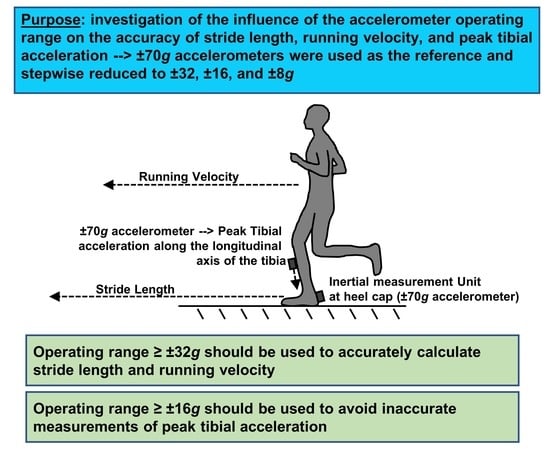

The Effect of the Accelerometer Operating Range on Biomechanical Parameters: Stride Length, Velocity, and Peak Tibial Acceleration during Running

Abstract

:1. Introduction

2. Materials and Methods

2.1. Participants

2.2. Test Procedure

2.3. Experimental Setup

2.4. Data Analyses

2.5. Footwear Conditions

2.6. Statistical Analyses

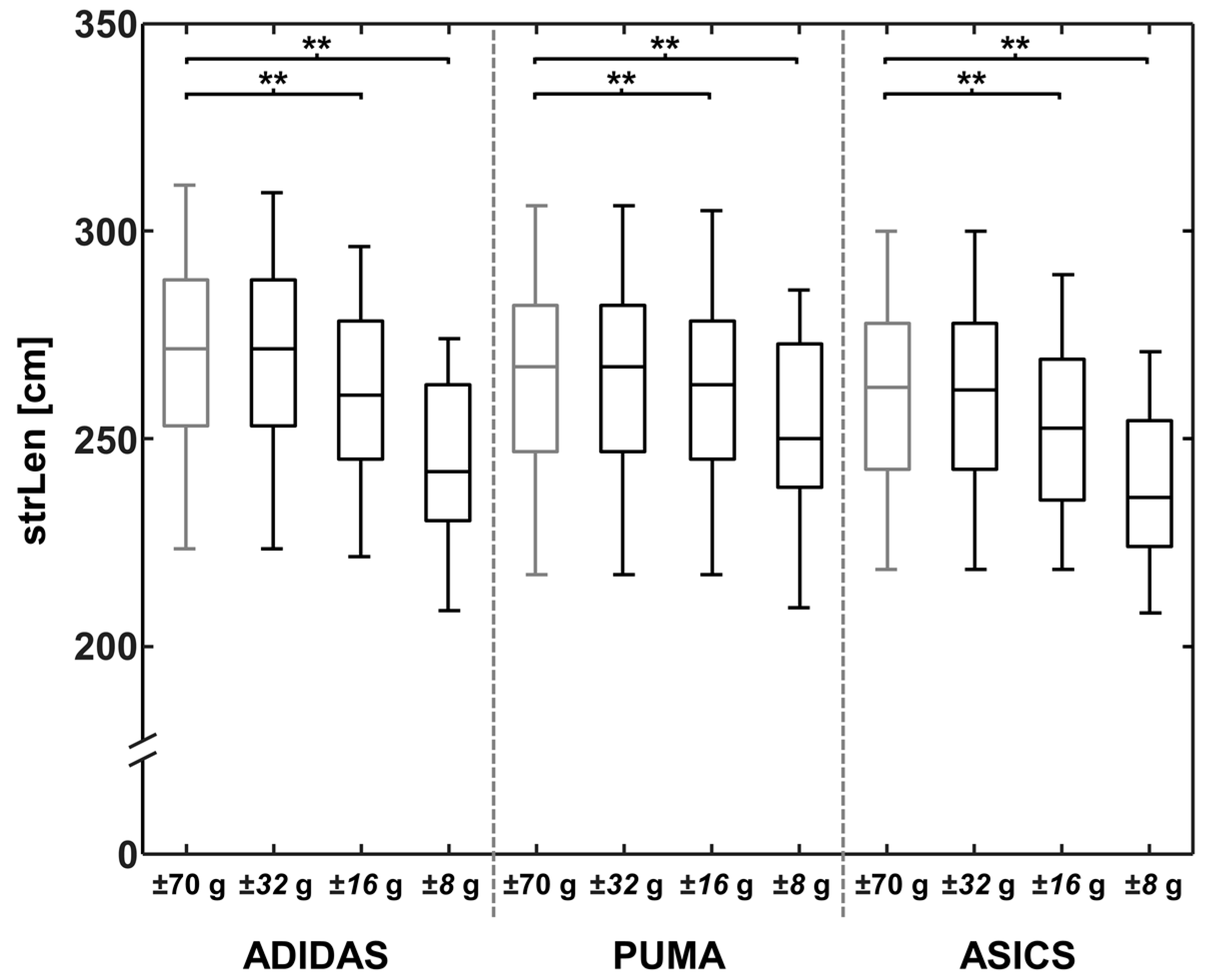

3. Results

3.1. Footwear Characteristics

3.2. Biomechanical Parameters: Stride Length, Running Velocity, and Peak Tibial Acceleration

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tao, W.; Liu, T.; Zheng, R.; Feng, H. Gait analysis using wearable sensors. Sensors 2012, 12, 2255–2283. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Inoue, Y.; Shibata, K. Development of a wearable sensor system for quantitative gait analysis. Measurement 2009, 42, 978–988. [Google Scholar] [CrossRef]

- Mayagoitia, R.E.; Nene, A.V.; Veltink, P.H. Accelerometer and rate gyroscope measurement of kinematics: An inexpensive alternative to optical motion analysis systems. J. Biomech. 2002, 35, 537–542. [Google Scholar] [CrossRef]

- Mitschke, C.; Öhmichen, M.; Milani, T.L. A single gyroscope can be used to accurately determine peak eversion velocity during locomotion at different speeds and in various shoes. Appl. Sci. 2017, 7, 659. [Google Scholar] [CrossRef]

- Mitschke, C.; Heß, T.; Milani, T.L. Which method detects foot strike in rearfoot and forefoot runners accurately when using an inertial measurement unit? Appl. Sci. 2017, 7, 959. [Google Scholar] [CrossRef]

- Shih, Y.; Ho, C.-S.; Shiang, T.-Y. Measuring kinematic changes of the foot using a gyro sensor during intense running. J. Sports Sci. 2014, 32, 550–566. [Google Scholar] [CrossRef] [PubMed]

- Clark, R.A.; Bartold, S.; Bryant, A.L. Tibial acceleration variability during consecutive gait cycles is influenced by the menstrual cycle. Clin. Biomech. 2010, 25, 557–562. [Google Scholar] [CrossRef] [PubMed]

- Chambon, N.; Sevrez, V.; Ly, Q.H.; Guéguen, N.; Berton, E.; Rao, G. Aging of running shoes and its effect on mechanical and biomechanical variables: Implications for runners. J. Sports Sci. 2014, 32, 1013–1022. [Google Scholar] [CrossRef] [PubMed]

- Mizrahi, J.; Verbitsky, O.; Isakov, E.; Daily, D. Effect of fatigue on leg kinematics and impact acceleration in long distance running. Hum. Mov. Sci. 2000, 19, 139–151. [Google Scholar] [CrossRef]

- Montgomery, G.; Abt, G.; Dobson, C.; Smith, T.; Ditroilo, M. Tibial impacts and muscle activation during walking, jogging and running when performed overground, and on motorised and non-motorised treadmills. Gait Posture 2016, 49, 120–126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gruber, A.H.; Boyer, K.A.; Derrick, T.R.; Hamill, J. Impact shock frequency components and attenuation in rearfoot and forefoot running. J. Sport Health Sci. 2014, 3, 113–121. [Google Scholar] [CrossRef]

- Milani, T.L.; Hennig, E.M.; Lafortune, M. Perceptual and biomechanical variables for running in identical shoe constructions with varying midsole hardness. Clin. Biomech. 1997, 12, 294–300. [Google Scholar] [CrossRef]

- Mercer, J.A.; Vance, J.; Hreljac, A.; Hamill, J. Relationship between shock attenuation and stride length during running at different velocities. Eur. J. Appl. Physiol. 2002, 87, 403–408. [Google Scholar] [CrossRef] [PubMed]

- Mercer, J.A.; Bates, B.T.; Dufek, J.S.; Hreljac, A. Characteristics of shock attenuation during fatigued running. J. Sports Sci. 2003, 21, 911–919. [Google Scholar] [CrossRef] [PubMed]

- Heidenfelder, J.; Sterzing, T.; Milani, T.L. Systematically modified crash-pad reduces impact shock in running shoes. Footwear Sci. 2010, 2, 85–91. [Google Scholar] [CrossRef]

- Meardon, S.; Hamill, J.; Derrick, T.R. Running injury and stride time variability over a prolonged run. Gait Posture 2011, 33, 36–40. [Google Scholar] [CrossRef] [PubMed]

- Oriwol, D.; Sterzing, T.; Milani, T.L. The position of medial dual density midsole elements in running shoes does not influence biomechanical variables. Footwear Sci. 2011, 3, 107–116. [Google Scholar] [CrossRef]

- Giandolini, M.; Horvais, N.; Farges, Y.; Samozino, P.; Morin, J.B. Impact reduction through long-term intervention in recreational runners: Midfoot strike pattern versus low-drop/low-heel height footwear. Eur. J. Appl. Physiol. 2013, 113, 2077–2090. [Google Scholar] [CrossRef] [PubMed]

- Sinclair, J.; Hobbs, S.J.; Protheroe, L.; Edmundson, C.J.; Greenhalgh, A. Determination of gait events using an externally mounted shank accelerometer. J. Appl. Biomech. 2013, 29, 118–122. [Google Scholar] [CrossRef] [PubMed]

- García-Pérez, J.A.; Pérez-Soriano, P.; Llana Belloch, S.; Lucas-Cuevas, Á.G.; Sánchez-Zuriaga, D. Effects of treadmill running and fatigue on impact acceleration in distance running. Sports Biomech. 2014, 13, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Sabatini, A.M.; Martelloni, C.; Scapellato, S.; Cavallo, F. Assessment of walking features from foot inertial sensing. IEEE Trans. Biomed. Eng. 2005, 52, 486–494. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mercer, J.A.; Chona, C. Stride length-velocity relationship during running with body weight support. J. Sport Health Sci. 2015, 4, 127–131. [Google Scholar] [CrossRef]

- Yang, S.; Mohr, C.; Li, Q. Ambulatory running speed estimation using an inertial sensor. Gait Posture 2011, 34, 462–466. [Google Scholar] [CrossRef] [PubMed]

- Reenalda, J.; Maartens, E.; Homan, L.; Buurke, J.H. Continuous three dimensional analysis of running mechanics during a marathon by means of inertial magnetic measurement units to objectify changes in running mechanics. J. Biomech. 2016, 49, 3362–3367. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, T.; Saito, H.; Koike, E.; Nitta, K. A preliminary test of measurement of joint angles and stride length with wireless inertial sensors for wearable gait evaluation system. Comput. Intell. Neurosci. 2011, 2011, 6. [Google Scholar] [CrossRef] [PubMed]

- Provot, T.; Chiementin, X.; Oudin, E.; Bolaers, F.; Murer, S. Validation of a high sampling rate inertial measurement unit for acceleration during running. Sensors 2017, 17, 1958. [Google Scholar] [CrossRef] [PubMed]

- Fong, D.T.P.; Chan, Y.Y. The use of wearable inertial motion sensors in human lower limb biomechanics studies: A systematic review. Sensors 2010, 10, 11556–11565. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, S.; Li, Q. Inertial sensor-based methods in walking speed estimation: A systematic review. Sensors 2012, 12, 6102–6116. [Google Scholar] [CrossRef] [PubMed]

- Alvarez, J.C.; González, R.C.; Alvarez, D.; López, A.M.; Rodríguez-Uría, J. Multisensor approach to walking distance estimation with foot inertial sensing. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology, Lyon, France, 22–26 August 2007; pp. 5719–5722. [Google Scholar]

- Jasiewicz, J.M.; Allum, J.H.J.; Middleton, J.W.; Barriskill, A.; Condie, P.; Purcell, B.; Li, R.C.T. Gait event detection using linear accelerometers or angular velocity transducers in able-bodied and spinal-cord injured individuals. Gait Posture 2006, 24, 502–509. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zifchock, R.A.; Davis, I.; Higginson, J.; McCaw, S.; Royer, T. Side-to-side differences in overuse running injury susceptibility: A retrospective study. Hum. Mov. Sci. 2008, 27, 888–902. [Google Scholar] [CrossRef] [PubMed]

- Mitschke, C.; Zaumseil, F.; Milani, T.L. The influence of inertial sensor sampling frequency on the accuracy of measurement parameters in rearfoot running. Comput. Methods Biomech. Biomed. Eng. 2017, 20, 1502–1511. [Google Scholar] [CrossRef] [PubMed]

- Ziebart, C.; Giangregorio, L.M.; Gibbs, J.C.; Levine, I.C.; Tung, J.; Laing, A.C. Measurement of peak impact loads differ between accelerometers—Effects of system operating range and sampling rate. J. Biomech. 2017, 58, 222–226. [Google Scholar] [CrossRef] [PubMed]

- Lieberman, D.E.; Venkadesan, M.; Werbel, W.A.; Daoud, A.I.; D’Andrea, S.; Davis, I.S.; Mang’eni, R.O.; Pitsiladis, Y. Foot strike patterns and collision forces in habitually barefoot versus shod runners. Nature 2010, 463, 531–535. [Google Scholar] [CrossRef] [PubMed]

- Hennig, E.M.; Milani, T.L.; Lafortune, M. Use of ground reaction force parameters in predicting peak tibial accelerations in running. J. Appl. Biomech. 1993, 9, 214–306. [Google Scholar] [CrossRef] [PubMed]

- Maiwald, C.; Dannemann, A.; Gaudel, J.; Oriwol, D. A simple method to detect stride intervals in continuous acceleration and gyroscope data recorded during treadmill running. Footwear Sci. 2015, 7, 143–144. [Google Scholar] [CrossRef]

- Peruzzi, A.; Della Croce, U.; Cereatti, A. Estimation of stride length in level walking using an inertial measurement unit attached to the foot: A validation of the zero velocity assumption during stance. J. Biomech. 2011, 44, 1991–1994. [Google Scholar] [CrossRef] [PubMed]

- Hamacher, D.; Hamacher, D.; Taylor, W.R.; Singh, N.B.; Schega, L. Towards clinical application: Repetitive sensor position re-calibration for improved reliability of gait parameters. Gait Posture 2014, 39, 1146–1148. [Google Scholar] [CrossRef] [PubMed]

- Schwanitz, S.; Odenwald, S. Long-term cushioning properties of running shoes (P152). In The Engineering of Sport 7; Springer: Paris, France, 2008; pp. 95–100. [Google Scholar]

- Brückner, K.; Odenwald, S.; Schwanitz, S.; Heidenfelder, J.; Milani, T. Polyurethane-foam midsoles in running shoes—Impact energy and damping. Procedia Eng. 2010, 2, 2789–2793. [Google Scholar] [CrossRef]

- Heidenfelder, J. Entwicklung Eines Dynamischen Tests zur Prüfung der Rückfußdämpfung von Laufschuhen Mittels Biomechanischer Messmethoden; TU Chemnitz: Chemnitz, Germany, 2011. [Google Scholar]

- Cohen, J. Quantitative methods in psychology. Psychol. Bull. 1992, 112, 155–159. [Google Scholar] [CrossRef] [PubMed]

- Strohrmann, C.; Harms, H.; Kappeler-Setz, C.; Tröster, G. Monitoring kinematic changes with fatigue in running using body-worn sensors. IEEE Trans. Inf. Technol. Biomed. 2012, 16, 983–990. [Google Scholar] [CrossRef] [PubMed]

- Mcnair, P.J.; Marshall, R.N. Kinematic and kinetic parameters associated with running in different shoes. Br. J. Sports Med. 1994, 28, 256–261. [Google Scholar] [CrossRef] [PubMed]

- Lucas-Cuevas, A.G.; Encarnación-Martínez, A.; Camacho-García, A.; Llana-Belloch, S.; Pérez-Soriano, P. The location of the tibial accelerometer does influence impact acceleration parameters during running. J. Sports Sci. 2017, 35, 1734–1738. [Google Scholar] [CrossRef] [PubMed]

| Footwear Condition | Stiffness (N/mm) | |

|---|---|---|

| Mean | SD | |

| ADIDAS | 210.3 | 0.4 |

| PUMA | 177.8 | 0.4 |

| ASICS | 156.9 | 0.1 |

| Footwear Condition | ADIDAS | PUMA | ASICS | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Operating ranges | ±70–±32 g | ±70–±16 g | ±70–±8 g | ±70–±32 g | ±70–±16 g | ±70–±8 g | ±70–±32 g | ±70–±16 g | ±70–±8 g |

| runVel | |||||||||

| MD (cm) | 0.01 | 0.13 | 0.36 | 0.00 | 0.04 | 0.18 | 0.00 | 0.09 | 0.29 |

| MD_rel (%) | 0.14 | 3.48 | 9.68 | 0.00 | 1.00 | 4.88 | 0.05 | 2.64 | 8.18 |

| p | 0.029 | <0.001 | <0.001 | 1 | <0.001 | <0.001 | 0.110 | <0.001 | <0.001 |

| Cohen’s d | - | 0.86 | 0.95 | - | 0.84 | 0.92 | - | 0.85 | 0.94 |

| RMSE (cm) | 0.01 | 0.11 | 0.27 | 0.00 | 0.03 | 0.14 | 0.00 | 0.08 | 0.22 |

| strLen | |||||||||

| MD (m/s) | 0.38 | 9.43 | 26.15 | 0.00 | 2.62 | 12.87 | 0.12 | 6.92 | 21.22 |

| MD_rel (%) | 0.14 | 3.49 | 9.68 | 0.00 | 0.99 | 4.85 | 0.05 | 2.67 | 8.17 |

| p | 0.024 | <0.001 | <0.001 | 1 | <0.001 | <0.001 | 0.096 | <0.001 | <0.001 |

| Cohen’s d | - | 0.86 | 0.95 | - | 0.84 | 0.92 | - | 0.85 | 0.94 |

| RMSE (m/s) | 0.57 | 7.75 | 19.44 | 0.00 | 2.19 | 9.88 | 0.23 | 5.75 | 15.98 |

| PTA | |||||||||

| MD (g) | 0.00 | 0.59 | 2.65 | 0.00 | 0.31 | 2.08 | 0.00 | 0.00 | 0.61 |

| MD_rel (%) | 0.00 | 6.25 | 28.17 | 0.00 | 3.48 | 23.02 | 0.00 | 0.04 | 9.76 |

| p | 1 | 0.043 | 0.002 | 1 | 0.109 | <0.001 | 1 | 0.317 | 0.005 |

| Cohen’s d | - | - | 0.65 | - | - | 0.77 | - | - | 0.60 |

| RMSE (g) | 0.00 | 1.23 | 3.39 | 0.00 | 0.83 | 2.72 | 0.00 | 0.01 | 1.13 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitschke, C.; Kiesewetter, P.; Milani, T.L. The Effect of the Accelerometer Operating Range on Biomechanical Parameters: Stride Length, Velocity, and Peak Tibial Acceleration during Running. Sensors 2018, 18, 130. https://doi.org/10.3390/s18010130

Mitschke C, Kiesewetter P, Milani TL. The Effect of the Accelerometer Operating Range on Biomechanical Parameters: Stride Length, Velocity, and Peak Tibial Acceleration during Running. Sensors. 2018; 18(1):130. https://doi.org/10.3390/s18010130

Chicago/Turabian StyleMitschke, Christian, Pierre Kiesewetter, and Thomas L. Milani. 2018. "The Effect of the Accelerometer Operating Range on Biomechanical Parameters: Stride Length, Velocity, and Peak Tibial Acceleration during Running" Sensors 18, no. 1: 130. https://doi.org/10.3390/s18010130

APA StyleMitschke, C., Kiesewetter, P., & Milani, T. L. (2018). The Effect of the Accelerometer Operating Range on Biomechanical Parameters: Stride Length, Velocity, and Peak Tibial Acceleration during Running. Sensors, 18(1), 130. https://doi.org/10.3390/s18010130