Fatigue Damage Evaluation of Short Carbon Fiber Reinforced Plastics Based on Phase Information of Thermoelastic Temperature Change

Abstract

:1. Introduction

2. Thermoelastic Stress Analysis Using Infrared Thermography

3. Experimental Setup

4. Experimental Results

4.1. Effect of Fiber Orientation on Thermoelastic Temperature Change

4.2. Fatigue Damage Identification Based on Thermoelastic Temperature Change and Its Phase Delay Information

5. Conclusions

- (1)

- It was found from the relationship between the thermoelastic temperature change ∆TE and the fiber orientation angle φf that ∆TE in the area where φf = 90° takes higher value compared with that in the area where φf = 0°.

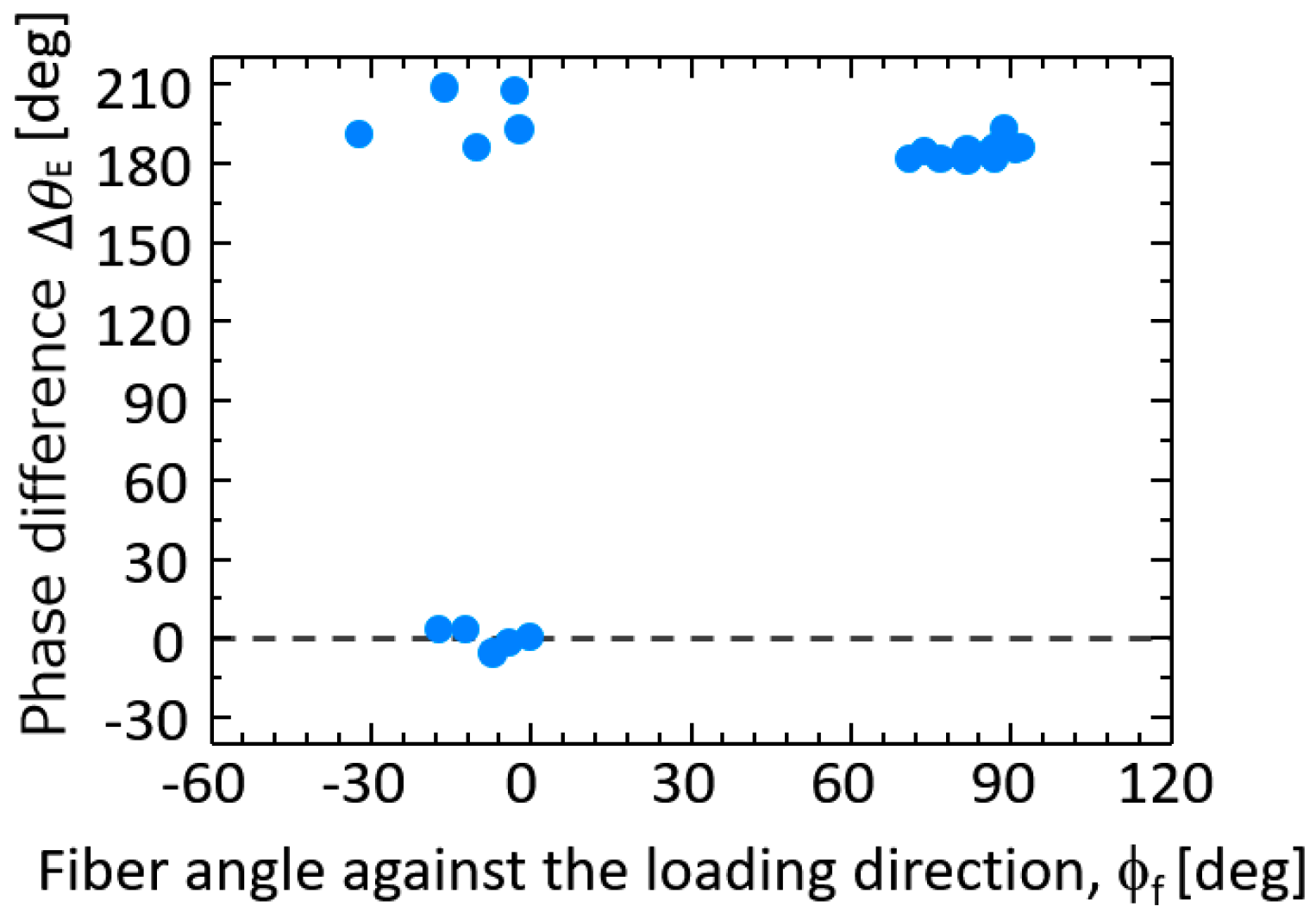

- (2)

- It was also found from the relationship between the fiber orientation angle φf and the phase difference ∆θE that ∆θE takes 180° in the area where φf = 90°. On the other hand, ∆θE takes 0° where φf = 0°. This is due to the negative thermoelastic constant of carbon fibers and the load sharing condition between resin and carbon fibers.

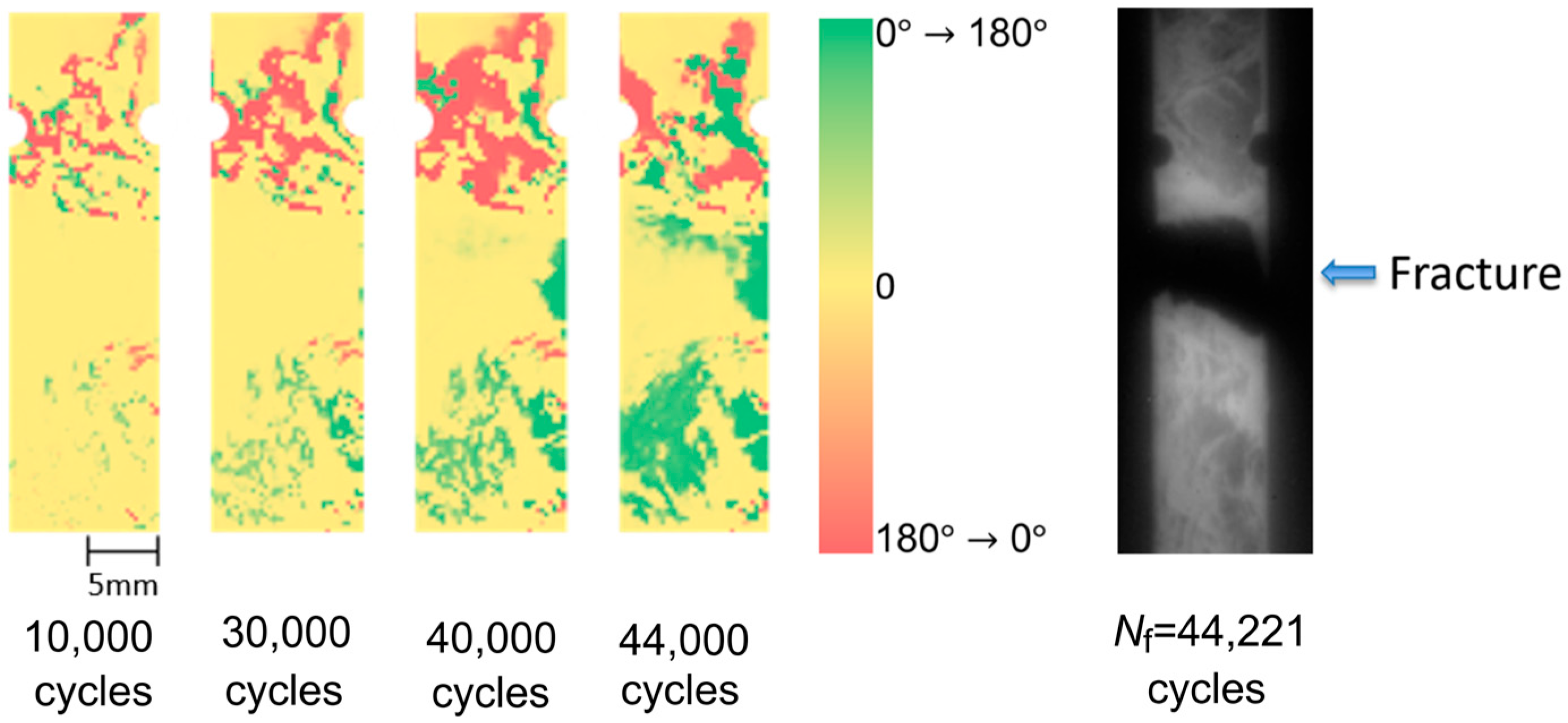

- (3)

- Fatigue damage was evaluated according to the conventional TDA procedure as well as the newly developed phase-delay based damage characterizing technique “thermoelastic phase damage analysis (TPDA)”. It was found from TPDA images that the significant change of phase values from 0 to 180° (indicating the change in load sharing condition between resin and carbon fibers due to fatigue damage evolution) was found in the region where the structural fracture was detected.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Avdelidis, N.P.; Almond, D.P.; Dobbinson, A.; Hawtin, B.C.; Ibarra-Castanedo, C.; Maldague, X. Aircraft composites assessment by means of transient thermal NDT. Prog. Aerosp. Sci. 2004, 40, 143–162. [Google Scholar] [CrossRef]

- Avdelidis, N.P.; Gan, T.-H. Non-destructive evaluation (NDE) of Composites: Infrared (IR) thermography of wind turbine blades. In Non-Destructive Evaluation (NDE) of Polymer Matrix Composites; Karbhari, V.M., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 634–648. ISBN 978-0-85709-344-8. [Google Scholar]

- Chatterjee, K.; Tuli, S.; Pickering, S.G.; Almond, D.P. A comparison of the pulsed, lock-in and frequency modulated thermography nondestructive evaluation techniques. NDT E Int. 2011, 44, 655–667. [Google Scholar] [CrossRef] [Green Version]

- Maldague, X.; Marinetti, S. Pulse phase infrared thermography. J. Appl. Phys. 1996, 79, 2694–2698. [Google Scholar] [CrossRef]

- Rajic, N. Principal component thermography for flaw contrast enhancement and flaw depth characterization in composite structures. Compos. Struct. 2002, 58, 521–528. [Google Scholar] [CrossRef]

- Griefahn, D.; Wollnack, J.; Hintze, W. Principal component analysis for fast and automated thermographic inspection of internal structures in sandwich parts. J. Sens. Sens. Syst. 2014, 3, 105–111. [Google Scholar] [CrossRef]

- Marinetti, S.; Grinzato, E.; Bison, P.G.; Bozzi, E.; Chimenti, M.; Pieri, G.; Salvetti, O. Statistical analysis of IR thermographic sequences by PCA. Infrared Phys. Technol. 2004, 46, 85–91. [Google Scholar] [CrossRef]

- Greene, R.J.; Patterson, E.A.; Rowlands, R.E. Thermoelastic Stress Analysis. In Springer Handbook of Experimental Solid Mechanics; Sharpe, W.N., Jr., Ed.; Springer Science + Business Media, LLC: New York, NY, USA, 2008; pp. 743–767. ISBN 978-0-387-26883-5. [Google Scholar]

- Dulieu-Barton, J.M.; Stanley, P. Development and applications of thermoelastic stress analysis. J. Strain Anal. Eng. Des. 1998, 33, 93–104. [Google Scholar] [CrossRef]

- Dulieu-Barton, J.M. Introduction to thermoelastic stress analysis. Strain 1999, 35, 35–39. [Google Scholar] [CrossRef]

- Pitarresi, G.; Patterson, E.A. A review of the general theory of thermoelastic stress analysis. J. Strain Anal. Eng. Des. 2003, 38, 405–417. [Google Scholar] [CrossRef]

- Sakagami, T. Remote nondestructive evaluation technique using infrared thermography for fatigue cracks in steel bridges. Fatigue Fract. Engng. Mater. Struct. 2015, 38, 755–779. [Google Scholar] [CrossRef]

- Tomlinson, R.A.; Olden, E.A. Thermoelasticity for the analysis of crack tip stress fields—A review. Strain 1999, 35, 49–55. [Google Scholar] [CrossRef]

- Ju, S.H.; Lesniak, J.R.; Sandor, B.I. Numerical simulation of stress intensity factors via the thermoelastic technique. Exp. Mech. 1997, 37, 278–284. [Google Scholar] [CrossRef]

- Diaz, F.A.; Patterson, E.A.; Tomlinson, R.A.; Yates, J.R. Measuring stress intensity factors during fatigue crack growth using thermoelasticity. Fatigue Fract. Engng. Mater. Struct. 2004, 27, 571–583. [Google Scholar] [CrossRef]

- Tomlinson, R.A.; Marsavina, L. Thermoelastic investigations for fatigue life assessment. Exp. Mech. 2004, 44, 487–494. [Google Scholar] [CrossRef]

- Diaz, F.A.; Yates, J.R.; Patterson, E.A. Some improvements in the analysis of fatigue cracks using thermoelasticity. Int. J. Fatigue 2004, 26, 365–376. [Google Scholar] [CrossRef]

- Lin, S.T.; Rowlands, R.E. Thermoelastic stress analysis of orthotropic composites. Exp. Mech. 1995, 35, 257–265. [Google Scholar] [CrossRef]

- Dulieu-Barton, J.M.; Stanley, P. Applications of thermoelastic stress analysis to composite materials. Strain 1999, 35, 41–48. [Google Scholar] [CrossRef]

- Emery, T.R.; Dulieu-Barton, J.M.; Earl, J.S.; Cunningham, P.R. A generalised approach to the calibration of orthotropic materials for thermoelastic stress analysis. Compos. Sci. Technol. 2008, 68, 743–752. [Google Scholar] [CrossRef]

- Palumbo, D.; De Finis, R.; Demelio, G.P.; Galietti, U. Study of damage evolution in composite materials based on the Theroelastic Phase Analysis (TPA) method. Compos. Part B Eng. 2017, 117, 49–60. [Google Scholar] [CrossRef]

- Sfarra, S.; Perilli, S.; Ambrosini, D.; Paoletti, D.; Nardi, I.; de Rubeis, T.; Santulli, C. A proposal of a new material for greenhouses on the basis of numerical, optical, thermal and mechanical approaches. Constr. Build. Mater. 2017, 155, 332–347. [Google Scholar] [CrossRef]

- Paynter, R.J.H.; Dutton, A.G. The use of a second harmonic correlation to detect damage in composite structures using thermoelastic stress measurements. Strain 2003, 39, 73–78. [Google Scholar] [CrossRef]

- Jones, R.; Molent, L. Application of constitutive modeling and advanced repair technology to F111C aircraft. Compos. Struct. 2004, 66, 145–157. [Google Scholar] [CrossRef]

- Emery, T.R.; Dulieu-Barton, J.M. Thermoelastic Stress Analysis of damage mechanisms in composite materials. Compos. Part A 2010, 41, 1729–1742. [Google Scholar] [CrossRef]

- Fruehmann, R.K.; Dulieu-Barton, J.M.; Quinn, S. Assessment of fatigue damage evolution in woven composite materials using infra-red techniques. Compos. Sci. Technol. 2010, 70, 937–946. [Google Scholar] [CrossRef]

- Uenoya, T.; Fujii, T. Damage characterization of woven fabric composite materials by thermoelastic analysis. J. Soc. Mater. Sci. Jpn. 2000, 49, 941–947. [Google Scholar] [CrossRef]

- Yoshida, T.; Uenoya, T.; Miyamoto, H. Impact damage characterization in cross-plied carbon fiber/ thermoplastic composites using thermoelastic stress analysis. Proc. SPIE 2012, 8347. [Google Scholar] [CrossRef]

- Sakagami, T.; Shiozawa, D.; Nakamura, Y.; Nonaka, S.; Hamada, K. Fatigue damage evaluation of short fiber CFRP based on phase information of thermoelastic temperature change. Proc. SPIE 2017, 10214. [Google Scholar] [CrossRef]

- Thomson, W. On the dynamical theory of heat. Trans. R. Soc. 1853, 20, 261–283. [Google Scholar]

- Enomae, T. FiberOri8single03.exe. Available online: http://www.enomae.com/FiberOri/index.htm (accessed on 4 December 2017).

- Sugimoto, S.; Ishikawa, T. Examination of quantitative infrared stress measurement of CFRP laminates and its application to non-destructive evaluation. Tech. Rep. Natl. Aerosp. Lab. 1999, 1396, 1–23. [Google Scholar]

| Infrared Detector | MCT |

|---|---|

| Detectable wavelength | 7.7–9.3 μm |

| Number of detectors | 320 × 256 |

| Temperature resolution (NETD) | 25 mK |

| Framing rate | 373 Hz |

| Time of data acquisition | 10 s |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shiozawa, D.; Sakagami, T.; Nakamura, Y.; Nonaka, S.; Hamada, K. Fatigue Damage Evaluation of Short Carbon Fiber Reinforced Plastics Based on Phase Information of Thermoelastic Temperature Change. Sensors 2017, 17, 2824. https://doi.org/10.3390/s17122824

Shiozawa D, Sakagami T, Nakamura Y, Nonaka S, Hamada K. Fatigue Damage Evaluation of Short Carbon Fiber Reinforced Plastics Based on Phase Information of Thermoelastic Temperature Change. Sensors. 2017; 17(12):2824. https://doi.org/10.3390/s17122824

Chicago/Turabian StyleShiozawa, Daiki, Takahide Sakagami, Yu Nakamura, Shinichi Nonaka, and Kenichi Hamada. 2017. "Fatigue Damage Evaluation of Short Carbon Fiber Reinforced Plastics Based on Phase Information of Thermoelastic Temperature Change" Sensors 17, no. 12: 2824. https://doi.org/10.3390/s17122824

APA StyleShiozawa, D., Sakagami, T., Nakamura, Y., Nonaka, S., & Hamada, K. (2017). Fatigue Damage Evaluation of Short Carbon Fiber Reinforced Plastics Based on Phase Information of Thermoelastic Temperature Change. Sensors, 17(12), 2824. https://doi.org/10.3390/s17122824