A Non-Linear Model of an All-Elastomer, in-Plane, Capacitive, Tactile Sensor Under the Application of Normal Forces

Abstract

:1. Introduction

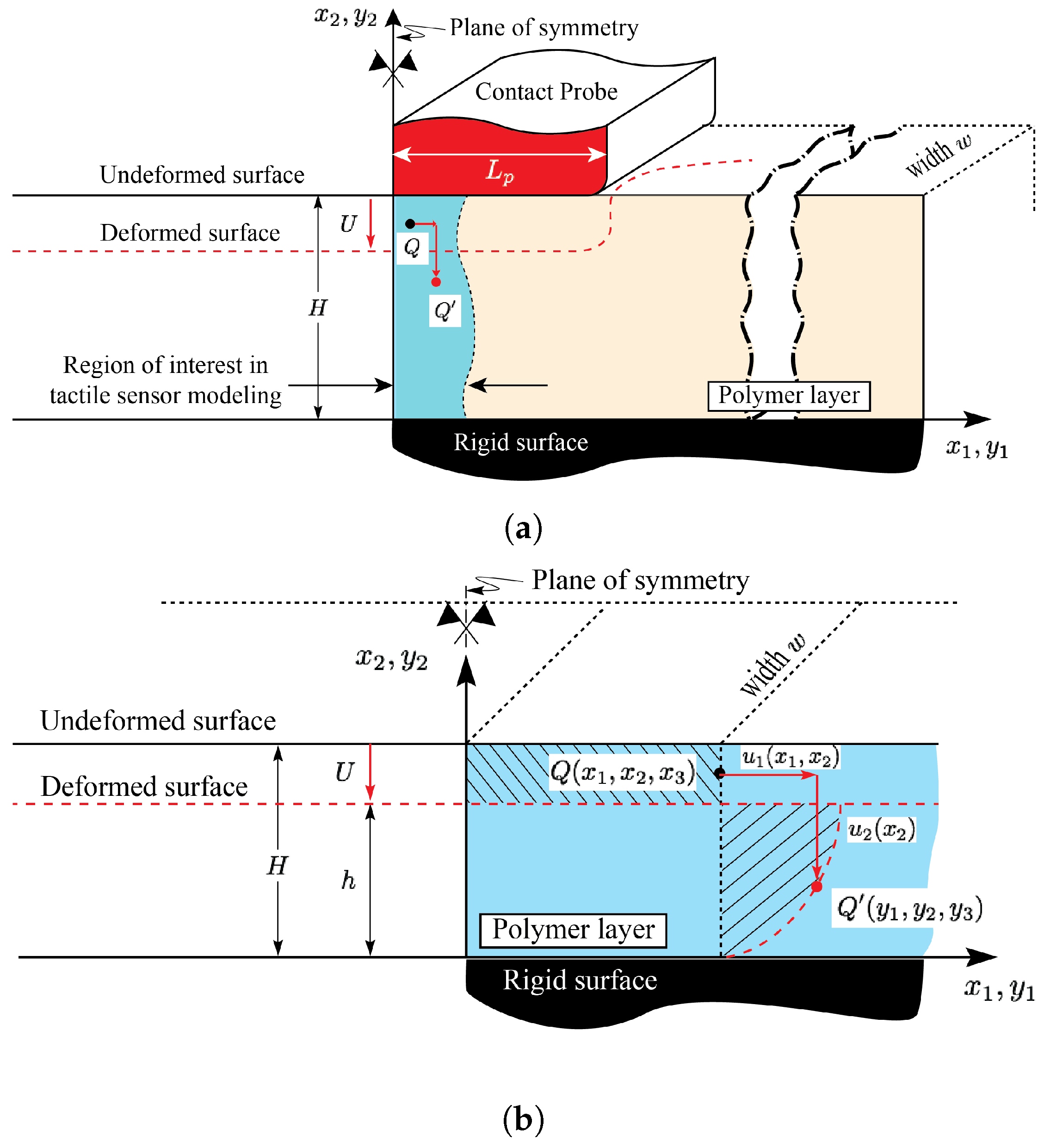

2. Summary of the Finite Flat Punch Indentation Model

2.1. Layer Kinematics

2.2. Stress Analysis

2.3. Contact Force Calculation

3. Tactile Unit-Sensor Model Development

3.1. Dimensions of Fabricated Sensors

3.2. Experimental Results

3.3. Tactile Unit-Sensor Capacitance Estimates

4. Identification of Constitutive Parameters From the Force-Deformation Curves

4.1. Finite Element Modeling

4.2. Inverse Analysis

5. Results and Discussion

5.1. The Sensor-Probe Contact Force

5.2. The Change in Capacitance-Applied Force Curves

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zou, L.; Ge, C.; Wang, Z.J.; Cretu, E.; Li, X. Novel Tactile Sensor Technology and Smart Tactile Sensing Systems: A Review. Sensors 2017, 17, 2653. [Google Scholar] [CrossRef] [PubMed]

- Chi, C.; Sun, X.; Xue, N.; Li, T.; Liu, C. Recent Progress in Technologies for Tactile Sensors. Sensors 2018, 18, 948. [Google Scholar] [CrossRef] [PubMed]

- Yogeswaran, N.; Dang, W.; Navaraj, W.; Shakthivel, D.; Khan, S.; Polat, E.; Gupta, S.; Heidari, H.; Kaboli, M.; Lorenzelli, L.; et al. New materials and advances in making electronic skin for interactive robots. Adv. Robot. 2015, 29, 1359–1373. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, K.; Sohgawa, M.; Kanashima, T.; Okuyama, M.; Norna, H. Identification of various kinds of papers using multi-axial tactile sensor with micro-cantilevers. In Proceedings of the 2013 World Haptics Conference (WHC), Daejeon, Korea, 14–18 April 2013. [Google Scholar]

- Xu, D.; Loeb, G.E.; Fishel, J.A. Tactile identification of objects using Bayesian exploration. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013. [Google Scholar]

- Friedl, K.E.; Voelker, A.R.; Peer, A.; Eliasmith, C. Human-Inspired Neurorobotic System for Classifying Surface Textures by Touch. IEEE Robot. Autom. Lett. 2016, 1, 516–523. [Google Scholar]

- Kaboli, M.; Cheng, G. Robust Tactile Descriptors for Discriminating Objects From Textural Properties via Artificial Robotic Skin. IEEE Trans. Robot. 2018, 34, 985–1003. [Google Scholar] [CrossRef]

- Kaboli, M.; Yao, K.; Feng, D.; Cheng, G. Tactile-based active object discrimination and target object search in an unknown workspace. Auton. Robot. 2018, 1–30. [Google Scholar] [CrossRef] [Green Version]

- Dahiya, R.; Metta, G.; Valle, M.; Sandini, G. Tactile Sensing—From Humans to Humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar]

- Ji, Z.; Zhu, H.; Liu, H.; Liu, N.; Chen, T.; Yang, Z.; Sun, L. The Design and Characterization of a Flexible Tactile Sensing Array for Robot Skin. Sensors 2016, 16, 2001. [Google Scholar] [CrossRef]

- Dai, C.; Lu, P.; Wu, C.; Chang, C. Fabrication of Wireless Micro Pressure Sensor Using the CMOS Process. Sensors 2009, 9, 8748–8760. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jindal, S.K.; Mahajan, A.; Raghuwanshi, S.K. Reliable before-fabrication forecasting of normal and touch mode MEMS capacitive pressure sensor: modeling and simulation. J. Micro/Nanolithogr. MEMS MOEMS 2017, 16, 1. [Google Scholar] [CrossRef]

- Parthasarathy, E.S.M. Modeling and analysis of MEMS capacitive differential pressure sensor structure for altimeter application. Microsyst. Technol. 2017, 23, 1343–1349. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Lin, C.L.; Lai, Y.T.; Yang, Y.J. A polymer-based capacitive sensing array for normal and shear force measurement. Sensors 2010, 10, 10211–10225. [Google Scholar] [CrossRef] [PubMed]

- Liu, C. Recent Developments in Polymer MEMS. Adv. Mater. 2007, 19, 3783–3790. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, Y.; Nomani, M.W.; Wen, X.; Hsia, T.Y.; Koley, G. A highly sensitive pressure sensor using a Au-patterned polydimethylsiloxane membrane for biosensing applications. J. Micromech. Microeng. 2013, 23, 025022. [Google Scholar] [CrossRef]

- Kilaru, R.; Celik-Butler, Z.; Butler, D.P.; Gonenli, I.E. NiCr MEMS Tactile Sensors Embedded in Polyimide Toward Smart Skin. J. Microelectromech. Syst. 2013, 22, 349–355. [Google Scholar] [CrossRef]

- Pyo, S.; Lee, J.I.; Kim, M.O.; Chung, T.; Oh, Y.; Lim, S.C.; Park, J.; Kim, J. Development of a flexible three-axis tactile sensor based on screen-printed carbon nanotube-polymer composite. J. Micromech. Microeng. 2014, 24, 075012. [Google Scholar] [CrossRef]

- Maita, F.; Maiolo, L.; Minotti, A.; Pecora, A.; Ricci, D.; Metta, G.; Scandurra, G.; Giusi, G.; Ciofi, C.; Fortunato, G. Ultraflexible Tactile Piezoelectric Sensor Based on Low-Temperature Polycrystalline Silicon Thin-Film Transistor Technology. IEEE Sens. J. 2015, 15, 3819–3826. [Google Scholar] [CrossRef]

- Park, Y.L.; Chen, B.R.; Wood, R.J. Design and Fabrication of Soft Artificial Skin Using Embedded Microchannels and Liquid Conductors. IEEE Sens. J. 2012, 12, 2711–2718. [Google Scholar] [CrossRef]

- Kim, K.; Lee, K.R.; Kim, W.H.; Park, K.B.; Kim, T.H.; Kim, J.S.; Pak, J.J. Polymer-based flexible tactile sensor up to 32*32 arrays integrated with interconnection terminals. Sens. Actuators A Phys. 2009, 156, 284–291. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Tsao, C.M.; Lai, Y.Z.; Yang, Y.J. The development of a highly twistable tactile sensing array with stretchable helical electrodes. Sens. Actuators A Phys. 2011, 166, 226–233. [Google Scholar] [CrossRef]

- Cheng, M.Y.; Huang, X.H.; Ma, C.W.; Yang, Y.J. A flexible capacitive tactile sensing array with floating electrodes. J. Micromech. Microeng. 2009, 19, 115001. [Google Scholar] [CrossRef]

- Seminara, L.; Pinna, L.; Valle, M.; Basirico, L.; Loi, A.; Cosseddu, P.; Bonfiglio, A.; Ascia, A.; Biso, M.; Ansaldo, A.; et al. Piezoelectric Polymer Transducer Arrays for Flexible Tactile Sensors. IEEE Sens. J. 2013, 13, 4022–4029. [Google Scholar] [CrossRef]

- Kim, M.S.; Ahn, H.R.; Lee, S.; Kim, C.; Kim, Y.J. A dome-shaped piezoelectric tactile sensor arrays fabricated by an air inflation technique. Sens. Actuators A Phys. 2014, 212, 151–158. [Google Scholar] [CrossRef]

- Du, W.Y. Resistive, Capacitive, Inductive, and Magnetic Sensor Technologies (Series in Sensors); CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Maiolino, P.; Galantini, F.; Mastrogiovanni, F.; Gallone, G.; Cannata, G.; Carpi, F. Soft dielectrics for capacitive sensing in robot skins: Performance of different elastomer types. Sens. Actuators A Phys. 2015, 226, 37–47. [Google Scholar] [CrossRef]

- Jang, H.; Yoon, H.; Ko, Y.; Choi, J.; Lee, S.; Jeon, I.; Kim, J.; Kim, H. Enhanced performance in capacitive force sensors using carbon nanotube/polydimethylsiloxane nanocomposites with high dielectric properties. Nanoscale 2016, 8, 5667–5675. [Google Scholar] [CrossRef] [PubMed]

- Charalambides, A.; Bergbreiter, S. All-elastomer in-plane MEMS capacitive tactile sensor for normal force detection. In Proceedings of the 2013 IEEE Sensors, Baltimore, MD, USA, 4–6 November 2013; pp. 1–4. [Google Scholar]

- Charalambides, A.; Cheng, J.; Li, T.; Bergbreiter, S. 3-axis all elastomer MEMS tactile sensor. In Proceedings of the 2015 28th IEEE International Conference Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 726–729. [Google Scholar]

- Kalayeh, K.M.; Charalambides, A.; Bergbreiter, S.; Charalambides, P.G. Development and Experimental Validation of a Non-Linear, All-Elastomer In-Plane Capacitive Pressure Sensor Model. IEEE Sens. J. 2017, 17, 274–285. [Google Scholar] [CrossRef]

- Phillips, J.; Johnson, K. Tactile spatial resolution. III. A continuum mechanics model of skin predicting mechanoreceptor responses to bars, edges, and gratings. J. Neurophysiol. 1981, 46, 1204–1225. [Google Scholar] [CrossRef] [PubMed]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Fearing, R.S.; Hollerbach, J.M. Basic solid mechanics for tactile sensing. Int. J. Robot. Res. 1985, 4, 40–54. [Google Scholar] [CrossRef]

- Maier-Schneider, D.; Maibach, J.; Obermeier, E. A new analytical solution for the load-deflection of square membranes. J. Microelectromech. Syst. 1995, 4, 238–241. [Google Scholar] [CrossRef]

- Wang, Q.; Ko, W.H. Modeling of touch mode capacitive sensors and diaphragms. Sens. Actuators A Phys. 1999, 75, 230–241. [Google Scholar] [CrossRef]

- Liang, G.; Deqing, M.; Yancheng, W.; Zichen, C. Modeling and Analysis of a Flexible Capacitive Tactile Sensor Array for Normal Force Measurement. IEEE Sens. J. 2014, 14, 4095–4103. [Google Scholar] [CrossRef]

- Liang, G.; Wang, Y.; Mei, D.; Xi, K.; Chen, Z. A modified analytical model to study the sensing performance of a flexible capacitive tactile sensor array. J. Micromech. Microeng. 2015, 25, 035017. [Google Scholar] [CrossRef]

- Liang, G.; Wang, Y.; Mei, D.; Xi, K.; Chen, Z. An analytical model for studying the structural effects and optimization of a capacitive tactile sensor array. J. Micromech. Microeng. 2016, 26, 045007. [Google Scholar] [CrossRef]

- Vásárhelyi, G.; Fodor, B.; Roska, T. Tactile sensing-processing: Interface-cover geometry and the inverse-elastic problem. Sens. Actuators A Phys. 2007, 140, 8–18. [Google Scholar] [CrossRef]

- Liu, W.; Gu, C.; Zeng, R.; Yu, P.; Fu, X. A Novel Inverse Solution of Contact Force Based on a Sparse Tactile Sensor Array. Sensors 2018, 18, 351. [Google Scholar] [CrossRef]

- Muhammad, H.; Oddo, C.; Beccai, L.; Recchiuto, C.; Anthony, C.; Adams, M.; Carrozza, M.; Hukins, D.; Ward, M. Development of a bioinspired MEMS based capacitive tactile sensor for a robotic finger. Sens. Actuators A Phys. 2011, 165, 221–229. [Google Scholar] [CrossRef]

- Tiwana, M.I.; Shashank, A.; Redmond, S.J.; Lovell, N.H. Characterization of a capacitive tactile shear sensor for application in robotic and upper limb prostheses. Sens. Actuators A Phys. 2011, 165, 164–172. [Google Scholar] [CrossRef]

- Jamali, N.; Sammut, C. Majority Voting: Material Classification by Tactile Sensing Using Surface Texture. IEEE Trans. Robot. 2011, 27, 508–521. [Google Scholar] [CrossRef]

- Decherchi, S.; Gastaldo, P.; Dahiya, R.S.; Valle, M.; Zunino, R. Tactile-Data Classification of Contact Materials Using Computational Intelligence. IEEE Trans. Robot. 2011, 27, 635–639. [Google Scholar] [CrossRef]

- Fishel, J.; Loeb, G. Bayesian exploration for intelligent identification of textures. Front Neurorobot. 2012, 6, 4. [Google Scholar] [CrossRef] [PubMed]

- Yaser, S.A.M.; Magdon-Ismail, M.; Lin, H. Learning from Data: A Short Course. 2012. Available online: AMLBook.com (accessed on 22 October 2018).

- Charalambides, A.; Bergbreiter, S. A novel all-elastomer MEMS tactile sensor for high dynamic range shear and normal force sensing. J. Micromech. Microeng. 2015, 25, 095009. [Google Scholar] [CrossRef]

- Kalayeh, K.M.; Charalambides, P.G. Large deformation mechanics of a soft elastomeric layer under compressive loading for a MEMS tactile sensor application. Int. J. Non-Linear Mech. 2015, 76, 120–134. [Google Scholar] [CrossRef]

- Kalayeh, K.M.; Charalambides, P.G. Large deformation mechanics of a soft elastomeric layer compressed by a finite flat rigid punch for tactile sensor applications. Int. J. Non-Linear Mech. 2018, 106, 115–129. [Google Scholar] [CrossRef]

- MATLAB. Version 9.1.0 (R2016b); The MathWorks Inc.: Natick, MA, USA, 2016. [Google Scholar]

- Gamonpilas, C.; Charalambides, M.; Williams, J.; Dooling, P.; Gibbon, S. Predicting the mechanical behaviour of starch gels through inverse analysis of indentation data. Appl. Rheol. 2010, 20, 33283. [Google Scholar]

- Fellay, L.S.; Fasce, L.A.; Czerner, M.; Pardo, E.; Frontini, P.M. On the Feasibility of Identifying First Order Ogden Constitutive Parameters of Gelatin Gels from Flat Punch Indentation Tests. Soft Mater. 2015, 13, 188–200. [Google Scholar] [CrossRef]

- Feng, Y.; Lee, C.; Sun, L.; Ji, S.; Zhao, X. Characterizing white matter tissue in large strain via asymmetric indentation and inverse finite element modeling. J. Mech. Behav. Biomed. Mater. 2017, 65, 490–501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Habbit Karlsson, S.I. Abaqus Documentation; Dassault Systèmes: Vélizy-Villacoublay, France, 2013. [Google Scholar]

- Lagarias, J.C.; Reeds, J.A.; Wright, M.H.; Wright, P.E. Convergence Properties of the Nelder–Mead Simplex Method in Low Dimensions. SIAM J. Optim. 1998, 9, 112–147. [Google Scholar] [CrossRef]

| U (m) | F (N) | (fF) |

|---|---|---|

| 30 | 0.9021 | 1.3710 |

| 60 | 1.7351 | 2.5004 |

| 90 | 1.5792 | 3.0618 |

| 120 | 3.4213 | 3.8438 |

| 150 | 4.2637 | 4.6920 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

M. Kalayeh, K.; G. Charalambides, P. A Non-Linear Model of an All-Elastomer, in-Plane, Capacitive, Tactile Sensor Under the Application of Normal Forces. Sensors 2018, 18, 3614. https://doi.org/10.3390/s18113614

M. Kalayeh K, G. Charalambides P. A Non-Linear Model of an All-Elastomer, in-Plane, Capacitive, Tactile Sensor Under the Application of Normal Forces. Sensors. 2018; 18(11):3614. https://doi.org/10.3390/s18113614

Chicago/Turabian StyleM. Kalayeh, Kourosh, and Panos G. Charalambides. 2018. "A Non-Linear Model of an All-Elastomer, in-Plane, Capacitive, Tactile Sensor Under the Application of Normal Forces" Sensors 18, no. 11: 3614. https://doi.org/10.3390/s18113614

APA StyleM. Kalayeh, K., & G. Charalambides, P. (2018). A Non-Linear Model of an All-Elastomer, in-Plane, Capacitive, Tactile Sensor Under the Application of Normal Forces. Sensors, 18(11), 3614. https://doi.org/10.3390/s18113614