Spiral Sound Wave Transducer Based on the Longitudinal Vibration

Abstract

:1. Introduction

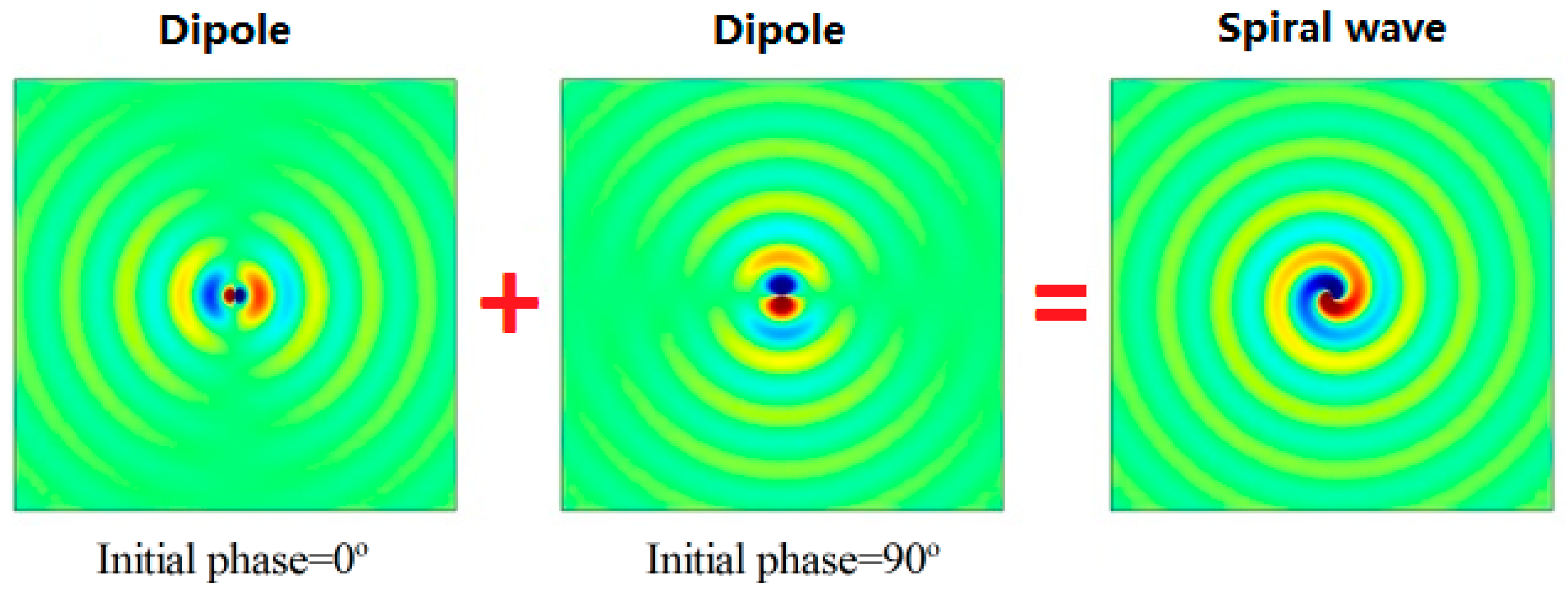

2. The Generation of Spiral Sound Waves

2.1. Mechanism of Spiral Sound Wave Generation

2.2. Excitation Mode of Spiral Sound Wave Transducer

3. Finite Element Simulation of the Spiral Sound Wave Transducer

3.1. The Structure and Size Design of Transducer

3.2. The Finite Element Simulation of Transducer

4. Fabrication and In-Water Testing of Transducer Prototype

4.1. The Measurement of Spiral Sound Field

4.2. The Test of Spiral Acoustic Wave Transducer

5. Conclusions

- (1)

- The transducer was composed of longitudinal vibration piezoelectric elements, which used a d33 piezoelectric coefficient, thus, improving the sound power radiation of the transducer.

- (2)

- The design and manufacture of the longitudinal vibration elements were not limited by the size of the piezoelectric ceramic material, which enabled the transducer to have a lower resonance frequency and thus improved the working distance of the underwater acoustic equipment that used spiral sound waves to achieve positioning and navigation.

- (3)

- The longitudinal vibration piezoelectric elements feature simple manufacturing processes and are of low cost, which made it possible to select longitudinal vibration piezoelectric elements with a consistent performance. These properties ensure the quality of the spiral sound field emitted by the transducer.

Author Contributions

Funding

Conflicts of Interest

Appendix A

- Aluminum alloy:Density: 2790 kg/m3, Young’s modulus: 71.5 GPa, Poisson’s ratio: 0.34.

- Copper:Density: 8960 kg/m3, Young’s modulus: 110 GPa, Poisson’s ratio: 0.35.

- Structure steel:Density: 7850 kg/m3, Young’s modulus: 200 GPa, Poisson’s ratio: 0.30.

- Alumina ceramic:Density: 3800 kg/m3, Young’s modulus: 350 GPa, Poisson’s ratio: 0.22.

- Piezoelectric ceramic (PZT-4) [22]:

| C11E (1010 N/m2) | C12E (1010 N/m2) | C13E (1010 N/m2) | C33E (1010 N/m2) | C44E (1010 N/m2) | C66E (1010 N/m2) |

|---|---|---|---|---|---|

| 13.9 | 7.78 | 7.43 | 11.5 | 2.56 | 3.06 |

| Density (kg/m3) | (C/m2) | (C/m2) | (C/m2) | ||

| 7500 | 730 | 635 | −5.2 | 15.1 | 12.7 |

References

- Uttam, B.J.; Amos, D.H.; Covino, J.M.; Morris, P. Terrestrial Radio-Navigation Systems. In Avionics Navigation Systems, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1997; pp. 99–177. [Google Scholar]

- Dzikowicz, B.R.; Hefner, B.T.; Leasko, R.A. Underwater Acoustic Navigation Using a Beacon with a Spiral Wave Front. J. Ocean. Eng. 2015, 40, 177–186. [Google Scholar] [CrossRef]

- Hefner, B.T.; Dzikowicz, B.R. A spiral wave front beacon for underwater navigation: Basic concept and modeling. J. Acoust. Soc. Am. 2012, 129, 3630–3639. [Google Scholar] [CrossRef] [PubMed]

- Dzikowicz, B.R.; Hefner, B.T. A spiral wave front beacon for underwater navigation Transducer prototypes and testing. J. Acoust. Soc. Am. 2012, 131, 3748–3754. [Google Scholar] [CrossRef] [PubMed]

- Dzikowicz, B.R.; Hefner, B.T. Aspect determination using a transducer with a spiral wavefront: Prototype and experimental results (A). J. Acoust. Soc. Am. 2009, 125, 2540–2548. [Google Scholar] [CrossRef]

- Dzikowicz, B.R. Underwater Acoustic Beacon and Method of Operating Same for Navigation. U.S. Patent 7,406,001, 29 July 2008. [Google Scholar]

- Brown, D.A.; Aronov, B.; Bachand, C. Cylindercial transducer for producing an acoustic spiral wave for underwater navigation. J. Acoust. Soc. Am. 2012, 132, 3611–3613. [Google Scholar] [CrossRef] [PubMed]

- Brown, D.A.; Bachand, C.; Aronov, B. Design, development and testing of transducers for creating spiral waves for underwater navigation. In Proceedings of the 21st International Congress on Acoustics, Montreal, QC, Canada, 2–7 June 2013. [Google Scholar]

- Brown, D.A.; Aronov, B.; Bachand, C. Acoustic Transducer for Underwater Navigation and Communication. U.S. Patent US20120236689A1, 20 September 2012. [Google Scholar]

- Decarpigny, J.; Hamonic, B.; Wilson, O.B. The design of low frequency underwater acoustic projectors: Present status and future trends. J. Ocean. Eng. 1991, 16, 107–122. [Google Scholar] [CrossRef]

- Mo, X.; Zhu, H.Q. Thirty years progress of underwater sound projectors in China. In Proceedings of the 3rd International Conference on Ocean Acoustics, Beijing, China, 21–25 May 2012. [Google Scholar]

- Butler, J.L.; Butler, A.L.; Butler, S.C. The modal projector. J. Acoust. Soc. Am. 2011, 129, 1881–1889. [Google Scholar] [CrossRef] [PubMed]

- Tocquet, B. Multi-Driver Piezoelectric Transducer with Single Counter Masses and Sonar Antennas Made There From. U.S. Patent 4,100,527, 11 July 1978. [Google Scholar]

- Bulter, A.L.; Butler, J.L.; Dalton, W.L.; Rice, J.A. Multimode directional telesonar transducer. In Proceedings of the OCEANS 2000 MTS/IEEE Conference and Exhibition, Providenc, RI, USA, 11–14 September 2000. [Google Scholar]

- Butler, A.L.; Butler, J.L. Modal Acoustic Array Transduction Apparatus. U.S. Patent US20070195647A1, 23 August 2007. [Google Scholar]

- Butler, J.L.; Butler, A.L.; Rice, A.J. A tri-modal directional transducer. J. Acoust. Soc. Am. 2004, 115, 658–665. [Google Scholar] [CrossRef] [PubMed]

- Oishi, T.; Aronov, B.; Brown, D.A. Broadband multimode baffled piezoelectric cylinderical shell transducer. J. Acoust. Soc. Am. 2007, 121, 3465–3471. [Google Scholar] [CrossRef] [PubMed]

- Brown, D.A.; Aronov, B. Baffled Ring Directional Transducers and Array. U.S. Patent US20020159336A1, 31 October 2002. [Google Scholar]

- Shevtsova, M.; Nasedkin, A.; Shevtsov, S. An optimal design of underwater piezoelectric transducer of new generation. In Proceedings of the 23rd International Congress on Sound and Vibration, Athens, Greece, 10–14 July 2016. [Google Scholar]

- Andrey, K. Morozov, Modeling and Testing of Carbon-Fiber Doubly-Resonant Underwater Acoustic Transducer. In Proceedings of the 2013 COMSOL Conference, Rotterdam, The Netherland, 23–25 October 2013. [Google Scholar]

- Nasedkin, A.V.; Chang, S.; Shevtsova, M. Multi-objective Optimization of an Underwater Acoustic Projector with Porous Piezocomposite Acitve Element. In Proceedings of the OCEANS’14 MTS/IEEE Conference, Taipei, Taiwan, 7–10 April 2014. [Google Scholar]

- Zhou, T.; Lan, Y.; Zhang, Q.; Yuan, J.; Li, S.; Lu, W. A Conformal Driving Class IV Flextensional Transducer. Sensors 2018, 18, 2102. [Google Scholar] [CrossRef] [PubMed]

| Voltage Number | Voltage Value | Normalization | Voltage Number | Voltage Value | Normalization |

|---|---|---|---|---|---|

| V11 | 1 | V15 | −1 | ||

| V12 | 0.4 | V16 | −0.4 | ||

| V13 | −0.4 | V17 | 0.4 | ||

| V14 | −1 | V18 | 1 |

| Voltage Number | Voltage Value | Normalization | Voltage Number | Voltage Value | Normalization |

|---|---|---|---|---|---|

| V21 | 0.4j | V25 | −0.4j | ||

| V22 | j | V26 | −j | ||

| V23 | j | V27 | −j | ||

| V24 | 0.4j | V28 | −0.4j |

| Voltage Number | Voltage Value | Normalization | Voltage Number | Voltage Value | Normalization |

|---|---|---|---|---|---|

| V31 | V11 + V21 = 1 + 0.4j | V35 | V15 + V25 = −1 − 0.4j | ||

| V32 | V12 + V22 = 0.4 + j | V36 | V16 + V26 = −0.4 − j | ||

| V33 | V13 + V23 = −0.4 + j | V37 | V17 + V27 = 0.4 − j | ||

| V34 | V14 + V24 = −1 + 0.4j | V38 | V18 + V28 = 1 − 0.4j |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, W.; Lan, Y.; Guo, R.; Zhang, Q.; Li, S.; Zhou, T. Spiral Sound Wave Transducer Based on the Longitudinal Vibration. Sensors 2018, 18, 3674. https://doi.org/10.3390/s18113674

Lu W, Lan Y, Guo R, Zhang Q, Li S, Zhou T. Spiral Sound Wave Transducer Based on the Longitudinal Vibration. Sensors. 2018; 18(11):3674. https://doi.org/10.3390/s18113674

Chicago/Turabian StyleLu, Wei, Yu Lan, Rongzhen Guo, Qicheng Zhang, Shichang Li, and Tianfang Zhou. 2018. "Spiral Sound Wave Transducer Based on the Longitudinal Vibration" Sensors 18, no. 11: 3674. https://doi.org/10.3390/s18113674