots based on the statistical uncertainty analysis. SAE Int. J. Mater. Manuf. 2015, 8, 263–270. [Google Scholar] [CrossRef]

- Siciliano, B.; Sciavicco, L.; Villani, L.; Oriolo, G. Robotics: Modelling, Planning and Control; Springer: London, UK, 2010. [Google Scholar]

- Qin, W.; Haung, M.; Wu, Y. Influence of manufacturing errors on performance of overconstrained mechanism. China Mech. Eng. 2002, 15, 011. [Google Scholar]

- Nakamura, Y.; Murai, A. Constraints and deformations analysis for machining accuracy assessment of closed kinematic chains. In Proceedings of the 2004 IEEE International Conference on Robotics and Automation (ICRA’04), New Orleans, LA, USA, 26 April–1 May 2004; pp. 1706–1712.

- Huang, Y.; Huang, M.; Qin, W. Analysis on the effects of constraint errors on planar 5 R parallel robot. China Mech. Eng. 2010, 7, 42–47. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, W.; Lu, T. Structural Mechanism; Higher Education Press: Beijing, China, 1992. [Google Scholar]

- Passive Polaris Spectra System. Available online: http://www.ndigital.com/medical/products-/polaris-family/ (accessed on 22 November 2016).

- International Organization for Standardization. Accuracy (Trueness and Precision) of Measurement Methods and Results-Part 2: Basic Method for the Determination of Repeatability and Reproducibility of a Standard Measurement Method; International Organization for Standardization: Geneva, Switzerland, 1994. [Google Scholar]

| Test No. | Theoretical Coordinate Value (x, y, z) (mm) | Measured Coordinate Values (x, y, z) (mm) |

|---|---|---|

| 1 | 45.00, 255.00, 0.00 | 44.64, 255.31, −0.01 |

| 2 | 60.00, 210.00, 0.00 | 60.43, 209.58, 0.01 |

| 3 | 0.00, 270.00, 0.00 | −0.33, 270.45, −0.02 |

| 4 | −10.00, 230.00, 0.00 | −9.57, 229.75, −0.02 |

| 5 | −60.00, 210.00, 0.00 | −60.26, 210.53, −0.01 |

| 6 | −25.00, 165.00, 0.00 | −24.64, 165.34, 0.02 |

| 7 | 0.00, 150.00, 0.00 | −0.24, 149.43, 0.02 |

| 8 | 30.00, 170.00, 0.00 | 30.35, 170.43, 0.01 |

| 9 | 20.00, 220.00, 0.00 | 20.34, 220.59, −0.01 |

| 10 | 27.00, 176.00, 0.00 | 27.31, 176.34, 0.01 |

| Test No. | Theoretical Coordinate Value (x, y, z) (mm) | Measured Coordinate Values (x, y, z) (mm) |

|---|---|---|

| 1 | 45.00, 255.00, 210.00 | 44.65, 255.24, 209.96 |

| 2 | 60.00, 210.00, 210.00 | 60.43, 209.74, 210.02 |

| 3 | 0.00, 270.00, 210.00 | −0.15, 270.37, 209.95 |

| 4 | −10.00, 230.00, 210.00 | −9.73, 230.41, 209.99 |

| 5 | −60.00, 210.00, 210.00 | −60.27, 210.38, 209.99 |

| 6 | −25.00, 165.00, 210.00 | −25.23, 165.32, 210.01 |

| 7 | 0.00, 150.00, 210.00 | −0.22, 149.73, 210.02 |

| 8 | 30.00, 170.00, 210.00 | 30.32, 170.35, 210.01 |

| 9 | 20.00, 220.00, 210.00 | 20.16, 219.66, 209.98 |

| 10 | 27.00, 176.00, 210.00 | 27.23, 175.51, 210.01 |

| Test No. | Data | Test No. | Data | Test No. | Data | Test No. | Data |

|---|---|---|---|---|---|---|---|

| 1 | 0.48 | 6 | 0.60 | 11 | 0.63 | 16 | 0.68 |

| 2 | 0.51 | 7 | 0.61 | 12 | 0.64 | 17 | 0.68 |

| 3 | 0.53 | 8 | 0.62 | 13 | 0.64 | 18 | 0.71 |

| 4 | 0.59 | 9 | 0.62 | 14 | 0.64 | 19 | 0.75 |

| 5 | 0.60 | 10 | 0.63 | 15 | 0.65 | 20 | 0.77 |

| Test No. | Data | Test No. | Data | Test No. | Data | Test No. | Data |

|---|---|---|---|---|---|---|---|

| 1 | 0.0808 | 6 | 0.1123 | 11 | 0.1295 | 16 | 0.1507 |

| 2 | 0.0915 | 7 | 0.1147 | 12 | 0.1370 | 17 | 0.1597 |

| 3 | 0.0957 | 8 | 0.1185 | 13 | 0.1375 | 18 | 0.1633 |

| 4 | 0.1023 | 9 | 0.1250 | 14 | 0.1411 | 19 | 0.1672 |

| 5 | 0.1058 | 10 | 0.1212 | 15 | 0.1425 | 20 | 0.1859 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, Q.; Du, Z.; Yu, H.; Wang, Y.; Dong, W. Error Analysis and Experimental Study of a Bi-Planar Parallel Mechanism in a Pedicle Screw Robot System. Sensors 2016, 16, 2022. https://doi.org/10.3390/s16122022

Duan Q, Du Z, Yu H, Wang Y, Dong W. Error Analysis and Experimental Study of a Bi-Planar Parallel Mechanism in a Pedicle Screw Robot System. Sensors. 2016; 16(12):2022. https://doi.org/10.3390/s16122022

Chicago/Turabian StyleDuan, Qingjuan, Zhijiang Du, Hongjian Yu, Yongfeng Wang, and Wei Dong. 2016. "Error Analysis and Experimental Study of a Bi-Planar Parallel Mechanism in a Pedicle Screw Robot System" Sensors 16, no. 12: 2022. https://doi.org/10.3390/s16122022

APA StyleDuan, Q., Du, Z., Yu, H., Wang, Y., & Dong, W. (2016). Error Analysis and Experimental Study of a Bi-Planar Parallel Mechanism in a Pedicle Screw Robot System. Sensors, 16(12), 2022. https://doi.org/10.3390/s16122022