A Batteryless, Wireless Strain Sensor Using Resonant Frequency Modulation

Abstract

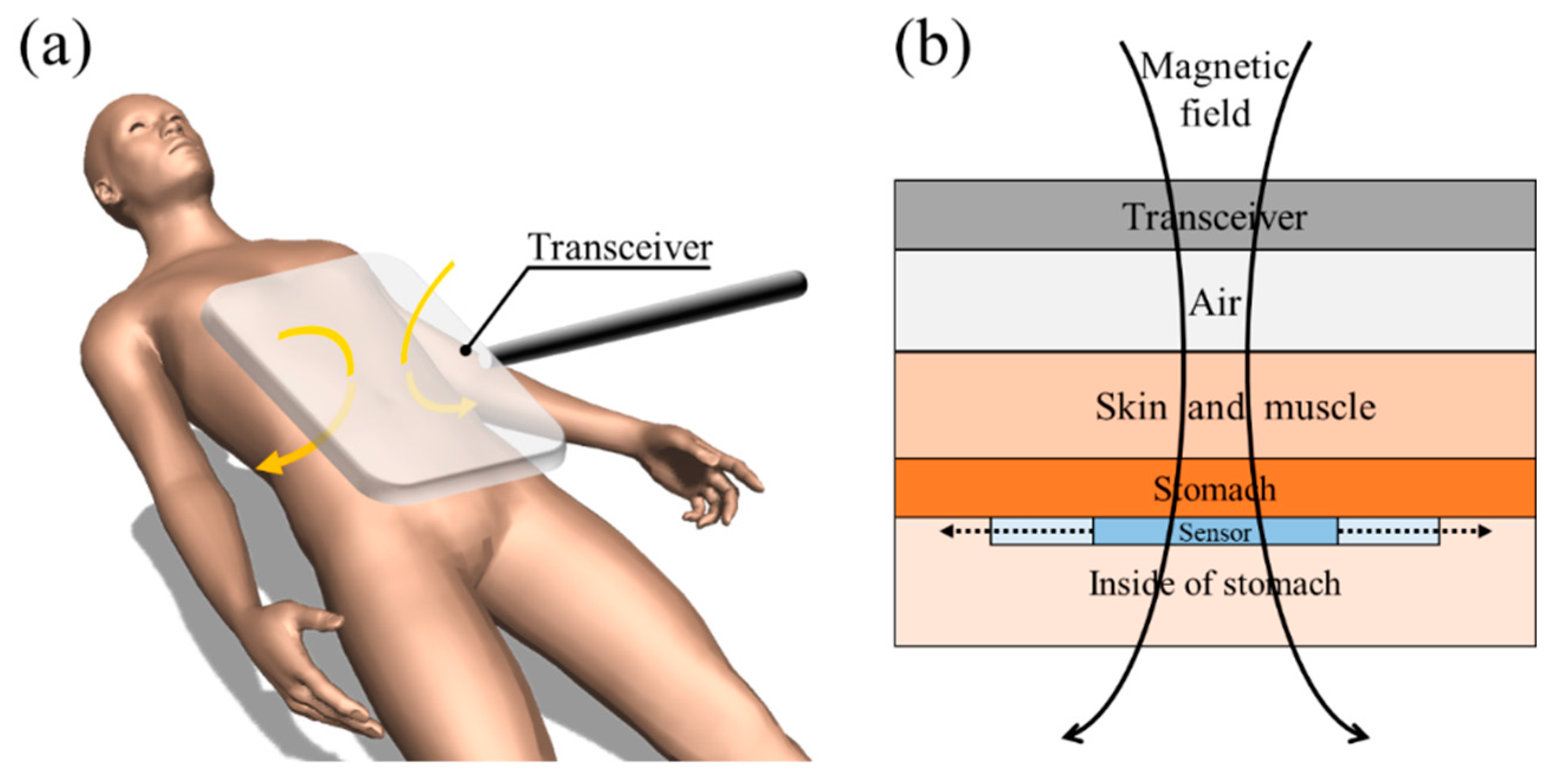

:1. Introduction

2. Materials and Methods

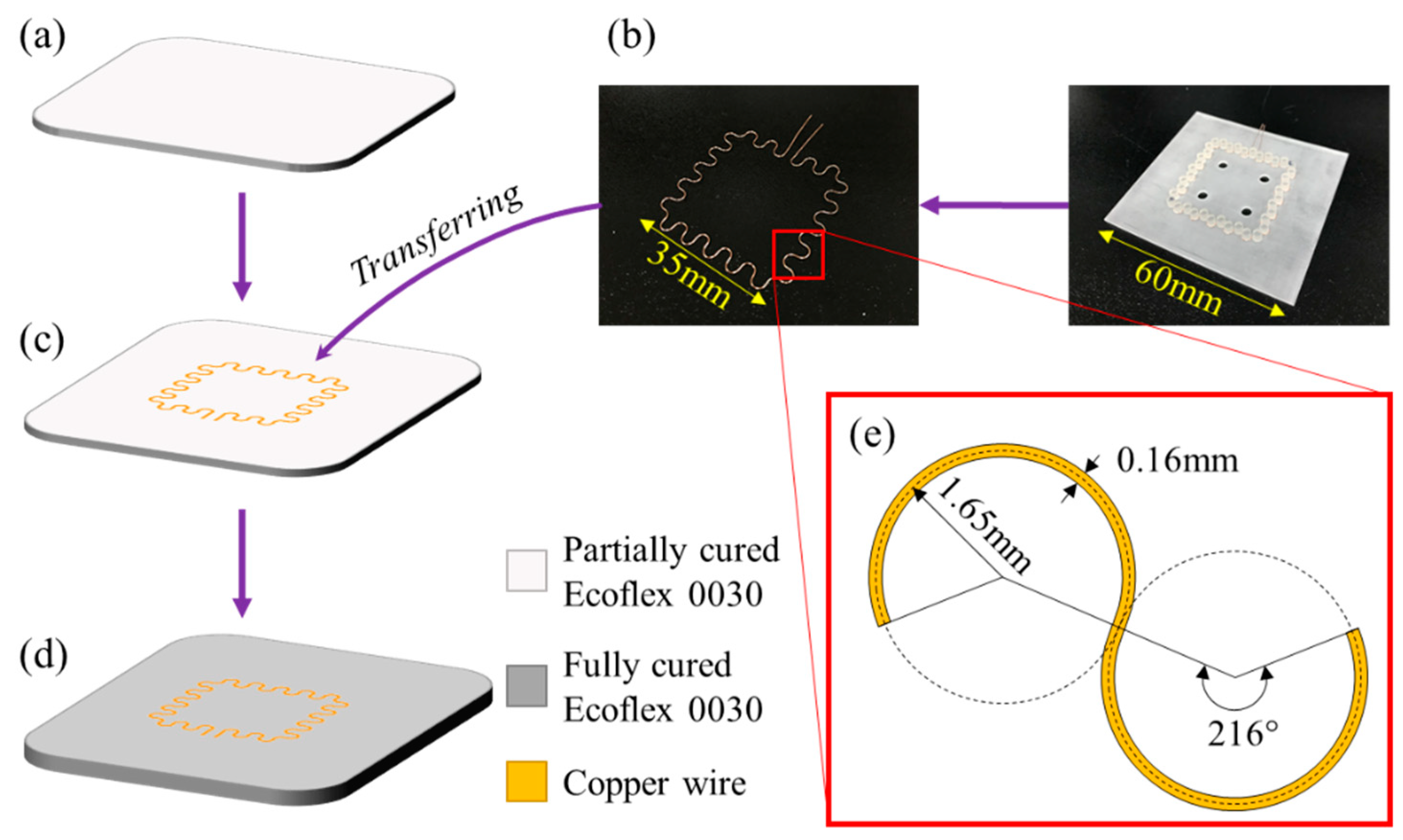

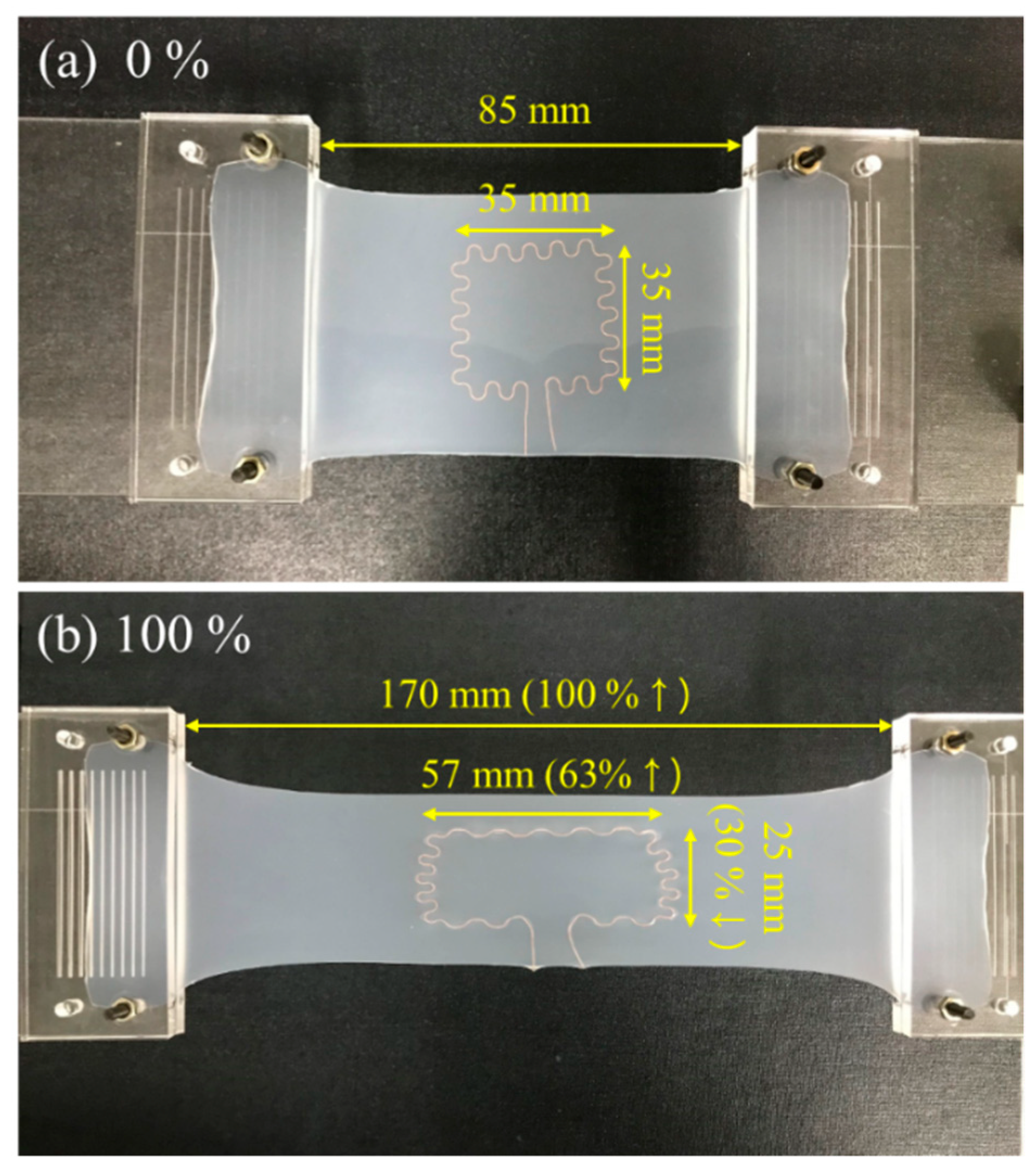

2.1. Fabrication of the Sensor

2.2. Calculation of Sensor Inductance

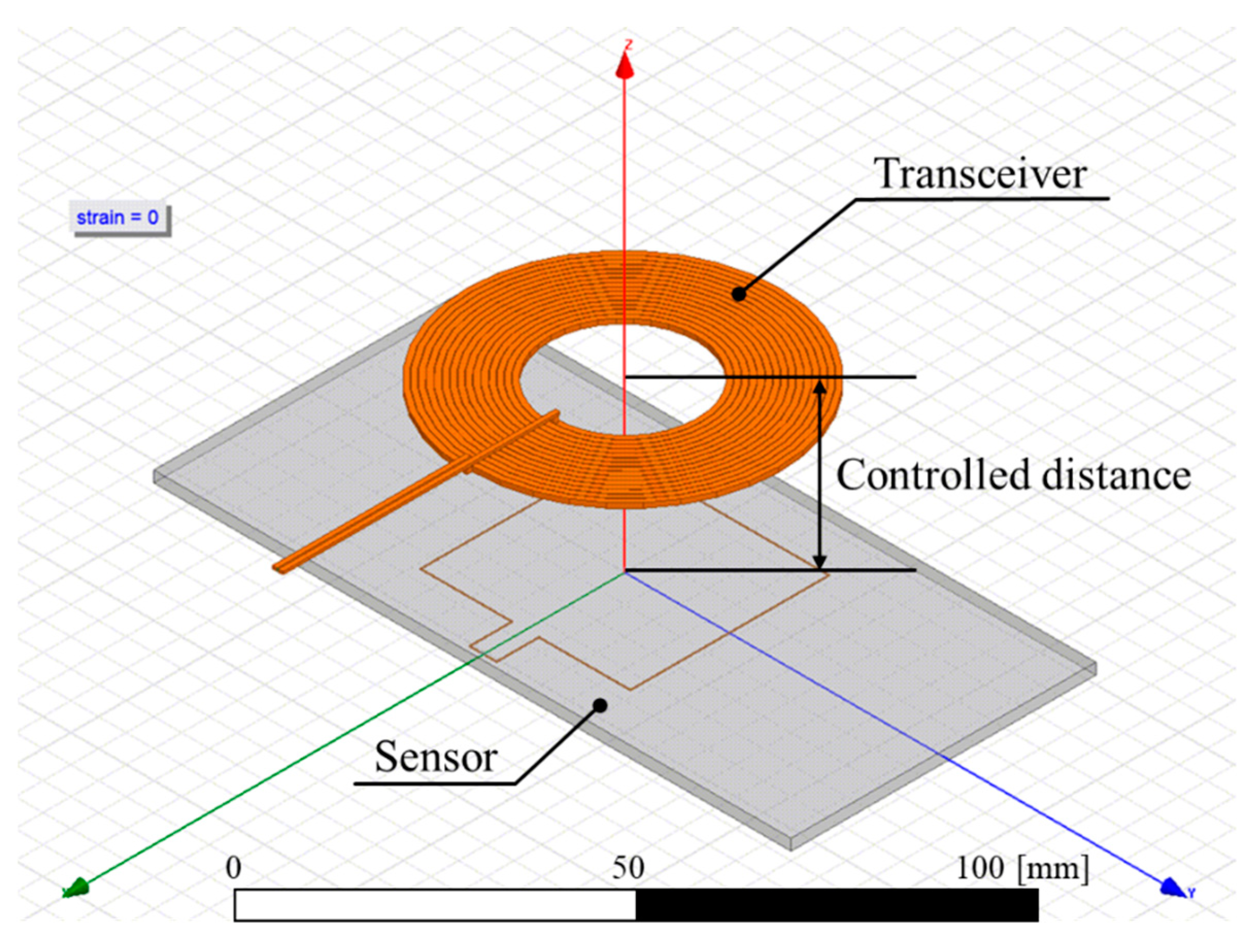

2.3. Finite Element Simulation of Wireless Sensing

2.4. Experimental Setup

3. Results

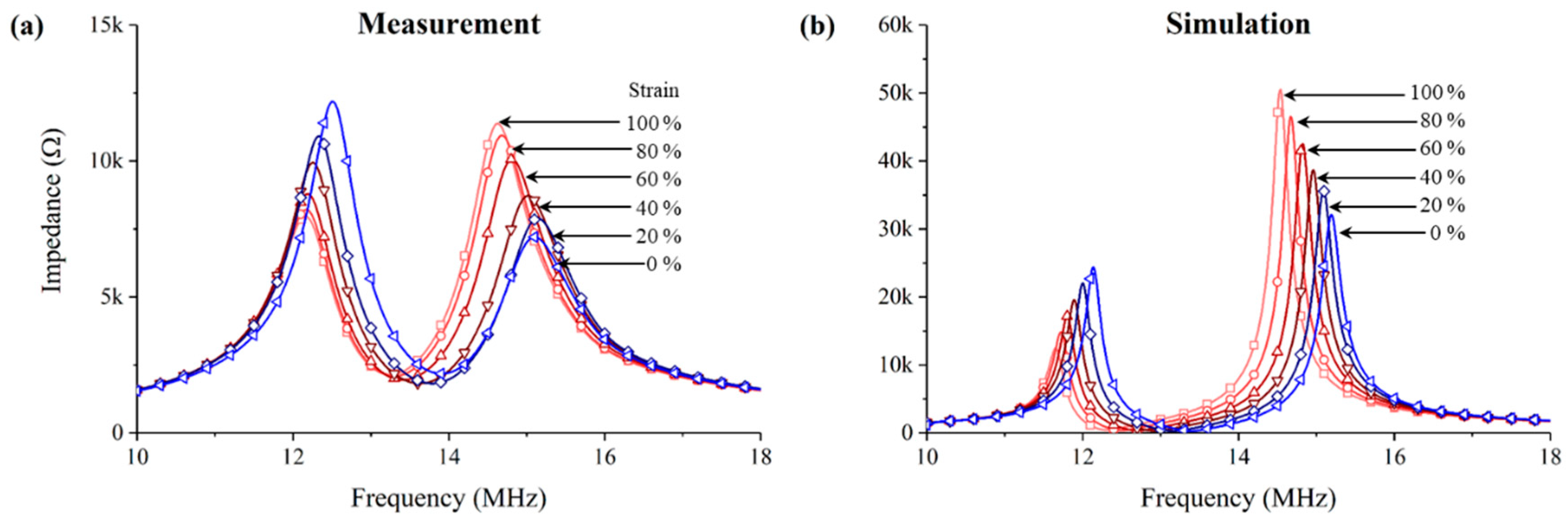

3.1. Tensile Impedance Test

3.2. Wireless Sensing Test

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Jung, K.-W.; Won, Y.-J.; Kong, H.-J.; Oh, C.-M.; Cho, H.; Lee, D.H.; Lee, K.H. Cancer Statistics in Korea: Incidence, Mortality, Survival, and Prevalence in 2012. Cancer Res. Treat. 2015, 47, 127–141. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, W.; Zheng, R.; Baade, P.D.; Zhang, S.; Zeng, H.; Bray, F.; Jemal, A.; Yu, X.Q.; He, J. Cancer Statistics in China. CA Cancer J. Clin. 2016, 66, 115–132. [Google Scholar] [CrossRef] [PubMed]

- Mochiki, E.; Kamiyama, Y.; Aihara, R.; Nakabayashi, T.; Asao, T.; Kuwano, H. Laparoscopic assisted distal gastrectomy for early gastric cancer: Five years’ experience. Surgery 2005, 137, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.H.; Noh, S.H.; Min, J.S.; Lee, K.S.; Kim, C.K. Clinical Analysis According to Reconstructive Type after Total Gastrectomy for Gastric Cancer. Ann. Surg. Treat. Res. 1991, 41, 734–743. [Google Scholar]

- Noh, S.H.; Yoo, C.H.; Kim, Y.; Kim, C.B.; Min, J.S.; Lee, K.S. Results after a Gastrectomy of 2,603 Patients with Gastric Cancer: Analysis of Survival Rate and Prognostic Factor. Ann. Surg. Treat. Res. 1998, 55, 206–213. [Google Scholar]

- Jung, H.J.; Kim, D.H.; Kim, D.H. Proximal Gastrectomy with Double Tract Reconstruction Using the Remnant Antrum in Early Upper Gastric Cancer. Ann. Surg. Treat. Res. 2008, 74, 261–266. [Google Scholar]

- Jeong, I.-U.; Song, Y.-J.; Yun, H.-Y. Gastric-Emptying Patterns after Gastroduodenal Reconstruction. Ann. Surg. Treat. Res. 2000, 59, 46–53. [Google Scholar]

- Kim, W.; Jeon, H.M.; Hur, H.; Lee, J.H.; Won, J.M. Jejunal Pouch Interposition (JPI) after Distal Gastrectomy. J. Korean Gastric Cancer Assoc. 2004, 4, 242–251. [Google Scholar] [CrossRef]

- Komorowski, D.; Pietraszek, S.; Tkacz, E.; Provaznik, I. The extraction of the new components from electrogastrogram (EGG), using both adaptive filtering and electrocardiographic (ECG) derived respiration signal. Biomed. Eng. Online 2015, 14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Estombelo-Montesco, C.A.; de Araujo, D.B.; Roque, A.C.; Moraes, E.R.; Barros, A.K.; Wakai, R.T.; Baffa, O.; Davies, M.E.; James, C.J.; Abdallah, S.A.; et al. Extraction of gastric electrical response activity from magnetogastrographic recordings by DCA. Indep. Compon. Anal. Signal Sep. Proc. 2007, 4666, 585–592. [Google Scholar]

- Kim, J.; Wang, Z.; Kim, W.S. Stretchable RFID for wireless strain sensing with silver nano ink. IEEE Sens. J. 2014, 14, 4395–4401. [Google Scholar] [CrossRef]

- Song, L.; Myers, A.C.; Adams, J.J.; Zhu, Y. Stretchable and reversibly deformable radio frequency antennas based on silver nanowires. ACS Appl. Mater. Interfaces 2014, 6, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Lazarus, N.; Meyer, C.D.; Turner, W.J. A microfluidic wireless power system. RSC Adv. 2015, 5, 78695–78700. [Google Scholar] [CrossRef]

- Egorov, V.I.; Schastlivtsev, I.V.; Prut, E.V.; Baranov, A.O.; Turusov, R.A. Mechanical properties of the human gastrointestinal tract. J. Biomech. 2002, 35, 1417–1425. [Google Scholar] [CrossRef]

- Neagu, C.R.; Jansen, H.V.; Smith, A.; Gardeniers, J.G.E.; Elwenspoek, M.C. Characterization of a planar microcoil for implantable microsystems. Sens. Actuators A Phys. 1997, 62, 599–611. [Google Scholar] [CrossRef] [Green Version]

- Rogers, J.A.; Someya, T.; Huang, Y. Materials and mechanics for stretchable electronics. Science 2010, 327, 1603–1607. [Google Scholar] [CrossRef] [PubMed]

- Fan, J.A.; Yeo, W.H.; Su, Y.; Hattori, Y.; Lee, W.; Jung, S.Y.; Zhang, Y.; Liu, Z.; Cheng, H.; Falgout, L.; et al. Fractal design concepts for stretchable electronics. Nat. Commun. 2014, 5. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Liu, Y.; Cheng, H.; Shin, W.J.; Fan, J.A.; Liu, Z.; Lu, C.J.; Kong, G.W.; Chen, K.; Patnaik, D.; et al. Materials and designs for wireless epidermal sensors of hydration and strain. Adv. Funct. Mater. 2014, 24, 3846–3854. [Google Scholar] [CrossRef]

- Ecoflex Series; MSDS No. 844; Smooth-On Inc.: Easton, PA, USA, 2013.

- Salvatore, G.A.; Sülzle, J.; Dalla Valle, F.; Cantarella, G.; Robotti, F.; Jokic, P.; Knobelspies, S.; Daus, A.; Büthe, L.; Petti, L.; et al. Biodegradable and Highly Deformable Temperature Sensors for the Internet of Things. Adv. Funct. Mater. 2017, 27, 1–10. [Google Scholar] [CrossRef]

- Park, G.; Chung, H.J.; Kim, K.; Lim, S.A.; Kim, J.; Kim, Y.S.; Liu, Y.; Yeo, W.H.; Kim, R.H.; Kim, S.S.; et al. Immunologic and tissue biocompatibility of flexible/stretchable electronics and optoelectronics. Adv. Healthc. Mater. 2014, 3, 515–525. [Google Scholar] [CrossRef] [PubMed]

- Chou, N.; Lee, J.; Kim, S. Large-sized out-of-plane stretchable electrodes based on poly-dimethylsiloxane substrate. Appl. Phys. Lett. 2014, 105, 241903. [Google Scholar] [CrossRef]

- Horowitz, P.; Winfield, H. The Art of Electronics, 3rd ed.; Cambridge University Press: Cambridge, UK, 2015; pp. 15–20. ISBN 0521809266. [Google Scholar]

- Greenhouse, H.M. Design of Planar Rectangular Microelectronic Inductors. IEEE Trans. Parts Hybrids Packag. 1974, 10, 101–109. [Google Scholar] [CrossRef]

- Agilent Technologies. Agilent 4294A Precision Impedance Analyzer Operation Manual, 7th ed.; Agilent Technologies: Santa Clara, CA, USA, 2003; pp. 249–253. [Google Scholar]

- So, J.H.; Thelen, J.; Qusba, A.; Hayes, G.J.; Lazzi, G.; Dickey, M.D. Reversibly deformable and mechanically tunable fluidic antennas. Adv. Funct. Mater. 2009, 19, 3632–3637. [Google Scholar] [CrossRef]

- Hayes, G.J.; So, J.-H.; Qusba, A.; Dickey, M.D.; Lazzi, G. Flexible Liquid Metal Alloy (EGaIn) Microstrip Patch Antenna. IEEE Trans. Antennas Propag. 2012, 60, 2151–2156. [Google Scholar] [CrossRef]

- Shin, G.; Gomez, A.M.; Al-Hasani, R.; Jeong, Y.R.; Kim, J.; Xie, Z.; Banks, A.; Lee, S.M.; Han, S.Y.; Yoo, C.J.; et al. Flexible Near-Field Wireless Optoelectronics as Subdermal Implants for Broad Applications in Optogenetics. Neuron 2017, 93, 509–521.e3. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, J.; Banks, A.; Xie, Z.; Heo, S.Y.; Gutruf, P.; Lee, J.W.; Xu, S.; Jang, K.I.; Liu, F.; Brown, G.; et al. Miniaturized Flexible Electronic Systems with Wireless Power and Near-Field Communication Capabilities. Adv. Funct. Mater. 2015, 25, 4761–4767. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, K.J.; Chou, N.; Kim, S. A Batteryless, Wireless Strain Sensor Using Resonant Frequency Modulation. Sensors 2018, 18, 3955. https://doi.org/10.3390/s18113955

Lee KJ, Chou N, Kim S. A Batteryless, Wireless Strain Sensor Using Resonant Frequency Modulation. Sensors. 2018; 18(11):3955. https://doi.org/10.3390/s18113955

Chicago/Turabian StyleLee, Kyeong Jae, Namsun Chou, and Sohee Kim. 2018. "A Batteryless, Wireless Strain Sensor Using Resonant Frequency Modulation" Sensors 18, no. 11: 3955. https://doi.org/10.3390/s18113955

APA StyleLee, K. J., Chou, N., & Kim, S. (2018). A Batteryless, Wireless Strain Sensor Using Resonant Frequency Modulation. Sensors, 18(11), 3955. https://doi.org/10.3390/s18113955