Vibro-Perception of Optical Bio-Inspired Fiber-Skin

Abstract

:1. Introduction

2. Optical Fiber-Skin Perception System

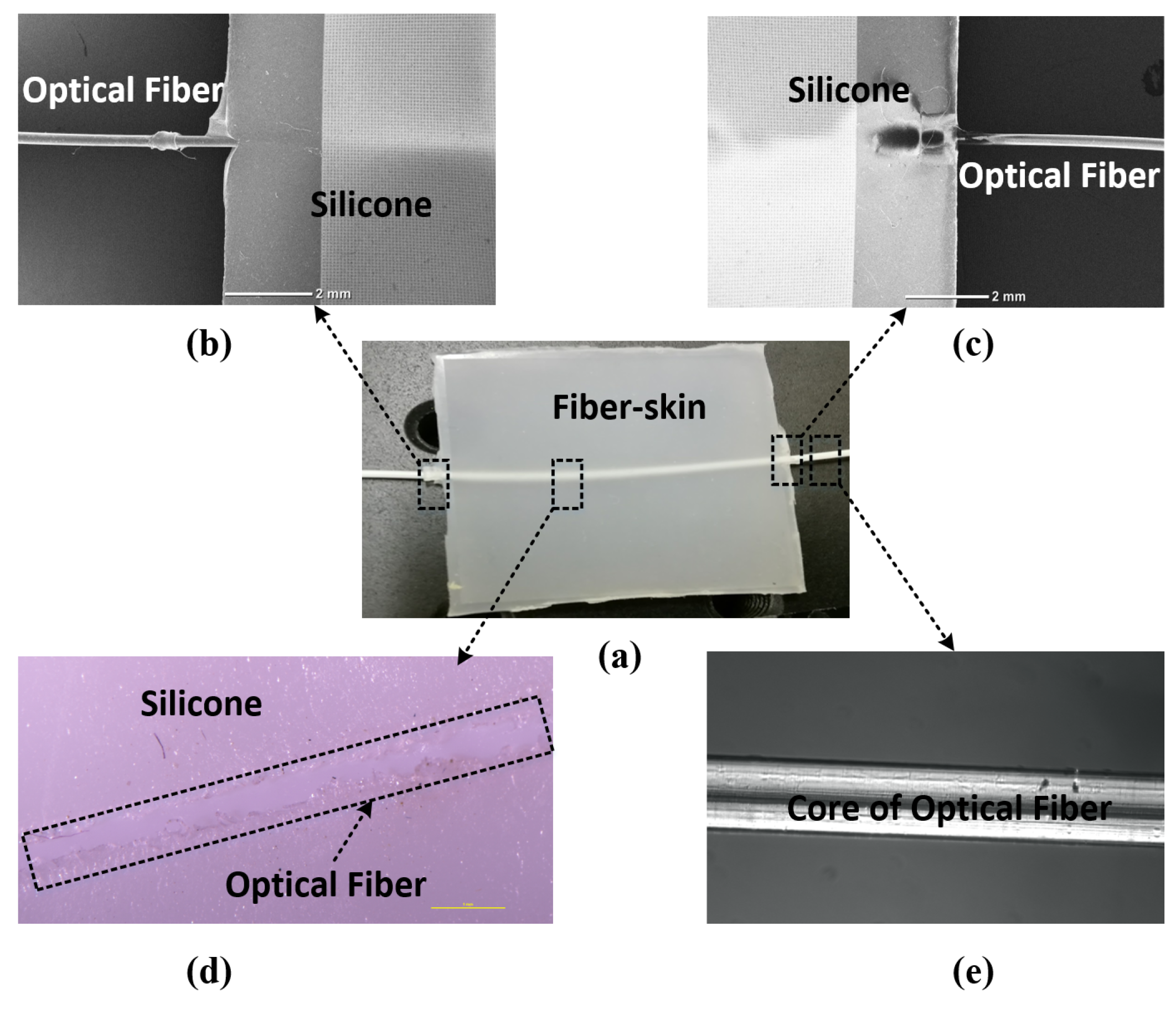

2.1. Bio-Inspired Optical Fiber-Skin

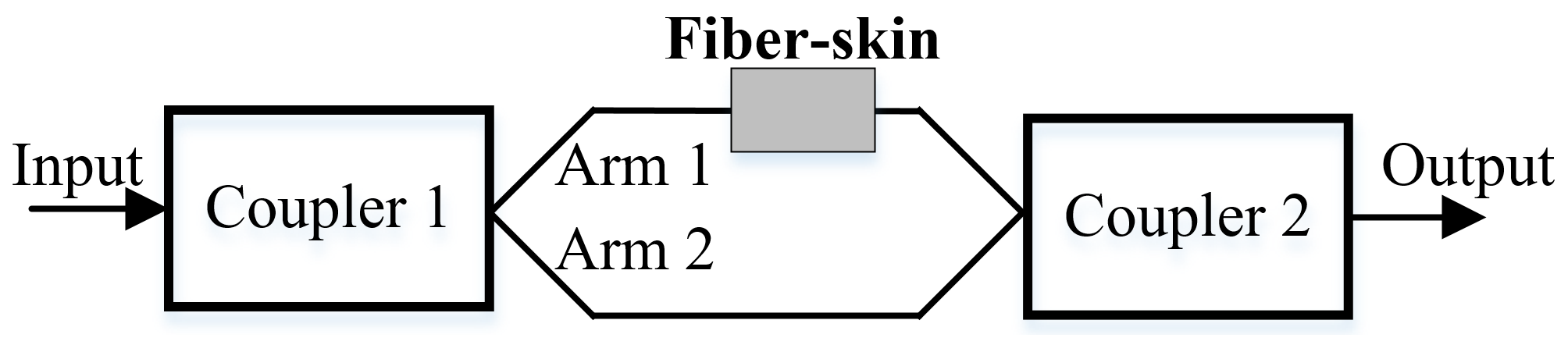

2.2. Mach-Zehnder Vibro-Perception Perception of Optical Fiber-Skin

2.3. OPLL Vibro-Perception System of Optical Fiber-Skin

3. Experiment

3.1. Experimental Setup

3.2. Experimental Details of Fiber-Skin Vibro-Perception System

4. Results and Discussion

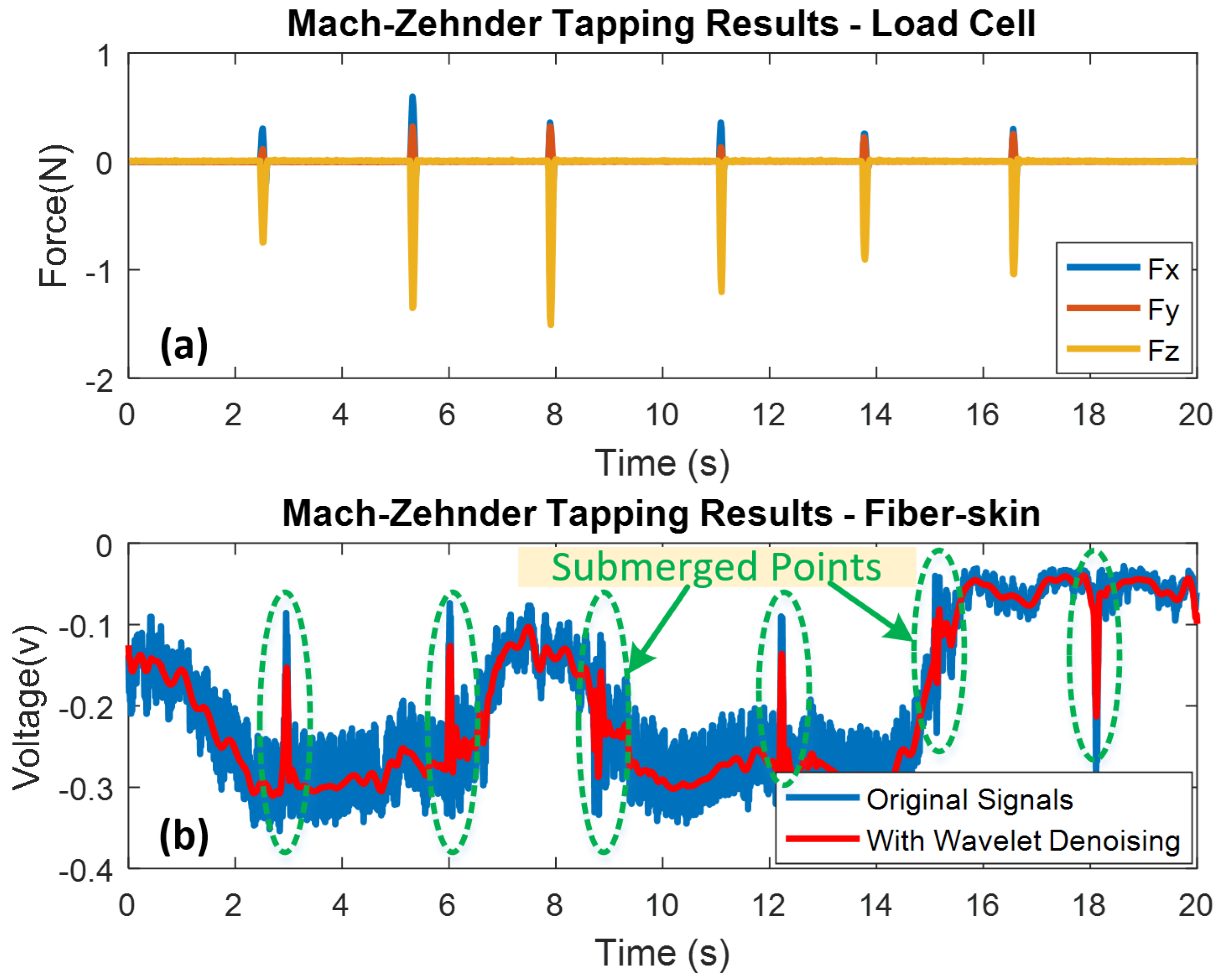

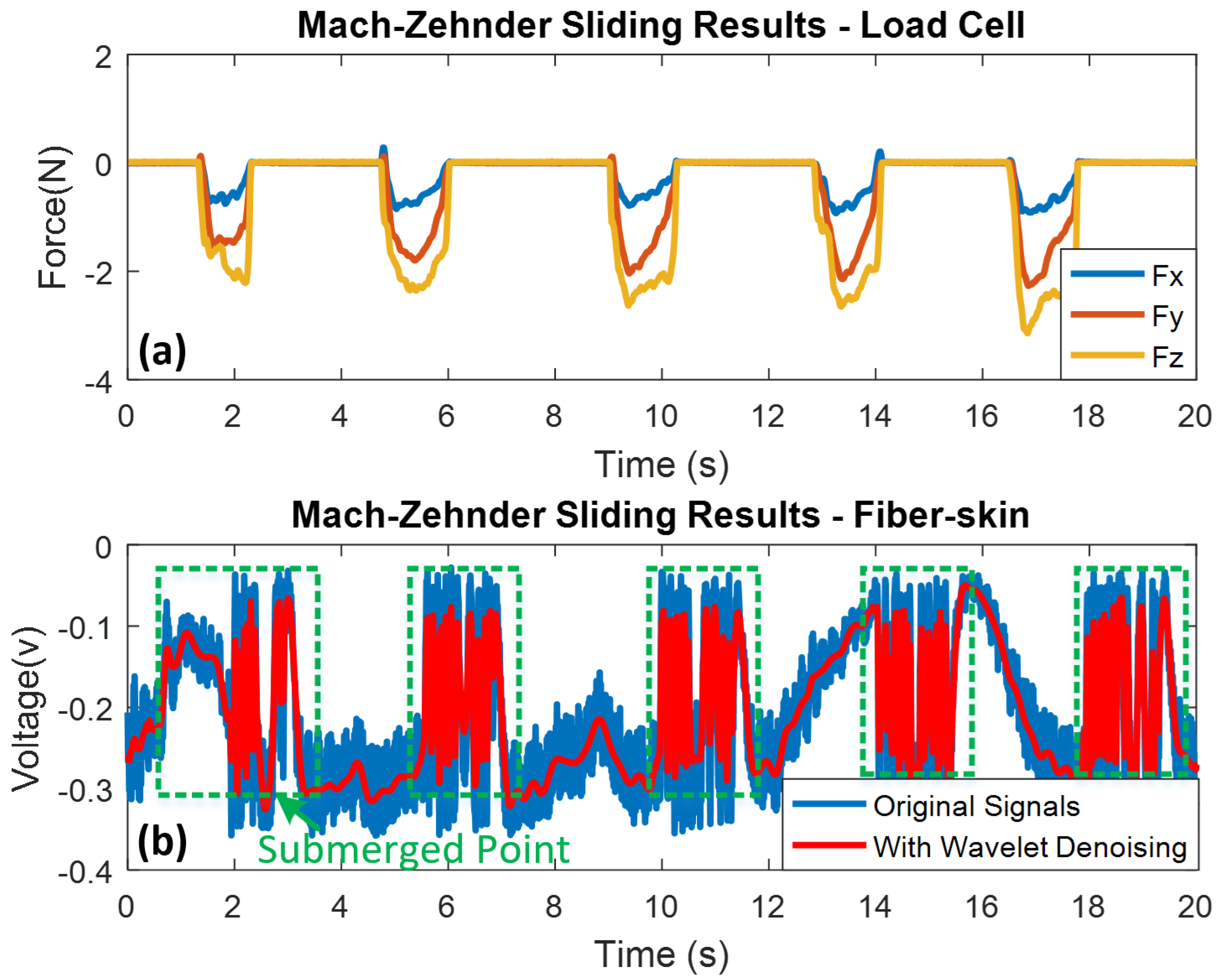

4.1. Experimental Results of Mach-Zehnder Vibro-Perception

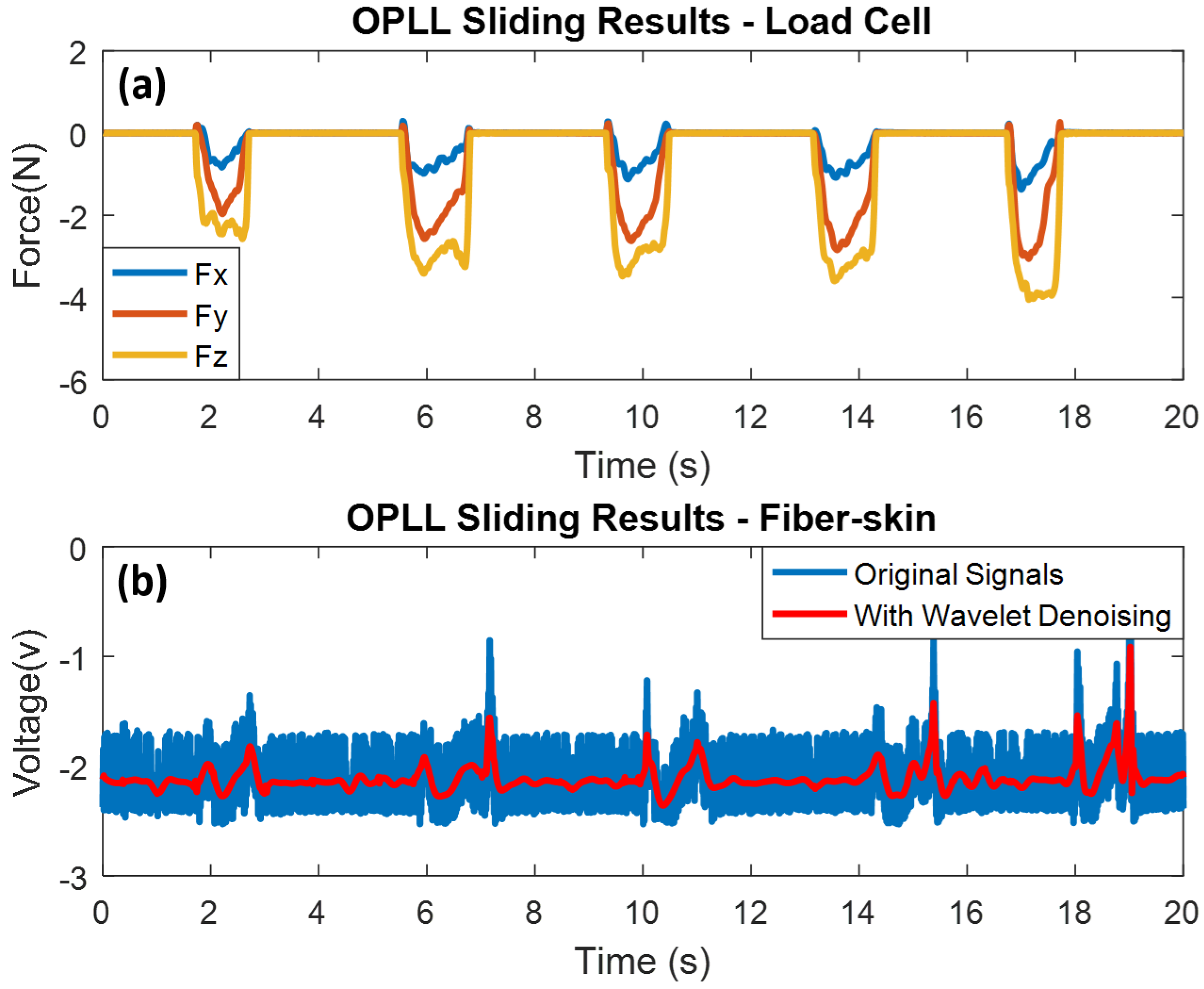

4.2. Experimental Results of OPLL Vibro-Perception

4.3. Results of Indirect Experiment

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Woo, S.H.; Lumpkin, E.A.; Patapoutian, A. Merkel cells and neurons keep in touch. Trends Cell Biol. 2015, 25, 74–81. [Google Scholar] [CrossRef] [PubMed]

- Zimmerman, A.; Bai, L.; Ginty, D.D. The gentle touch receptors of mammalian skin. Science 2014, 346, 950–954. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Zeng, X.; Matthews, D.; Igartua, A.; Rodriguez-Vidal, E.; Fortes, J.C.; Van Der Heide, E. Texture design for light touch perception. Biosurface Biotribol. 2017, 3, 25–34. [Google Scholar] [CrossRef]

- TermehYousefi, A.; Azhari, S.; Khajeh, A.; Hamidon, M.N.; Tanaka, H. Development of haptic based piezoresistive artificial fingertip: Toward efficient tactile sensing systems for humanoids. Mater. Sci. Eng. C 2017, 77, 1098–1103. [Google Scholar] [CrossRef] [PubMed]

- Kappassov, Z.; Corrales, J.A.; Perdereau, V. Tactile sensing in dexterous robot hands. Robot. Auton. Syst. 2015, 74, 195–220. [Google Scholar] [CrossRef]

- Lou, Z.; Chen, S.; Wang, L.; Shi, R.; Li, L.; Jiang, K.; Chen, D.; Shen, G. Ultrasensitive and ultraflexible e-skins with dual functionalities for wearable electronics. Nano Energy 2017, 38, 28–35. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Adhikary, P.; Jana, S.; Biswas, A.; Sencadas, V.; Gupta, S.D.; Tudu, B.; Mandal, D. Electrospun gelatin nanofiber based self-powered bio-e-skin for health care monitoring. Nano Energy 2017, 36, 166–175. [Google Scholar] [CrossRef]

- Sheikh, F.A.; Ju, H.W.; Lee, J.M.; Moon, B.M.; Park, H.J.; Lee, O.J.; Kim, J.H.; Kim, D.K.; Park, C.H. 3D electrospun silk fibroin nanofibers for fabrication of artificial skin. Nanomed. Nanotechnol. Biol. Med. 2015, 11, 681–691. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Fu, Y.; Zhao, T.; Gao, X.; Xing, L.; Zhang, Y.; Xue, X. All-solid-state flexible self-charging power cell basing on piezo-electrolyte for harvesting/storing body-motion energy and powering wearable electronics. Nano Energy 2017, 39, 590–600. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788–792. [Google Scholar] [CrossRef] [PubMed]

- Cirillo, A.; Cirillo, P.; De Maria, G.; Natale, C.; Pirozzi, S. An artificial skin based on optoelectronic technology. Sens. Actuators A Phys. 2014, 212, 110–122. [Google Scholar] [CrossRef]

- Ai, Y.; Lou, Z.; Chen, S.; Chen, D.; Wang, Z.M.; Jiang, K.; Shen, G. All rGO-on-PVDF-nanofibers based self-powered electronic skins. Nano Energy 2017, 35, 121–127. [Google Scholar] [CrossRef]

- Dong, C.; Fu, Y.; Zang, W.; He, H.; Xing, L.; Xue, X. Self-powering/self-cleaning electronic-skin basing on PVDF/TiO 2 nanofibers for actively detecting body motion and degrading organic pollutants. Appl. Surface Sci. 2017, 416, 424–431. [Google Scholar] [CrossRef]

- Wang, X.; Yin, Y.; Yi, F.; Dai, K.; Niu, S.; Han, Y.; Zhang, Y.; You, Z. Bioinspired stretchable triboelectric nanogenerator as energy-harvesting skin for self-powered electronics. Nano Energy 2017, 39, 429–436. [Google Scholar] [CrossRef]

- Zhou, D.; Sun, Y.; Bai, J.; Hauser, E.J.; Wang, S.; Han, B. Modeling and experimental investigation of the maximum stresses due to bending in a tubular-shaped artificial skin sensor. IEEE Sens. J. 2016, 16, 1549–1556. [Google Scholar] [CrossRef]

- Park, J.; Lee, Y.; Hong, J.; Lee, Y.; Ha, M.; Jung, Y.; Lim, H.; Kim, S.Y.; Ko, H. Tactile-direction-sensitive and stretchable electronic skins based on human-skin-inspired interlocked microstructures. ACS Nano 2014, 8, 12020–12029. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Kim, M.; Lee, Y.; Lee, H.S.; Ko, H. Fingertip skin–inspired microstructured ferroelectric skins discriminate static/dynamic pressure and temperature stimuli. Sci. Adv. 2015, 1, e1500661. [Google Scholar] [CrossRef] [PubMed]

- Xuan, H.; Jin, W.; Zhang, M. CO2 laser induced long period gratings in optical microfibers. Opt. Express 2009, 17, 21882–21890. [Google Scholar] [CrossRef] [PubMed]

- Xuan, H.; Jin, W.; Liu, S. Long-period gratings in wavelength-scale microfibers. Opt. Lett. 2010, 35, 85–87. [Google Scholar] [CrossRef] [PubMed]

- Tong, L.; Gattass, R.R.; Ashcom, J.B.; He, S.; Lou, J.; Shen, M.; Maxwell, I.; Mazur, E. Subwavelength-diameter silica wires for low-loss optical wave guiding. Nature 2003, 426, 816. [Google Scholar] [CrossRef] [PubMed]

- Fu, C. Readout of the vibration of nanowires using fibre optics: Combining light scattering and the interference effect. Phys. Lett. A 2017, 381, 2837–2840. [Google Scholar] [CrossRef]

- Pan, C.; Liu, X.; Zhu, H.; Shan, X.; Sun, X. Distributed optical fiber vibration sensor based on Sagnac interference in conjunction with OTDR. Opt. Express 2017, 25, 20056–20070. [Google Scholar] [CrossRef] [PubMed]

- Kamalesh, S.; Tan, P.; Wang, J.; Lee, T.; Kang, E.T.; Wang, C.H. Biocompatibility of electroactive polymers in tissues. J. Biomed. Mater. Res. Part A 2000, 52, 467–478. [Google Scholar] [CrossRef]

- Li, J.; Suh, M.G.; Vahala, K. Microresonator Brillouin gyroscope. Optica 2017, 4, 346–348. [Google Scholar] [CrossRef]

- Liang, W.; Ilchenko, V.; Eliyahu, D.; Savchenkov, A.; Matsko, A.; Maleki, L. On a feasibility of a resonant stimulated Raman scattering gyroscope. In Proceedings of the 2017 IEEE International Symposium on Inertial Sensors and Systems (INERTIAL), Kauai, HI, USA, 27–30 March 2017; pp. 8–10. [Google Scholar]

- Velázquez-González, J.S.; Monzón-Hernández, D.; Martínez-Piñón, F.; May-Arrioja, D.A.; Hernández-Romano, I. Surface Plasmon Resonance-Based Optical Fiber Embedded in PDMS for Temperature Sensing. IEEE J. Sel. Top. Quant. Electr. 2017, 23, 1–6. [Google Scholar] [CrossRef]

- Munendhar, P.; Zhang, L.; Tong, L.; Yu, S. Highly sensitive temperature sensor using intrinsic Mach-Zehnder interferometer formed by bent micro-fiber embedded in polymer. In Proceedings of the 2017 25th Optical Fiber Sensors Conference (OFS), Jeju, Korea, 24–28 April 2017; pp. 1–4. [Google Scholar]

- Warren-Smith, S.C.; Nguyen, L.V.; Ebendorff-Heidepriem, H.; Monro, T.M. High temperature sensing with single material silica optical fibers. In Proceedings of the 2017 25th Optical Fiber Sensors Conference (OFS), Jeju, Korea, 24–28 April 2017; pp. 1–4. [Google Scholar]

- Lee, B.; Roh, S.; Park, J. Current status of micro-and nano-structured optical fiber sensors. Opt. Fiber Technol. 2009, 15, 209–221. [Google Scholar] [CrossRef]

- Kang, M.S.; Brenn, A.; Wiederhecker, G.S.; Russell, P.S.J. Optical excitation and characterization of gigahertz acoustic resonances in optical fiber tapers. Appl. Phys. Lett. 2008, 93, 131110. [Google Scholar] [CrossRef]

- Tee, B.C.K.; Chortos, A.; Berndt, A.; Nguyen, A.K.; Tom, A.; McGuire, A.; Lin, Z.C.; Tien, K.; Bae, W.G.; Wang, H.; et al. A skin-inspired organic digital mechanoreceptor. Science 2015, 350, 313–316. [Google Scholar] [CrossRef] [PubMed]

- Bernardi, L.; Hopf, R.; Ferrari, A.; Ehret, A.; Mazza, E. On the large strain deformation behavior of silicone-based elastomers for biomedical applications. Polymer Testing 2017, 58, 189–198. [Google Scholar] [CrossRef]

- Iacob, M.; Bele, A.; Patras, X.; Pasca, S.; Butnaru, M.; Alexandru, M.; Ovezea, D.; Cazacu, M. Preparation of electromechanically active silicone composites and some evaluations of their suitability for biomedical applications. Mater. Sci. Eng. C 2014, 43, 392–402. [Google Scholar] [CrossRef] [PubMed]

- Zheng, W.; Xie, J.; Li, Y.; Xu, B.; Kang, J.; Shen, C.; Wang, J.; Jin, Y.; Liu, H.; Ni, K.; et al. A fiber air-gap Fabry–Pérot temperature sensor demodulated by using frequency modulated continuous wave. Opt. Commun. 2014, 324, 234–237. [Google Scholar] [CrossRef]

- Ang, K.H.; Chong, G.; Li, Y. PID control system analysis, design, and technology. IEEE Trans. Control Syst. Technol. 2005, 13, 559–576. [Google Scholar]

- Proakis, J.; Salehi, M. Digital Communications; McGraw-Hill: New York, NY, USA, 2008; pp. 722–726. [Google Scholar]

- Hurtado, M.M.; Peppelman, M.; Zeng, X.; van Erp, P.; Van Der Heide, E. Tribological behaviour of skin equivalents and ex-vivo human skin against the material components of artificial turf in sliding contact. Tribol. Int. 2016, 102, 103–113. [Google Scholar] [CrossRef]

- Zhang, S.; Zeng, X.; Matthews, D.; Igartua, A.; Rodriguez-Vidal, E.; Fortes, J.C.; Van Der Heide, E. Finger pad friction and tactile perception of laser treated, stamped and cold rolled micro-structured stainless steel sheet surfaces. Friction 2017, 5, 207–218. [Google Scholar] [CrossRef]

- Yoshioka, T.; Bensmaia, S.J.; Craig, J.C.; Hsiao, S.S. Texture perception through direct and indirect touch: An analysis of perceptual space for tactile textures in two modes of exploration. Somatosens. Motor Res. 2007, 24, 53–70. [Google Scholar] [CrossRef] [PubMed]

| Types | Direct Contact | Indirect Contact |

|---|---|---|

| Mach-Zehnder | Tapping & Sliding | Texture Sliding |

| OPLL | Tapping & Sliding | Texture Sliding |

| Types | No. | Maximum (N) | Minimum (N) | Mean (N) |

|---|---|---|---|---|

| Mach-Zehnder | 1 | 1.43 | 0.95 | 1.16 |

| 2 | 1.64 | 0.73 | 1.09 | |

| 3 | 1.35 | 0.68 | 0.92 | |

| OPLL | 1 | 3.01 | 1.90 | 2.32 |

| 2 | 3.04 | 1.25 | 2.06 | |

| 3 | 2.90 | 1.56 | 2.18 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, T.; Zhang, S.; Lu, G.-W.; Sunami, Y. Vibro-Perception of Optical Bio-Inspired Fiber-Skin. Sensors 2018, 18, 1531. https://doi.org/10.3390/s18051531

Li T, Zhang S, Lu G-W, Sunami Y. Vibro-Perception of Optical Bio-Inspired Fiber-Skin. Sensors. 2018; 18(5):1531. https://doi.org/10.3390/s18051531

Chicago/Turabian StyleLi, Tao, Sheng Zhang, Guo-Wei Lu, and Yuta Sunami. 2018. "Vibro-Perception of Optical Bio-Inspired Fiber-Skin" Sensors 18, no. 5: 1531. https://doi.org/10.3390/s18051531

APA StyleLi, T., Zhang, S., Lu, G.-W., & Sunami, Y. (2018). Vibro-Perception of Optical Bio-Inspired Fiber-Skin. Sensors, 18(5), 1531. https://doi.org/10.3390/s18051531