The Effect of Assistive Anchor-Like Grousers on Wheeled Rover Performance over Unconsolidated Sandy Dune Inclines

Abstract

:1. Introduction

1.1. Conventional Fixed Grousers

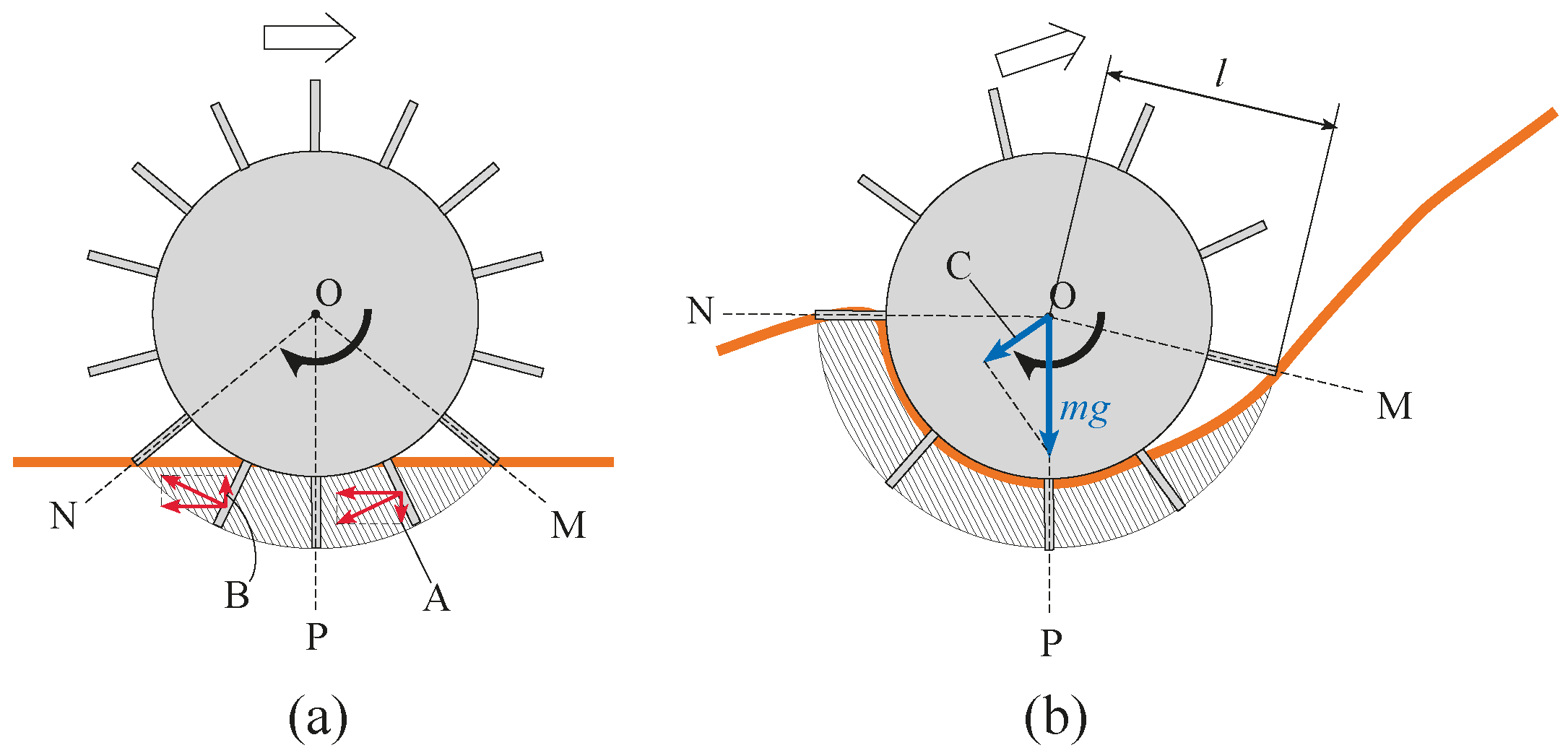

1.2. Proposed Assistive Grousers

1.3. Performance Comparison Tests

2. Materials and Methods

2.1. Wheeled Rover Equipped with Assistive Grousers (Modified Wheeled Rover)

2.2. Wheeled Rover Equipped with Conventional Fixed Grousers (Conventional Wheeled Rover)

2.3. Indoor Sand Incline Mobility Test Field

3. Traversing Performance Evaluation

3.1. Maximum Wheel Sinkage Angle

3.2. Sand Displacement Volume

3.3. Current Consumption

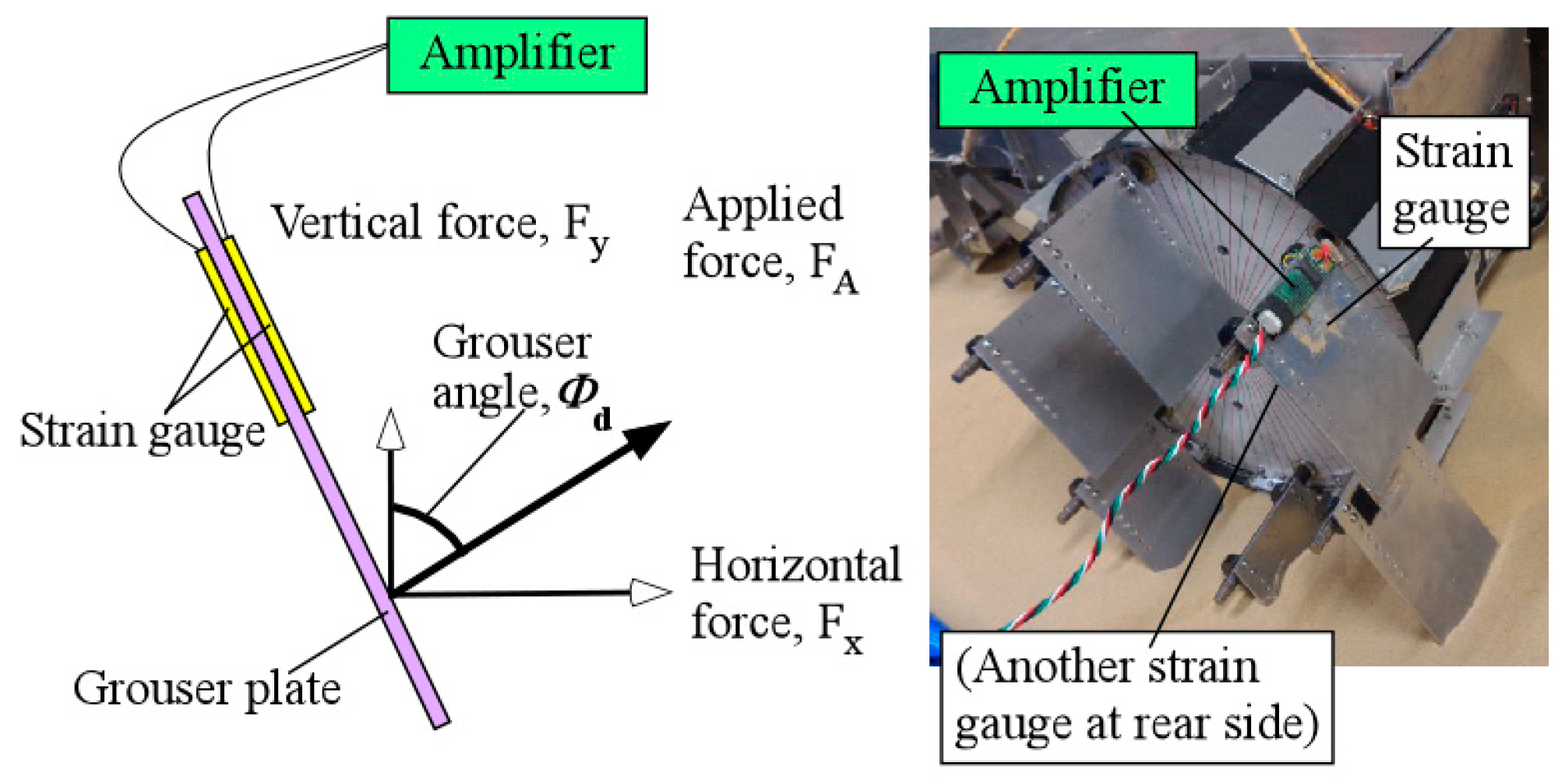

3.4. Force Applied to a Grouser

4. Results

4.1. Understanding the Problem by Using a Wheeled Rover Equipped with Conventional Wheels

4.2. Mobility Experiments Using a Wheeled Rover Equipped with Assistive Grousers

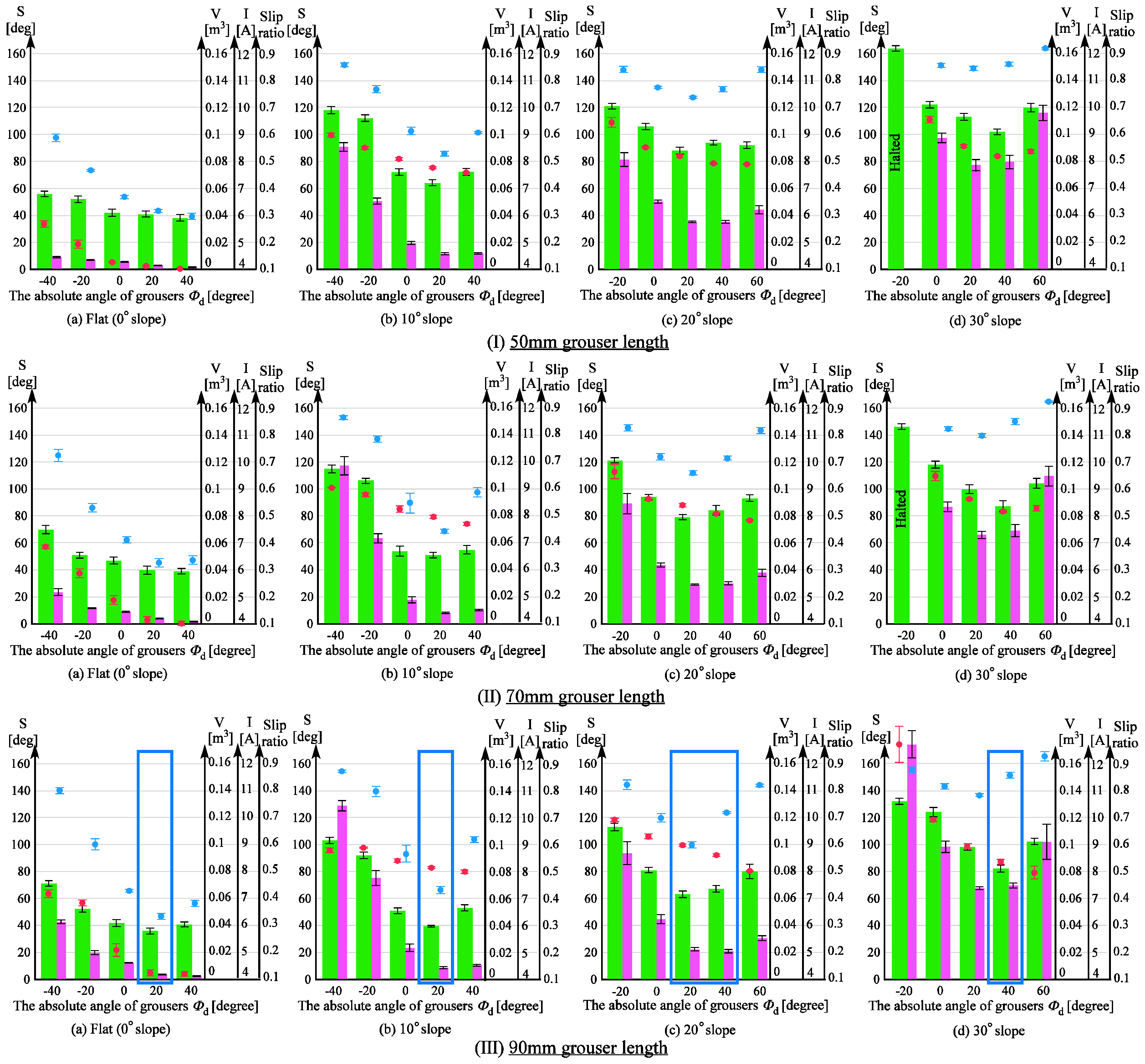

4.2.1. Configurations Tested in the Mobility Experiments

4.2.2. Comparison of Results between Conventional Wheels and Wheels Equipped with Assistive Grouser in the Optimal Configuration

4.2.3. Performance Comparison of the Assistive Grouser with Different Grouser Lengths

4.2.4. Performance Comparison of Rovers with Different Assistive Grouser Angles

4.2.5. Relationship between Slip Ratio and Sand Displacement Volume

5. Discussion

5.1. Assistive Grouser Effectiveness

5.2. The Effects of Other Wheel Configurations on Modified Wheeled Rover Performance

5.3. Expected Issues and Future Work for Use in a Natural Environment

5.3.1. Climbing a Slope with Non-Uniform Inclination Angles

5.3.2. Deploying and Stowing the Assistive Grousers

5.3.3. Running on Terrain with Different Soil Types

5.3.4. Turning and Steering

5.3.5. Durability of Longer Grousers

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Arvidson, R.E.; Bell, J.F.; Bellutta, P.; Cabrol, N.A.; Catalano, J.G.; Cohen, J.; Crumpler, L.S.; Des Marais, D.J.; Estlin, T.A.; Farrand, W.H.; et al. Spirit Mars Rover Mission: Overview and selected results from the northern Home Plate Winter Haven to the side of Scamander crater. J. Geophys. Res. 2010, 115, E00F03. [Google Scholar] [CrossRef]

- Arvidson, R.E.; Ashley, J.W.; Bell, J.F.; Chojnacki, M.; Cohen, J.; Economou, T.E.; Farrand, W.H.; Fergason, R.; Fleischer, I.; Geissler, P.; et al. Opportunity Mars Rover mission: Overview and selected results from Purgatory ripple to traverses to Endeavour crater. J. Geophys. Res. 2011, 116, E00F15. [Google Scholar] [CrossRef]

- Heverly, M.; Matthews, J.; Lin, J.; Fuller, D.; Maimone, M.; Biesiadecki, J.; Leichty, J. Traverse performance characterization for the Mars Science Laboratory rover. J. Field Robot. 2013, 30, 835–846. [Google Scholar] [CrossRef]

- Wakabayashi, S.; Sato, H.; Nishida, S.-I. Design and mobility evaluation of tracked lunar vehicle. J. Terramech. 2009, 46, 105–114. [Google Scholar] [CrossRef]

- Sutoh, M.; Yusa, J.; Ito, T.; Nagatani, K.; Yoshida, K. Traveling performance evaluation of planetary rovers on loose soil. J. Field Robot. 2012, 29, 648–662. [Google Scholar] [CrossRef]

- Lindemann, R.A.; Voorhees, C.J. Mars Exploration Rover mobility assembly design, test and performance. In Proceedings of the 2005 IEEE International Conference on Systems, Man and Cybernetics, Waikoloa, HI, USA, 10–12 October 2005; Volume 1, pp. 450–455.

- Kohanbash, D.; Moreland, S.; Wettergreen, D. Plowing for rover control on extreme slopes. In Field and Service Robotics; Yoshida, K., Tadokoro, S., Eds.; Springer Berlin Heidelberg: Heidelberg, Germany, 2014; pp. 399–413. [Google Scholar]

- Nesnas, I.A.D.; Matthews, J.B.; Abad-Manterola, P.; Burdick, J.W.; Edlund, J.A.; Morrison, J.C.; Peters, R.D.; Tanner, M.M.; Miyake, R.N.; Solish, B.S.; et al. Axel and DuAxel rovers for the sustainable exploration of extreme terrains. J. Field Robot. 2012, 29, 663–685. [Google Scholar] [CrossRef]

- Wettergreen, D.; Jonak, D.; Kohanbash, D.; Moreland, S.; Spiker, S.; Teza, J. Field experiments in mobility and navigation with a lunar rover prototype. In Field and Service Robotics; Springer Berlin Heidelberg: Heidelberg, Germany, 2010; pp. 489–498. [Google Scholar]

- Nakashima, H.; Shioji, Y.; Kobayashi, T.; Aoki, S.; Shimizu, H.; Miyasaka, J.; Ohdoi, K. Determining the angle of repose of sand under low-gravity conditions using discrete element method. J. Terramech. 2011, 48, 17–26. [Google Scholar] [CrossRef]

- Ding, L.; Gao, H.; Deng, Z.; Nagatani, K.; Yoshida, K. Experimental study and analysis on driving wheels’ performance for planetary exploration rovers moving in deformable soil. J. Terramech. 2011, 48, 27–45. [Google Scholar] [CrossRef]

- Nakashima, H.; Fujii, H.; Oida, A.; Momozu, M.; Kanamori, H.; Aoki, S.; Yokoyama, T.; Shimizu, H.; Miyasaka, J.; Ohdoi, K. Discrete element method analysis of single wheel performance for a small lunar rover on sloped terrain. J. Terramech. 2010, 47, 307–321. [Google Scholar] [CrossRef] [Green Version]

- Yamamoto, R.; Yang, Y.; Sun, Y.; Ma, S. Characteristics of lug-soil interaction forces acting on a rotating lug in sandy soil. In Proceedings of the 2014 IEEE International Conference on Robotics and Biomimetics (ROBIO), Bali, Indonesia, 5–10 December 2014; pp. 451–456.

- Iizuka, K.; Yoshida, T.; Kubota, T. Effect of tractive given by grousers mounted on wheels for lunar rovers on loose soil. In Proceedings of the 37th Annual Conference on IEEE Industrial Electronics Society (IECON 2011), Melbourne, Australia, 7–10 November 2011; pp. 110–115.

- Hermawan, W.; Yamazaki, M.; Oida, A. Theoretical analysis of soil reaction on a lug of the movable lug cage wheel. J. Terramech. 2000, 37, 65–86. [Google Scholar] [CrossRef]

- Yang, Y.; Sun, Y.; Ma, S. Drawbar pull of a wheel with an actively actuated lug on sandy terrain. J. Terramech. 2014, 56, 17–24. [Google Scholar] [CrossRef]

- Hermawan, W.; Yamazaki, M.; Oida, A. Design and traction performance of the movable lug wheel. J. Terramech. 1998, 35, 159–177. [Google Scholar] [CrossRef]

- Bellotti, R.; Benoît, J.; Fretti, C.; Jamiolkowski, M. Stiffness of toyoura sand from dilatometer tests. J. Geotech. Geoenviron. 1997, 123, 836–846. [Google Scholar] [CrossRef]

- Wong, J.Y. Predicting the performances of rigid rover wheels on extraterrestrial surfaces based on test results obtained on earth. J. Terramech. 2012, 49, 49–61. [Google Scholar] [CrossRef]

- Kobayashi, T.; Fujiwara, Y.; Yamakawa, J.; Yasufuku, N.; Omine, K. Mobility performance of a rigid wheel in low gravity environments. J. Terramech. 2010, 47, 261–274. [Google Scholar] [CrossRef]

- Lyasko, M. Slip sinkage effect in soil-vehicle mechanics. J. Terramech. 2010, 47, 21–31. [Google Scholar] [CrossRef]

- Onafeko, O.; Reece, A.R. Soil stresses and deformations beneath rigid wheels. J. Terramech. 1967, 4, 59–80. [Google Scholar] [CrossRef]

- Fukami, K.; Ueno, M.; Hashiguchi, K.; Okayasu, T. Mathematical models for soil displacement under a rigid wheel. J. Terramech. 2006, 43, 287–301. [Google Scholar] [CrossRef]

- Saengprachatanarug, K.; Ueno, M.; Taira, E.; Okayasu, T. Modeling of soil displacement and soil strain distribution under a traveling wheel. J. Terramech. 2013, 50, 5–16. [Google Scholar] [CrossRef]

- Liu, J.; Gao, H.; Deng, Z. Effect of straight grousers parameters on motion performance of small rigid wheel on loose sand. Inf. Technol. J. 2008, 7, 1125–1132. [Google Scholar] [CrossRef]

- Bauer, R.; Leung, W.; Barfoot, T. Experimental and simulation results of wheel-soil interaction for planetary rovers. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 586–591.

- Skonieczny, K.; Moreland, S.J.; Wettergreen, D.S. A grouser spacing equation for determining appropriate geometry of planetary rover wheels. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vilamoura-Algarve, Portugal, 7–11 October 2012; pp. 5065–5070.

- Ding, L.; Deng, Z.; Gao, H.; Guo, J.; Zhang, D.; Iagnemma, K.D. Experimental study and analysis of the wheels’ steering mechanics for planetary exploration wheeled mobile robots moving on deformable terrain. Int. J. Robot. Res. 2013, 32, 712–743. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim, A.N.; Aoshima, S.; Shiroma, N.; Fukuoka, Y. The Effect of Assistive Anchor-Like Grousers on Wheeled Rover Performance over Unconsolidated Sandy Dune Inclines. Sensors 2016, 16, 1507. https://doi.org/10.3390/s16091507

Ibrahim AN, Aoshima S, Shiroma N, Fukuoka Y. The Effect of Assistive Anchor-Like Grousers on Wheeled Rover Performance over Unconsolidated Sandy Dune Inclines. Sensors. 2016; 16(9):1507. https://doi.org/10.3390/s16091507

Chicago/Turabian StyleIbrahim, Ahmad Najmuddin, Shinichi Aoshima, Naoji Shiroma, and Yasuhiro Fukuoka. 2016. "The Effect of Assistive Anchor-Like Grousers on Wheeled Rover Performance over Unconsolidated Sandy Dune Inclines" Sensors 16, no. 9: 1507. https://doi.org/10.3390/s16091507

APA StyleIbrahim, A. N., Aoshima, S., Shiroma, N., & Fukuoka, Y. (2016). The Effect of Assistive Anchor-Like Grousers on Wheeled Rover Performance over Unconsolidated Sandy Dune Inclines. Sensors, 16(9), 1507. https://doi.org/10.3390/s16091507