Robust Switched Tracking Control for Wheeled Mobile Robots Considering the Actuators and Drivers

Abstract

:1. Introduction

1.1. Control Algorithms Based on the Kinematic Model

1.1.1. Only Kinematics of the Mechanical Structure

1.1.2. Kinematics of the Mechanical Structure + Dynamics of the Actuators

1.1.3. Kinematics of the Mechanical Structure + Dynamics of the Actuators + Dynamics of the Power Stage

1.2. Control Algorithms Based on the Dynamic Model

1.2.1. Only Dynamics of the Mechanical Structure

1.2.2. Dynamics of the Mechanical Structure + Dynamics of the Actuators

1.3. Discussion of Related Work, Motivation, and Contribution

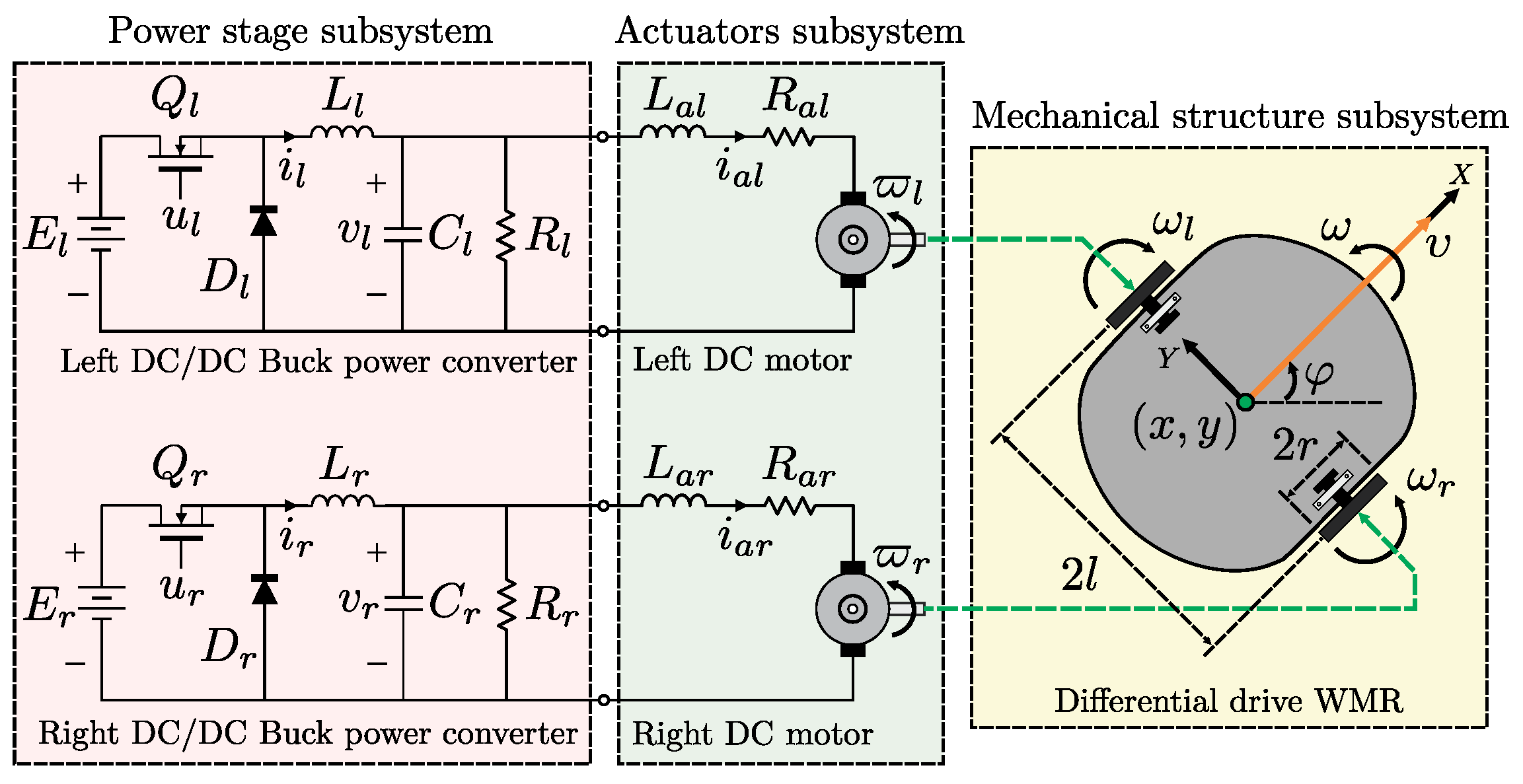

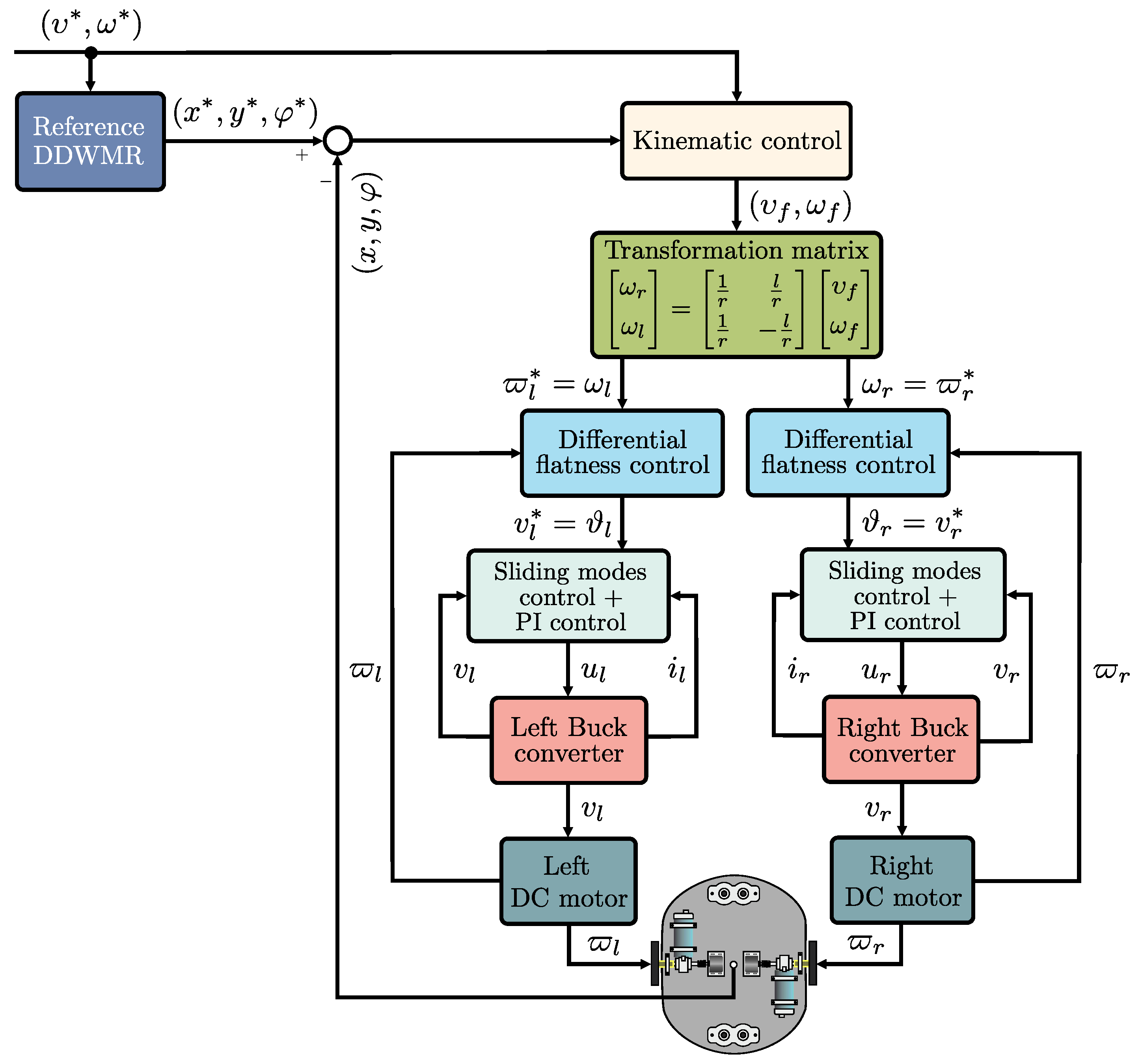

2. Robust Hierarchical Switched Tracking Controller That Considers the Dynamics of All Subsystems Associated with a DDWMR

- (1)

- In the high hierarchy level, a kinematic control, and , expressed in terms of and is proposed for the mechanical structure. This control allows the DDWMR to track a desired trajectory, i.e., , and also corresponds to the desired angular velocity profiles that the shafts of the DC motors have to track.

- (2)

- In the medium hierarchy level, two controls based on differential flatness, and , are designed so as to ensure that the shafts of the DC motors execute the angular velocity trajectory tracking task, i.e., . These controls also impose the desired voltage profiles that must be tracked by the output voltages of the DC/DC Buck power converters.

- (3)

- In the low hierarchy level, via two cascade switched controls based on SMC and PI control, and , it is assured that the output voltages of the DC/DC Buck power converters will track the desired voltage profiles imposed by the medium level, i.e., .

- (4)

- By following the hierarchical controller approach, the controls described in previous items (1), (2), and (3) are interconnected so as to carry out the trajectory tracking task for the DDWMR.

2.1. High-Level Control

2.2. Medium-Level Control

2.3. Low-Level Control

2.4. Hierarchical Switched Tracking Controller Design

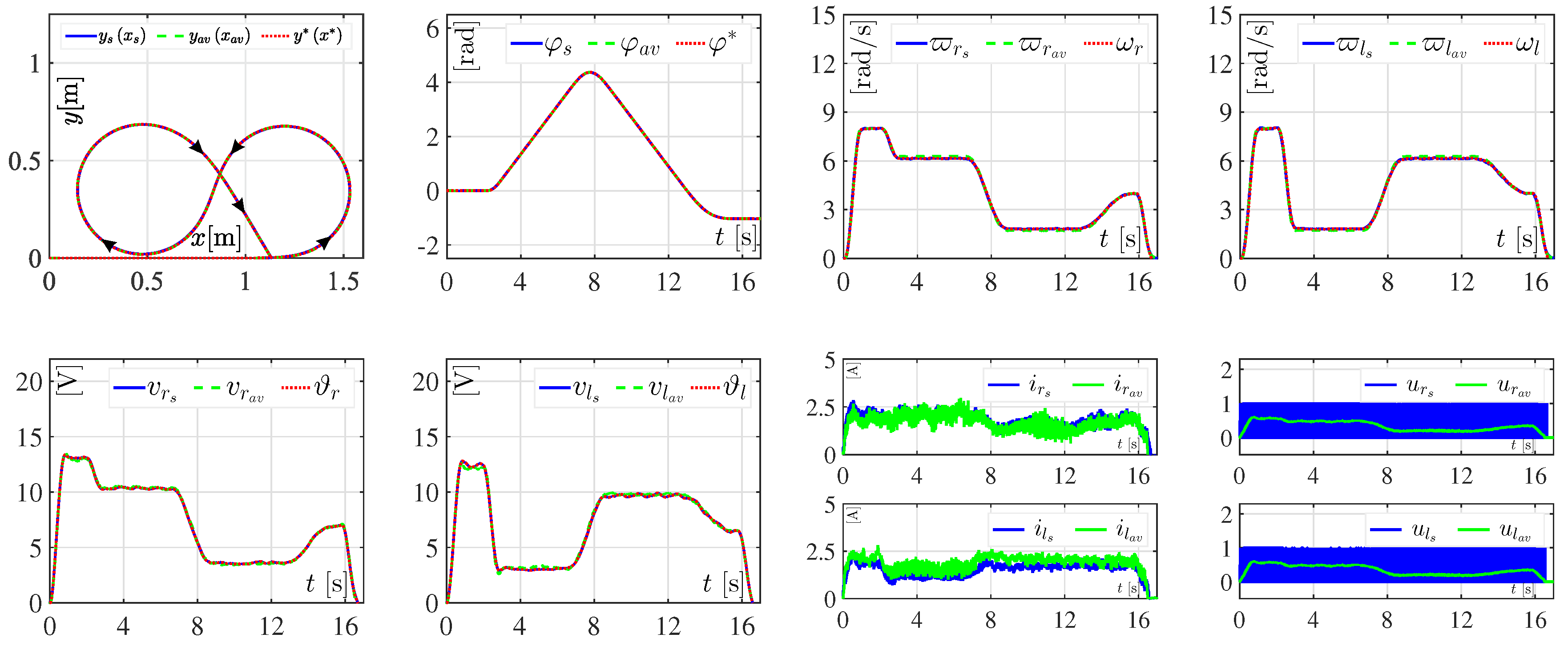

3. Experimental Results

3.1. Controllers to be Experimentally Implemented

- Hierarchical switched controller (developed in Section 2). This controller is composed by the following three stages.High level: Mechanical structurewhere .Medium level: Actuatorsand the gains were found to beLow level: Power stagewhereand the gains are positive.

- Hierarchical average controller (reported in [7]). This controller also comprises three levels of control: high level for the mechanical structure, medium level for the actuators, and low level for the power stage. The controls associated with the high level and the medium level correspond to Equations (37)–(40), respectively. On the other hand, the control related to the low level is given byand the gains , and are defined as

3.2. Experimental Prototype

- Trajectory tracking controllers. The synthesis and programming of the hierarchical switched controller, Equations (37)–(42), and the hierarchical average controller, Equations (37)–(40), (43), and (44), were carried out as described here via MATLAB-Simulink. In this block, the following six sub-blocks can be observed:(1) Kinematic control. This control corresponds to the high level of both hierarchical controllers. It is given by Equations (37) and (38) and requires the following information associated with the DDWMR:(2) Differential flatness control. This is related to the medium-level control of both hierarchical controllers. It is defined by Equations (39) and (40) and requires the parameters given by (15) and (16). That is,(3) Sliding mode control + PI control. This control is associated with the low level of the hierarchical switched controller, Equations (41) and (42), and considers some parameters of the DC/DC Buck power converters. Such parameters are(4) Differential flatness average control. Corresponds to the low level of the hierarchical average controller reported in [7], Equations (43) and (44), and uses all parameters of the DC/DC Buck power converters. Those parameters areIt is worth noting that the hierarchical average controller, composed of the previous items (1), (2), and (4), was designed on the basis of the average model associated with the power stage (DC/DC Buck power converters). Because of this, a modulator is required for its appropriate experimental implementation. In this direction, the sigma-delta modulator (-modulator) was used in order to make a fair comparison between both controllers, i.e., the switched one and the average one.(5) Gains of the hierarchical switched controller. Here, the gains associated with the controls of the high, medium, and low levels are specified. For the high level, the gains were chosen asMeanwhile, the gains linked to the medium level, i.e., , were obtained by choosing their parameters as follows:Lastly, the gains of the low level were proposed as(6) Gains of the hierarchical average controller. In this block, the gains of the three levels of control (high, medium, and low) are defined. For the high level, the gains were selected asOn the other hand, the gains , related to the medium level, were found by choosing the following parameters:Lastly, the gains of the low level, i.e., , were determined by selecting their parameters,

- Desired trajectory. The results presented in this paper are applied using the following Bézier polynomials to obtain the reference velocities and :where and are the initial and final times of the given trajectory, the pairs and represent the transference linear and angular velocities related to and , and is a polynomial function given byThrough Equations (45) and (46), the reference velocities and were generated according to Table 1. Thus, by using Equation (3), the trajectory to be tracked by the DDWMR in the plane, i.e., , is found. On the other hand, after substituting and in (2), and after some algebraic manipulation, and are found.

- DDWMR, data acquisition, and signal conditioning. This block shows the connections between the DS1104 board and the DDWMR. The voltages , currents , and angular velocities are acquired via two Tektronix P5200A voltage probes, two Tektronix A622 current probes, and two Omron E6B2-CWZ6C incremental encoders, respectively. As can be observed, signal conditioning (SC) is performed in each signal.

3.3. Experimental Results Related to the Controllers

3.3.1. Experiment 1: Results Associated with Abrupt Changes in Loads

3.3.2. Experiment 2: Results Associated with Abrupt Changes in Power Supplies

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Campion, G.; d’Andréa-Novel, B.; Bastin, G. Modelling and state feedback control of nonholonomic mechanical systems. In Proceedings of the 30th IEEE Conference on Decision and Control, Brighton, UK, 11–13 December 1991; pp. 1184–1189. [Google Scholar]

- Bloch, A.M.; Reyhanoglu, M.; McClamroch, N.H. Control and stabilization of nonholonomic dynamic systems. IEEE Trans. Autom. Control 1992, 37, 1746–1757. [Google Scholar] [CrossRef]

- Kolmanovsky, I.; McClamroch, N.H. Developments in nonholonomic control problems. IEEE Control Syst. Mag. 1995, 15, 20–36. [Google Scholar] [CrossRef]

- Brockett, R.W. Asymptotic stability and feedback stabilization. In Differential Geometric Control Theory; Brockett, R.W., Millman, R.S., Sussmann, H.H., Eds.; Birkhaüser: Boston, MA, USA, 1983; ISBN 978-0-81763-091-1. [Google Scholar]

- Silva-Ortigoza, R.; García-Sánchez, J.R.; Hernández-Guzmán, V.M.; Márquez-Sánchez, C.; Marcelino-Aranda, M. Trajectory tracking control for a differential drive wheeled mobile robot considering the dynamics related to the actuators and power stage. IEEE Lat. Am. Trans. 2016, 14, 657–664. [Google Scholar] [CrossRef]

- García-Sánchez, J.R.; Tavera-Mosqueda, S.; Silva-Ortigoza, R.; Antonio-Cruz, M.; Silva-Ortigoza, G.; de Jesus Rubio, J. Assessment of an average tracking controller that considers all the subsystems involved in a WMR: Implementation via pwm or sigma-delta modulation. IEEE Lat. Am. Trans. 2016, 14, 1093–1102. [Google Scholar] [CrossRef]

- García-Sánchez, J.R.; Silva-Ortigoza, R.; Tavera-Mosqueda, S.; Márquez-Sánchez, C.; Hernández-Guzmán, V.M.; Antonio-Cruz, M.; Silva-Ortigoza, G.; Taud, H. Tracking control for mobile robots considering the dynamics of all their subsystems: Experimental implementation. Complexity 2017, 2017, 5318504. [Google Scholar] [CrossRef]

- Linares-Flores, J.; Sira-Ramírez, H.; Cuevas-López, E.F.; Contreras-Ordaz, M.A. Sensorless passivity based control of a DC motor via solar powered sepic converter-full bridge combination. J. Power Electron. 2011, 11, 743–750. Available online: http://www.jpe.or.kr/archives/view_articles.asp?seq=567 (accessed on 3 September 2018).

- An, L.; Lu, D.D.-C. Design of a single-switch DC/DC converter for a PV-battery-powered pump system with PFM+PWM control. IEEE Trans. Ind. Electron. 2015, 62, 910–921. [Google Scholar] [CrossRef]

- Shukla, S.; Singh, B. Single-stage PV array fed speed sensorless vector control of induction motor drive for water pumping. IEEE Trans. Ind. Appl. 2018, 54, 3575–3585. [Google Scholar] [CrossRef]

- Ashok, R.S.; Shtessel, Y.B.; Ghanes, M. Sliding model control of hydrogen fuel cell and ultracapitor based electric power system: Electric vehicle application. In Proceedings of the 20th IFAC World Congress, Tolouse, France, 9–14 July 2017; pp. 14794–14799. [Google Scholar]

- Amine, M.M.; Abdeslem, B.Z.; Abdelkader, B.M.; Zakariah, M.; Alsulaiman, M.; Hedjar, R.; Faisal, M.; Algabri, M.; AlMuteb, K. Visual tracking in unknown environments using fuzzy logic and dead reckoning. Int. J. Adv. Robot. Syst. 2016, 50, 1–8. [Google Scholar] [CrossRef]

- Li, B.; Fang, Y.; Hu, G.; Zhang, X. Model-free unified tracking and regulation visual servoing of wheeled mobile robots. IEEE Trans. Control Syst. Technol. 2016, 24, 1328–1339. [Google Scholar] [CrossRef]

- Renny, S.K.; Uchiyama, N.; Sano, S. Real-time smooth trajectory generation for nonholonomic mobile robots using Bézier curves. Robot. Comput. Integr. Manuf. 2016, 41, 31–42. [Google Scholar] [CrossRef]

- Li, B.; Fang, Y.; Zhang, X. Visual servo regulation of wheeled mobile robots with an uncalibrated onboard camera. IEEE-ASME Trans. Mechatron. 2016, 21, 2330–2342. [Google Scholar] [CrossRef]

- Chwa, D. Robust distance-based tracking control of wheeled mobile robots using vision sensors in the presence of kinematic disturbances. IEEE Trans. Ind. Electron. 2016, 63, 6172–6183. [Google Scholar] [CrossRef]

- Li, W.; Liu, Z.; Gao, H.; Zhang, X.; Tavakoli, M. Stable kinematic teleoperation of wheeled mobile robots with slippage using time-domain passivity control. Mechatronics 2016, 39, 196–203. [Google Scholar] [CrossRef]

- Chen, W.-J.; Jhong, B.-G.; Chen, M.-Y. Design of path planning and obstacle avoidance for a wheeled mobile robot. Int. J. Fuzzy Syst. 2016, 18, 1080–1091. [Google Scholar] [CrossRef]

- Lages, W.F.; Vasconcelos, A.J.A. Differential-drive mobile robot control using a cloud of particles approach. Int. J. Adv. Robot. Syst. 2017, 14, 1–12. [Google Scholar] [CrossRef]

- Xiao, H.; Li, Z.; Yang, C.; Zhang, L.; Yuan, P.; Ding, L.; Wang, T. Robust stabilization of a wheeled mobile robot using model predictive control based on neurodynamics optimization. IEEE Trans. Ind. Electron. 2017, 64, 505–516. [Google Scholar] [CrossRef]

- Škrjanc, I.; Klančar, G. A comparison of continuous and discrete tracking-error model-based predictive control for mobile robots. Robot. Auton. Syst. 2017, 87, 177–187. [Google Scholar] [CrossRef]

- Zhang, X.; Fang, Y.; Li, B.; Wang, J. Visual servoing of nonholonomic mobile robots with uncalibrated camera-to-robot parameters. IEEE Trans. Ind. Electron. 2017, 64, 390–400. [Google Scholar] [CrossRef]

- Li, W.; Ding, L.; Liu, Z.; Wang, W.; Gao, H.; Tavakoli, M. Kinematic bilateral teledriving of wheeled mobile robots coupled with slippage. IEEE Trans. Ind. Electron. 2017, 64, 2147–2157. [Google Scholar] [CrossRef]

- Seder, M.; Baotić, M.; Petrović, I. Receding horizon control for convergent navigation of a differential drive mobile robot. IEEE Trans. Control Syst. Technol. 2017, 25, 653–660. [Google Scholar] [CrossRef]

- Yee, L.K.; Cho, H.; Ha, C.; Lee, D. First-person view semi-autonomous teleoperation of cooperative wheeled mobile robots with visuo-haptic feedback. Int. J. Robot. Res. 2017, 36, 840–860. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, F.; Li, Y.; Wang, Y. A novel iterative learning path-tracking control for nonholonomic mobile robots against initial shifts. Int. J. Adv. Robot. Syst. 2017, 14, 1–9. [Google Scholar] [CrossRef]

- Mallikarjuna, R.A.; Ramji, K.; Sundara-Siva, R.B.S.K.; Vasu, V.; Puneeth, C. Navigation of non-holonomic mobile robot using neuro-fuzzy logic with integrated safe boundary algorithm. Int. J. Autom. Comput. 2017, 14, 285–294. [Google Scholar] [CrossRef]

- Sun, C.-H.; Chen, Y.-J.; Wang, Y.-T.; Huang, S.-K. Sequentially switched fuzzy-model-based control for wheeled mobile robot with visual odometry. Appl. Math. Model. 2017, 47, 765–776. [Google Scholar] [CrossRef]

- Mu, J.; Yan, X.-G.; Spurgeon, K.S.; Mao, Z. Generalized regular form based SMC for nonlinear systems with application to a WMR. IEEE Trans. Ind. Electron. 2017, 64, 6714–6723. [Google Scholar] [CrossRef]

- Liu, C.; Gao, J.; Xu, D. Lyapunov-based model predictive control for tracking of nonholonomic mobile robots under input constraints. Int. J. Control Autom. Syst. 2017, 15, 2313–2319. [Google Scholar] [CrossRef]

- Sun, Z.; Xia, Y.; Dai, L.; Liu, K.; Ma, D. Disturbance rejection MPC for tracking of wheeled mobile robot. IEEE-ASME Trans. Mechatron. 2017, 22, 2576–2587. [Google Scholar] [CrossRef]

- Li, B.; Zhang, X.; Fang, Y.; Shi, W. Visual servo regulation of wheeled mobile robots with simultaneous depth identification. IEEE Trans. Ind. Electron. 2018, 65, 460–469. [Google Scholar] [CrossRef]

- Alouache, A.; Wu, Q. Fuzzy logic PD controller for trajectory tracking of an autonomous differential drive mobile robot (i.e., Quanser Qbot). Ind. Robot. 2018, 45, 23–33. [Google Scholar] [CrossRef]

- Nascimento, T.P.; Trabuco, D.C.E.; Gonçalves, G.L.M. Nonlinear model predictive control for trajectory tracking of nonholonomic mobile robots: A modified approach. Int. J. Adv. Robot. Syst. 2018, 15, 1–14. [Google Scholar] [CrossRef]

- Li, L.; Liu, Y.-H.; Jiang, T.; Wang, K.; Fang, M. Adaptive trajectory tracking of nonholonomic mobile robots using vision-based position and velocity estimation. IEEE Trans. Cybern. 2018, 48, 571–582. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Guo, M.; Xia, Y.; Cheng, L. Trajectory tracking for wheeled mobile robots via model predictive control with softening constraints. IET Control Theory Appl. 2018, 12, 206–214. [Google Scholar] [CrossRef]

- Ke, F.; Li, Z.; Yang, C. Robust tube-based predictive control for visual servoing of constrained differential-drive mobile robots. IEEE Trans. Ind. Electron. 2018, 65, 3437–3446. [Google Scholar] [CrossRef]

- Márquez-Sánchez, C.; García-Sánchez, J.R.; Sosa-Cervantes, C.Y.; Silva-Ortigoza, R.; Hernández-Guzmán, V.M.; Alba-Juárez, J.N.; Marcelino-Aranda, M. Trajectory generation for wheeled mobile robots via Bézier polynomials. IEEE Lat. Am. Trans. 2016, 14, 4482–4490. [Google Scholar] [CrossRef]

- Mu, J.; Yan, X.-G.; Spurgeon, K.S.; Mao, Z. Nonlinear sliding mode control of a two-wheeled mobile robot system. Int. J. Model. Identif. Control 2017, 27, 75–83. [Google Scholar] [CrossRef]

- Saleem, O.; Hassan, H.; Khan, A.; Javaid, U. Adaptive fuzzy-pd tracking controller for optimal visual-servoing of wheeled mobile robots. Control Eng. Appl. Inform. 2017, 19, 56–68. Available online: http://www.ceai.srait.ro (accessed on 3 September 2018).

- Roy, S.; Kar, I.N. Adaptive robust tracking control of a class of nonlinear systems with input delay. Nonlinear Dyn. 2016, 85, 1127–1139. [Google Scholar] [CrossRef] [Green Version]

- Huang, D.; Zhai, J.; Ai, W.; Fei, S. Disturbance observer-based robust control for trajectory tracking of wheeled mobile robots. Neurocomputing 2016, 198, 74–79. [Google Scholar] [CrossRef]

- Li, I.-H.; Chien, Y.-H.; Wang, W.-Y.; Kao, Y.-F. Hybrid intelligent algorithm for indoor path planning and trajectory-tracking control of wheeled mobile robot. Int. J. Fuzzy Syst. 2016, 18, 595–608. [Google Scholar] [CrossRef]

- Vos, E.; van der Schaft, A.J.; Scherpen, J.M.A. Formation control and velocity tracking for a group of nonholonomic wheeled robots. IEEE Trans. Autom. Control 2016, 61, 2702–2707. [Google Scholar] [CrossRef]

- Rudra, S.; Barai, R.K.; Maitra, M. Design and implementation of a block-backstepping based tracking control for nonholonomic wheeled mobile robot. Int. J. Robust Nonlinear Control 2015, 26, 3018–3035. [Google Scholar] [CrossRef]

- Peng, Z.; Wen, G.; Yang, S.; Rahmani, A. Distributed consensus-based formation control for nonholonomic wheeled mobile robots using adaptive neural network. Nonlinear Dyn. 2016, 86, 605–622. [Google Scholar] [CrossRef]

- Lian, C.; Xu, X.; Chen, H.; He, H. Near-optimal tracking control of mobile robots via receding-horizon dual heuristic programming. IEEE Trans. Cybern. 2016, 46, 2484–2496. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Tang, S.; Gao, H.; Zhao, J. Two time-scale tracking control of nonholonomic wheeled mobile robots. IEEE Trans. Control Syst. Technol. 2016, 24, 2059–2069. [Google Scholar] [CrossRef]

- Chen, M. Disturbance attenuation tracking control for wheeled mobile robots with skidding and slipping. IEEE Trans. Ind. Electron. 2017, 64, 3359–3368. [Google Scholar] [CrossRef]

- Peng, S.; Shi, W. Adaptive fuzzy integral terminal sliding mode control of a nonholonomic wheeled mobile robot. Math. Probl. Eng. 2017, 2017, 3671846. [Google Scholar] [CrossRef]

- Lashkari, N.; Biglarbegian, M.; Yang, S.-X. Development of a new robust controller with velocity estimator for docked mobile robots: Theory and experiments. IEEE-ASME Trans. Mechatron. 2017, 22, 1287–1298. [Google Scholar] [CrossRef]

- Yue, M.; Wang, L.; Ma, T. Neural network based terminal sliding mode control for WMRs affected by an augmented ground friction with slippage effect. IEEE/CAA J. Autom. Sin. 2017, 4, 498–506. [Google Scholar] [CrossRef]

- Capraro, F.; Rossomando, F.G.; Soria, C.; Scaglia, G. Cascade sliding control for trajectory tracking of a nonholonomic mobile robot with adaptive neural compensator. Math. Probl. Eng. 2017, 2017, 8501098. [Google Scholar] [CrossRef]

- Chen, Y.Y.; Chen, H.Y.; Huang, Y.C. Wheeled mobile robot design with robustness properties. Adv. Mech. Eng. 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Nguyen, T.; Le, L. Neural network-based adaptive tracking control for a nonholonomic wheeled mobile robot with unknown wheel slips, model uncertainties, and unknown bounded disturbances. Turk. J. Electr. Eng. Comput. Sci. 2018, 26, 378–392. [Google Scholar] [CrossRef]

- Shen, Z.; Ma, Y.; Song, Y. Robust adaptive fault-tolerant control of mobile robots with varying center of mass. IEEE Trans. Ind. Electron. 2018, 65, 2419–2428. [Google Scholar] [CrossRef]

- Bian, Y.; Peng, J.; Han, C. Finite-time control for nonholonomic mobile robot by brain emotional learning-based intelligent controller. Int. J. Innov. Comp. Inf. Control 2018, 14, 683–695. Available online: http://www.ijicic.org/ijicic-140221.pdf (accessed on 3 September 2018).

- Spandan, R.; Narayan, K.I.; Lee, J.; Jin, M. Adaptive-robust time-delay control for a class of uncertain euler-lagrange systems. IEEE Trans. Ind. Electron. 2017, 64, 7109–7119. [Google Scholar] [CrossRef]

- Spandan, R.; Narayan, K.I. Adaptive sliding mode control of a class of nonlinear systems with artificial delay. J. Frankl. Inst. Eng. Appl. Math. 2017, 354, 8156–8179. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Fang, W.-L. Global fuzzy adaptive hierarchical path tracking control of a mobile robot with experimental validation. IEEE Trans. Fuzzy Syst. 2016, 24, 724–740. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, B.K. Time-optimal trajectory planning based on dynamics for differential-wheeled mobile robots with a geometric corridor. IEEE Trans. Ind. Electron. 2017, 64, 5502–5512. [Google Scholar] [CrossRef]

- Sira-Ramírez, H.; Agrawal, S.K. Differentially Flat Systems; Marcel Dekker: New York, NY, USA, 2004; ISBN 978-0-82475-470-9. [Google Scholar]

- Avendaño-Juárez, J.L.; Hernández-Guzmán, V.M.; Silva-Ortigoza, R. Velocity and current inner loops in a wheeled mobile robot. Adv. Robot. 2010, 24, 1385–1404. [Google Scholar] [CrossRef]

- Fukao, T.; Nakagawa, H.; Adachi, N. Adaptive tracking control of nonholonomic mobile robot. IEEE Trans. Robot. Autom. 2000, 16, 609–615. [Google Scholar] [CrossRef]

- Hernández-Guzmán, V.M.; Silva-Ortigoza, R. Velocity Control of a Permanent Magnet Brushed Direct Current Motor. In Automatic Control with Experiments. Advanced Textbooks in Control and Signal Processing; Springer: Cham, Switzerland, 2019; pp. 605–644. ISBN 978-3-319-75804-6. [Google Scholar]

- Sira-Ramírez, H.; Silva-Ortigoza, R. Control Design Techniques in Power Electronics Devices; Springer: London, UK, 2006; ISBN 978-1-84628-458-8. [Google Scholar]

- Silva-Ortigoza, R.; Hernández-Guzmán, V.M.; Antonio-Cruz, M.; Muñoz-Carrillo, D. DC/DC Buck power converter as a smooth starter for a DC motor based on a hierarchical control. IEEE Trans. Power Electron. 2015, 30, 1076–1084. [Google Scholar] [CrossRef]

- Ravankar, A.; Ravankar, A.A.; Kobayashi, Y.; Hoshino, Y.; Peng, C.-C. Path smoothing techniques in robot navigation: State-of-the-art, current and future challenges. Sensors 2018, 18, 170. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Sánchez, J.R.; Tavera-Mosqueda, S.; Silva-Ortigoza, R.; Hernández-Guzmán, V.M.; Sandoval-Gutiérrez, J.; Marcelino-Aranda, M.; Taud, H.; Marciano-Melchor, M. Robust Switched Tracking Control for Wheeled Mobile Robots Considering the Actuators and Drivers. Sensors 2018, 18, 4316. https://doi.org/10.3390/s18124316

García-Sánchez JR, Tavera-Mosqueda S, Silva-Ortigoza R, Hernández-Guzmán VM, Sandoval-Gutiérrez J, Marcelino-Aranda M, Taud H, Marciano-Melchor M. Robust Switched Tracking Control for Wheeled Mobile Robots Considering the Actuators and Drivers. Sensors. 2018; 18(12):4316. https://doi.org/10.3390/s18124316

Chicago/Turabian StyleGarcía-Sánchez, José Rafael, Salvador Tavera-Mosqueda, Ramón Silva-Ortigoza, Victor Manuel Hernández-Guzmán, Jacobo Sandoval-Gutiérrez, Mariana Marcelino-Aranda, Hind Taud, and Magdalena Marciano-Melchor. 2018. "Robust Switched Tracking Control for Wheeled Mobile Robots Considering the Actuators and Drivers" Sensors 18, no. 12: 4316. https://doi.org/10.3390/s18124316

APA StyleGarcía-Sánchez, J. R., Tavera-Mosqueda, S., Silva-Ortigoza, R., Hernández-Guzmán, V. M., Sandoval-Gutiérrez, J., Marcelino-Aranda, M., Taud, H., & Marciano-Melchor, M. (2018). Robust Switched Tracking Control for Wheeled Mobile Robots Considering the Actuators and Drivers. Sensors, 18(12), 4316. https://doi.org/10.3390/s18124316