Novel Tactile Sensor Technology and Smart Tactile Sensing Systems: A Review

Abstract

:1. Introduction

2. Tactile Sensing Principles and Structures

2.1. Capacitive Tactile Sensors

2.2. Piezo-Resistive Tactile Sensors

2.3. Piezoelectric Tactile Sensors

2.4. Optical Tactile Sensors

2.5. Trade-offs and Challenge

3. Materials for Tactile Sensing

3.1. Capacitive Tactile Sensors

3.2. Piezo-Resistive Tactile Sensors

3.3. Piezoelectric Tactile Sensors

3.4. Optical Tactile Sensors

3.5. Material Functionalization: Towards Multiple Domain Tactile Sensing

3.6. Comparisons and Trade-Off Discussion

4. Fabrication Technology

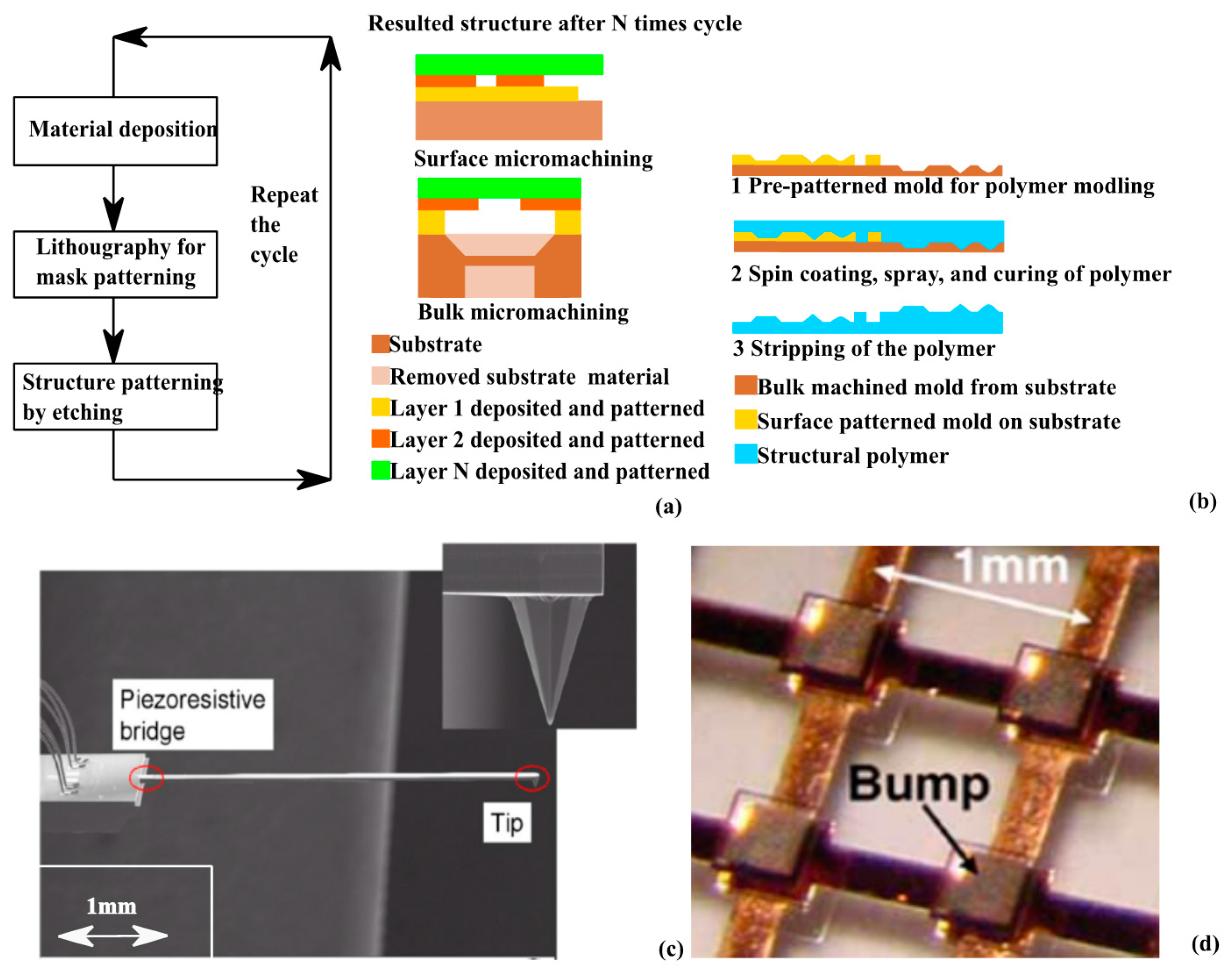

4.1. Standard Fabrication: Micromachining and Molding

4.2. Lithography Based Rapid Micro 3D Fabrication

4.3. Comparison of Fabrication Technologies

5. Smart Tactile Sensor Applications

5.1. Tactile Sensing for Artificial Skin (E-Skin)

5.2. Tactile Sensing for Unstructured Environments

5.3. Tactile Sensing for Biomedical Applications

6. Intelligent Signal Processing for Smart Tactile Sensing

6.1. Data Acquisition and Artifacts Removal

6.2. Smart Tactile Sensing Based on Machine Learning

6.3. Tactile Sensor Fusion

7. Challenges for the Application of Tactile Sensing

- (1)

- Cost. One of the challenges facing the researchers is finding a way to cut down the sophisticated tactile sensor system’s cost. Most existing tactile systems reported in the literature are still at the experiment level. It is desirable to get the cost down to a point affordable for the market.

- (2)

- Hardware related to sensor performances (e.g., sensitivity, ability to measure various parameters), physical aspects (e.g., spatial resolution, conformability), tactile sensors arrangement, wireless communication and crosstalk. Nanotechnology and microfabrication may provide a way to integrate different sensing modalities and signal processing units. They further can provide a high density array of sensors.

- (3)

- Software. Even if people have already developed numerous tactile sensors with fantastic characters, such as mimic the human sense of touch, tactile sensors are rarely used in real applications. Practical tactile sensing systems highly demand not only suitable hardware but also powerful software, especially for the systems working in unconstructed environments. The development of tactile sensing requires not only better sensors, but also efficient and effective techniques to process these sensors’ data. Difficulties with data acquisition and interpretation have consistently been cited as one main reason for the slow development.

- (4)

- Modularization design and transportability. Ease of assembly and disassembly is another concern that should be better addressed. Tactile sensing systems, including the hardware and the software, are generally designed based on certain task-specific criteria. From the design point, modularization designs which can facilitate the transportability between different devices are highly desired.

8. Conclusions

Acknowledgments

Conflicts of Interest

References

- Jütte, R. Haptic perception: An historical approach. In Human Haptic Perception: Basics and Applications; Grunwald, M., Ed.; Birkhäuser Basel: Basel, Switzerland, 2008; pp. 3–13. [Google Scholar]

- Tiwana, M.I.; Redmond, S.J.; Lovell, N.H. A review of tactile sensing technologies with applications in biomedical engineering. Sens. Actuators A Phys. 2012, 179, 17–31. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Metta, G.; Valle, M.; Sandini, G. Tactile sensing—From humans to humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Mittendorfer, P.; Valle, M.; Cheng, G.; Lumelsky, V.J. Directions toward Effective Utilization of Tactile Skin: A Review. IEEE Sens. J. 2013, 13, 4121–4138. [Google Scholar] [CrossRef]

- Sokhanvar, S.; Dargahi, J.; Najarian, S.; Arbatani, S. Introduction to Tactile Sensing and Display. In Tactile Sens. Disp; John Wiley & Sons, Ltd.: Chichester, UK, 2012; pp. 1–21. [Google Scholar]

- Dahiya, R.S.; Valle, M. Tactile sensing technologies. In Robotic Tactile Sensing; Springer: Dordrecht, The Netherlands, 2013; pp. 79–136. [Google Scholar]

- Yousef, H.; Boukallel, M.; Althoefer, K. Tactile sensing for dexterous in-hand manipulation in robotics—A review. Sens. Actuators A Phys. 2011, 167, 171–187. [Google Scholar] [CrossRef]

- Drimus, A.; Kootstra, G.; Bilberg, A.; Kragic, D. Design of a flexible tactile sensor for classification of rigid and deformable objects. Robot. Auton. Syst. 2014, 62, 3–15. [Google Scholar] [CrossRef]

- Buscher, G.H.; Koiva, R.; Schurmann, C.; Haschke, R.; Ritter, H.J. Flexible and stretchable fabric-based tactile sensor. Robot. Auton. Syst. 2015, 63, 244–252. [Google Scholar] [CrossRef]

- Lee, J.S.; Shin, K.Y.; Cheong, O.J.; Kim, J.H.; Jang, J. Highly Sensitive and Multifunctional Tactile Sensor Using Free-Standing ZnO/PVDF Thin Film with Graphene Electrodes for Pressure and Temperature Monitoring. Sci. Rep. 2015, 5, 7887. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, P.A.; Mael, E.; Wuertz, R.P. A sensor for dynamic tactile information with applications in human-robot interaction and object exploration. Robot. Auton. Syst. 2006, 54, 1005–1014. [Google Scholar] [CrossRef]

- Maheshwari, V.; Saraf, R.F. High-resolution thin-film device to sense texture by touch. Science 2006, 312, 1501–1504. [Google Scholar] [CrossRef] [PubMed]

- Heo, J.S.; Chung, J.H.; Lee, J.J. Tactile sensor arrays using fiber Bragg grating sensors. Sens. Actuators A Phys. 2006, 126, 312–327. [Google Scholar] [CrossRef]

- Lee, M.H. Tactile sensing: New directions, new challenges. Int. J. Robot. Res. 2000, 19, 636–643. [Google Scholar] [CrossRef]

- Grunwald, M. Human Haptic Perception: Basics Applications; Birkhäuser Basel: Basel, Switzerland, 2008. [Google Scholar]

- Kroemer, O.; Lampert, C.H.; Peters, J. Learning Dynamic Tactile Sensing with Robust Vision-Based Training. IEEE Trans. Robot. 2011, 27, 545–557. [Google Scholar] [CrossRef]

- Gastaldo, P.; Pinna, L.; Seminara, L.; Valle, M.; Zunino, R. A tensor-based approach to touch modality classification by using machine learning. Robot. Autono. Syst. 2015, 63, 268–278. [Google Scholar] [CrossRef]

- Girão, P.S.; Ramos, P.M.P.; Postolache, O.; Pereira, J.M.D. Tactile sensors for robotic applications. Measurement 2013, 46, 1257–1271. [Google Scholar] [CrossRef]

- Konstantinova, J.; Jiang, A.; Althoefer, K.; Dasgupta, P.; Nanayakkara, T. Implementation of Tactile Sensing for Palpation in Robot-Assisted Minimally Invasive Surgery: A Review. IEEE Sens. J. 2014, 14, 2490–2501. [Google Scholar] [CrossRef] [Green Version]

- Puangmali, P.; Althoefer, K.; Seneviratne, L.D.; Murphy, D.; Dasgupta, P. State-of-the-art in force and tactile sensing for minimally invasive surgery. IEEE Sens. J. 2008, 8, 371–381. [Google Scholar] [CrossRef]

- Wolffenbuttel, M.R.; Regtien, P.P.L. polysilicon bridges for the realization of tactile sensors. Sens. Actuators A Phys. 1991, 26, 257–264. [Google Scholar] [CrossRef]

- Chu, Z.; Sarro, P.M.; Middelhoek, S. Silicon three-axial tactile sensor. Sens. Actuators A Phys. 1996, 54, 505–510. [Google Scholar] [CrossRef]

- Ko, C.T.; Tseng, S.H.; Lu, M.S.C. A CMOS micromachined capacitive tactile sensor with high-frequency output. J. Microelectromech. Syst. 2006, 15, 1708–1714. [Google Scholar] [CrossRef]

- Lee, H.K.; Chang, S.I.; Yoon, E. A flexible polymer tactile sensor: Fabrication and modular expandability for large area deployment. J. Microelectromech. Syst. 2006, 15, 1681–1686. [Google Scholar] [CrossRef]

- Lee, H.K.; Chung, J.; Chang, S.I.; Yoon, E. Normal and shear force measurement using a flexible polymer tactile sensor with embedded multiple capacitors. J. Microelectromech. Syst. 2008, 17, 934–942. [Google Scholar]

- Cheng, M.Y.; Lin, C.L.; Lai, Y.T.; Yang, Y.J. A Polymer-Based Capacitive Sensing Array for Normal and Shear Force Measurement. Sensors 2010, 10, 10211–10225. [Google Scholar] [CrossRef] [PubMed]

- Mannsfeld, S.C.B.; Tee, B.C.K.; Stoltenberg, R.M.; Chen, C.; Barman, S.; Muir, B.V.O.; Sokolov, A.N.; Reese, C.; Bao, Z.N. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef] [PubMed]

- Muhammad, H.B.; Oddo, C.M.; Beccai, L.; Recchiuto, C.; Anthony, C.J.; Adams, M.J.; Carrozza, M.C.; Hukins, D.W.L.; Ward, M.C.L. Development of a bioinspired MEMS based capacitive tactile sensor for a robotic finger. Sens. Actuators A Phys. 2011, 165, 221–229. [Google Scholar] [CrossRef]

- Surapaneni, R.; Guo, Q.; Xie, Y.; Young, D.J.; Mastrangelo, C.H. A three-axis high-resolution capacitive tactile imager system based on floating comb electrodes. J. Micromech. Microeng. 2013, 23, 12. [Google Scholar] [CrossRef]

- Hollander, L.E.; Vick, G.L.; Diesel, T. The piezoresistive effect and its applications. Rev. Sci. Instrum. 1960, 31, 323–327. [Google Scholar] [CrossRef]

- Shikida, M.; Shimitzu, T.; Sato, K.; Itoigawa, K. Active tactile sensor for detecting contact force and hardness of an object. Sens. Actuators A Phys. 2003, 103, 213–218. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Shikida, M.; Shimizu, T.; Miyaji, T.; Sasaki, H.; Sato, K.; Itoigawa, K. Amicromachined active tactile sensor for hardness detection. Sens. Actuators A Phys. 2004, 114, 141–146. [Google Scholar] [CrossRef]

- Frank, T.; Doering, L.; Heinrich, G.; Thronicke, N.; Lobner, C.; Völlmeke, St.; Steinke, A.; Reich, S. Silicon cantilevers with piezo-resistive measuring bridge for tactile line measurement. Microsyst. Technol. Micro Nanosyst. Inf. Storage Process. Syst. 2014, 20, 927–931. [Google Scholar] [CrossRef]

- Tu, S.Y.; Lai, W.C.; Fang, W.L. Vertical integration of capacitive and piezo-resistive sensing units to enlarge the sensing range of CMOS-MEMS tactile sensor. In Proceedings of the 30th IEEE International Conference on Micro Electro Mechanical Systems, Las Vegas, NV, USA, 22–26 January 2017; IEEE: New York, NY, USA, 2017; pp. 1048–1051. [Google Scholar]

- Damjanovic, D. Ferroelectric, dielectric and piezoelectric properties of ferroelectric thin films and ceramics. Rep. Prog. Phys. 1998, 61, 1267–1324. [Google Scholar] [CrossRef]

- Krishna, G.M.; Rajanna, K. Tactile sensor based on piezoelectric resonance. IEEE Sens. J. 2004, 4, 691–697. [Google Scholar] [CrossRef]

- Li, C.Y.; Wu, P.M.; Lee, S.; Gorton, A.; Schulz, M.J.; Ahn, C.H. Flexible dome and bump shape piezoelectric tactile sensors using PVDF-TrFE copolymer. J. Microelectromech. Syst. 2008, 17, 334–341. [Google Scholar]

- Qasaimeh, M.A.; Sokhanvar, S.; Dargahi, J.; Kahrizi, M. PVDF-Based Microfabricated Tactile Sensor for Minimally Invasive Surgery. J. Microelectromech. Syst. 2009, 18, 195–207. [Google Scholar] [CrossRef]

- Bao, R.R.; Wang, C.F.; Dong, L.; Yu, R.M.; Zhao, K.; Wang, Z.L.; Pan, C.F. Flexible and Controllable Piezo-Phototronic Pressure Mapping Sensor Matrix by ZnO NW/p-Polymer LED Array. Adv. Funct. Mater. 2015, 25, 2884–2891. [Google Scholar] [CrossRef]

- Xie, H.; Liu, H.B.; Luo, S.; Seneviratne, L.D.; Althoefer, K. Fiber Optics Tactile Array Probe for Tissue Palpation during Minimally Invasive Surgery. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; Amato, N., Ed.; IEEE: New York, NY, USA, 2013; pp. 2539–2544. [Google Scholar]

- Liu, X.; Iordachita, I.I.; He, X.; Taylor, R.H.; Kang, J.U. Miniature fiber-optic force sensor based on low-coherence Fabry-Perot interferometry for vitreoretinal microsurgery. Biomed. Opt. Express 2012, 3, 1062–1076. [Google Scholar] [CrossRef] [PubMed]

- Windecker, R.; Tiziani, H.J. Optical roughness measurements using extended white-light interferometry. Opt. Eng. 1999, 38, 1081–1087. [Google Scholar] [CrossRef]

- Ohka, M.; Mitsuya, Y.; Higashioka, I.; Kabeshita, H. An experimental optical three-axis tactile sensor for micro-robots. Robotica 2005, 23, 457–465. [Google Scholar] [CrossRef]

- Missinne, J.; Bosman, E.; Van Hoe, B.; Van Steenberge, G.; Kalathimekkad, S.; Van Daele, P.; Vanfleteren, J. Flexible Shear Sensor Based on Embedded Optoelectronic Components. IEEE Photonics Technol. Lett. 2011, 23, 771–773. [Google Scholar] [CrossRef]

- Ahmadi, R.; Packirisamy, M.; Dargahi, J.; Cecere, R. Discretely Loaded Beam-Type Optical Fiber Tactile Sensor for Tissue Manipulation and Palpation in Minimally Invasive Robotic Surgery. IEEE Sens. J. 2012, 12, 22–32. [Google Scholar] [CrossRef]

- Schwenke, H.; Waldele, F.; Weiskirch, C.; Kunzmann, H. Opto-tactile sensor for 2D and 3D measurement of small structures on coordinate measuring machines. CIRP Ann. Manuf. Technol. 2001, 50, 361–364. [Google Scholar] [CrossRef]

- Puangmali, P.; Liu, H.B.; Seneviratne, L.D.; Dasgupta, P.; Althoefer, K. Miniature 3-Axis Distal Force Sensor for Minimally Invasive Surgical Palpation. IEEE-ASME Trans. Mechatron. 2012, 17, 646–656. [Google Scholar] [CrossRef]

- Konstantinova, J.; Stilli, A.; Althoefer, K. Force and Proximity Fingertip Sensor to Enhance Grasping Perception. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–3 October 2015; IEEE: New York, NY, USA; pp. 2118–2123. [Google Scholar]

- Noh, Y.; Sareh, S.; Back, J.; Würdemann, H.A.; Ranzani, T.; Secco, E.L.; Faragasso, A.; Liu, H.; Althoefer, K. A Three-Axial Body Force Sensor for Flexible Manipulators. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; IEEE: New York, NY, USA; pp. 6388–6393. [Google Scholar]

- Windecker, R.; Franz, S.; Tiziani, H.J. Optical roughness measurements with fringe projection. Appl. Opt. 1999, 38, 2837–2842. [Google Scholar] [CrossRef] [PubMed]

- Cotton, D.P.J.; Chappell, P.H.; Cranny, A.; White, N.M.; Beeby, S.P. A novel thick-film piezoelectric slip sensor for a prosthetic hand. IEEE Sens. J. 2007, 7, 752–761. [Google Scholar] [CrossRef]

- Omata, S.; Terunuma, Y. New tactile sensor like the human hand and its applications. Sens. Actuators A Phys. 1992, 35, 9–15. [Google Scholar] [CrossRef]

- Luo, Y.Z.; Xiao, Q.; Li, B.Y. A Stretchable Pressure-Sensitive Array Based on Polymer Matrix. Sensors 2017, 17, 12. [Google Scholar]

- Park, S.H.; Kim, S.Y.; Kim, J.H.; Kang, I. Carbon Nano Artificial Neuron System for Flexible Tactile Sensing. In Proceedings of the 2013 10th International Conference on Ubiquitous Robots and Ambient Intelligence, Jeju, Korea, 30 October–2 November 2013; IEEE: New York, NY, USA; pp. 728–729. [Google Scholar]

- Strohmayr, M.W.; Saal, H.P.; Potdar, A.H.; van der Smagt, P. The DLR Touch Sensor I: A Flexible Tactile Sensor for Robotic Hands based on a Crossed-Wire Approach. In Proceedings of the IEEE/RSJ 2010 International Conference on Intelligent Robots and Systems, Taipei, Taiwan, 18–22 October 2010; IEEE: New York, NY, USA; pp. 897–903. [Google Scholar]

- Cai, X.Y.; Li, Y.; Lei, L.H.; Fan, G.F.; Jian, L.; Zhang, X.D.; Zhuang, S.L. A nano measurement machine equipped with a 3D piezo-resistive micro tactile probe. Precis. Eng. J. Int. Soc. Precis. Eng. Nanotechnol. 2015, 42, 37–41. [Google Scholar] [CrossRef]

- Dahiya, R.S.; Adami, A.; Collini, C.; Lorenzelli, L. POSFET tactile sensing arrays using CMOS technology. Sens. Actuators A Phys. 2013, 202, 226–232. [Google Scholar] [CrossRef]

- Nozik, A.J.; Beard, M.C.; Luther, J.M.; Law, M.; Ellingson, R.J.; Johnson, J.C. Semiconductor quantum dots and quantum dot arrays and applications of multiple exciton generation to third-generation photovoltaic solar cells. Chem. Rev. 2010, 110, 6873–6890. [Google Scholar] [CrossRef] [PubMed]

- Alivisatos, A.P. Semiconductor clusters, nanocrystals, and quantum dots. Science 1996, 271, 933–937. [Google Scholar] [CrossRef]

- Chan, W.C.W.; Nie, S.M. Quantum dot bioconjugates for ultrasensitive nonisotopic detection. Science 1998, 281, 2016–2018. [Google Scholar] [CrossRef] [PubMed]

- Wolf, S.A.; Awschalom, D.D.; Buhrman, R.A.; Daughton, J.M.; von Molnar, S.; Roukes, M.L.; Chtchelkanova, A.Y.; Treger, D.M. Spintronics: A spin-based electronics vision for the future. Science 2001, 294, 1488–1495. [Google Scholar] [CrossRef] [PubMed]

- Michalet, X.; Pinaud, F.F.; Bentolila, L.A.; Tsay, J.M.; Doose, S.; Li, J.J.; Sundaresan, G.; Wu, A.M.; Gambhir, S.S.; Weiss, S. Quantum dots for live cells, in vivo imaging, and diagnostics. Science 2005, 307, 538–544. [Google Scholar] [CrossRef] [PubMed]

- Ostrowsky, D.; Jacques, A. Formation of optical waveguides in photoresist films. Appl. Phys. Lett. 1971, 18, 556–557. [Google Scholar] [CrossRef]

- Shang, X.; Ke, M.; Wang, Y.; Lancaster, M.J. WR-3 band waveguides and filters fabricated using SU8 photoresist micromachining technology. IEEE Trans. Terahertz Sci. Technol. 2012, 2, 629–637. [Google Scholar] [CrossRef]

- Mittendorfer, P.; Cheng, G. Humanoid Multimodal Tactile-Sensing Modules. IEEE Trans. Robot. 2011, 27, 401–410. [Google Scholar] [CrossRef]

- Martell, J.; Elmer, T.; Gopalsami, N.; Park, Y.S. Visual Measurement of Suture Strain for Robotic Surgery. Comput. Math. Method Med. 2011, 2011. [Google Scholar] [CrossRef] [PubMed]

- Ge, C.; Cretu, E. MEMS transducers low-cost fabrication using SU-8 in a sacrificial layer-free process. J. Micromech. Microeng. 2017, 27, 11. [Google Scholar] [CrossRef]

- Tung, T.T.; Robert, C.; Castro, M.; Feller, J.F.; Kim, T.Y.; Suh, K.S. Enhancing the sensitivity of graphene/polyurethane nanocomposite flexible piezo-resistive pressure sensors with magnetite nano-spacers. Carbon 2016, 108, 450–460. [Google Scholar] [CrossRef]

- Wu, W.Z.; Wen, X.N.; Wang, Z.L. Taxel-Addressable Matrix of Vertical-Nanowire Piezotronic Transistors for Active and Adaptive Tactile Imaging. Science 2013, 340, 952–957. [Google Scholar] [CrossRef] [PubMed]

- Dargahi, J. A piezoelectric tactile sensor with three sensing elements for robotic, endoscopic and prosthetic applications. Sens. Actuators A Phys. 2000, 80, 23–30. [Google Scholar] [CrossRef]

- Dargahi, J.; Parameswaran, M.; Payandeh, S. A micromachined piezoelectric tactile sensor for an endoscopic grasper-Theory, fabrication and experiments. J. Microelectromech. Syst. 2000, 9, 329–335. [Google Scholar] [CrossRef]

- Choi, J.J.; Hahn, B.D.; Ryu, J.; Yoon, W.H.; Lee, B.K.; Park, D.S. Preparation and characterization of piezoelectric ceramic-polymer composite thick films by aerosol deposition for sensor application. Sens. Actuators A Phys. 2009, 153, 89–95. [Google Scholar] [CrossRef]

- Takashima, K.; Horie, S.; Mukai, T.; Ishida, K.; Matsushige, K. Piezoelectric properties of vinylidene fluoride oligomer for use in medical tactile sensor applications. Sens. Actuators A Phys. 2008, 144, 90–96. [Google Scholar] [CrossRef]

- Wang, Y.R.; Zheng, J.M.; Ren, G.Y.; Zhang, P.H.; Xu, C. A flexible piezoelectric force sensor based on PVDF fabrics. Smart Mat. Struct. 2011, 20, 7. [Google Scholar] [CrossRef]

- Seminara, L.; Pinna, L.; Valle, M.; Basirico, L.; Loi, A.; Cosseddu, P.; Bonfiglio, A.; Ascia, A.; Biso, M.; Ansaldo, A.; et al. Piezoelectric Polymer Transducer Arrays for Flexible Tactile Sensors. IEEE Sens. J. 2013, 13, 4022–4029. [Google Scholar] [CrossRef]

- Khan, S.; Tinku, S.; Lorenzelli, L.; Dahiya, R.S. Flexible Tactile Sensors Using Screen-Printed P(VDF-TrFE) and MWCNT/PDMS Composites. IEEE Sens. J. 2015, 15, 3146–3155. [Google Scholar] [CrossRef]

- Kim, J.-H.; Yun, S.; Kim, J.-H.; Kim, J. Fabrication of piezoelectric cellulose paper and audio application. J. Bion. Eng. 2009, 6, 18–21. [Google Scholar] [CrossRef]

- Csoka, L.; Hoeger, I.C.; Rojas, O.J.; Peszlen, I.; Pawlak, J.J.; Peralta, P.N. Piezoelectric effect of cellulose nanocrystals thin films. ACS Macro Lett. 2012, 1, 867–870. [Google Scholar] [CrossRef]

- Van Uitert, L.; Wemple, S. ZnCl2 glass: A potential ultralow-loss optical fiber material. Appl. Phys. Lett. 1978, 33, 57–59. [Google Scholar] [CrossRef]

- Knight, J.; Birks, T.; Russell, P.S.J.; Atkin, D. All-silica single-mode optical fiber with photonic crystal cladding. Opt. Lett. 1996, 21, 1547–1549. [Google Scholar] [CrossRef] [PubMed]

- Ma, H.; Jen, A.Y.; Dalton, L.R. Polymer-Based optical waveguides: Materials, processing, and devices. Adv. Mater. 2002, 14, 1339–1365. [Google Scholar] [CrossRef]

- Balasubramanian, K.; Burghard, M. Chemically functionalized carbon nanotubes. Small 2005, 1, 180–192. [Google Scholar] [CrossRef] [PubMed]

- Okpalugo, T.I.T.; Papakonstantinou, P.; Murphy, H.; McLaughlin, J.; Brown, N.M.D. High resolution XPS characterization of chemical functionalised MWCNTs and SWCNTs. Carbon 2005, 43, 153–161. [Google Scholar] [CrossRef]

- Basabe-Desmonts, L.; Reinhoudt, D.N.; Crego-Calama, M. Design of fluorescent materials for chemical sensing. Chem. Soc. Rev. 2007, 36, 993–1017. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.L.; Stoddart, J.F. Noncovalent Functionalization of Single-Walled Carbon Nanotubes. Acc. Chem. Res. 2009, 42, 1161–1171. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Qi, D.; Liu, Z.; Chandran, B.K.; Wang, T.; Yu, J.; Chen, X. Soft Thermal Sensor with Mechanical Adaptability. Adv. Mater. 2016, 28, 9175–9181. [Google Scholar] [CrossRef] [PubMed]

- Young, S.J.; Lin, Z.D.; Hsiao, C.H.; Huang, C.S. Ethanol Gas Sensors Composed of Carbon Nanotubes with Adsorbed Gold Nanoparticles. Int. J. Electrochem. Sci. 2012, 7, 11634–11640. [Google Scholar]

- Kim, S.Y.; Park, S.; Park, H.W.; Park, D.H.; Jeong, Y.; Kim, D.H. Highly Sensitive and Multimodal All-Carbon Skin Sensors Capable of Simultaneously Detecting Tactile and Biological Stimuli. Adv. Mater. 2015, 27, 4178–4185. [Google Scholar] [CrossRef] [PubMed]

- Cagatay, E.; Abdellah, A.; Lugli, P.; Mittendorfer, P.; Cheng, G. Integrating CNT Force Sensors Into a Multimodal Modular Electronic Skin. In Proceedings of the 2015 IEEE 15th International Conference on Nanotechnology (IEEE-Nano), Rome, Italy, 27–30 July 2015; pp. 1299–1302. [Google Scholar]

- Wang, X.D.; Dong, L.; Zhang, H.L.; Yu, R.M.; Pan, C.F.; Wang, Z.L. Recent Progress in Electronic Skin. Adv. Sci. 2015, 2, 21. [Google Scholar] [CrossRef] [PubMed]

- Kudryashov, V.; Yuan, X.-C.; Cheong, W.-C.; Radhakrishnan, K. Grey scale structures formation in SU-8 with e-beam and UV. Microelectron. Eng. 2003, 67, 306–311. [Google Scholar] [CrossRef]

- Sato, H.; Matsumura, H.; Keino, S.; Shoji, S. An all SU-8 microfluidic chip with built-in 3D fine microstructures. J. Micromech. Microeng. 2006, 16, 2318. [Google Scholar] [CrossRef]

- Taff, J.; Kashte, Y.; Spinella-Mamo, V.; Paranjape, M. Fabricating multilevel SU-8 structures in a single photolithographic step using colored masking patterns. J. Vac. Sci. Technol. A Vac. Surf. Films 2006, 24, 742–746. [Google Scholar] [CrossRef]

- Rammohan, A.; Dwivedi, P.K.; Martinez-Duarte, R.; Katepalli, H.; Madou, M.J.; Sharma, A. One-step maskless grayscale lithography for the fabrication of 3-dimensional structures in SU-8. Sens. Actuators B Chem. 2011, 153, 125–134. [Google Scholar] [CrossRef]

- Accoto, C.; Qualtieri, A.; Pisanello, F.; Ricciardi, C.; Pirri, C.F.; De Vittorio, M.; Rizzi, F. Two-Photon Polymerization Lithography and Laser Doppler Vibrometry of a SU-8-Based Suspended Microchannel Resonator. J. Microelectromech. Syst. 2015, 24, 1038–1042. [Google Scholar] [CrossRef]

- Schmitz, A.; Maiolino, P.; Maggiali, M.; Natale, L.; Cannata, G.; Metta, G. Methods and Technologies for the Implementation of Large-Scale Robot Tactile Sensors. IEEE Trans. Robot. 2011, 27, 389–400. [Google Scholar] [CrossRef]

- Li, K.R.; Fang, Y.F.; Zhou, Y.; Liu, H.H. Non-Invasive Stimulation-Based Tactile Sensation for Upper-Extremity Prosthesis: A Review. IEEE Sens. J. 2017, 17, 2625–2635. [Google Scholar] [CrossRef]

- Saccomandi, P.; Zollo, L.; Ciancio, A.; Schena, E.; Fasano, A.; Oddo, C.; Carrozza, M.; Camboni, D. Tactile Piezoresistive Sensors for Robotic Application: Design and Metrological Characterization. In Proceedings of the 2017 IEEE International on Instrumentation and Measurement Technology Conference (I2MTC), Turino, Italy, 22–25 May 2017; pp. 1–6. [Google Scholar]

- Park, M.; Park, Y.J.; Chen, X.; Park, Y.K.; Kim, M.S.; Ahn, J.H. MoS2-based tactile sensor for electronic skin applications. Adv. Mater. 2016, 28, 2556–2562. [Google Scholar] [CrossRef] [PubMed]

- Canavese, G.; Stassi, S.; Fallauto, C.; Corbellini, S.; Cauda, V.; Camarchia, V.; Pirola, M.; Pirri, C.F. Piezoresistive flexible composite for robotic tactile applications. Sens. Actuators A Phys. 2014, 208, 1–9. [Google Scholar] [CrossRef]

- Ibrahim, A.; Gastaldo, P.; Chible, H.; Valle, M. Real-Time Digital Signal Processing Based on FPGAs for Electronic Skin Implementation. Sensors 2017, 17, 558. [Google Scholar] [CrossRef] [PubMed]

- Kanao, K.; Harada, S.; Yamamoto, Y.; Honda, W.; Arie, T.; Akita, S.; Takei, K. Highly selective flexible tactile strain and temperature sensors against substrate bending for an artificial skin. RSC Adv. 2015, 5, 30170–30174. [Google Scholar] [CrossRef]

- Harada, S.; Kanao, K.; Yamamoto, Y.; Arie, T.; Akita, S.; Takei, K. Fully Printed Flexible Fingerprint-like Three-Axis Tactile and Slip Force and Temperature Sensors for Artificial Skin. ACS Nano 2014, 8, 12851–12857. [Google Scholar] [CrossRef] [PubMed]

- Takei, K.; Takahashi, T.; Ho, J.C.; Ko, H.; Gillies, A.G.; Leu, P.W.; Fearing, R.S.; Javey, A. Nanowire active-matrix circuitry for low-voltage macroscale artificial skin. Nat. Mater. 2010, 9, 821–826. [Google Scholar] [CrossRef] [PubMed]

- Chou, H.H.; Nguyen, A.; Chortos, A.; To, J.W.F.; Lu, C.; Mei, J.G.; Kurosawa, T.; Bae, W.G.; Tok, J.B.H.; Bao, Z.A. A chameleon-inspired stretchable electronic skin with interactive colour changing controlled by tactile sensing. Nat. Commun. 2015, 6. [Google Scholar] [CrossRef] [PubMed]

- Nunez, C.G.; Navaraj, W.T.; Polat, E.O.; Dahiya, R. Energy-Autonomous, Flexible, and Transparent Tactile Skin. Adv. Funct. Mater. 2017, 27. [Google Scholar] [CrossRef]

- Kaltenbrunner, M.; Sekitani, T.; Reeder, J.; Yokota, T.; Kuribara, K.; Tokuhara, T.; Drack, M.; Schwodiauer, R.; Graz, I.; Bauer-Gogonea, S.; et al. An ultra-lightweight design for imperceptible plastic electronics. Nature 2013, 499, 458–463. [Google Scholar] [CrossRef] [PubMed]

- He, H.X.; Fu, Y.M.; Zang, W.L.; Wang, Q.; Xing, L.L.; Zhang, Y.; Xue, X.Y. A flexible self-powered T-ZnO/PVDF/fabric electronic-skin with multi functions of tactile-perception, atmosphere-detection and self-clean. Nano Energy 2017, 31, 37–48. [Google Scholar] [CrossRef]

- Sokolov, A.N.; Tee, B.C.K.; Bettinger, C.J.; Tok, J.B.H.; Bao, Z.N. Chemical and Engineering Approaches to Enable Organic Field-Effect Transistors for Electronic Skin Applications. Acc. Chem. Res. 2012, 45, 361–371. [Google Scholar] [CrossRef] [PubMed]

- Tee, B.C.-K.; Chortos, A.; Berndt, A.; Nguyen, A.K.; Tom, A.; McGuire, A.; Lin, Z.C.; Tien, K.; Bae, W.-G.; Wang, H. A skin-inspired organic digital mechanoreceptor. Science 2015, 350, 313–316. [Google Scholar] [CrossRef] [PubMed]

- Dargahi, J.; Sokhanvar, S.; Najarian, S.; Arbatani, S. Tactile Sensing and Display: Haptic Feedback for Minimally Invasive Surgery and Robotics; John Wiley & Sons: Chichester, West Sussex, UK, 2012. [Google Scholar]

- Kemp, C.C.; Edsinger, A.; Torres-Jara, E. Challenges for robot manipulation in human environments-Developing robots that perform useful work in everyday settings. IEEE Robot. Autom. Mag. 2007, 14, 20–29. [Google Scholar] [CrossRef]

- Khatib, O.; Chung, S.Y. SupraPeds: Humanoid Contact-Supported Locomotion for 3D Unstructured Environments. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 2319–2325. [Google Scholar]

- Jain, A. Mobile Manipulation in Unstructured Environments with Haptic Sensing and Compliant Joints. Ph.D. Dissertation, Georgia Institute of Technology, Atlanta, GA, USA, 2012. [Google Scholar]

- Kim, J.; Lee, M.; Shim, H.J.; Ghaffari, R.; Cho, H.R.; Son, D.; Jung, Y.H.; Soh, M.; Choi, C.; Jung, S. Stretchable silicon nanoribbon electronics for skin prosthesis. Nat. Commun. 2014, 5, 5747. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Zou, J.D.; Xing, F.; Zhang, M.; Cao, X.; Wang, N.; Wang, Z.L. From Dual-Mode Triboelectric Nanogenerator to Smart Tactile Sensor: A Multiplexing Design. ACS Nano 2017, 11, 3950–3956. [Google Scholar] [CrossRef] [PubMed]

- Saccomandi, P.; Schena, E.; Oddo, C.M.; Zollo, L.; Silvestri, S.; Guglielmelli, E. Microfabricated tactile sensors for biomedical applications: A review. Biosensors 2014, 4, 422–448. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lucarotti, C.; Oddo, C.M.; Vitiello, N.; Carrozza, M.C. Synthetic and Bio-Artificial Tactile Sensing: A Review. Sensors 2013, 13, 1435–1466. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, H.; O’Brien, K.; Li, S.; Shepherd, R.F. Optoelectronically innervated soft prosthetic hand via stretchable optical waveguides. Sci. Robot. 2016, 1. [Google Scholar] [CrossRef]

- Edwards, J. Signal Processing in Next-Generation Prosthetics. IEEE Signal Process. Mag. 2015, 32, 9–12. [Google Scholar] [CrossRef]

- SureTouch Digital Breast Exam. Available online: http://suretouch.us/ (accessed on 4 October 2017).

- Ahn, B.M.; Kim, J.; Ian, L.; Rha, K.H.; Kim, H.J. Mechanical Property Characterization of Prostate Cancer Using a Minimally Motorized Indenter in an Ex Vivo Indentation Experiment. Urology 2010, 76, 1007–1011. [Google Scholar] [CrossRef] [PubMed]

- Afshari, E.; Najarian, S.; Simforoosh, N.; Farkoush, S.H. Design and fabrication of a novel tactile sensory system applicable in artificial palpation. Minim. Invasive Ther. 2011, 20, 22–29. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, C.V.; Saraf, R.F. Tactile Imaging of an Imbedded Palpable Structure for Breast Cancer Screening. ACS Appl. Mater. Interfaces 2014, 6, 16368–16374. [Google Scholar] [CrossRef] [PubMed]

- Dahiya, R.S.; Valle, M.; Metta, G. System approach: A paradigm for robotic tactile sensing. In Proceedings of the International Workshop on Advanced Motion Control (AMC ’08: 10th), Trento, Italy, 26–28 March 2008; Volumes 1–2, pp. 110–115. [Google Scholar]

- Wang, X.D.; Zhang, H.L.; Dong, L.; Han, X.; Du, W.M.; Zhai, J.Y.; Pan, C.F.; Wang, Z.L. Self-Powered High-Resolution and Pressure-Sensitive Triboelectric Sensor Matrix for Real-Time Tactile Mapping. Adv. Mater. 2016, 28, 2896–2903. [Google Scholar] [CrossRef] [PubMed]

- Yuan, W.Z.; Srinivasan, M.A.; Adelson, E.H. Estimating Object Hardness with a GelSight Touch Sensor. In Proceedings of the 2016 IEEE/Rsj International Conference on Intelligent Robots and Systems (IROS 2016), Daejeon, Korea, 9–14 October 2016; pp. 208–215. [Google Scholar]

- Lee, W.W.; Kukreja, S.L.; Thakor, N.V. A kilohertz kilotaxel tactile sensor array for investigating spatiotemporal features in neuromorphic touch. In Proceedings of the 2015 IEEE on Biomedical Circuits and Systems Conference (BioCAS), Atlanta, GA, USA, 22–24 October 2015; pp. 1–4. [Google Scholar]

- Hollis, B.; Patterson, S.; Trinkle, J. Compressed Sensing for Scalable Robotic Tactile Skins. arXiv, 2017; arXiv:1705.05247. [Google Scholar]

- Tien, N.T.; Jeon, S.; Kim, D.I.; Trung, T.Q.; Jang, M.; Hwang, B.U.; Byun, K.E.; Bae, J.; Lee, E.; Tok, J.B.H.; et al. A Flexible Bimodal Sensor Array for Simultaneous Sensing of Pressure and Temperature. Adv. Mater. 2014, 26, 796–804. [Google Scholar] [CrossRef] [PubMed]

- Sekitani, T.; Yokota, T.; Zschieschang, U.; Klauk, H.; Bauer, S.; Takeuchi, K.; Takamiya, M.; Sakurai, T.; Someya, T. Organic nonvolatile memory transistors for flexible sensor arrays. Science 2009, 326, 1516–1519. [Google Scholar] [CrossRef] [PubMed]

- Yokoyama, H.; Sohgawa, M.; Kanashima, T.; Azuma, T.; Okuyama, M.; Noma, H. Fabrication and Noise Reduction of the Miniature Tactile Sensor Using Through-Silicon-Via Connection with Signal Amplifier. Jpn. J. Appl. Phys. 2013, 52. [Google Scholar] [CrossRef]

- Servati, A.; Zou, L.; Wang, Z.J.; Ko, F.; Servati, P. Novel Flexible Wearable Sensor Materials and Signal Processing for Vital Sign and Human Activity Monitoring. Sensors 2017, 17, 1622. [Google Scholar] [CrossRef] [PubMed]

- Zou, L.; Chen, X.; Servati, A.; Soltanian, S.; Servati, P.; Wang, Z.J. A Blind Source Separation Framework for Monitoring Heart Beat Rate Using Nanofiber-Based Strain Sensors. IEEE Sens. J. 2016, 16, 762–772. [Google Scholar] [CrossRef]

- Sweeney, K.T.; Ward, T.E.; McLoone, S.F. Artifact Removal in Physiological Signals-Practices and Possibilities. IEEE Trans. Inf. Technol. Biomed. 2012, 16, 488–500. [Google Scholar] [CrossRef] [PubMed]

- Decherchi, S.; Gastaldo, P.; Dahiya, R.S.; Valle, M.; Zunino, R. Tactile-Data Classification of Contact Materials Using Computational Intelligence. IEEE Trans. Robot. 2011, 27, 635–639. [Google Scholar] [CrossRef]

- Madry, M.; Bo, L.F.; Kragic, D.; Fox, D. ST-HMP: Unsupervised Spatio-Temporal Feature Learning for Tactile Data. In Proceedings of the 2014 IEEE International Conference on Robotics and Automation (ICRA), Hong Kong, China, 31 May–7 June 2014; pp. 2262–2269. [Google Scholar]

- Hoelscher, J.; Peters, J.; Hermans, T. Evaluation of Tactile Feature Extraction for Interactive Object Recognition. In Proceedings of the 2015 IEEE-Ras 15th International Conference on Humanoid Robots (Humanoids), Seoul, Korea, 3–5 November 2015; pp. 310–317. [Google Scholar]

- Spiers, A.J.; Liarokapis, M.V.; Calli, B.; Dollar, A.M. Single-Grasp Object Classification and Feature Extraction with Simple Robot Hands and Tactile Sensors. IEEE Trans. Haptics 2016, 9, 207–220. [Google Scholar] [CrossRef] [PubMed]

- Heyneman, B.; Cutkosky, M.R. Slip classification for dynamic tactile array sensors. Int. J. Robot. Res. 2016, 35, 404–421. [Google Scholar] [CrossRef]

- Fishel, J.A.; Loeb, G.E. Bayesian exploration for intelligent identification of textures. Front. Neurorobot. 2012, 6. [Google Scholar] [CrossRef] [PubMed]

- Wong, R.D.P.; Hellman, R.B.; Santos, V.J. Haptic Exploration of Fingertip-Sized Geometric Features Using a Multimodal Tactile Sensor. Proc. SPIE 2014, 9116. [Google Scholar] [CrossRef]

- Schöpfer, M.; Pardowitz, M.; Haschke, R.; Ritter, H. Identifying relevant tactile features for object identification. In Towards Service Robots for Everyday Environments; Erwin, P., Ed.; Springer: New York, NY, USA, 2012; pp. 417–430. [Google Scholar]

- Bo, L.; Ren, X.; Fox, D. Hierarchical matching pursuit for image classification: Architecture and fast algorithms. In Proceedings of the 24th International Conference on Neural Information Processing Systems, Granada, Spain, 12–17 December 2011; pp. 2115–2123. [Google Scholar]

- Bhattacharjee, T.; Rehg, J.M.; Kemp, C.C. Haptic Classification and Recognition of Objects Using a Tactile Sensing Forearm. In Proceedings of the 2012 IEEE/Rsj International Conference on Intelligent Robots and Systems (IROS), Vilamoura-Algarve, Portugal, 7–12 October 2012; pp. 4090–4097. [Google Scholar]

- Gastaldo, P.; Pinna, L.; Seminara, L.; Valle, M.; Zunino, R. A Tensor-Based Pattern-Recognition Framework for the Interpretation of Touch Modality in Artificial Skin Systems. IEEE Sens. J. 2014, 14, 2216–2225. [Google Scholar] [CrossRef]

- Chathuranga, D.S.; Wang, Z.K.; Noh, Y.; Nanayakkara, T.; Hirai, S. Robust Real time Material Classification Algorithm Using Soft Three Axis Tactile Sensor: Evaluation of the Algorithm. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–2 October 2015; pp. 2093–2098. [Google Scholar]

- Hu, H.H.; Han, Y.Z.; Song, A.G.; Chen, S.G.; Wang, C.H.; Wang, Z. A Finger-Shaped Tactile Sensor for Fabric Surfaces Evaluation by 2-Dimensional Active Sliding Touch. Sensors 2014, 14, 4899–4913. [Google Scholar] [CrossRef] [PubMed]

- Sohn, K.-S.; Chung, J.; Cho, M.-Y.; Timilsina, S.; Park, W.B.; Pyo, M.; Shin, N.; Sohn, K.; Kim, J.S. An extremely simple macroscale electronic skin realized by deep machine learning. Sci. Rep. 2017, 7, 11601. [Google Scholar] [CrossRef] [PubMed]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet Classification with Deep Convolutional Neural Networks. In Proceedings of the NIPS2012, Lake Tahoe, CA, USA, 3–8 December 2012; pp. 1097–1105. [Google Scholar]

- Li, X.D.; Ho, J.K.L.; Chow, T.W.S. Approximation of dynamical time-variant systems by continuous-time recurrent neural networks. IEEE Trans. Circuits Syst. II-Express Briefs 2005, 52, 656–660. [Google Scholar]

- Zou, L.; Zheng, J.; Miao, C.; McKeown, M.J.; Wang, Z.J. 3D CNN based Automatic Diagnosis of Attention Deficit Hyperactivity Disorder Using Functional and Structural MRI. IEEE Access 2017, 5. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, Z.; Yang, Y.; Wang, Z.J.; Leung, V.C. Incomplete Multi-View Clustering via Deep Semantic Mapping. Neurocomputing 2017, in press. [Google Scholar] [CrossRef]

- Yuan, W.; Zhu, C.; Owens, A.; Srinivasan, M.A.; Adelson, E.H. Shape-independent Hardness Estimation Using Deep Learning and a GelSight Tactile Sensor. arXiv, 2017; arXiv:1704.03955. [Google Scholar]

- Liggins, M., II; Hall, D.; Llinas, J. Handbook of Multisensor Data Fusion: Theory and Practice; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Jia, S.; Santos, V.J. Multimodal haptic perception within granular media via recurrent neural networks. In Proceedings of the RSS Workshop Tactile Sensing for Manipulation: Hardware, Modeling, and Learning, Boston, MA, USA, 15 July 2017. [Google Scholar]

- Halatci, I.; Brooks, C.A.; Iagnemma, K. Terrain classification and classifier fusion for planetary exploration rovers. In Proceedings of the 2007 IEEE Aerospace Conference, Big Sky, MT, USA, 3–10 March 2007. [Google Scholar] [CrossRef]

- Bernardin, K.; Ogawara, K.; Ikeuchi, K.; Dillmann, R. A sensor fusion approach for recognizing continuous human grasping sequences using hidden Markov models. IEEE Trans. Robot. 2005, 21, 47–57. [Google Scholar] [CrossRef]

- Lin, C.H.; Erickson, T.W.; Fishel, J.A.; Wettels, N.; Loeb, G.E. Signal Processing and Fabrication of a Biomimetic Tactile Sensor Array with Thermal, Force and Microvibration Modalities. In Proceedings of the 2009 IEEE International Conference on Robotics and Biomimetics (ROBIO 2009), Guilin, China, 19–23 December 2009; Volumes 1–4, pp. 129–134. [Google Scholar]

- Liu, H.; Yu, Y.; Sun, F.; Gu, J. Visual–Tactile fusion for object recognition. IEEE Trans. Autom. Sci. Eng. 2017, 14, 996–1008. [Google Scholar] [CrossRef]

| Sensing Principle | Trade-Offs | |

|---|---|---|

| Sensing Structure Related | Read out System Related | |

| Capacitive | High sensitivity and resolution | Highly integratable |

| Large dynamic measurement range | Medium complexity | |

| Static and dynamic measurement | Medium power consumption | |

| Easily affected by noise | High portability | |

| Piezo-resistive | High sensitivity and resolution | Highly integratable |

| Robust to noise | Highly Low complexity | |

| In-situ structured sensor | High portability | |

| Susceptible to hysteresis | High power consumption | |

| Piezoelectric | High sensitivity | Highly integratable |

| Large dynamic range | Medium complexity | |

| High frequency response | Medium portability, little bulky | |

| Low spatial resolution | Medium power consumption | |

| Optic | High sensitivity | Highly integrable |

| Large dynamic range | Medium complexity | |

| High frequency response | Medium power consumption | |

| High spatial resolution | Medium portability | |

| Material Type | Patterning | Properties | |

|---|---|---|---|

| Deposit | Etch | ||

| Silicic | High temperature | Highly dangerous chemical | Good mechanical properties |

| High vacuum requirement | Tunable electrical conductivity | ||

| Complex equipment | Complex equipment | Good thermal conductivity | |

| Low rate | Good optical properties | ||

| High chemical stability | |||

| Metallic | Flexible temperature | Flexible and simpler etching method | Good electrical conductivity |

| Flexible vacuum requirement | Good thermal conductivity | ||

| Medium equipment complexity | Simpler equipment | Medium chemical stability | |

| Medium rate | |||

| Polymer | Low temperature | Safe chemical | Medium to low mechanical properties |

| Low vacuum requirement | Insulator | ||

| High flexibility in functionalization | |||

| Simple equipment | High rate | Good optical properties | |

| High rate | Low chemical stability, prone to oxidation | ||

| Sensing Principles | Complexity and Cost | ||

| Surface/Bulk Machining | Mold/Imprinting | Rapid 3D Fabrication | |

| Capacitive | High | Medium | Low |

| Piezo-resistive | Medium | Medium | Low |

| Piezoelectric | Low | Medium | Low |

| Optic | Medium | Low | Low |

| Sensing Principles | Robustness | ||

| Surface/Bulk Machining | Mold/Imprinting | Rapid 3D Fabrication | |

| Capacitive | Low | High | Low |

| Piezo-resistive | Medium | High | High |

| Piezoelectric | High | High | High |

| Optic | Medium | High | High |

| Reference | Characters | Function |

|---|---|---|

| [104] | Pressure-sensitive, macroscale | Electronic skin capable of monitoring pressure with high spatial resolution |

| [106] | Energy-Autonomous, Flexible, and Transparent, sensitive to touch | Mimic human skin and can perform task ranging from simple touching to grabbing of soft objects |

| [107] | Ultra-lightweight, unbreakable and imperceptible | electronic skin, health care and monitoring and many others |

| [108] | Flexible, self-powered, self-clean | multi-functional e-skin, such as elbow bending or finger pressing |

| [109] | Unprecedented sensitivity for tactile pressure | Mimic human skin, with potential application in novel prosthetics and robotic surgery |

| Reference | Tactile Sensors (Hardware) | Extracted Features | Machine Learning Method | Aim |

|---|---|---|---|---|

| [141] | BioTac (Pressure sensor) | Taction, roughness and fitness | Bayes | Texture classification |

| [143] | Tactile sensor array | 226 features | Decision trees | Object identification |

| [137] | Schunk Dexterous, Schunk Parallel and iCub hands | Spatio-Temporal structures by unsupervised feature learning | Support vector machine (SVM) | Grasp stability assessment and object recognition |

| [149] | Macroscale electronic skin with a brilliant strain and position sensor | Features from electrical resistance change by DNN | Deep neural network (DNN) | Position recognition and pressure evaluation |

| [154] | GelSight Tactile Sensor | Features from tactile images by DNN | Deep convolutional and recurrent neural network | Hardness Estimation |

| [139] | Barometric pressure sensors | 34 “haptic adjectives” | Random Forests | Estimation of metabolic equivalent of tasks |

| [145] | Humanoid robot, Cody, with force sensitive skin | Maximum force, contact area, and contact motion et al. | k-nearest neighbor (KNN) | Haptic classification and object recognition |

| [146] | A tactile sensing system with spatially distributed PVDF sensors | Spatial and temporal features from tactile imaging | Kernel-based Extreme Learning Machines and SVM | Interpretation of Touch modality |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, L.; Ge, C.; Wang, Z.J.; Cretu, E.; Li, X. Novel Tactile Sensor Technology and Smart Tactile Sensing Systems: A Review. Sensors 2017, 17, 2653. https://doi.org/10.3390/s17112653

Zou L, Ge C, Wang ZJ, Cretu E, Li X. Novel Tactile Sensor Technology and Smart Tactile Sensing Systems: A Review. Sensors. 2017; 17(11):2653. https://doi.org/10.3390/s17112653

Chicago/Turabian StyleZou, Liang, Chang Ge, Z. Jane Wang, Edmond Cretu, and Xiaoou Li. 2017. "Novel Tactile Sensor Technology and Smart Tactile Sensing Systems: A Review" Sensors 17, no. 11: 2653. https://doi.org/10.3390/s17112653

APA StyleZou, L., Ge, C., Wang, Z. J., Cretu, E., & Li, X. (2017). Novel Tactile Sensor Technology and Smart Tactile Sensing Systems: A Review. Sensors, 17(11), 2653. https://doi.org/10.3390/s17112653