Surface Plasmon Resonance Based Measurement of the Dielectric Function of a Thin Metal Film

Abstract

:1. Introduction

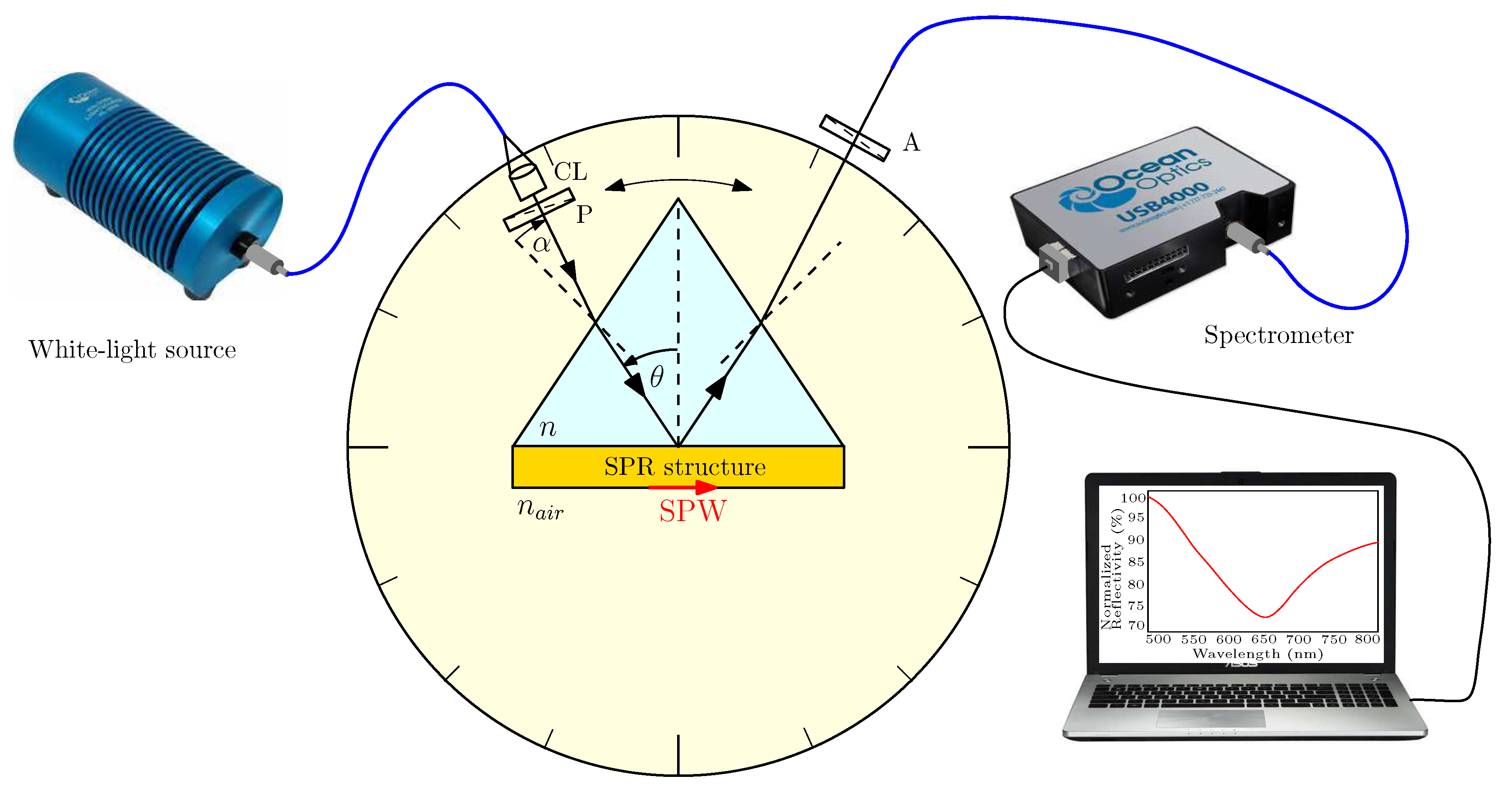

2. Experimental Method

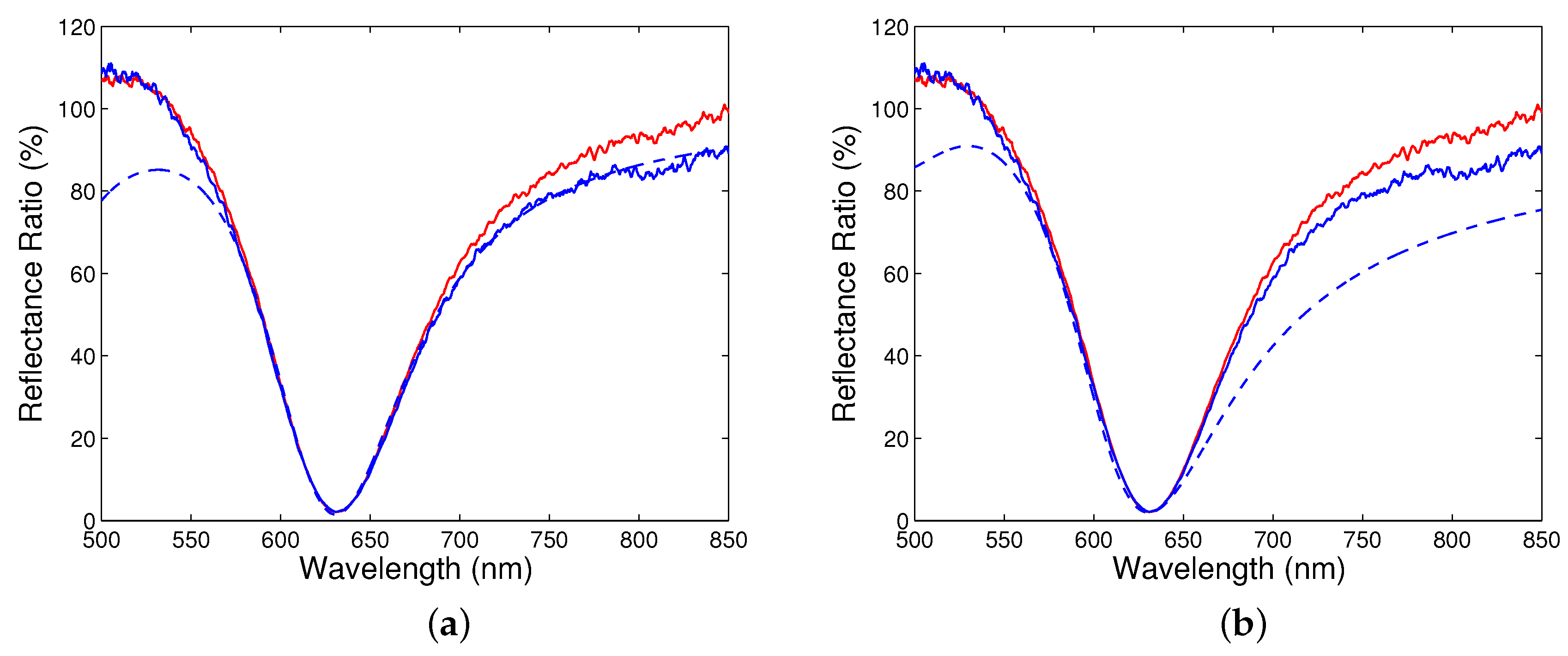

3. Processing Procedure

3.1. SPR Structure—Reflection Coefficients

3.2. Material Characterization

3.2.1. Air

3.2.2. SF10 Glass

3.2.3. Adhesion Film

3.2.4. Gold Film

3.2.5. Effective Medium

4. Experimental Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kretschmann, E.; Raether, H. Radiative decay of nonradiative surface plasmons excited by light. Z. Naturforsch. 1968, A23, 2135–2136. [Google Scholar]

- Otto, A. Excitation of nonradiative surface plasma waves in silver by the method of frustrated total reflection. Z. Phys. 1968, 216, 398–410. [Google Scholar] [CrossRef]

- Raether, H. Surface Plasmons on Smooth and Rough Surfaces and on Gratings; Springer: New York, NY, USA, 1988. [Google Scholar]

- Manuel, M.; Vidal, B.; Lopéz, R.; Alegret, S.; Alonso-Chamarro, J.; Garces, I.; Mateo, J. Determination of probable alcohol yield in musts by means of an SPR optical sensor. Sens. Actuators B 1993, 11, 455–459. [Google Scholar] [CrossRef]

- Homola, J. Surface Plasmon Resonance Based Sensors; Springer: New York, NY, USA, 2006. [Google Scholar]

- Pitarke, J.M.; Silkin, V.M.; Chulkov, E.V.; Echenique, P.M. Theory of surface plasmons and surface-plasmon polaritons. Rep. Prog. Phys. 2007, 70, 1–87. [Google Scholar] [CrossRef]

- Nikitin, P.; Beloglazov, A.; Kochergin, V.; Valeiko, M.; Ksenevich, T. Surface plasmon resonance interferometry for biological and chemical sensing. Sens. Actuators B 1999, 54, 43–50. [Google Scholar] [CrossRef]

- Liedberg, B.; Nylander, C.; Lundström, I. Principles of biosensing with an extended coupling matrix and surface plasmon resonance. Sens. Actuators B 1993, 11, 63–72. [Google Scholar] [CrossRef]

- Dostálek, J.; Vaisocherova, H.; Homola, J. Multichannel surface plasmon resonance biosensor with wavelength division multiplexing. Sens. Actuators B 2005, 108, 758–764. [Google Scholar] [CrossRef]

- Gwon, H.R.; Lee, S.H. Spectral and angular responses of surface plasmon resonance based on the Kretschmann prism configuration. Mater. Trans. 2010, 51, 1150–1155. [Google Scholar] [CrossRef]

- El-Gohary, S.H.; Choi, M.; Kim, Y.L.; Byun, K.M. Dispersion curve engineering of TiO2/silver hybrid substrates for enhanced surface plasmon resonance detection. Sensors 2016, 16, 1442. [Google Scholar] [CrossRef] [PubMed]

- Meng, Q.Q.; Zhao, X.; Lin, C.Y.; Chen, S.J.; Ding, Y.C.; Chen, Z.Y. Figure of merit enhancement of a surface plasmon resonance sensor using a low-refractive-index porous silica film. Sensors 2017, 17, 1846. [Google Scholar] [CrossRef] [PubMed]

- Shalabney, A.; Abdulhalim, I. Figure-of-merit enhancement of surface plasmon resonance sensors in the spectral interrogation. Opt. Lett. 2012, 37, 1175–1177. [Google Scholar] [CrossRef] [PubMed]

- Hlubina, P.; Duliakova, M.; Kadulova, M.; Ciprian, D. Spectral interferometry-based surface plasmon resonance sensor. Opt. Commun. 2015, 354, 240–245. [Google Scholar] [CrossRef]

- Suvarnaphaet, P.; Pechprasarn, S. Quantitative crossp-platform performance comparison between different detection mechanisms in surface plasmon sensors for voltage sensing. Sensors 2018, 18, 3136. [Google Scholar] [CrossRef] [PubMed]

- Hlubina, P.; Ciprian, D. Spectral phase shift of surface plasmon resonance in the Kretschmann configuration: Theory and experiment. Plasmonics 2017, 12, 1071–1078. [Google Scholar] [CrossRef]

- Kaňok, R.; Ciprian, D.; Hlubina, P. Sensing of liquid analytes via the phase shift induced by surface plasmon resonance. Proc. SPIE 2018, 10680, 106801Q. [Google Scholar]

- de Bruijn, H.E.; Kooyman, R.P.H.; Greve, J. Determination of dielectric permittivity and thickness of a metal layer from a surface plasmon resonance experiment. Appl. Opt. 1990, 29, 1974–1978. [Google Scholar] [CrossRef] [PubMed]

- Pokrowsky, P. Optical methods for thickness measurements on thin metal films. Appl. Opt. 1991, 30, 3228–3232. [Google Scholar] [CrossRef] [PubMed]

- Posudievsky, O.; Samoylov, A.; Surovtseva, E.; Khristosenko, R.; Kukla, A.; Shirshov, Y. Extraction of optical constants of polyaniline thin films by surface plasmon resonance. Thin Solid Films 2008, 515, 6104–6109. [Google Scholar] [CrossRef]

- Fujiwara, H. Spectroscopic Ellipsometry: Principles and Applications; John Wiley and Sons Ltd.: Chichester, UK, 2007. [Google Scholar]

- Zhang, M.Y.; Wang, Z.Y.; Zhang, T.N.; Zhang, Y.; Zhang, R.J.; Chen, X.; Sun, Y.; Zheng, Y.X.; Wang, S.Y.; Chen, L.Y. Thickness-dependent free-electron relaxation time of Au thin films in near-infrared region. J. Nanophotonics 2016, 516, 033009. [Google Scholar] [CrossRef]

- Hu, E.T.; Cai, Q.Y.; Zhang, R.J.; Wei, Y.F.; Zhou, W.C.; Wang, S.Y.; Zheng, Y.X.; Wei, W.; Chen, L.Y. Effective method to study the thickness-dependent dielectric functions of nanometal thin film. Opt. Lett. 2016, 41, 4907–4910. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Hong, R.; Hou, H.; Fan, Z.; Shao, J. Thickness dependence of structure and optical properties of silver films deposited by magnetron sputtering. Thin Solid Films 2007, 515, 6962–6966. [Google Scholar] [CrossRef]

- Qi, Z.M.; Wei, M.; Matsuda, H.; Honma, I.; Zhou, H. Broadband surface plasmon resonance spectroscopy for determination of refractive index dispersion of dielectric thin films. Appl. Phys. Lett. 2007, 90, 181112. [Google Scholar] [CrossRef]

- Yan, H.; Hong-An, Y.; Song-Quan, L.; Yin-Feng, D. The determination of the thickness and the optical dispersion property of gold film using spectroscopy of a surface plasmon in the frequency domain. Chin. Phys. B 2013, 22, 027301. [Google Scholar]

- Kanso, M.; Cuenot, S.; Louarn, G. Roughness effect on the SPR measurements for an optical fiber configuration: Experimental and numerical approaches. J. Opt. A Pure Appl. Opt. 2007, 9, 586–592. [Google Scholar] [CrossRef]

- Born, M.; Wolf, E. Principles of Optics: Electromagnetic Theory of Propagation, Interference and Diffraction of Light, 7th ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Yeh, P. Optical Waves in Layered Media; John Wiley and Sons, Inc.: New York, NY, USA, 1988. [Google Scholar]

- Bach, H.; Neuroth, N. (Eds.) The Properties of Optical Glass; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- SCHOTT Technical Information, TIE-29: Refractive Index and Dispersion. Available online: https://www.us.schott.com (accessed on 15 October 2018).

- SCHOTT Technical Information, TIE-29: Temperature Coefficient of the Refractive Index. Available online: https://www.us.schott.com (accessed on 15 October 2018).

- Vial, A.; Laroche, T. Description of dispersion properties of metals by means of the critical points model and application to the study of resonant structures using the FDTD method. J. Phys. D Appl. Phys. 2007, 40, 7152–7158. [Google Scholar] [CrossRef]

- Vial, A.; Grimault, A.S.; Macías, D.; Barchiesi, D.; de la Chapelle, M.L. Improved analytical fit of gold dispersion: Application to the modeling of extinction spectra with a finite-difference time-domain method. Phys. Rev. B 2005, 71, 085416. [Google Scholar] [CrossRef]

- Yang, Z.; Gu, D.; Gao, Y. An improved dispersion law of thin metal film and application to the study of surface plasmon resonance phenomenon. Opt. Commun. 2014, 329, 180–183. [Google Scholar] [CrossRef]

- Watad, I.; Abdulhalim, I. Spectropolarimetric surface plasmon resonance sensor and the selection of the best polarimetric function. IEEE J. Sel. Top. Quant. Electr. 2017, 23. [Google Scholar] [CrossRef]

| Drude Term Parameter | Value | Oscillator 1 Parameter | Value | Oscillator 2 Parameter | Value |

|---|---|---|---|---|---|

| 1.1297 | 33.086 | 1.659 | |||

| (nm) | 213.67 | (nm) | 1082.3 | (nm) | 496.5 |

| (nm) | 4849.8 | (nm) | 1153.2 | (nm) | 2559.7 |

| - | - | (rad) | −0.25722 | (rad) | 0.83533 |

| Drude Term Parameter | Value | Oscillator 1 Parameter | Value | Oscillator 2 Parameter | Value |

|---|---|---|---|---|---|

| 1 | 3.613 | 1.423 | |||

| (nm) | 133.85 | (nm) | 309.11 | (nm) | 424.06 |

| (nm) | 27,851.5 | (nm) | 2591.3 | (nm) | 1515.2 |

| Drude Term Parameter | Value | Oscillator 1 Parameter | Value | Oscillator 2 Parameter | Value |

|---|---|---|---|---|---|

| 1 | 8.88 | 1.70 | |||

| (nm) | 130.77 | (nm) | 255.5 | (nm) | 660.67 |

| (nm) | 6608.3 | (nm) | −29.73 | (nm) | −819.68 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chlebus, R.; Chylek, J.; Ciprian, D.; Hlubina, P. Surface Plasmon Resonance Based Measurement of the Dielectric Function of a Thin Metal Film. Sensors 2018, 18, 3693. https://doi.org/10.3390/s18113693

Chlebus R, Chylek J, Ciprian D, Hlubina P. Surface Plasmon Resonance Based Measurement of the Dielectric Function of a Thin Metal Film. Sensors. 2018; 18(11):3693. https://doi.org/10.3390/s18113693

Chicago/Turabian StyleChlebus, Radek, Jakub Chylek, Dalibor Ciprian, and Petr Hlubina. 2018. "Surface Plasmon Resonance Based Measurement of the Dielectric Function of a Thin Metal Film" Sensors 18, no. 11: 3693. https://doi.org/10.3390/s18113693