Modeling and Calibration of a Novel One-Mirror Galvanometric Laser Scanner

Abstract

:1. Introduction

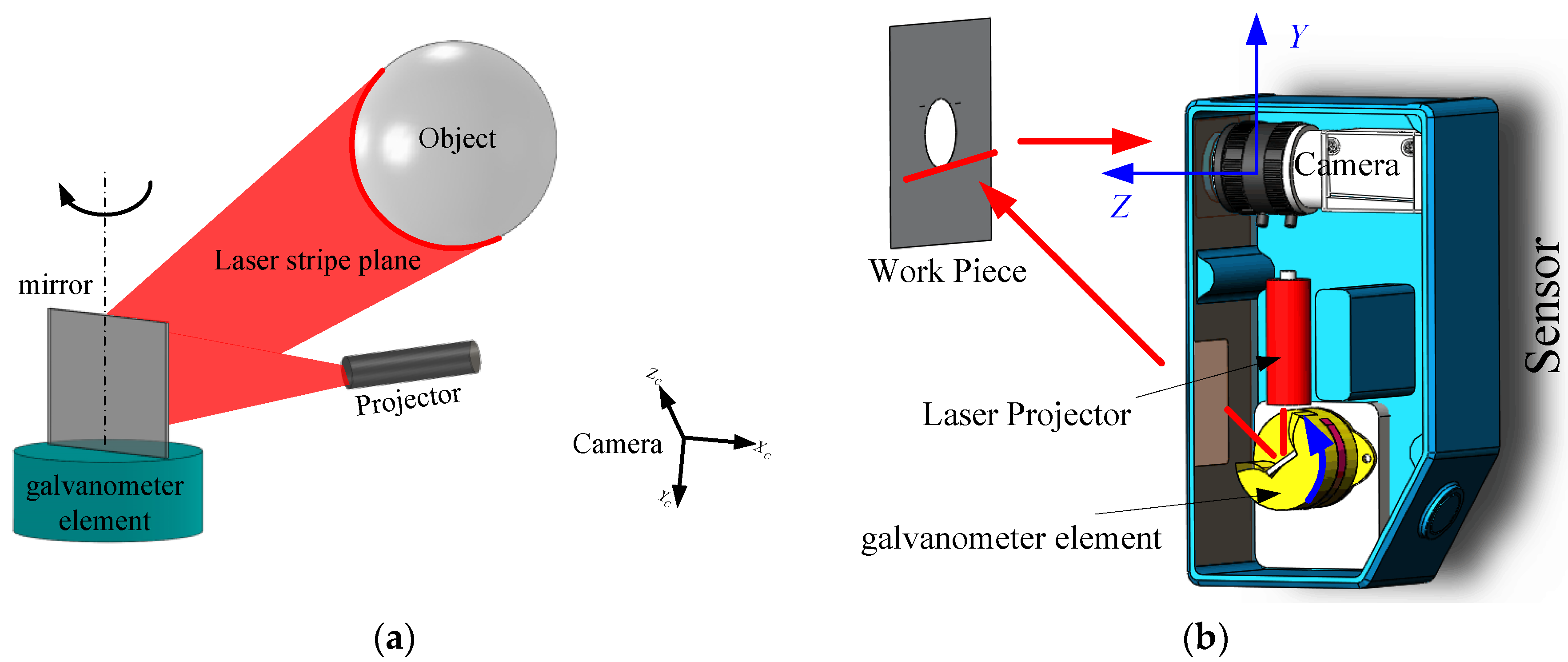

2. System Working Principles

3. Modeling and Calibration of the Galvanometric Laser Scanner

3.1. Camera Calibration

3.2. Computing Control Points via the Plane-Constraint-Based Method

3.3. Mathematical Model of the Galvanometric Laser Scanner

3.3.1. Mathematical Model of Basic Elements

3.3.2. Equation of the Rotated Reflective Mirror

3.3.3. Equation of the Reflected Laser Plane

3.4. Estimation of the Galvanometric Laser Scanner’s Parameters

3.5. Summary

- The planar calibration target is located at several different poses, and each pose of the planar calibration target is captured by the galvanometric laser scanner. The last two poses are captured twice in two cases, one with no laser stripe line projected onto the planar calibration target for camera calibration and the other with the laser stripe line for projector calibration.

- The captured images without the laser stripe line are used for camera calibration and both intrinsic parameters and extrinsic parameters are determined.

- Extracting all image coordinates of control points in two captured images.

- Correcting distortion for those image coordinates according to the lens distortion model.

- Calculating control points in the local world coordinate system based on plane-constraint method and transforming the local world coordinate of control points to the global camera coordinate system according the extrinsic parameters.

- Estimating the 11 independent unknown parameters according to Equation (14).

- Calibration of the galvanometric laser scanner is completed.

4. Experiments

4.1. System Calibration

4.2. Repeatability Evaluation

4.3. Accuracy Evaluation

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, L.; Wu, C.Y.; Zou, Y.Y. An on-line visual seam tracking sensor system during laser beam welding. In Proceedings of the International Conference on Information Technology and Computer Science, ITCS 2009, Kiev, Ukraine, 25–26 July 2009; pp. 361–364.

- Huang, W.; Kovacevic, R. A laser-based vision system for weld quality inspection. Sensors 2011, 11, 506–521. [Google Scholar] [CrossRef]

- Baeg, M.H.; Baeg, S.H.; Moon, C.; Jeong, G.M.; Ahn, H.S.; Kim, D.H. A new robotic 3D inspection system of automotive screw hole. Int. J. Control Autom. Syst. 2008, 6, 740–745. [Google Scholar]

- Gan, Z.; Tang, Q. Visual Sensing and Its Applications: Integration of Laser Sensors to Industrial Robots; Zhejiang University Press: Zhejiang, China; Springer: Berlin, Germany, 2011. [Google Scholar]

- Li, J.F.; Guo, Y.K.; Zhu, J.H.; Lin, X.D.; Xin, Y.; Duan, K.L.; Tang, Q. Large depth-of-view portable three-dimensional laser scanner and its segmental calibration for robot vision. Opt. Lasers Eng. 2007, 45, 1077–1087. [Google Scholar] [CrossRef]

- Li, J.F.; Zhu, J.H.; Guo, Y.K.; Lin, X.D.; Duan, K.L.; Wang, Y.S.; Tang, Q. Calibration of a portable laser 3-D scanner used by a robot and its use in measurement. Opt. Eng. 2008, 47, 017202. [Google Scholar] [CrossRef]

- Li, J.F.; Chen, M.; Jin, X.B.; Chen, Y.; Dai, Z.Y.; Ou, Z.H.; Tang, Q. Calibration of a multiple axes 3-D laser scanning system consisting of robot, portable laser scanner and turntable. Optik 2011, 122, 324–329. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, X.; Chi, S. Simultaneous calibration of the intrinsic and extrinsic parameters of structured-light sensors. Opt. Lasers Eng. 2014, 58, 9–18. [Google Scholar] [CrossRef]

- Abzal, A.; Varshosaz, M.; Saadatseresht, M. Development of a new laser triangulation system based on an optical frame of reference. Photogramm. Record 2011, 26, 293–306. [Google Scholar] [CrossRef]

- Zhang, Z.; Lin, Y. Building a 3D scanner system based on monocular vision. Appl. Opt. 2012, 51, 1638–1644. [Google Scholar] [CrossRef] [PubMed]

- Furukawa, R.; Kawasaki, H. Laser range scanner based on self-calibration techniques using coplanarities and metric constraints. Comput. Vis. Image Underst. 2009, 113, 1118–1129. [Google Scholar] [CrossRef]

- Ozan, S.; Gumustekin, S. Calibration of double stripe 3D laser scanner systems using planarity and orthogonality constraints. Digit. Signal Proc. 2014, 24, 231–243. [Google Scholar] [CrossRef]

- Ren, Y.; Yin, S.; Zhu, J. Calibration technology in application of robot-laser scanning system. Opt. Eng. 2012, 51, 114204. [Google Scholar] [CrossRef]

- Yin, S.; Ren, Y.; Guo, Y.; Zhu, J.; Yang, S.; Ye, S. Development and calibration of an integrated 3D scanning system for high-accuracy large-scale metrology. Measurement 2014, 54, 65–76. [Google Scholar] [CrossRef]

- Li, L.; Xi, J. Free and Global Pose Calibration of a Rotating Laser Monocular Vision Sensor for Robotic 3D Measurement System. Proc. SPIE 2013, 8769. [Google Scholar] [CrossRef]

- Xiao, J.; Hu, X.; Lu, W.; Ma, J.; Guo, X. A new three-dimensional laser scanner design and its performance analysis. Optik Int. J. Light Electron Opt. 2015, 126, 701–707. [Google Scholar] [CrossRef]

- Liu, Z.; Li, X.; Li, F.; Zhang, G. Calibration method for line-structured light vision sensor based on a single ball target. Opt. Lasers Eng. 2015, 69, 20–28. [Google Scholar] [CrossRef]

- Liu, Z.; Li, X.; Yin, Y. On-site calibration of line-structured light vision sensor in complex light environments. Opt. Express 2015, 23, 29896–29911. [Google Scholar] [CrossRef]

- Huynh, D.Q.; Owens, R.A.; Hartmann, P. Calibrating a structured light stripe system: A novel approach. Int. J. Comput. Vis. 1999, 33, 73–86. [Google Scholar] [CrossRef]

- Wei, Z.Z.; Zhang, G.J.; Xu, Y. Calibration approach for structured-light-stripe vision sensor based on the invariance of double cross-ratio. Opt. Eng. 2003, 42, 2956–2966. [Google Scholar] [CrossRef]

- Zhou, F.Q.; Zhang, G.J.; Jiang, J. Constructing feature points for calibrating a structured light vision sensor by viewing a plane from unknown orientations. Opt. Lasers Eng. 2005, 43, 1056–1070. [Google Scholar] [CrossRef]

- Manakov, A.; Seidel, H.P.; Ihrke, I. A mathematical model and calibration procedure for galvanometric laser scanning systems. In Proceedings of the 16th Annual Workshop on Vision, Modeling, and Visualization, Berlin, Germany, 4–6 October 2011; pp. 348–357.

- Wagner, B.; Stuber, P.; Wissel, T.; Bruder, R.; Schweikard, A.; Ernst, F. Accuracy analysis for triangulation and tracking based on time-multiplexed structured light. Med. Phys. 2014, 41, 082701. [Google Scholar] [CrossRef] [PubMed]

- Wissel, T.; Wagner, B.; Stuber, P.; Schweikard, A. Data-driven learning for calibrating galvanometric laser scanners. IEEE Sens. J. 2015, 15, 5709–5717. [Google Scholar] [CrossRef]

- Chi, S.; Xie, Z.; Chen, W. A laser line auto-scanning system for underwater 3D reconstruction. Sensors 2016, 16, 1534. [Google Scholar] [CrossRef]

- Perceptron. Tricam. Available online: http://perceptron.com/products/perceptron-sensor-technology/ (accessed on 17 November 2016).

- Tsai, R.Y. A versatile camera calibration technique for high-accuracy 3D machine vision metrology using off-the-shelf tv cameras and lenses. Robot. Autom. IEEE J. 1987, 3, 323–344. [Google Scholar] [CrossRef]

- Heikkila, J.; Silven, O. A four-step camera calibration procedure with implicit image correction. In Proceedings of the 1997 IEEE Computer Society Conference on Computer Vision & Pattern Recognition, San Juan, Puerto Rico, 17–19 June 1997; pp. 1106–1112.

- Zhang, Z. A flexible new technique for camera calibration. IEEE Trans. Pattern Anal. Mach. Intell. 2000, 22, 1330–1334. [Google Scholar] [CrossRef]

- Forest Collado, J. New Methods for Triangulation-Based Shape Acquisition Using Laser Scanners; Universitat de Girona: Girona, Spain, 2004. [Google Scholar]

- Haug, K.; Pritschow, G. Robust laser-stripe sensor for automated weld-seam-tracking in the shipbuilding industry. In Proceedings of the 24th Annual Conference of the IEEE Industrial Electronics Society, IECON’98, Aachen, Germany, 31 August–4 September 1998; pp. 1236–1241.

- Murray, R.M.; Li, Z.; Sastry, S.S. A Mathematical Introduction to Robotic Manipulation; CRC Press: Boca Raton, FL, USA, 1994. [Google Scholar]

- Moré, J.J. The levenberg-marquardt algorithm: Implementation and theory. In Numerical Analysis; Springer: Berlin, Germany, 1978; pp. 105–116. [Google Scholar]

- Sun, W.J.; Hill, M.; McBride, J.W. An investigation of the robustness of the nonlinear least-squares sphere fitting method to small segment angle surfaces. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2008, 32, 55–62. [Google Scholar] [CrossRef]

- Chernov, N. Circular and Linear Regression: Fitting Circles and Lines by Least Squares; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Illingworth, J.; Kittler, J. A survey of the hough transform. Comput. Vis. Graph. Image Proc. 1988, 44, 87–116. [Google Scholar] [CrossRef]

- Niola, V.; Rossi, C.; Savino, S.; Strano, S. A method for the calibration of a 3-D laser scanner. Robot. Comput. Integr. Manuf. 2011, 27, 479–484. [Google Scholar] [CrossRef]

- Nakatani, T.; Li, S.; Ura, T.; Bodenmann, A.; Sakamaki, T. 3D visual modeling of hydrothermal chimneys using a rotary laser scanning system. In Proceedings of the 2011 IEEE Symposium on Underwater Technology (UT) and 2011 Workshop on Scientific Use of Submarine Cables and Related Technologies (SSC), Tokyo, Japan, 5–8 April 2011; pp. 1–5.

| Sphere (R) | Slot (L) | Square (H × W) | Circle (R) | |

|---|---|---|---|---|

| True value | 12.7080 mm | 9.9900 mm | 10.01752 mm × 10.03618 mm | 4.9862 mm |

| Std | 12.1 μm | 0.5 μm | 0.8 μm × 2.1 μm | 1.5 μm |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, C.; Chen, X.; Xi, J. Modeling and Calibration of a Novel One-Mirror Galvanometric Laser Scanner. Sensors 2017, 17, 164. https://doi.org/10.3390/s17010164

Yu C, Chen X, Xi J. Modeling and Calibration of a Novel One-Mirror Galvanometric Laser Scanner. Sensors. 2017; 17(1):164. https://doi.org/10.3390/s17010164

Chicago/Turabian StyleYu, Chengyi, Xiaobo Chen, and Juntong Xi. 2017. "Modeling and Calibration of a Novel One-Mirror Galvanometric Laser Scanner" Sensors 17, no. 1: 164. https://doi.org/10.3390/s17010164

APA StyleYu, C., Chen, X., & Xi, J. (2017). Modeling and Calibration of a Novel One-Mirror Galvanometric Laser Scanner. Sensors, 17(1), 164. https://doi.org/10.3390/s17010164