1. Introduction

Airborne earth observation takes the aircraft as the platform, and it uses remote sensing load such as synthesize aperture radar (SAR) and charge coupled device (CCD) array camera to acquire a wide range, highly accurate and multilayered space-time information of global surface and deep earth [

1]. A position and orientation system (POS) is a dedicated strapdown inertial navigation system (SINS)/Global Positioning System (GPS) integrated system for airborne remote sensing [

2]. As a direct georeferencing (DG) system, the POS provides the ability to directly relate the data collected by a remote sensing system to earth without using traditional ground-based measurements [

3]. To improve mapping accuracy and efficiency, the POS is required to provide the position information to centimeter-level accuracy, and orientation data to sub-arcminute accuracy in either real-time navigation or post-mission, such as the current state-of-the-art airborne system POS AV610 [

3,

4]. This is primarily accomplished by the inertial measurement unit (IMU) integrated with a Carrier-phase Differential GPS (CDGPS).

The key algorithm for POS is still SINS/GPS integrated navigation [

5,

6]. For the loosely-coupled integration method discussed here, the positions and velocities of the SINS and GPS solutions are compared, and the resulting differences are used as the measurement values for a Kalman filter [

7,

8]. Due to the extremely high positioning accuracy of a CDGPS, typically 1–2 cm plus 1 ppm of baseline separation in real-time kinematic (RTK) or post-processing [

9,

10], many overlooked errors must be treated seriously. Among these, the time and space asynchronies are the dominant error sources. The time asynchrony means the time delay of the GPS position and the velocity information with respect to the SINS data in real-time systems, which will badly influence the accuracy of the SINS/GPS navigation solution. Based on one pulse per second (1PPS) of the GPS, which can deliver very high time accuracies such as 20 ns, the time delay can be significantly attenuated by the professional time synchronization technology [

11]. The space asynchrony means the lever arm between the GPS antenna and the IMU. Generally, the GPS antenna is mounted on the roof of the plane for better GPS satellite visibility [

7,

12], while the IMU is installed inside the plane cabin or under the aircraft belly as close to the surveying sensors as possible to weaken the influence of flexural deformation. Therefore, the phase center of the GPS antenna and the measuring center of the IMU are separated by a lever arm. Since the lever arm in length is usually several meters, it severely deteriorates measurement values under angular excitations if no compensation is provided.

Many efforts have been devoted to improving SINS/GPS integration accuracy by attenuating the lever arm uncertainty. One method is manual measurement by a total station [

13,

14], which can obtain the length of the lever arm with sufficient accuracy, but suffers from complicated operation. Furthermore, it is a difficult task in itself to determine the phase center of a GPS antenna and the sensing center of an IMU. Repeated measurements are inevitable if the GPS antenna or IMU is replaced or remounted. The other method is automatic identification of the lever arm by the SINS/GPS integration navigation [

1,

15,

16,

17,

18,

19,

20], in which the lever arm is extended as an error state of the Kalman filter to be estimated, while the vehicle maneuvers. The latter method is simple and effective, but practical only if the lever arm is constant.

To maintain imaging quality, aerial surveying sensors are required to move in a straight line with a given direction, but a plane may deviate from the ideal motion trajectory, due to gusts, air turbulence, or flight control errors [

7,

21]. Consequently, an inertially stabilized platform (ISP) with three gimbals is usually used to isolate the angular motion interference and to focus the surveying sensor onto the desired targets, such as the general ISP PAV80 and GSM3000 [

7,

22,

23]. The use of ISP makes the lever arm problem more complicated. Generally, the surveying sensor and the IMU are rigidly mounted close together on the ISP, but the measuring center of the IMU cannot be ensured to coincide with the rotating center of the ISP. When the ISP rotates, the lever arm between the IMU center and the GPS antenna center changes; for this reason, we call it a dynamic lever arm. Since the lever arm is not constant in this situation, traditional lever arm estimation methods do not work. In [

7,

12], the dynamic lever arm is decomposed into two constant lever arms to be compensated in flying missions, but they are still manually measured in advance. In order to avoid complex manual measurements and to improve surveying efficiency, we propose an automatic approach to estimating two separate lever arms that provide equivalent compensation.

The rest of this paper is organized as follows:

Section 2 describes the system model and the problems to be solved.

Section 3 presents the proposed integrated navigation approach and analyzes the corresponding observability in detail.

Section 4 verifies our method through simulation tests, and conclusions are drawn in

Section 5.

2. System Description

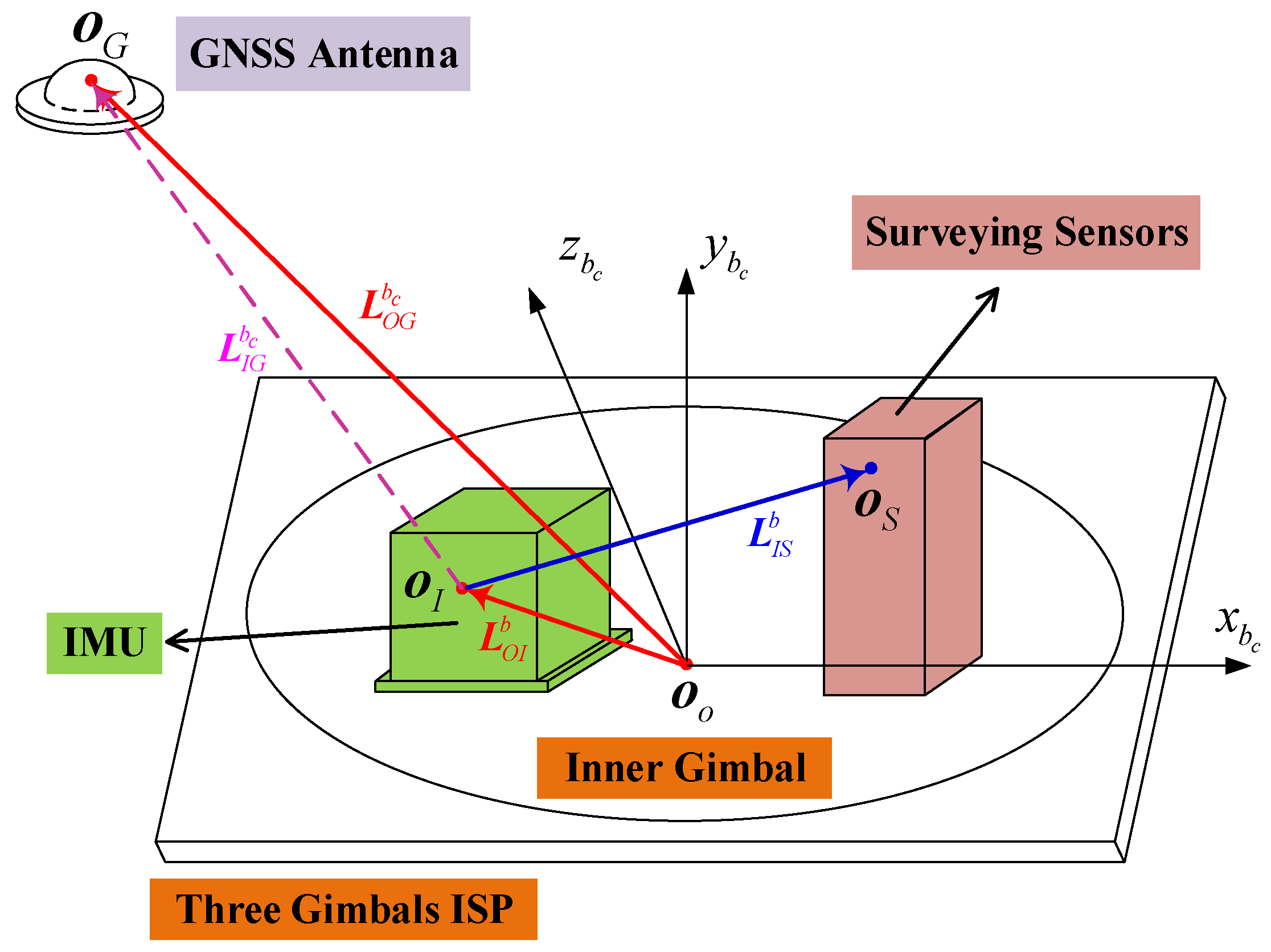

As shown in

Figure 1, the IMU and surveying sensors are usually fixed on the inner gimbal of the ISP. Thus, the mounting angle and lever arm between the two are constant, reducing the accuracy requirements for the ISP. The GPS antenna is mounted on the roof of the plane for better satellite visibility. The related coordinate systems are defined as follows:

-frame, the navigation frame, chosen as the local level east–north–up (ENU) coordinate;

-frame, the IMU body frame, implicitly predefined by the calibrated sensitive axes of the inertial sensors, with the origin located at the sensitive center of IMU (point ), and axes pointing right, forward, and upward;

-frame, the carrier frame, fixed to the flight vehicle and originating at the rotating center of the ISP (point ). The axis directions of -frame do not rotate with the gimbals, and coincide with the ISP only if the encoder data of three gimbals are all zeros;

-frame, the surveying sensor frame, rigidly fixed to the surveying sensor with the origin located at the surveying center (point ).

Based on the established frames, the related lever arms are defined as follows:

, the lever arm from the rotating center of the ISP (point ) to the sensitive center of IMU (point ) projected in the -frame;

, the lever arm from the rotating center of the ISP (point ) to the phase center of the GPS antenna (point ) projected in the -frame. Whether the ISP rotates or not, there is no relative motion between the point and point in the -frame; thus, the lever arm is a constant;

, the lever arm from the sensitive center of the IMU (point ) to the phase center of the GPS antenna (point ) projected in the -frame;

, the lever arm from the sensitive center of the IMU (point ) to the measuring center of the surveying center (point ), projected in the -frame.

Three lever arms—, , and —are constant, while lever arm changes with the ISP rotation. Because the lever arm is uncertain and time-varying, it is referred to as a dynamic lever arm.

Since the attitude matrix

can be obtained from the SINS solution, the transformation matrix

from

-frame to the

-frame can be obtained as follows:

in which the direction cosine matrix

is formed with the encoder data of the ISP [

7]:

where:

the angles

,

, and

are encoder data obtained from the inner, middle, and outer gimbals of the ISP, respectively.

Referring to Equation (2), the angular rate of the

-frame with respect to the

-frame, denoted as

, can be calculated as follows [

7]:

where

,

, and

are the angular rates of roll, pitch, and heading gimbals of the ISP, respectively, which are obtained by the time differentiation of the corresponding encoder data.

According to the lever arm effect [

24], if the position and velocity parameters at point

are obtained from navigation solutions, and the lever arm

is known, the corresponding information at point

can be calculated as follows:

where

and

denote the position information consisting of latitude, longitude, altitude;

and

are the velocity data at point

and point

in the

-frame;

and

are the local latitude and height;

and

denote the transverse and meridian radius of curvature. The relative angular rate

is obtained by

, in which

can be acquired from the output of gyros, and

denotes earth’s rotation rate vector in the

-frame.

Similarly, the position and velocity parameter correlations among the point

, point

, and point

are formulated as:

where

and

denote the velocities at point

and point

in the

-frame, and the relative angular rate

can be obtained by:

In a normal integrated navigation mechanism, the velocity and/or position differences between the SINS and GPS solutions are generally taken as the measurement values. To improve the measurement accuracy, the dynamic lever arm

must be compensated precisely even if it is difficult. Based on Equations (7) and (8), the dynamic lever arm can be compensated as follows:

Combining Equations (9) and (11) yields:

This means that the dynamic lever arm

can be decomposed into two constant lever arms

and

, because of the fact that the ISP rotating center

is fixed to both the

-frame and the

-frame. From the geometric location relationship shown in

Figure 1, we can deduce the same results as Equation (12). Therefore, if the two constant lever arms

and

are precisely measured in advance, the dynamic lever arm

can be compensated as Equation (12). However, as mentioned before, manual measurement is complex, tedious, and inefficient. To avoid these drawbacks and enhance the efficiency of surveying, we propose a method to automatically estimate the lever arm and to accomplish the integrated navigation simultaneously.

3. Proposed SINS/GPS Integrated Navigation Model

3.1. SINS/GPS Integrated Navigation Model

As shown in Equation (11), if the SINS/GPS integrated navigation model can be designed to estimate the lever arms

and

, the complex dynamic lever arm

can be compensated automatically, and the tedious work of manual measurement can be eliminated. Combining the classical error model of SINS and the constant lever arms

and

, we define a 21-dimensional error state vector of SINS/GPS integration as:

where

is the misalignment angles of SINS;

is the velocity errors;

denotes the position errors consisting of latitude, longitude, and height errors;

and

are the gyro and accelerometer biases in the

-frame, respectively.

The corresponding state equation of Kalman filter is:

where

is a 15 × 15 transition matrix based on typical SINS error model as detailed in [

25]. The symbols

and

are the noises of gyros and accelerometers, and

denotes an

zero matrix.

For loosely coupled SINS/GPS integrated navigation, there are two measurement models to be selected in practical POS, including position measurements and position/velocity measurements. The associated measurement equations are:

where

and

represent the position and velocity noises of the GPS.

Since Equation (11) can be rewritten as:

the measurement matrices

and

in Equation (15) are obtained as:

In this paper, we depict the position measurement equation as an example, while the position/velocity measurement equations have the same results.

3.2. Observability Analysis for Lever Arms

Usually, an observability analysis for an integrated navigation system is conducted to determine whether a specific error state is observable, and under what conditions it can be estimated [

26]. According to global observability theory [

27], a state is said to be observable if it can be determined uniquely from the measurements for a finite time and under a possible condition. Therefore, we investigate the observability of lever arms directly, depending on the measurement equation in this section.

The position measurement in Equation (15) can be rewritten as an error model:

Clearly, this is not a deterministic system, but a stochastic case. However, the related theoretical analysis is still useful for revealing the observable conditions and guiding the design of verification trajectories. Ignoring the driving noise and measurement noise temporarily, Equation (18) itself determines the observability of the associated errors , , and . It can be seen that the acceleration or deceleration excitations have little effect on lever arms and , and their observabilities are determined by direction cosine matrices and .

If only the ISP rotates, changes while remains constant; thus, the lever arm will be distinguished. In this situation, the SINS position error cannot be accurately estimated for the unobserved lever arm . Considering the construction of attitude matrix , the rotation of one ISP gimbal can reveal two components of the lever arm perpendicular to the rotating axis. Consequently, rotations of at least two gimbals are needed to estimate all three components.

If only the attitude of the vehicle changes, varies while stays the same, and the combined lever arm can be estimated. Thus, position measurement accuracy can be improved in spite of the unseparated lever arm . It can be seen that the change in is crucial to determining the final positioning accuracies. Similarly, improvement of all three dimensional position accuracies depends on attitude changing in at least two directions of the vehicle.

In summary, the estimate of constant lever arms and requires the change of direction cosine matrices and . The greater the change of the matrixes, the stronger the observability of the corresponding lever arms. Certainly, the final estimation accuracies of associated lever arms are limited by the measurement error noise .

In aerial mapping missions, the aircraft usually maneuvers intentionally before entering the sensing area to enhance the observability of the POS [

17,

20], especially to improve the heading accuracy. During the mapping process, long straight portions of the flight will cause heading error growth; thus, periodical aircraft maneuvers are required to separate the navigation errors from inertial sensor errors [

18]. Common flight maneuvers include circling, coordinated turn, or “8” shaped flight, in which at least two directions of attitude change occur, such as in the heading and roll axes. Thus, in those cases without ISP, the lever arm

is usually treated as a constant to be estimated in these planned maneuver processes, and satisfactory results can be obtained [

1,

17]. As long as any two gimbals of ISP are controlled to rotate during these auxiliary maneuvering processes, the two constant lever arms

and

are solvable. Therefore, the observable conditions for the dynamic lever arm estimation are easy to satisfy in practical applications.

It should be noted that the auxiliary matrix

is constructed from the encoder data of the ISP, as shown in Equation (2). Since there are some unavoidable errors in the encoder angle measurements, their influences should be evaluated. Denoting the angle measurement errors as

, the introduced position errors are deduced as follows:

The term

determines the magnitude of the position errors that are introduced by encoder errors. Assuming that the lever arm

is 2 m and the encoder angle errors of the ISP are 3 arcminutes, the related position errors will be at the 2 mm level. The commonly used ISP PAV80 [

22] and GSM3000 [

23] can provide such angular accuracy. In this situation, the influence of encoder angle errors is limited and much smaller than the positioning accuracy of typical CDGPS. However, if the lever arm

is too large, the interrelated influence will not be negligible. The residual encoder error of the ISP can be modelled as a zero mean white noises process, which has the same effect on automatic estimation method and manual measurement method of lever arm. Thus, the GPS antenna and the ISP should be installed as close as possible, otherwise higher performance ISP is needed.

The time delay of the GPS information relative to SINS is another major error source. Since the GPS receiver and the SINS unit are two separate subsystems, the frequency difference between the 1PPS and SINS sampling clock could cause the time delay to be a variable (usually a ramp or triangular wave). Thus, the method of taking the time delay as a constant error state to be estimated will not work. The effective way is to discipline the SINS sampling clock with 1PPS [

28], or to record the delayed time with a counter for software compensation [

11]. Even so, it is difficult for the time delay to be perfectly compensated. In addition, although the same sampling clock is used in the IMU, the time-asynchrony between each inertial sensor is inevitable, due to the differences of physical characteristics [

29], which makes the time synchronization more complicated. Denoting the time-asynchrony error as

, its influence on position measurement is:

Assuming that is 0.1 ms and the normal flight velocity is 50 m/s, the introduced position error is about 5 mm. Clearly, larger time-asynchrony error is intolerable at this speed. After time compensation as mentioned earlier, the residual time-asynchrony error can be modelled as a zero mean white noises process for analysis.

3.3. Error Distribution Analysis

The purpose of error distribution analysis for stochastic systems is to evaluate the final estimation accuracy of the concerned states, and to distinguish which error sources primarily contribute to the concerned estimation uncertainties. Monte-Carlo simulations are appropriate to determine error distributions, but suffer from a large computational burden. Based on the law of large numbers [

30], Monte-Carlo simulations necessitate a large number of single-factor simulation tests and very long times to establish the error distributions if many error sources are involved. Considering linear error propagation, covariance simulation programs [

31,

32] are commonly used to provide numerical time histories depicting the accuracy of a given system configuration in terms of the covariance of its associated linearized error state vector, avoiding large numbers of simulations. According to the established SINS/GPS Kalman filter, we designed a covariance analysis method to get the error distribution budgets, especially focusing on which error sources contribute to the estimation uncertainty of lever arms and the final position errors.

Three system models are involved in the covariance analysis method: the real world model, the full-order design filter, and the reduced-order filter model [

33]. The real world model, also known as true model, describes the behavior of the actual system, to the best of one’s knowledge and ability. The full-order filter is dedicated to yielding the estimate for all state errors of the real world. The reduced-order filter model is designed for filtering calculation in actual system, in which some weakly observable states have been excluded from the full-order filter to ease computational burden.

In this paper, the real world model is defined in

Appendix A, the corresponding full-order filter is depicted in

Appendix B, and the reduced-order filter model is designed in

Section 3.1. The state vector of the reduced-order filter is composed of the first 21 elements of the full-order filter state. In addition, the full-order filter model contains three types of measurement noise, the GPS positioning noise, the ISP encoder noise and the time-asynchrony noise, and only the first type is selected as the measurement noise of the reduced-order filter model.

For the reduced-order filter model, after the state equation and measurement equation are established and discretized, we update the standard linear Kalman model in two calculation loops [

34]: the state filtering loop and covariance calculation loop. For ease of depiction, the discretized state filtering loop is listed here:

while the covariance calculation loop is updated as follows:

where the hat label “^” denotes the calculated value in the reduced-order filter model, distinguishing it from that of the full-order filter model; the subscript

and

denote the last and current cycle, while

expresses the propagation value;

,

and

are discretized values from the state equation and measurement equation;

and

are the previously set covariance values of process noises and measurement noises;

is the current covariance matrix recursively calculated from the initial value

; and

is the calculated filtering gain matrix.

It can be seen that the covariance calculation loop is independent of the state filtering loop. Once the filter is designed and the trajectory is selected, the associated matrices , , , and are uniquely determined, so is the gain matrix . The filtering program only needs to be run once, so that the gain matrix can be obtained at every measurement update. It should be recorded and substituted into the full-order filter model for covariance analysis.

In the full-order filter model, the state equation and measurement equation are extended as follows:

where the superscript “*” denotes the matrix involved in the full-order filter model.

It can be seen that there are three types of errors that affect the estimation results: the initial state errors

, the process noises

, and the measurement noises

. Based on the linear error model, the estimated error of a concerned state at any moment can be expressed as a linear cumulative sum:

where

is the propagation matrix of initial errors;

,

, and

are the nonzero element numbers of the initial state, process noise, and measurement noise, respectively;

or

denotes the estimated error of

th state caused by the

th process noise

or the

th measurement noise

. For the sake of simplicity, the current cycle

is omitted in Equation (28).

The filtering gain matrix

is the crucial link between the reduced-order filter model and the full-order filter model, which can be extended into the full-order filter model as follows:

Since the gain matrix

of full-order filter model is known, the covariance calculation loop is updated as follows:

Firstly, based on linear propagation characteristics of associated errors, and setting

and

in Equations (30) and (31), the mean square deviation propagation matrix of initial errors can be calculated as follows:

with the initial value

.

Secondly, setting

and

in Equations (30) and (31), the propagation matrix of the

th process noise

is obtained by:

with the initial value

, where

denotes the 39 × 39 matrix with

and all else zeros. If there are

-dimensional nonzero process noises, Equations (33) and (34) should be executed

times with different

to obtain all of the propagation matrices.

Thirdly, setting

and

in Equations (30) and (31), the propagation matrix of the

th measurement noise

is obtained by:

with the initial value

and

calculations required for

-dimensional measurement noises.

Therefore, the estimation accuracy of

in Equation (28) can be evaluated by the corresponding mean square deviation

:

where

,

, and

are the deviations of the

th initial state error,

th process noise, and

th measurement noise, respectively, while

and

are the

th diagonal elements of covariance matrices

and

, respectively. Based on the linear error model, the mean square deviation

of linear combination of

and

can be expressed as

, and so on.

Therefore, according to the above covariance analyzing method, the error distribution budgets of the full order filter or real-world model can be constructed from the calculation of the reduced order filter. The complexity and computational burden of simulation are greatly reduced.