Robust Powerline Equipment Inspection System Based on a Convolutional Neural Network

Abstract

:1. Introduction

- (1)

- Unlike earlier studies that use handcraft features, we explore the robustness of the CNN features and use them for the task of multi-type insulator detection in a highly cluttered environment.

- (2)

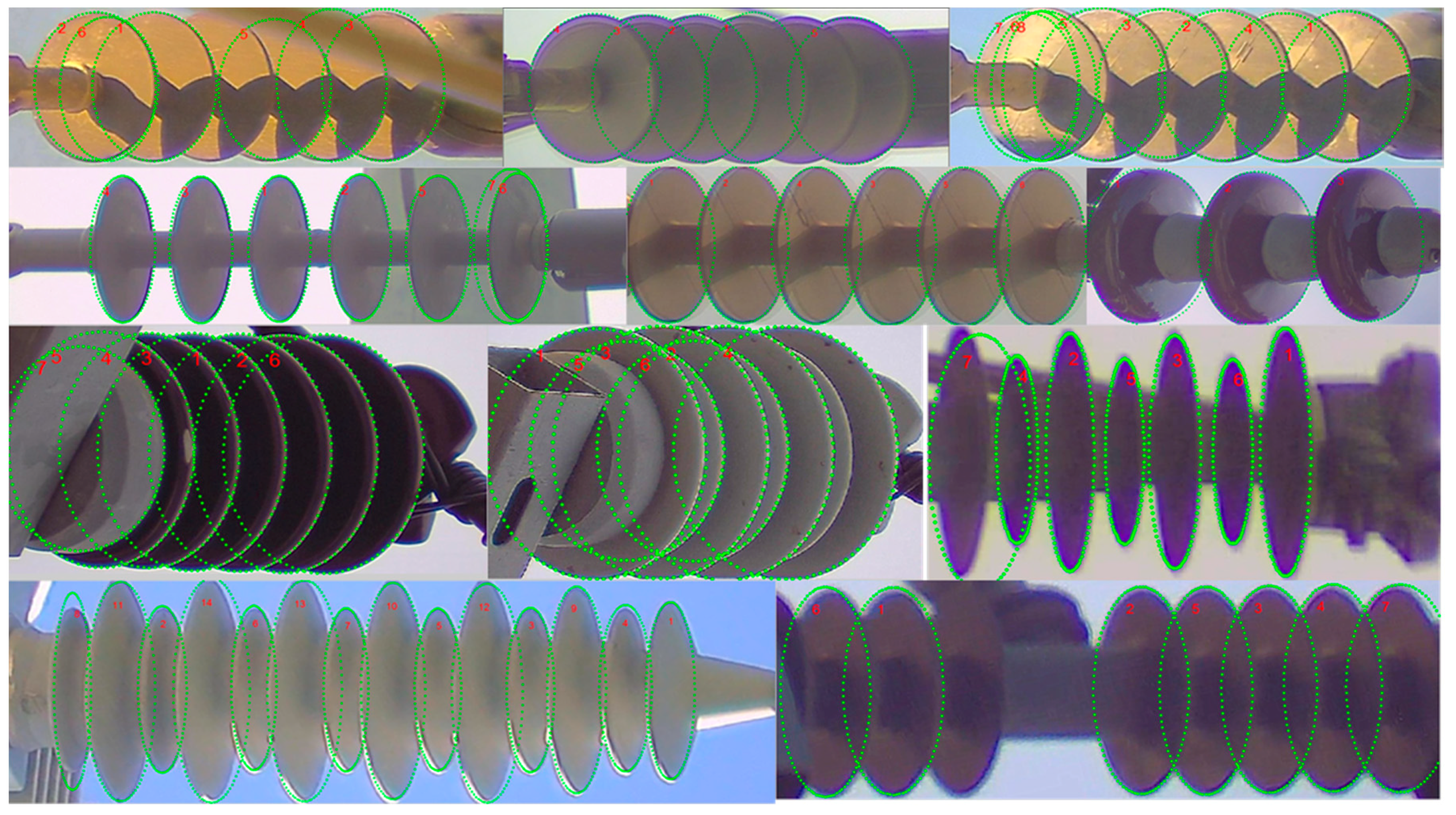

- We present an ellipse detection method specifically designed for segmenting the caps from various types of insulators.

- (3)

- We propose a novel insulator rotation normalization method that normalizes the in-plane rotation of insulators, irrespective of their types.

- (4)

- We propose a novel defect analysis method that can detect gunshot defect in polymer insulators.

- (5)

- We present a complete automatic real-time multi-type insulator detection and defect analysis system.

2. Overview of the Proposed System

2.1. CNN-Based Robust Insulator Detector

2.1.1. Rotation Invariant Multi-Type LR Insulator Detector

2.1.2. Rotation Invariant Multi-Type HR_1 Insulator Detector

2.1.3. Multi-Type HR_2 Insulator Detector

2.2. Insulator Rotation Normalization Method

- (1)

- In order to find the best rotation angle, the edge map of the detected insulator in the high-resolution image is computed using the Canny edge detector. The edge map is rotated to all possible angles between 1 to 180 degrees.

- (2)

- Low-level visual features of all the edge maps are analyzed exhaustively; feature points are extracted and clustered by their appearance similarities.

- (3)

- The appearance similarity between any two feature points is computed by folding the edge map with respect to the center of the two feature points and then applying convolution.

- (4)

- High convolution score implies that the feature points in the two folds have high appearance similarity. Hence, we do max voting on convolution scores to find candidate point cluster which is consistent with the geometrical relationship of the insulator shape.

- (5)

- Finally, a tight bounding box encapsulating the maximum voted point cluster is returned, whose longest side represents the final orientation of the insulator.

3. Defect Analyzer

3.1. The Ellipse Detector

3.1.1. Adaptive Thresholding

3.1.2. Insulator Core Removal

3.1.3. Edge Refinement

3.1.4. Arc Labeling

3.1.5. Arc Triplet Selection-Constraint 1

3.1.6. Arc Triplet Selection-Constraint 2

- (i)

- if

- (ii)

- if

- (iii)

- if

- (iv)

- if

3.1.7. Ellipse Parameter Estimation and Candidate Ellipse Selection

3.1.8. Combining Multiple Detections

3.1.9. Clustering Detected Ellipses

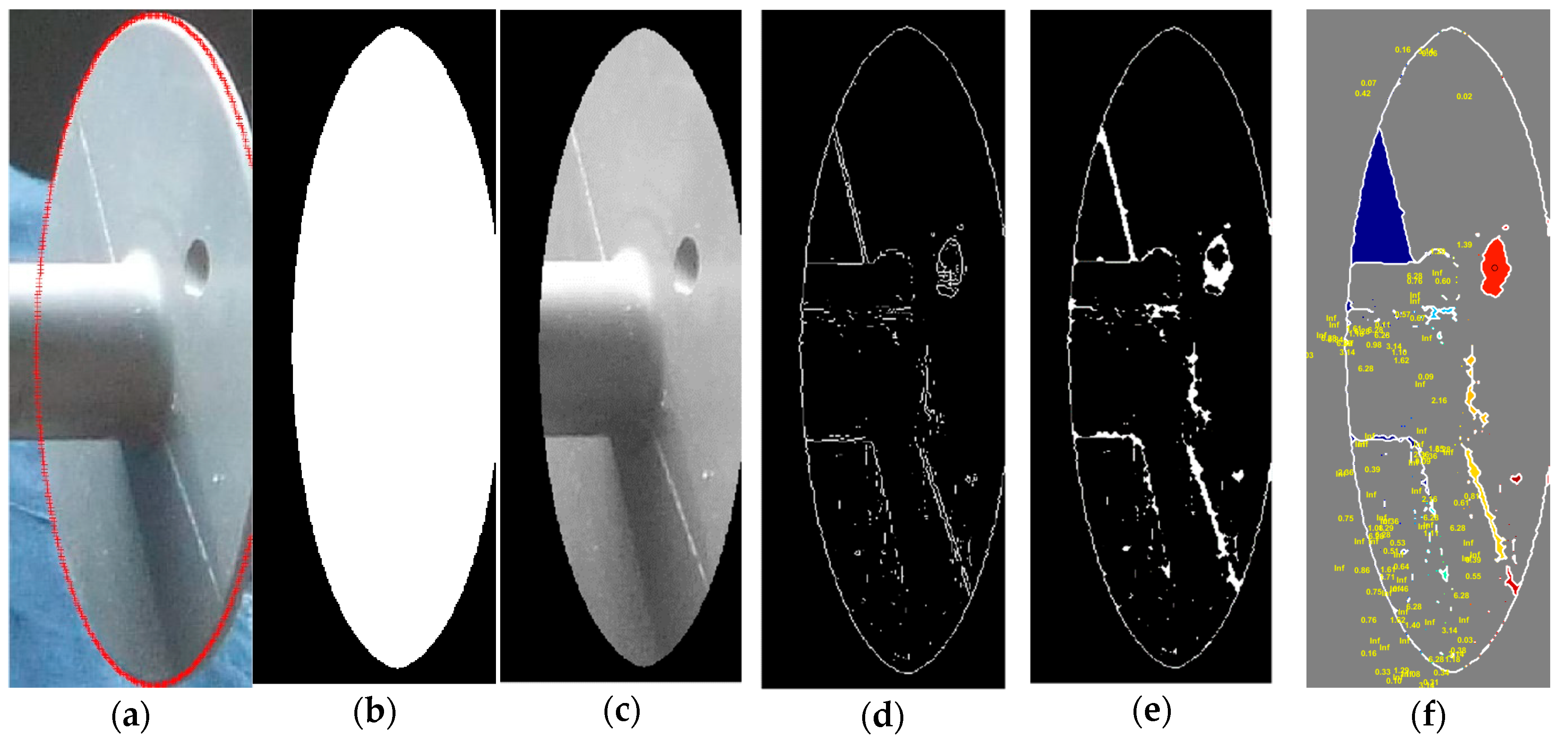

3.2. The Novel Bullet Shot Defect Analyzer

- (1)

- Ellipse detection to segment caps from insulators.

- (2)

- Masking to remove the extra background.

- (3)

- Edge detection followed by some morphological operations to remove noisy edges.

- (4)

- Labeling all the edges inside the cap.

- (5)

- Connected component analysis for blob detection.

- (6)

- The bullet shots normally create circular shaped holes on insulator caps. Hence, in order to differentiate between noisy edges and edges caused by gunshots, we compute the circularity [46] of every closed contour as:where and are the area and perimeter of a closed contour, respectively. The circularity of a perfect circle is equal to 1. The perimeter is a scalar quantity defined as the distance around the boundary of the contour, computed by summing together the positive distance between each adjoining pair of pixels around the border of the contour. If there are total I points on the curve, then can be computed as:

- (7)

- A priori information related to the color intensity of the hole created by bullet shot puts a final constraint in classifying the detected contour as bullet shot or not. We observed that in every insulator image with bullet shot damage, the color intensity of the area inside the hole of bullet shot is lower than the surroundings.

- (8)

- Let and represent the mean intensity of the hole and boundary pixels, respectively, then the final detected contour is classified as a bullet shot if:where represents the minimum ratio of the area of bullet shot hole divided by the size of the cap in pixels, and denotes the minimum value of circularity of the detected hole to be considered as a bullet shot defect.

- (9)

- If there are total G contours classified as gunshot damage, then the final percentage of damage per cap due to the gunshot is computed as:where represents the area of ith gunshot contour.

4. Experimental Results and Discussion

4.1. Database Acquisition

4.2. Insulator Detection Results

4.2.1. Rotation Invariant Multi-Type Low Resolution Insulator Detector (LR)

4.2.2. Rotation Invariant Multi-Type High-Resolution Insulator Detector 1 (HR_1)

4.2.3. Multi-Type High-Resolution Insulator Detector 2 (HR_2)

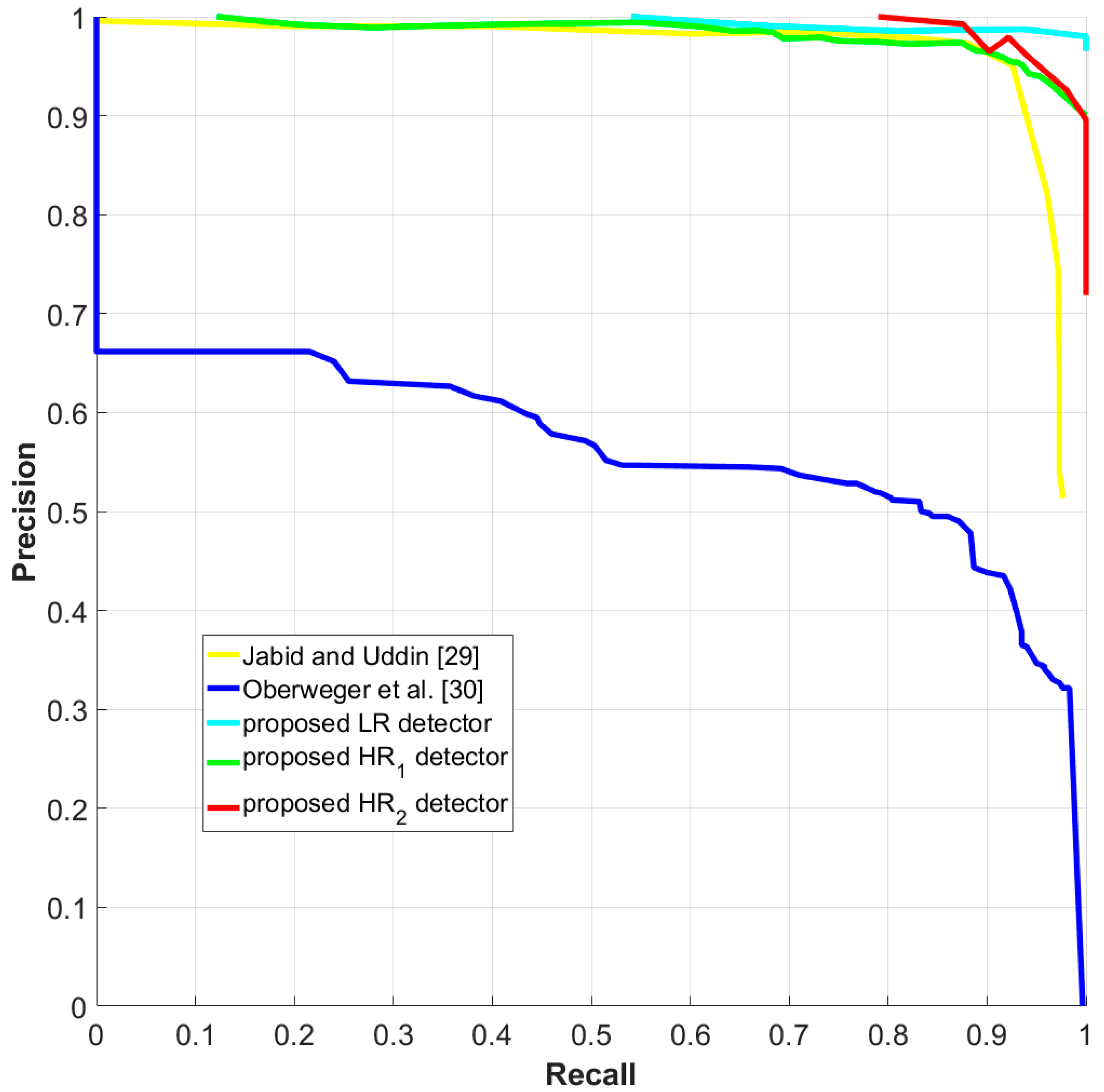

4.3. Comparison with the State-of-the-Art

4.4. Defect Analyzer Results

4.5. Discussion about the Results and Challenges of the Proposed System

4.5.1. Availability of Annotated Data

4.5.2. Train Data Class Imbalance

4.5.3. Training Time

4.5.4. Valid False Positives

4.5.5. Limitations in the Ellipse Detection Algorithm

4.5.6. Availability of Defected Cap Images

5. Conclusions and Future Directions

Author Contributions

Funding

Conflicts of Interest

References

- Mei, X.; Lu, T.; Wu, X.; Zhang, B. Insulator surface dirt image detection technology based on improved watershed algorithm. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012; pp. 1–5. [Google Scholar] [CrossRef]

- Li, J.; Li, M.; Wang, Q. A novel insulator detection method for aerial images. In Proceedings of the 9th International Conference on Computer and Automation Engineering, Sydney, Australia, 18–21 February 2017; pp. 141–144. [Google Scholar] [CrossRef]

- Wu, Q.; An, J. An active contour model based on texture distribution for extracting inhomogeneous insulators from aerial images. IEEE Trans. Geosci. Remote Sens. 2014, 52, 3613–3626. [Google Scholar] [CrossRef]

- Jiang, X.; Yuan, J.; Shu, L.; Zhang, Z.; Hu, J.; Mao, F. Comparison of DC pollution flashover performances of various types of porcelain, glass, and composite insulators. IEEE Trans. Power Deliv. 2008, 23, 1183–1190. [Google Scholar] [CrossRef]

- Oliveira, S.C.; Fontana, E. Optical detection of partial discharges on insulator strings of high-voltage transmission lines. IEEE Trans. Instrum. Meas. 2009, 58, 2328–2334. [Google Scholar] [CrossRef]

- Shong, K.M.; Kim, Y.S.; Kim, S.G. Images detection and diagnosis of corona discharge on porcelain insulators at 22.9kV D/L. In Proceedings of the IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives, Cracow, Poland, 6–8 September 2007; pp. 462–466. [Google Scholar] [CrossRef]

- Yang, T.W.; Yin, H.; Ruan, Q.Q.; da Han, J.; Qi, J.T.; Yong, Q.; Wang, Z.T.; Sun, Z.Q. Overhead power line detection from UAV video images. In Proceedings of the 19th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 28–30 November 2012; pp. 74–79. [Google Scholar]

- Yetgin, Ö.E.; Şentürk, Z.; Gerek, Ö.N. A comparison of line detection methods for power line avoidance in aircrafts. In Proceedings of the 9th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Turkey, 26–28 November 2015; pp. 241–245. [Google Scholar] [CrossRef]

- Liu, Y.; Mejias, L.; Li, Z. Fast power line detection and localization using steerable filter for active UAV guidance. In Proceedings of the 12th International Society for Photogrammetry and Remote Sensing (ISPRS2012), Melbourne, Australia, 25 August–1 September 2012; pp. 491–496. [Google Scholar] [CrossRef]

- Cerón, A.; Mondragón, B.I.F.; Prieto, F. Towards visual based navigation with power line detection. In Advances in Visual Computing, ISVC 2014, Lecture Notes in Computer Science; Bebis, G., Boyle, R., Parvin, B., Koracin, D., McMahan, R., Jerald, J., Zhang, H., Drucker, S.M., Kambhamettu, C., Choubassi, M.E., et al., Eds.; Springer: Berlin, Germany, 2014; Volume 8887, pp. 827–836. ISBN 978-3-319-14249-4. [Google Scholar]

- Sampedro, C.; Martinez, C.; Chauhan, A.; Campoy, P. A supervised approach to electric tower detection and classification for power line inspection. In Proceedings of the 2014 International Joint Conference on Neural Networks (IJCNN), Beijing, China, 6–11 July 2014; pp. 1970–1977. [Google Scholar] [CrossRef]

- Han, B.; Wang, X. Learning for tower detection of power line inspection. DEStech Trans. Comput. Sci. Eng. 2016, 216–220. [Google Scholar] [CrossRef]

- Martinez, C.; Sampedro, C.; Chauhan, A.; Campoy, P. Towards autonomous detection and tracking of electric towers for aerial power line inspection. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Orlando, FL, USA, 27–30 May 2014; pp. 284–295. [Google Scholar] [CrossRef]

- Lin, J.; Han, J.; Chen, F. Defects detection of glass insulator based on color image. Power Syst. Technol. 2011, 35, 127–133. [Google Scholar]

- Huang, X.; Zhang, Z. A method to extract insulator image from aerial image of helicopter patrol. Power Syst. Technol. 2010, 34, 194–197. [Google Scholar]

- Li, W.G.; Ye, G.; Huang, F.; Wang, S.; Chang, W.Z. Recognition of insulator based on developed MPEG-7 texture feature. In Proceedings of the 3rd International Congress on Image and Signal Processing, Yantai, China, 16–18 October 2010; pp. 265–268. [Google Scholar] [CrossRef]

- Zhang, X.; An, J.; Chen, F. A simple method of tempered glass insulator recognition from airborne image. In Proceedings of the 2010 International Conference on Optoelectronics and Image Processing, Haikou, China, 11–12 November 2010; pp. 127–130. [Google Scholar] [CrossRef]

- Prasad, D.S.; Reddy, B.S. Digital image processing techniques for estimating power released from the corona discharges. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 75–82. [Google Scholar] [CrossRef]

- Dudczyk, J.; Kawalec, A. Adaptive forming of the beam pattern of microstrip antenna with the use of an artificial neural network. Int. J. Antennas Propag. 2012, 2012, 1–13. [Google Scholar] [CrossRef]

- Matuszewski, J.; Sikorska-Łukasiewicz, K. Neural network application for emitter identification. In Proceedings of the 2017 18th International Radar Symposium (IRS), Prague, Czech Republic, 28–30 June 2017; pp. 1–8. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, R. Insulators recognition for 220kv/330kv high-voltage live-line cleaning robot. In Proceedings of the 18th International Conference on Pattern Recognition (ICPR’06), Hong Kong, China, 20–24 August 2006; pp. 630–633. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, X.; Sun, J.; Lei, L. Detecting insulators in the image of overhead transmission lines. In Intelligent Computing Technology. ICIC 2012. Lecture Notes in Computer Science; Huang, D.S., Jiang, C., Bevilacqua, V., Figueroa, J.C., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; Volume 7389, ISBN 978-3-642-31588-6. [Google Scholar]

- Liao, S.; An, J. A robust insulator detection algorithm based on local features and spatial orders for aerial images. IEEE Geosci. Remote Sens. Lett. 2015, 12, 963–967. [Google Scholar] [CrossRef]

- Zhai, Y.; Wu, Y.; Chen, H.; Zhao, X. A method of insulator detection from aerial images. Sens. Transducers 2014, 177, 7. [Google Scholar]

- Li, B.; Wu, D.; Cong, Y.; Xia, Y.; Tang, Y. A method of insulator detection from video sequence. In Proceedings of the 2012 Fourth International Symposium on Information Science and Engineering, Shanghai, China, 14–16 December 2012; pp. 386–389. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y. Insulator identification from aerial images using support vector machine with background suppression. In Proceedings of the 2016 International Conference on Unmanned Aircraft Systems (ICUAS), Arlington, VA, USA, 7–10 June 2016; pp. 892–897. [Google Scholar] [CrossRef]

- Murthy, V.S.; Tarakanath, K.; Mohanta, D.K.; Gupta, S. Insulator condition analysis for overhead distribution lines using combined wavelet and support vector machine (SVM). IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 89–99. [Google Scholar] [CrossRef]

- Murthy, V.S.; Gupta, S.; Mohanta, D.K. Digital image processing approach using combined wavelet hidden Markov model for well-being analysis of insulators. IET Image Process. 2011, 5, 171–183. [Google Scholar] [CrossRef]

- Jabid, T.; Uddin, M.Z. Rotation invariant power line insulator detection using local directional pattern and support vector machine. In Proceedings of the 2016 International Conference on Innovations in Science, Engineering and Technology (ICISET), Dhaka, Bangladesh, 28–29 October 2016; pp. 1–4. [Google Scholar] [CrossRef]

- Oberweger, M.; Wendel, A.; Bischof, H. Visual recognition and fault detection for power line insulators. In Proceedings of the 19th Computer Vision Winter Workshop, Krtiny, Czech Republic, 1 January 2014; pp. 1–8. [Google Scholar]

- Razavian, A.S.; Azizpour, H.; Sullivan, J.; Carlsson, S. CNN features off-the-shelf: An astounding baseline for recognition. In Proceedings of the Computer Vision and Pattern Recognition Workshops, Columbus, OI, USA, 23 March 2014. [Google Scholar] [CrossRef]

- Zhao, Z.; Xu, G.; Qi, Y.; Liu, N.; Zhang, T. Multi-patch deep features for power line insulator status classification from aerial images. In Proceedings of the 2016 International Joint Conference on Neural Networks (IJCNN), Vancouver, BC, Canada, 24–29 July 2016; pp. 3187–3194. [Google Scholar] [CrossRef]

- Zhai, Y.; Chen, R.; Yang, Q.; Li, X.; Zhao, Z. Insulator fault detection based on spatial morphological features of aerial images. IEEE Access 2018, 6, 35316–35326. [Google Scholar] [CrossRef]

- Zhai, Y.; Cheng, H.; Chen, R.; Yang, Q.; Li, X. Multi-saliency aggregation-based approach for insulator flashover fault detection using aerial images. Energies 2018, 11, 340. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, H.; Zhang, Y. Automatic identification and location technology of glass insulator self-shattering. J. Electron. Imaging 2017, 26, 1–12. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, N.; Wang, L. Localization of multiple insulators by orientation angle detection and binary shape prior knowledge. IEEE Trans. Dielectr. Electr. Insul. 2015, 22, 3421–3428. [Google Scholar] [CrossRef]

- Han, Y.; Liu, Z.; Lee, D.; Liu, W.; Chen, J.; Han, Z. Computer vision–based automatic rod-insulator defect detection in high-speed railway catenary system. Intern. J. Adv. Robot. Syst. 2018, 2018, 1–15. [Google Scholar] [CrossRef]

- Iruansi, U.; Tapamo, J.R.; Davidson, I.E. An active contour approach to insulator segmentation. In Proceedings of the AFRICON 2015, Addis Ababa, Ethiopia, 14–17 September 2015; pp. 1–5. [Google Scholar] [CrossRef]

- Redmon, J. Darknet: Open Source Neural Networks in C. Available online: http://pjreddie.com/darknet/ (accessed on 2 October 2018).

- Redmon, J.; Farhadi, A. YOLO9000: Better, faster, stronger. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017. [Google Scholar] [CrossRef]

- Fornaciari, M.; Prati, A.; Cucchiara, R. A fast and effective ellipse detector for embedded vision applications. Patten Recognit. 2014, 47, 3693–3708. [Google Scholar] [CrossRef]

- Kwon, B.K.; Teng, Z.; Roh, T.J.; Kang, D.J. Fast ellipse detection based on three point algorithm with edge angle information. Int. J. Control Autom. Syst. 2016, 14, 804–813. [Google Scholar] [CrossRef]

- Fitzgibbon, A.; Pilu, M.; Fisher, R.B. Direct least square fitting of ellipses. IEEE Trans. Patten Anal. Mach. Intell. 1999, 21, 476–480. [Google Scholar] [CrossRef] [Green Version]

- Burnham, J.T.; Waidelich, R.J. Gunshot damage to ceramic and non-ceramic insulators. IEEE Trans. Power Deliv. 1997, 2, 1651–1656. [Google Scholar] [CrossRef]

- Electric Power Research Institute. Field Guide: Visual Inspection of Polymer Insulators. EPRI, 2014. Available online: https://www.epri.com/#/pages/product/3002003720/ (accessed on 8 November 2018).

- Roussillon, T.; Sivignon, I.; Tougne, L. Measure of circularity for parts of digital boundaries and its fast computation. Patten Recognit. 2010, 43, 37–46. [Google Scholar] [CrossRef] [Green Version]

- Everingham, M.; Gool, L.J.V.; Williams, C.K.I.; Winn, J.M.; Zisserman, A. The pascal visual object classes (VOC) challenge. Intern. J. Comput. Vis. 2010, 88, 303–338. [Google Scholar] [CrossRef]

- Pietrow, D.; Matuszewski, J. Objects detection and recognition system using artificial neural networks and drones. In Proceedings of the Signal Processing Symposium (SPSympo), Jachranka, Poland, 12–14 September 2017; pp. 1–5. [Google Scholar] [CrossRef]

| Method | Published Year | # of Equip. that Can Be Detected | Can Handle Variations in | Background Type | Major Drawback | |||

|---|---|---|---|---|---|---|---|---|

| Color | Lighting | Shape | View-Point | |||||

| [2] | ‘17 | 1 | △ | Saliency only works when the main object is close to the camera. Single image used for training and test which cannot prove the robustness of the system | ||||

| [14,15] | ’11 | 1 | △ | High dependency upon color pixel values | ||||

| [16] | ‘10 | 1 | ⬤ | Simple template matching based approach | ||||

| [17] | ‘10 | 1 | △ | Works only when there is low intensity bg and high intensity fg | ||||

| [25] | ‘12 | 1 | ⌘ | Works with close shot images only. Whole technique depends upon naïve approach of binarizing the intensity image. | ||||

| [33] | ‘18 | 2 | ⌘ | Naïve color thresholding | ||||

| [35] | ‘17 | 1 | △ | Color based detection is severely affected by lighting variations. Assumption of structural symmetry fails when view-point-changes. | ||||

| [36] | ‘15 | 1 | ⌘ | Whole technique depends upon naïve binarizing the intensity image. | ||||

| [26] | ‘16 | 1 | ✓ | △ | Whole technique depends upon color thresholding. Single image for testing and training which cannot prove the robustness of the system. | |||

| [21] | ‘06 | 1 | ✓ | ⌘ | Single image is used to train and test, so robustness of the scheme cannot be proved | |||

| [38] | ‘15 | 1 | ✓ | △ | Active contour model only works when the main object is very close to camera and bg color is discriminant with respect to fg. Testing dataset contains only 12 images. | |||

| [22] | ‘12 | 2 | ✓ | ✓ | ⌘ | Algorithm completely depends upon structural symmetry, which is lost when viewing angle changes, Detection results are shown on only two images | ||

| [34] | ‘18 | 1 | ✓ | ✓ | △ | Saliency only works when main object is close to the camera and bg is far from the main object. Color and structural feature are effected by lighting and view point changes | ||

| [23] | ‘15 | 5 | ✓ | ✓ | ✓ | ⌘ | Cannot handle out-of-plane rotation | |

| [24] | ‘14 | 1 | ✓ | ✓ | ✓ | ⬤ | Low precision and recall, Small testing data (only 10 images) | |

| [27,28] | 1 | ⬤ | Segmentation algorithm is not given so the results are implausible | |||||

| [30] | ‘14 | 1 | ✓ | ✓ | ✓ | Par. | ⌘ | Cannot detect multiple instances of insulator in an image, precision is also very low |

| [29] | ‘17 | 1 | ✓ | ✓ | ✓ | Par. | ⌘ | Sliding window based detection, as well as detection at multiple rotation angles limits the real-time processing |

| [37] | ‘18 | 1 | ✓ | ✓ | ✓ | Par. | ⬤ | Only applicable to rod-insulator in railway catenary system. System require special type of camera module. Precision is very low, almost 1 false positive per image. |

| Our | 17 | ✓ | ✓ | ✓ | ✓ | ⌘ | Require GPU for real-time processing. Takes 3~4 days for training with large dataset. Require two cameras. | |

| Equipment Type | LR Detector | HR_1 and HR_2 Detectors | LR Detector | HR_1 Detector | HR_2 Detector | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| #Train Samples | #Test Samples | Total #Samples | #Train Samples | #Test Samples | Total #Samples | Precision (%) | Recall (%) | Precision (%) | Recall (%) | Precision (%) | Recall (%) | |

| Polymer Insulator | 730 | 204 | 934 | 2745 | 644 | 3389 | 99.05 | 89.94 | 98.11 | 92.69 | 96.94 | 93.76 |

| Porcelain Insulator | 64 | 20 | 84 | 50 | 13 | 63 | 11.63 | 29.41 | 92.31 | 97.30 | 79.49 | 81.58 |

| COS | 132 | 23 | 155 | 148 | 39 | 187 | 49.21 | 68.89 | 85.54 | 100.00 | 88.73 | 85.14 |

| LP | 117 | 45 | 162 | 140 | 32 | 172 | 76.32 | 54.74 | 75.86 | 93.62 | 50.46 | 96.49 |

| LA | 127 | 19 | 146 | 65 | 26 | 91 | 29.03 | 36 | 60.00 | 94.74 | 86.49 | 72.73 |

| Add-on | 112 | 28 | 140 | 208 | 53 | 261 | 60.00 | 58.82 | 98.88 | 87.13 | 76.19 | 48.98 |

| Total #Samples | 1282 | 339 | 1621 | 3356 | 807 | 4163 | ||||||

| Avg. | 77.08 | 77.37 | 92.14 | 92.98 | 88.39 | 87.18 | ||||||

| Method | Evaluation Dataset Size | Recall (%) | Precision (%) |

|---|---|---|---|

| Jabid [29] | 500 | 94.24 | 89.54 |

| Wu and An [3] | 50 | 86.47 | 85.59 |

| Liao and An [23] | 100 | 91 | 87 |

| Oberweger et al. [30] | 375 | 98 | 33 |

| Proposed LR | 204 | 99.05 | 89.94 |

| Proposed HR_1 | 644 | 97.92 | 92.16 |

| Proposed HR_2 | 644 | 95.91 | 91.57 |

| Defect Type | Precision (%) | Recall (%) | ||

|---|---|---|---|---|

| Bullet shot defect (results at different values of and ) | 100 | 75.00 | 0.007 | 0.4 |

| 77.87 | 87.5 | 0.0045 | 0.3 | |

| 65.92 | 100 | 0.001 | 0.2 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siddiqui, Z.A.; Park, U.; Lee, S.-W.; Jung, N.-J.; Choi, M.; Lim, C.; Seo, J.-H. Robust Powerline Equipment Inspection System Based on a Convolutional Neural Network. Sensors 2018, 18, 3837. https://doi.org/10.3390/s18113837

Siddiqui ZA, Park U, Lee S-W, Jung N-J, Choi M, Lim C, Seo J-H. Robust Powerline Equipment Inspection System Based on a Convolutional Neural Network. Sensors. 2018; 18(11):3837. https://doi.org/10.3390/s18113837

Chicago/Turabian StyleSiddiqui, Zahid Ali, Unsang Park, Sang-Woong Lee, Nam-Joon Jung, Minhee Choi, Chanuk Lim, and Jang-Hun Seo. 2018. "Robust Powerline Equipment Inspection System Based on a Convolutional Neural Network" Sensors 18, no. 11: 3837. https://doi.org/10.3390/s18113837

APA StyleSiddiqui, Z. A., Park, U., Lee, S.-W., Jung, N.-J., Choi, M., Lim, C., & Seo, J.-H. (2018). Robust Powerline Equipment Inspection System Based on a Convolutional Neural Network. Sensors, 18(11), 3837. https://doi.org/10.3390/s18113837