Comparison of Inspecting Non-Ferromagnetic and Ferromagnetic Metals Using Velocity Induced Eddy Current Probe

Abstract

:1. Introduction

2. Velocity Induced Eddy Current Method

3. Experimental Tests

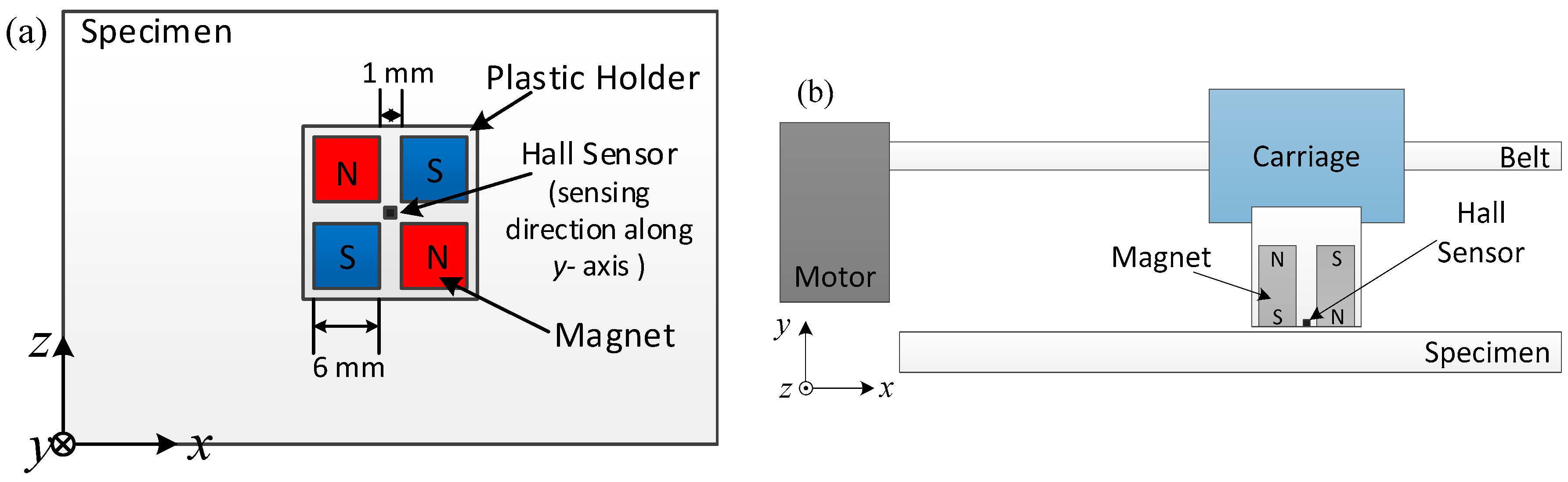

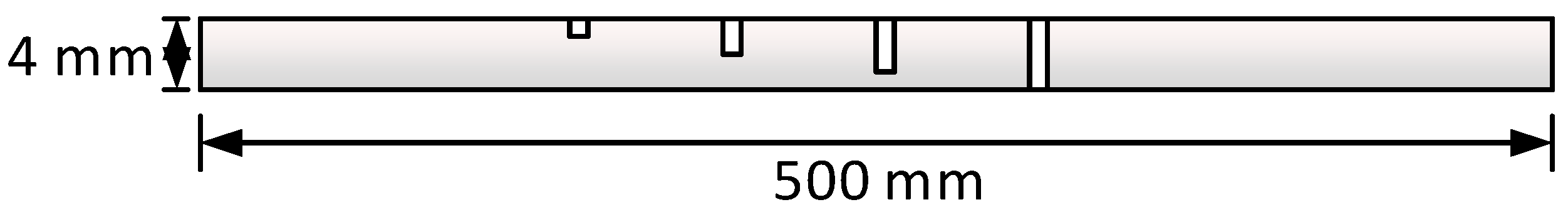

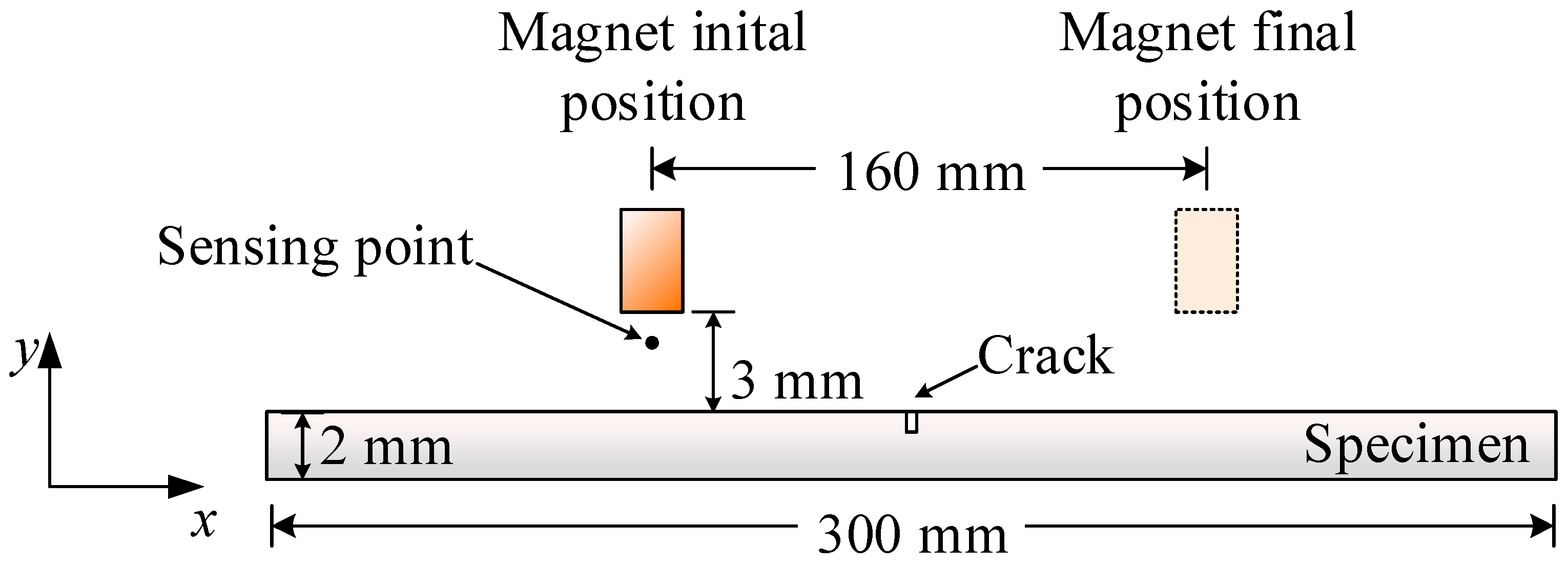

3.1. Experimental Setup

3.2. Inspection of Aluminum Plates

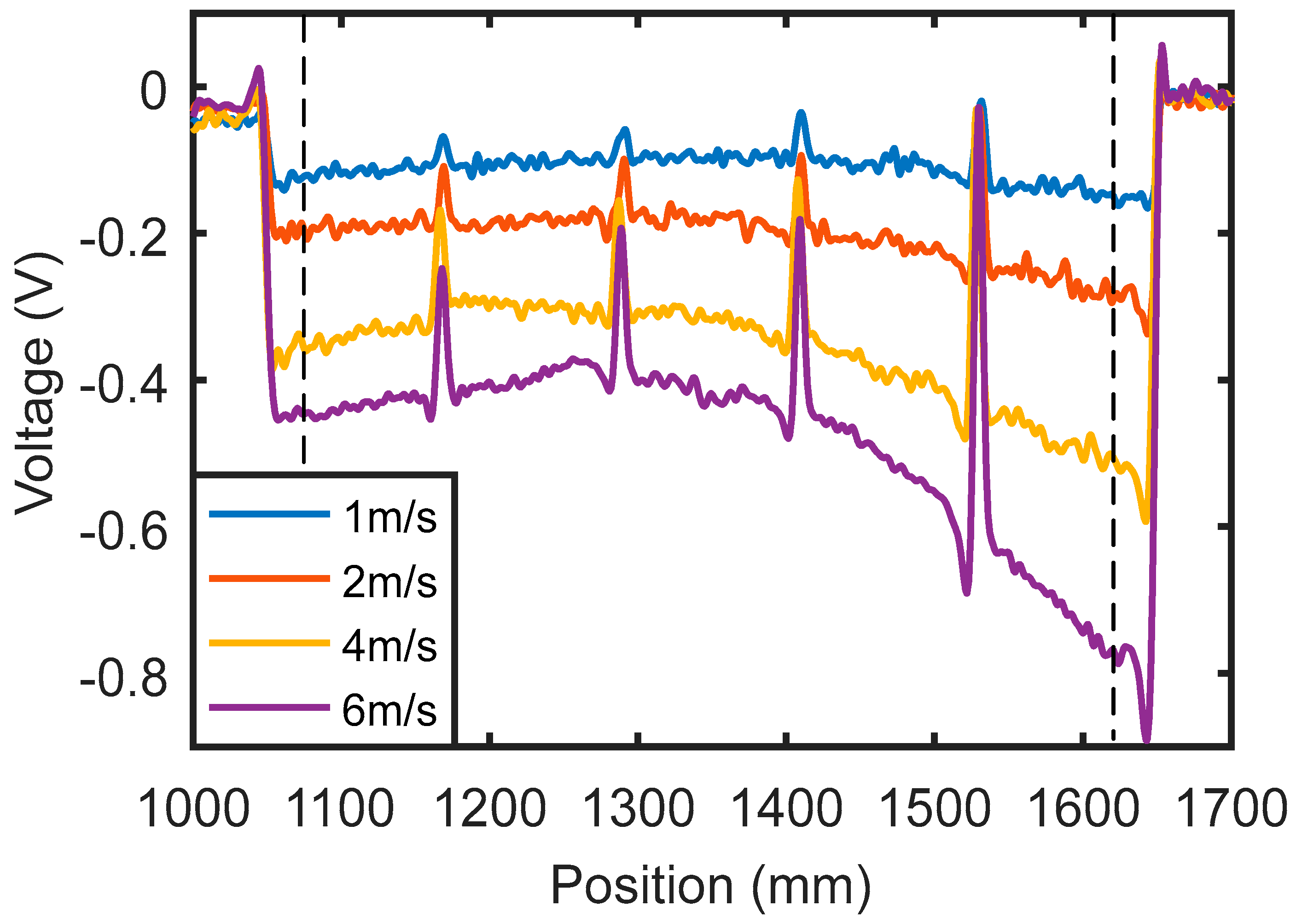

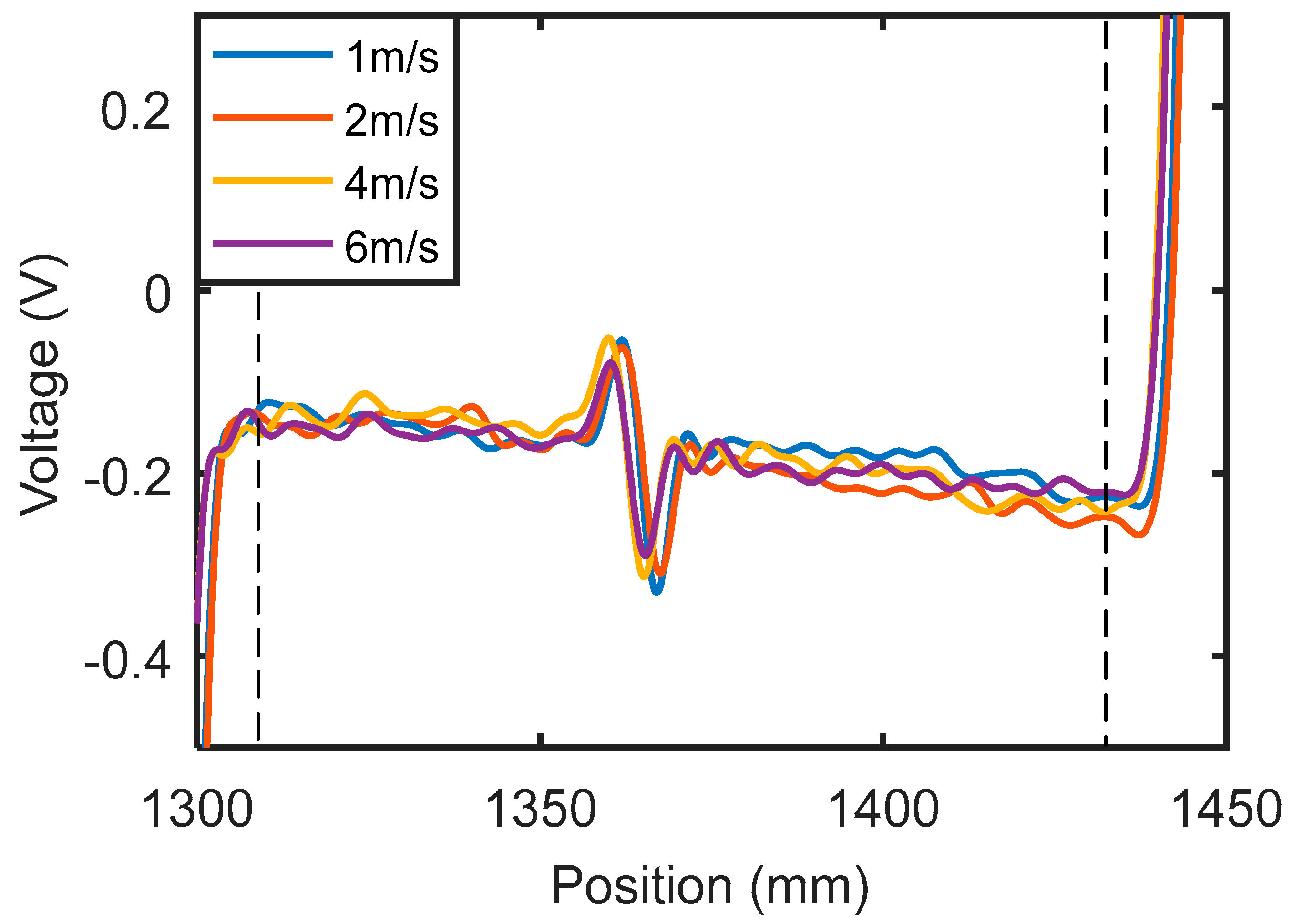

3.3. Inspection of Steel Plates

4. Finite Element Simulations

4.1. Finite Element Model

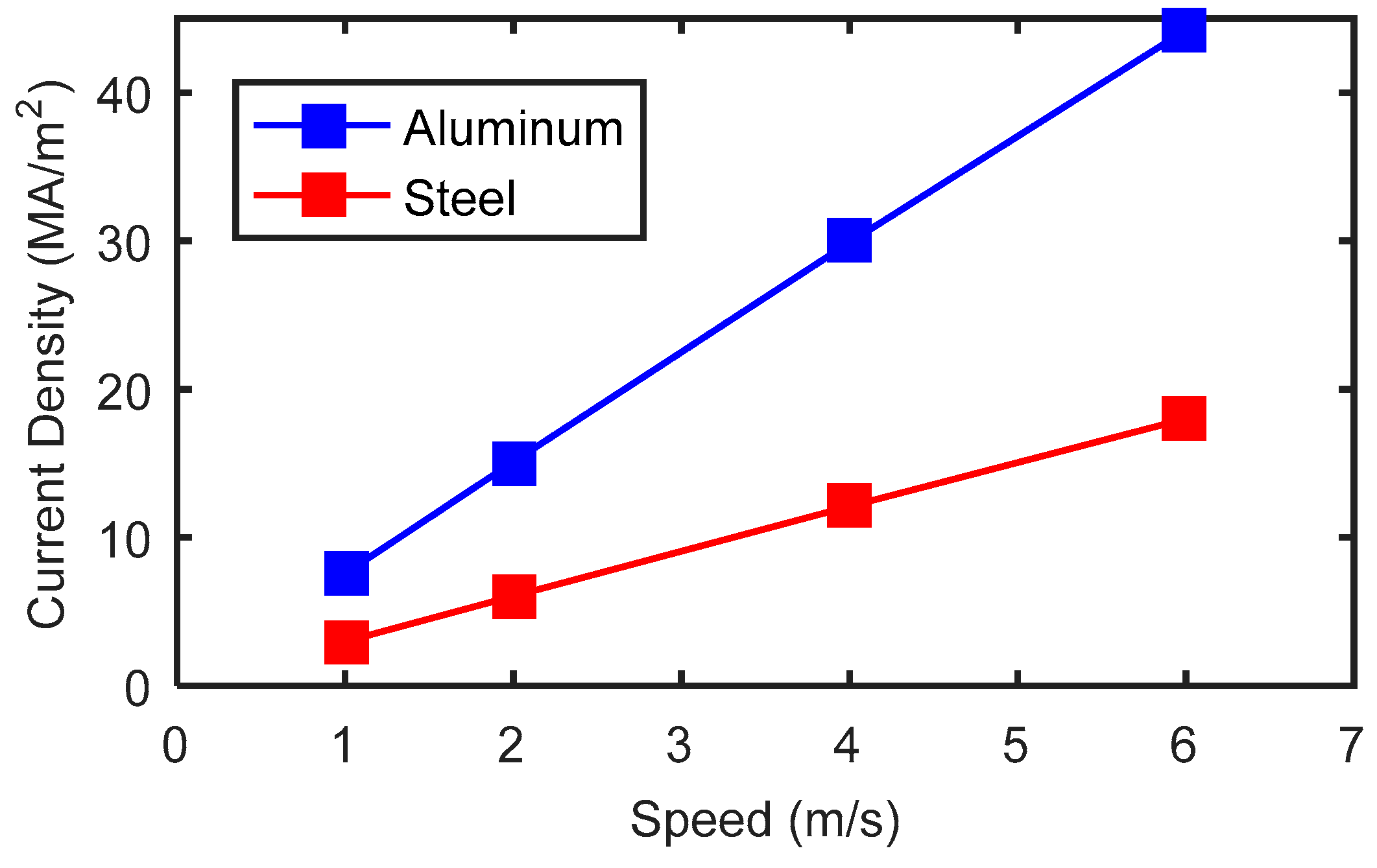

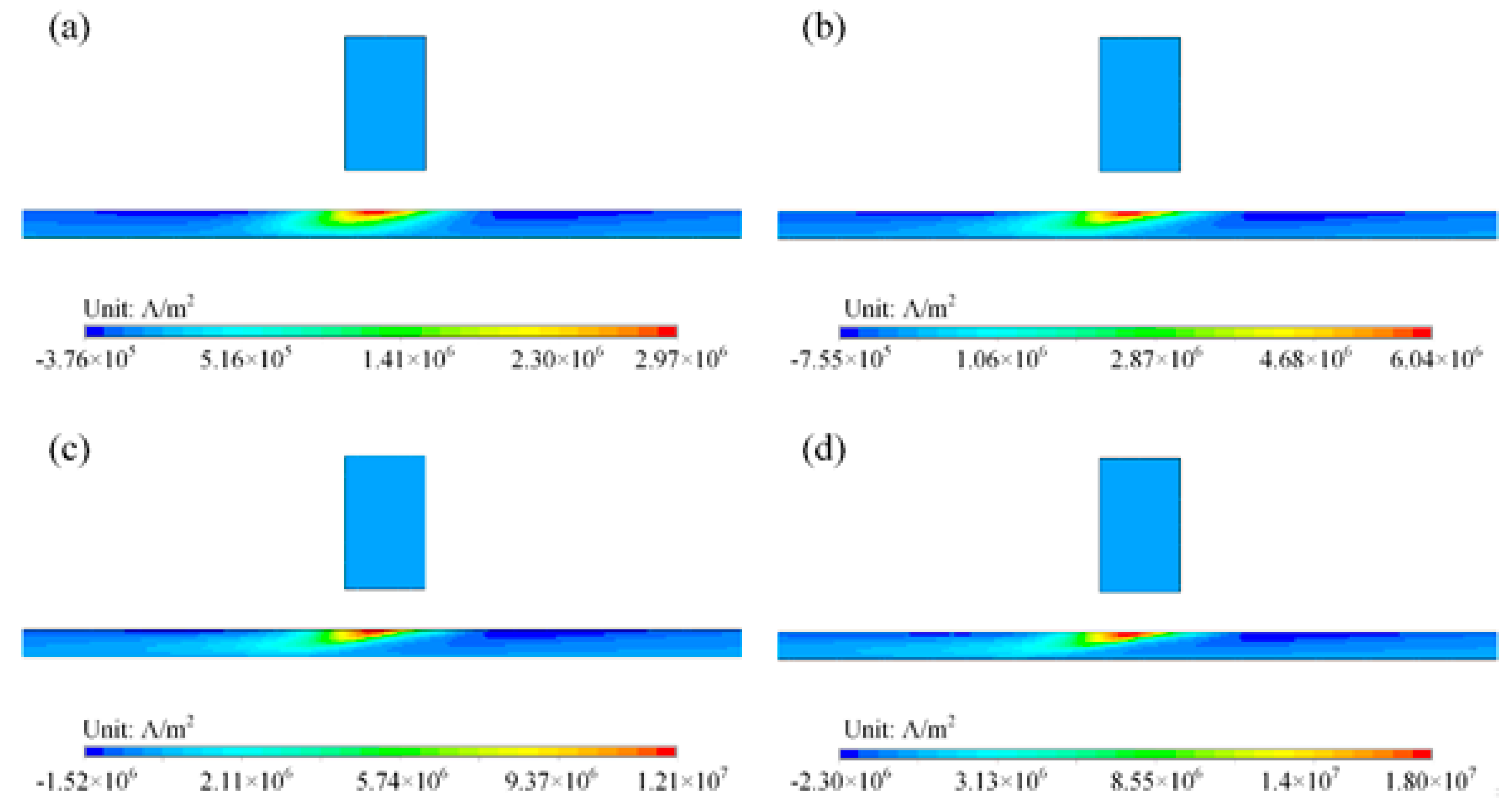

4.2. Aluminum Plates

4.3. Steel Plates

5. Conclusions

- The velocity induced eddy current probe can detect cracks in aluminum plates. The velocity induced eddy current inside the aluminum plate is approximately proportional to the speed of the moving magnet. The inspection signal amplitude increases with crack depth and probe speed.

- The velocity induced eddy current probe can detect cracks in steel plates. The experimental results show that the signal amplitude does not increase linearly with probe speed, which means that the signal is not caused by eddy current. Two effects, namely the eddy current effect and direct magnetic field perturbation, exist when inspecting steel plates. The simulation results show that the signals obtained with and without eddy currents have almost the same amplitude, which means that the direct magnetic field perturbation is responsible for the crack detection in steel plates.

Author Contributions

Funding

Conflicts of Interest

References

- Mix, P.E. Introduction to Nondestructive Testing: A Training Guide, 2nd ed.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Rao, B.P.B. Practical Eddy Current Testing; Alpha Science International Limited: Oxford, UK, 2006. [Google Scholar]

- Pasadas, D.J.; Ribeiro, A.L.; Ramos, H.G.; Rocha, T.J. Inspection of Cracks in Aluminum Multilayer Structures Using Planar ECT Probe and Inversion Problem. IEEE Trans. Instrum. Meas. 2017, 66, 920–927. [Google Scholar] [CrossRef]

- He, Y.; Luo, F.; Pan, M.; Weng, F.; Hu, X.; Gao, J.; Liu, B. Pulsed eddy current technique for defect detection in aircraft riveted structures. NDT E Int. 2010, 43, 176–181. [Google Scholar] [CrossRef]

- Tian, G.Y.; Sophian, A.; Taylor, D.; Rudlin, J. Multiple sensors on pulsed eddy-current detection for 3-D subsurface crack assessment. IEEE Sens. J. 2005, 5, 90–96. [Google Scholar] [CrossRef]

- Ribeiro, A.L.; Ramos, H.G. Inductive probe for flaw detection in non-magnetic metallic plates using eddy currents. In Proceedings of the Instrumentation and Measurement Technology Conference, Victoria, BC, Canada, 12–15 May 2008. [Google Scholar]

- Rocha, T.J.; Ramos, H.G.; Ribeiro, A.L.; Pasadas, D.J. Magnetic sensors assessment in velocity induced eddy current testing. Sens. Actuator A Phys. 2015, 228, 55–61. [Google Scholar] [CrossRef]

- Feng, B.; Kang, Y.; Sun, Y. Theoretical Analysis and Numerical Simulation of the Feasibility of Inspecting Nonferromagnetic Conductors by an MFL Testing Apparatus. Res. Nondestruct. Eval. 2016, 27, 100–111. [Google Scholar] [CrossRef]

- Weise, K.; Schmidt, R.; Carlstedt, M.; Ziolkowski, M.; Brauer, H.; Toepfer, H. Optimal magnet design for Lorentz force eddy-current testing. IEEE Trans. Magn. 2015, 51, 1–15. [Google Scholar] [CrossRef]

- Mandayam, S.; Udpa, L.; Udpa, S.S.; Lord, W.I.S.U. Signal processing for in-line inspection of gas transmission pipelines. Res. Nondestruct. Eval. 1996, 8, 233–247. [Google Scholar] [CrossRef]

- Park, G.S.; Park, S.H. Analysis of the velocity-induced eddy current in MFL type NDT. IEEE Trans. Magn. 2004, 40, 663–666. [Google Scholar] [CrossRef]

- Feng, B.; Kang, Y.; Sun, Y.; Yang, Y.; Yan, X. Influence of motion induced eddy current on the magnetization of steel pipe and MFL signal. Int. J. Appl. Electromagn. Mech. 2016, 52, 357–362. [Google Scholar] [CrossRef]

- Li, Y.; Tian, G.Y.; Ward, S. Numerical simulation on magnetic flux leakage evaluation at high speed. NDT E Int. 2006, 39, 367–373. [Google Scholar] [CrossRef]

- Wu, J.; Sun, Y.; Feng, B.; Kang, Y. The effect of motion-induced eddy current on circumferential magnetization in MFL testing for a steel pipe. IEEE Trans. Magn. 2017, 53, 1–6. [Google Scholar] [CrossRef]

- Rocha, T.J. Velocity Induced Eddy Current Testing. Ph.D. Thesis, Instituto Superior Técnico, Lisbon, Portugal, 2017. [Google Scholar]

- Rocha, T.J.; Ramos, H.G.; Ribeiro, A.L.; Pasadas, D.J.; Angani, C.S. Studies to optimize the probe response for velocity induced eddy current testing in aluminium. Measurement 2015, 67, 108–115. [Google Scholar] [CrossRef]

- Rocha, T.J.; Ramos, H.G.; Ribeiro, A.L.; Pasadas, D.J. Evaluation of subsurface defects using diffusion of motion-induced eddy currents. IEEE Trans. Instrum. Meas. 2016, 65, 1182–1187. [Google Scholar] [CrossRef]

- Uhlig, R.P.; Zec, M.; Ziolkowski, M.; Brauer, H.; Thess, A. Lorentz force sigmometry: A contactless method for electrical conductivity measurements. J. Appl. Phys. 2012, 111, 094914. [Google Scholar] [CrossRef] [Green Version]

- Petković, B.; Haueisen, J.; Zec, M.; Uhlig, R.P.; Brauer, H.; Ziolkowski, M. Lorentz force evaluation: A new approximation method for defect reconstruction. NDT E Int. 2013, 59, 57–67. [Google Scholar] [CrossRef]

- Sun, Y.; Kang, Y.; Qiu, C. A new NDT method based on permanent magnetic field perturbation. NDT E Int. 2011, 44, 1–7. [Google Scholar] [CrossRef]

- Aguila-Muñoz, J.; Espina-Hernández, J.H.; Pérez-Benítez, J.A.; Caleyo, F.; Hallen, J.M. A magnetic perturbation GMR-based probe for the nondestructive evaluation of surface cracks in ferromagnetic steels. NDT E Int. 2016, 79, 132–141. [Google Scholar] [CrossRef]

| Speed | Amplitude |

|---|---|

| 1 m/s | 3.7 mT |

| 2 m/s | 3.8 mT |

| 4 m/s | 3.9 mT |

| 6 m/s | 4.0 mT |

| Without eddy current | 3.6 mT |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, B.; Ribeiro, A.L.; Rocha, T.J.; Ramos, H.G. Comparison of Inspecting Non-Ferromagnetic and Ferromagnetic Metals Using Velocity Induced Eddy Current Probe. Sensors 2018, 18, 3199. https://doi.org/10.3390/s18103199

Feng B, Ribeiro AL, Rocha TJ, Ramos HG. Comparison of Inspecting Non-Ferromagnetic and Ferromagnetic Metals Using Velocity Induced Eddy Current Probe. Sensors. 2018; 18(10):3199. https://doi.org/10.3390/s18103199

Chicago/Turabian StyleFeng, Bo, Artur L. Ribeiro, Tiago J. Rocha, and Helena G. Ramos. 2018. "Comparison of Inspecting Non-Ferromagnetic and Ferromagnetic Metals Using Velocity Induced Eddy Current Probe" Sensors 18, no. 10: 3199. https://doi.org/10.3390/s18103199

APA StyleFeng, B., Ribeiro, A. L., Rocha, T. J., & Ramos, H. G. (2018). Comparison of Inspecting Non-Ferromagnetic and Ferromagnetic Metals Using Velocity Induced Eddy Current Probe. Sensors, 18(10), 3199. https://doi.org/10.3390/s18103199