3.1. Structure and Chemical Composition

In this research, three samples of microresonators made of PZT and three different binding materials (PVB, PMMA, and PS) were fabricated and investigated. The SEM view of each sample is presented (

Figure 5). The surface of the first sample, PZT with PVB binder, was rather smooth with small pileups of 10–20 μm in diameter observed on top of the surface (

Figure 5a). The sample made of a PZT layer with PMMA binder was smooth, and very small pileups of less than 5 μm diameter were observed on the surface (

Figure 5b). The third sample made of PZT with PS binder was also smooth with some small pileups of 5–15 μm in diameter (

Figure 5c). Finally, the results showed that a binder PMMA loaded in PZT matrix might be the origin of its irregular shape, nucleation, and growth in the solution, thus forming the smaller grain group and smoother surface, compared to the PVB/PZT and PS/PZT samples.

The chemical composition of the samples was evaluated using an energy-dispersive (ED) spectrometer with a pulse height analysis. Here, an electrical charge was produced when incident X-ray photons caused ionization to occur. In the registered energy dispersive spectrum, the x axis represents the X-ray energy in Channels 1 to 6 from 0 to 6 keV, and the y axis represents the number of counts per channel up to 18 cps/keV. In all three samples, five main elements were defined: carbon (C), oxygen (O), titanium (Ti), zirconium (Zr), and lead (Pb). The energy dispersive spectrum of all samples is given in

Figure 6 below.

From the PVB/PZT sample ED spectrum (

Figure 6) C K

β energy resolution, the peak was specified at about 0.2 keV. For the O K

β energy resolution, the peak was specified at about 0.5 keV. For the Ti K

β energy resolution, the peak was specified at about 0.3 keV and 4.5 keV. For Zr L

α, the peak was achieved at 2.1 keV and 15.8 keV. For Pb L

α, the peak was achieved at 2.4 keV and 10.5 keV. Thus, the map of the distribution and relative proportion (intensity) of defined elements over the scanned area is presented in

Table 1 and

Figure 7.

From the PMMA/PZT sample ED spectrum (

Figure 6) C K

β energy resolution, the peak was specified at about 0.2 keV. For the O K

β energy resolution, the peak was specified at about 0.5 keV. For the Ti K

β energy resolution, the peak was specified at about 0.4 keV and 4.5 keV. For the Al K

β energy resolution, the peak was specified at about 1.4 keV. For Zr L

α, the peak was achieved at 2.1 keV and 15.8 keV. For Pb L

α, the peak was achieved at 2.4 keV and 10.5 keV. Thus, the values were almost identical to the PVB/PZT sample, except that the aluminum element appeared. The map of the distribution and relative proportion (intensity) of defined elements over the scanned area and chemical characterization of the sample are presented in

Table 2 and

Figure 8.

The PS/PZT sample showed five main elements registered in the ED spectrum (

Figure 6). The element C K

β energy resolution peak was specified at about 0.2 keV. For the O K

β energy resolution, the peak was specified at about 0.4 keV. For the Ti K

β energy resolution, the peak was specified at about 0.4 keV and 4.5 keV. For Zr L

α, the peak was achieved at 2.1 keV and 15.7 keV. For Pb L

α, the peak was achieved at 2.4 keV and 10.6 keV. Thus, the values were almost identical to the PVB/PZT and PMMA/PZT samples. The map of the distribution and relative proportion (intensity) of defined elements over the scanned area and chemical characterization of the sample are presented in

Table 3 and

Figure 9.

Thus, each element had its defined positions of the characteristic peak in the piezoelectric sample corresponding to the transitions in its electron shell. Chemical analysis shows that five main elements were dominant in all three samples: C, O, Ti, Zr, and Pb. Only in the PMMA/PZT sample, one more dominating element, Al, appeared. Moreover, the intensity value was dependent on the exciting X-ray’s intensity, on the X-ray detector’s efficiency, on the energy spectrum, and on the geometry of the investigated sample.

Further, FTIR analysis of different microresonator samples was carried out (

Figure 10,

Figure 11 and

Figure 12). The typical FTIR absorbance spectrum is at 4000–500 cm

−1.

In the FTIR spectra of the PVB/PZT sample (

Figure 10), strong and broad absorption peaks were observed at 3502 cm

−1 (O–H stretch), 2971 cm

−1 (C–H stretch), 1726 cm

−1 (C=O stretch), 1436 cm

−1 (CH

3 bend), 1382 cm

−1 (CH

2 bend), 1154 cm

−1 (C–O–C stretch), and 1006 cm

−1 (C–O stretch). The entire array of these peaks corresponds to the FTIR absorbance spectra of polyvinyl butyral (PVB) [

33].

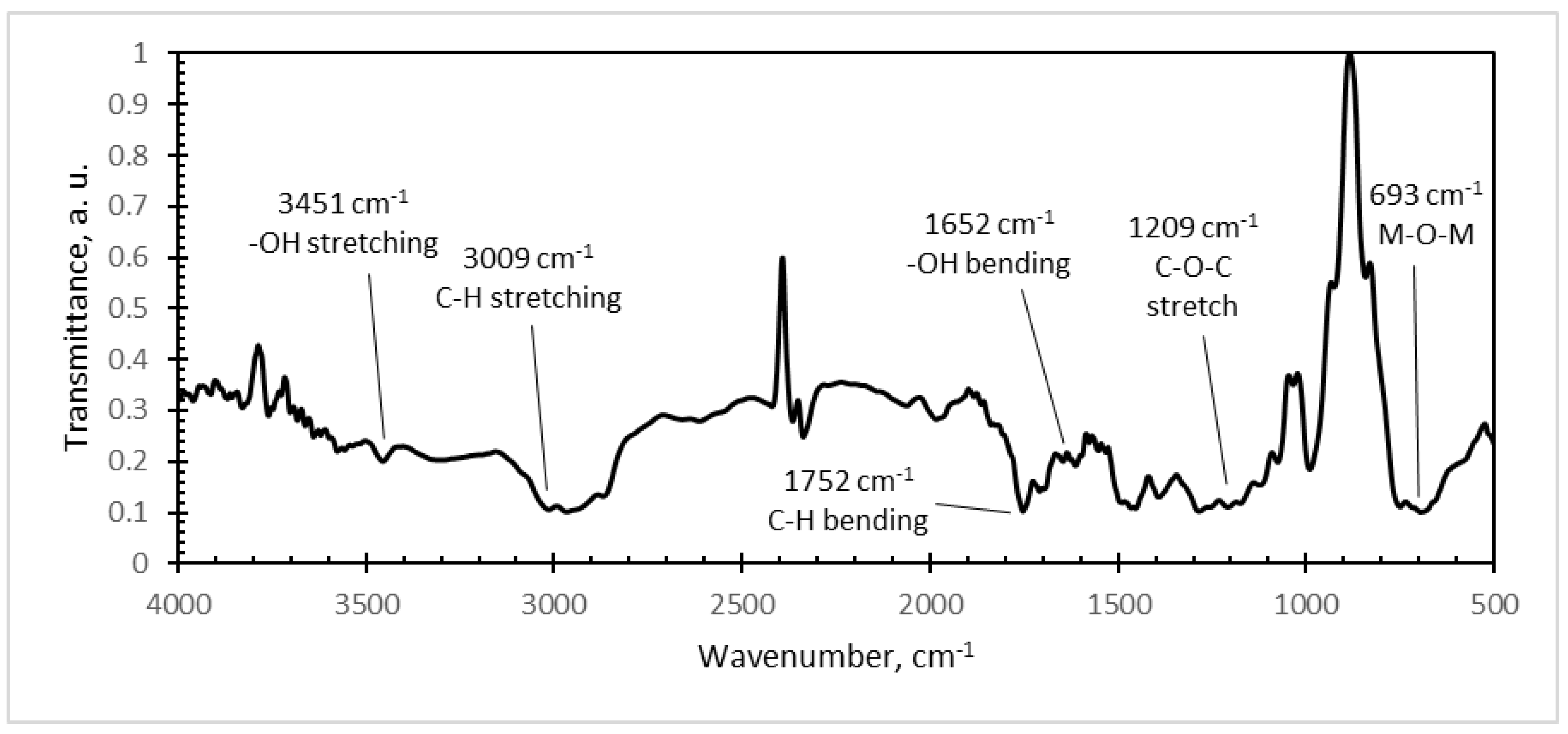

Strong and broad absorption peaks were observed at 3451 cm

−1 (–OH stretch), 3009 cm

−1 (C–H stretch), 1752 cm

−1 (C–H bend), 1652 cm

−1 (–OH bend), and 1209 cm

−1 (C–O–C stretch) in the PMMA/PZT FTIR spectra (

Figure 11). The entire array of these peaks corresponds to the FTIR absorbance spectra of polymethyl methacrylate (PMMA) [

34].

PMMA/PZT FTIR spectra are given in

Figure 12. Absorption peaks were observed at 2941 cm

−1 (C–H stretch), 1732 cm

−1 (C=C bend), 1601 cm

−1 (C=C stretch), 1271 cm

−1 (–CH

2 stretch), and 764 cm

−1 (C–H stretch). The received results correspond to the FTIR absorbance spectra of polystyrene (PS) [

35].

In infrared spectra of all three samples, the absorption bands in diapason of 4000–1000 cm

−1 confirmed the presence of polymers. It is obvious that PZT strongly absorbs at 700 cm

−1, making identification of the 511 cm

−1 band difficult for composites with ceramic contents over 20 wt.%. A wide and strong peak observed in the range of 800–550 cm

−1 corresponds to the M–O–M bonds (M is metal) of PZT (e.g., Ti–O, Ti–O–Ti, Zr–O, and Zr–O–Zr) [

36]. It may be indicating that with increasing PZT content, the PZT peak remains dominant, making the presence of binders’ peaks weak.

3.2. Piezoresistive Characteristics of Microresonators

Piezoresistive characteristics’ analysis of the samples was performed with a Keithley meter scanner. The width and height of the sample were 24 and 0.5 mm, respectively. The distance between the acting force points was 42 mm and 24 mm, designated as L and l. All of the different binders had the same Young’s modulus of 350 GPa. According to

Figure 2 given above, the following experimental data were obtained and are presented in

Table 4.

The PVB/PZT coating possessed a negative gauge factor of −139.5; the PMMA/PZT gauge factor was 1151; and the PS/PZT coating possessed the highest negative gauge factor of −3458.8. A negative polarity of the gauge factor indicates that the resistance decreases with the increasing applied strain.

The force-resistance relationship in all three samples (

Figure 13) was linear or ascending from a certain point. For the PVB/PZT coating, this relationship became linear from ~3 N force and up (

Figure 13a). Increasing force, only small changes of resistance were observed. For the PMMA/PZT coating, the resistance dramatically dropped at ~4.2 N force and then started increasing with increasing force (

Figure 13b). For the PS/PZT coating, the resistance dropped till the force reached ~7 N and then started to linearly increase (

Figure 13c). Thus, this piezoelectric film had an obvious turn-on threshold, i.e., a force that must be present before the resistance dropped to a value below 7 pΩ, where the relationship became more linear. The results showed that the resistance of the piezoelectric coating was highly dependent on the type of binder. All three experiments were held 15 times each with the same environmental conditions.

Figure 13 shows only the average of all measurements.

Another important factor when designing piezoelectric materials is the value of capacitance. When a piezoelectric material operates well below the resonant frequency, it behaves as a capacitor. The value of capacitance depends on the area and thickness of the coating, as well as the material properties. In this research, the capacitance of the piezoelectric coatings was estimated by [

37]:

where

C is capacitance (F),

n the number of coating layers,

ε33 the dielectric constant (As/Vm),

A the electrode surface area of a layer (m

2), and

dS the distance between the individual electrodes (layer-thickness) (m). Calculation results of each microresonators capacitance are given in

Table 5 below.

Therefore, the capacitance of a piezoelectric coatings constructed of a 70 μm-thick layer was almost the same in all three samples; however, the highest capacitance was observed in the PMMA/PZT coating.

Further, the Keithley meter was used to evaluate the current-voltage (

I-

V) characteristic of each designed piezoelectric coating by sourcing the voltage from 0–200 V (2 V step) (

Figure 14).

The current-voltage characteristic was defined as the relationship of the current

I through the device and the voltage

V across its terminals. Each experiment was done 10 times, five for each terminal. Calculations involved stepping the voltage level across a device from one level to another and measuring the resulting currents in an operation (a sweep). Thus, while sweeping a voltage from 0–200 V, the measured current of PS/PZT linearly increased up to ~23 nA and for PMMA/PZT up to ~51 nA, while PVB/PZT had a very low current increase up to 0.94 nA (

Figure 14). The obtained results correspond to those found in the literature [

38,

39]. These results suggest making the microresonators from the PMMA/PZT material in order to increase the performance of the device, i.e., PMMA/PZT gives a significant increase in the current intensity.

Using the PicoScope system together with a simulation model in COMSOL Multiphysics (for calculations of the first vibration mode), a dynamic analysis was performed for each sample, suspending a mass on a pendulum and releasing it to hit the sample, then stopping the pendulum after contact. A vibrational response of the PS/PZT coating to a mechanical impulse was registered (

Figure 15).

For evaluation of the main factors of the microresonators’ quality, a value of damping ratio and Young modulus were defined (

Table 6). Damping (either constructional or environmental) is one of the factors imposing an upper limit on the quality of the microresonator [

40], i.e., improving the negative damping feedback, its quality is ameliorated, as well. The Young modulus defines the stiffness of the coating, i.e., stress and strain relationship in the material. Using the obtained experimental results, the main properties of each microresonator were calculated (

Table 6).

The highest Young’s modulus value was obtained for the PMMA/PZT coating (6.3 GPa), while usage of PS and PVB led to a lower stiffness of 5.3 and 3.9 GPa, respectively. Since 80% of the designed material consisted of PZT nanoparticles and only 20% of binding material (PVB, PMMA, or PS), this allowed reducing the Young modulus approximately 10 times. The obtained experimental results were in good correlation with the results founded in the literature: the Young’s modulus of PMMA was 6.3 GPa [

41] and PS 5.3 GPa [

42], and PVB had the lowest modulus of elasticity of 3.9 GPa [

43].

Using the PRISM system, holographic interferograms together with resonant frequencies of the designed microresonators were obtained (

Figure 16).

The vibration amplitude of the PVB/PZT microresonator was 100 nm at a 114-Hz resonant frequency when 100 V of voltage were applied. For PMMA/PZT, the vibration amplitude was 164 nm at a 114-Hz resonant frequency and for PS/PZT 366 nm at 114 Hz.

When the direct piezoelectric effect for further investigations of the designed microresonators was applied, the results showed that periodically-excited specimens were able to generate electrical potential due to the piezoelectric effect of the PZT material (

Figure 17). The highest value of the harvested electrical energy was registered in the PS/PZT microresonator (up to 3 mV of generated voltage). The lowest result was 2.1 mV, indicated for PVB/PZT, and PMMA/PZT generated up to a 2.5-mV voltage.

The sheet resistivity of each coating was measured by the VSWR meter P2-67. Each sample was placed between a waveguide open end and a λ/4 jumper. The waveguide inner cross-section was 16 × 8 mm

2. Thus, the results showed that each sample’s measured sheet resistance was higher than 20,000 ohms per square (

Table 7). These measurements characterize the uniformity of the conductive coating for quality assurance.

3.3. Microhardness of Microresonators

Microhardness measurements were performed with a dynamic microhardness meter with base HM 2000S. Each sample was measured 10 times with a maximum indentation depth of 4 μm. Measurements were performed gradually under the maximum load of 200 g. Martins microhardness (HM) and Vickers microhardness (HV) were measured (

Table 8).

Results showed, that there was a very slight difference in the Martins and Vickers microhardness between the different coatings, i.e., HM differed by about 17 N/mm

2 and HV only by ~3 (

Figure 18). However, the microresonators’ film with PMMA/PZT showed more elastic deformation than the other materials.

During the scratch test, a critical load together with the coefficient of friction, frictional, and normal forces of the microresonators surface were identified. The failure of the coating was determined by optical microscopy, acoustic emission, and variation in penetration depth. A scratch test on a microresonator with an ~2 μm-thin coating was performed for each coating (PVB/PZT, PMMA/PZT, and PS/PZT) with a 0.2-mm radius diamond and a 5-mm scratch length. The normal load was increased over 30 s from 0–6 N. Four repetitions for each coating were done, and the main data recorded during the scratch tests are shown in

Figure 19.

The obtained results imply that the PMMA/PZT coating was almost twice as hard compared to the other two, i.e., the average critical load was 3.988 N, meaning a very resistant coating to the scratch damage. The PVB/PZT coating was rather soft and not that resistant with a critical load of 1.865 N. The PS/PZT average critical load was 2.556 N. In the given panorama images, an area corresponds to the critical failure (critical load, marked vertical line in

Figure 19) in the scratch track. The coating was completely removed as the substrate (brighter area) was reached during the test. The obtained critical load values showed excellent repeatability in the test results (

Table 9).

The scratch testing method belongs to these new characterization techniques, which is used for adhesion measurement of functional surface coatings. The advances in adhesion testing (including panorama and prescan/post-scan procedures) now readily allow for testing of the adhesion and scratch resistance of microresonators surface coatings, which are used for the improvement of osseointegration or for reducing friction and wear. This test allows for fast and simple characterization of new functional coatings, of their adhesion, and scratch resistance in a well-controlled manner.