Temperature Resistant Fiber Bragg Gratings for On-Line and Structural Health Monitoring of the Next-Generation of Nuclear Reactors

Abstract

:1. Introduction

2. Key Aspects of Fiber Bragg Grating Sensing Technology for Nuclear Applications

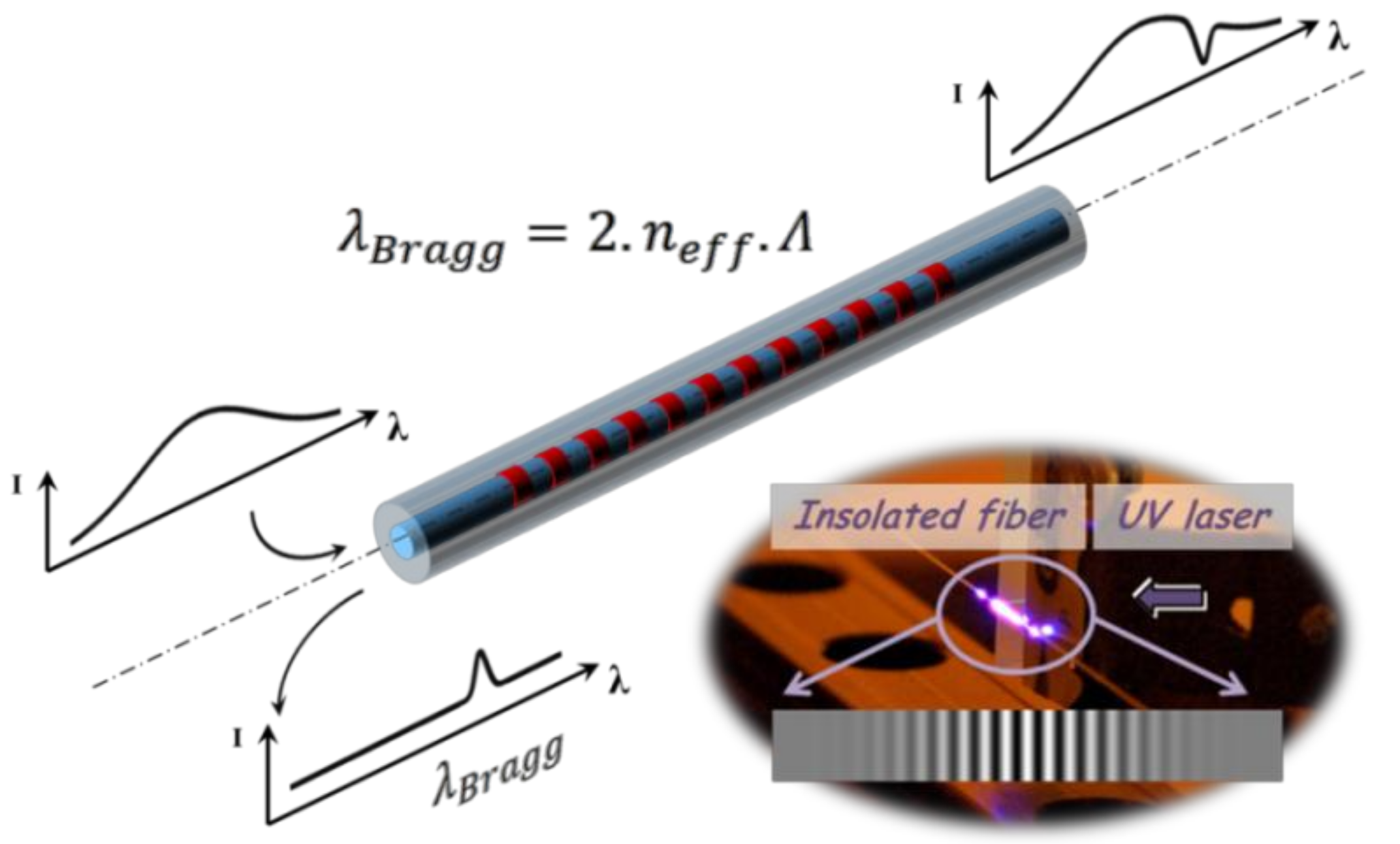

2.1. Fiber Bragg Gratings Temperature and Strain Transducers

2.2. FBG Wavelength Multiplexing

2.3. FBGs and Radiative Environments

3. Manufacturing Techniques of High Temperature Resistant Fiber Bragg Gratings

3.1. Regenerated FBGs

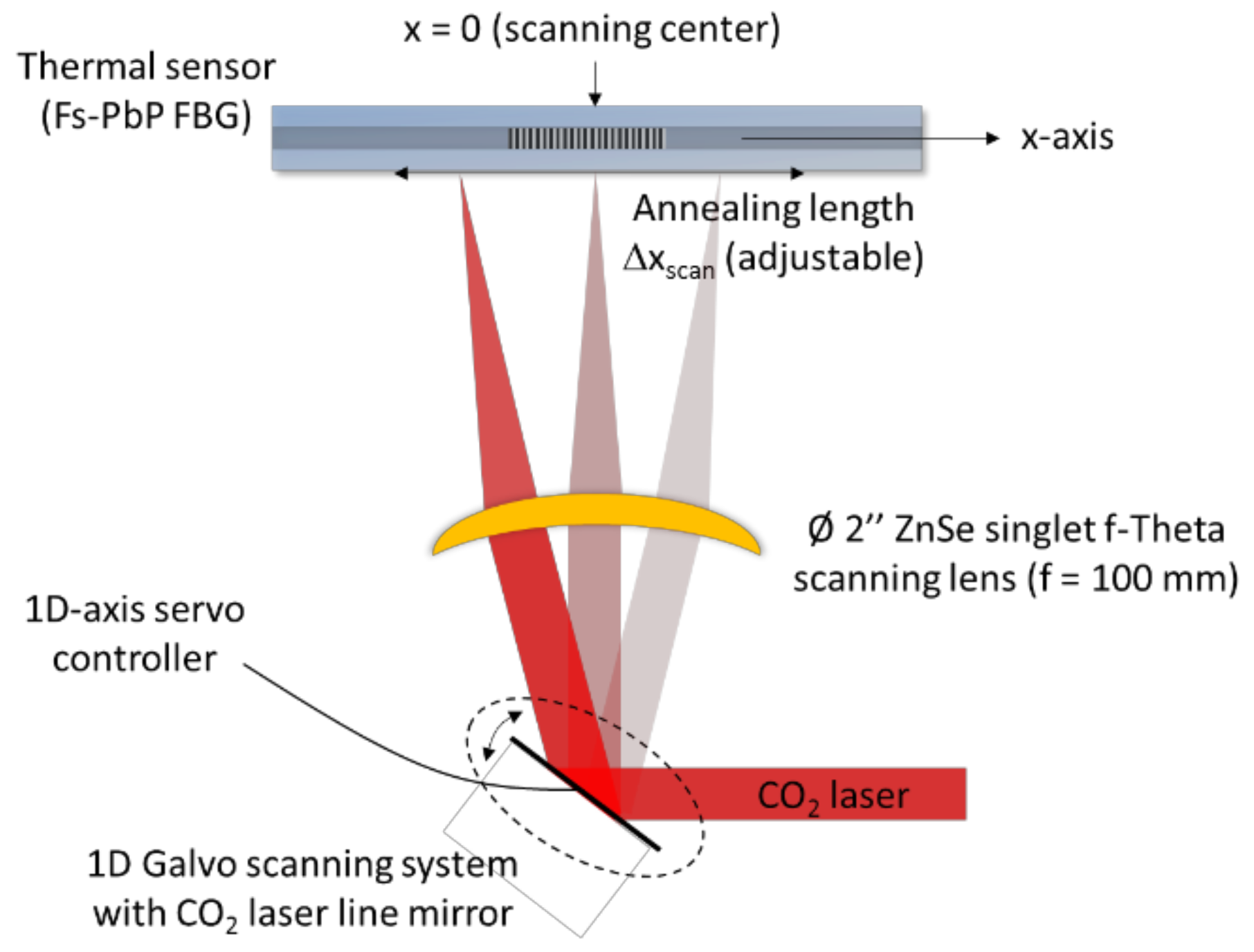

3.2. All-Optical Setup for FBG Regeneration

3.3. Femtosecond Fiber Bragg Gratings

4. Deployment of Temperature-Resistant FBGs into Sodium

5. High Temperature Fiber Bragg Grating Strain Transducers

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Mihailov, S.J. Fiber Bragg Grating Sensors for Harsh Environments. Sensors 2012, 12, 1898–1918. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Laffont, G.; Cotillard, R.; Ferdinand, P. Multiplexed regenerated Fiber Bragg Gratings for high temperature measurement. Meas. Sci. Technol. 2013, 24, 094010. [Google Scholar] [CrossRef]

- Voigtlander, T.J.; Becker, R.G.; Richter, D.; Tünnermann, A.; Nolte, S. Femtosecond pulse written fiber Bragg gratings: A new avenue to integrated fiber technology. Laser Photonics Rev. 2012, 6, 709–723. [Google Scholar] [CrossRef]

- Jeannot, J.P.; Rodriguez, G.; Jammes, C.; Bernardin, B.; Portier, J.L.; Jadot, F.; Maire, S.; Verrier, D.; Loisy, F.; Préle, G. R&D program for core instrumentation improvements devoted for French Sodium fast reactors. In Proceedings of the 2nd International Conference on Advancements in Nuclear Instrumentation, Measurement Methods and their Applications, Ghent, Belgium, 6–9 June 2011. [Google Scholar] [CrossRef]

- Jadot, F.; Baqué, F.; Jeannot, J. Ph.; De Dinechin, G.; Augem, J.M.; Sibilo, J.G. ASTRID sodium cooled fast reactor: Program for improving in service inspection and repair. In Proceedings of the 2nd International Conference on Advancements in Nuclear Instrumentation, Measurement Methods and their Applications, Ghent, Belgium, 6–9 June 2011. [Google Scholar] [CrossRef]

- Baqué, F.; Reverdy, F.; Augem, J.-M.; Sibilo, J. Development of tools, instrumentation and codes for improving periodic examination and repairs of SFRs. Sci. Technol. Nucl. Install. 2012. [Google Scholar] [CrossRef]

- Giot, M.; Vermeeren, L.; Lyoussi, A.; Reynard-Carette, Ch.; Lhuillier, Ch.; Mégret, P.; Deconinck, F.; Gonçalves, B.S. Nuclear instrumentation and measurement: A review based on the ANIMMA conferences. EPJ Nucl. Sci. Technol. 2017, 3. [Google Scholar] [CrossRef]

- Paumel, K.; Jeannot, J.-P.; Laffont, G.; Vanderhaegen, M.; Massacret, N. R&D on early detection of the Total Instantaneous Blockage for 4th Generation Reactors—Inventory of non-nuclear methods investigated by CEA. In Proceedings of the 3rd International Conference on Advancements in Nuclear Instrumentation, Measurement Methods and Their Applications, Marseille, France, 23–27 June 2013. [Google Scholar] [CrossRef]

- Ferdinand, P.; Magne, S.; Laffont, G. Optical Fibre Sensors to improve safety of Nuclear Power Plants. In Proceedings of the 4th Asia Pacific Optical Sensors Conference (APOS), Wuhan, China, 15–18 October 2013. [Google Scholar] [CrossRef]

- Hawn, D.P.; Petrie, C.M.; Blue, T.E.; Windl, W. In-situ gamma radiation induced attenuation in silica optical fibers heated up to 600 °C. J. Non-Cryst. Solids 2013, 379, 192–200. [Google Scholar] [CrossRef]

- Canning, J.; Bandyopadhyay, D.; Stevenson, M.; Biswas, P.; Fenton, J.; Aslund, M. Regenerated gratings. J. Eur. Opt. Soc. Rapid Publ. 2009, 4, 09052. [Google Scholar] [CrossRef]

- Mihailov, S.J.; Grobnic, D.; Hnatovsky, C.; Walker, R.B.; Lu, P.; Coulas, D.; Ding, H. Extreme environment sensing using femtosecond laser-inscribed Fiber Bragg Gratings. Sensors 2017, 17, 2909. [Google Scholar] [CrossRef] [PubMed]

- Habel, J.; Boilard, T.; Frenière, J.-S.; Trépanier, F.; Bernier, M. Femtosecond FBG Written through the Coating for Sensing Applications. Sensors 2017, 17, 2519. [Google Scholar] [CrossRef] [PubMed]

- Hill, K.O.; Fujii, Y.; Johnson, D.C.; Kawasaki, B.S. Photosensitivity in optical fiber waveguides: Application to reflection filter fabrication. Appl. Phys. Lett. 1978, 32, 647. [Google Scholar] [CrossRef]

- Kashyap, R. Fiber Bragg Gratings, 2nd ed.; Academic Press: New York, NY, USA, 2017; ISBN 9780080919911. [Google Scholar]

- Ferdinand, P.; Magne, S.; Laffont, G.; Dewynter, V.; Maurin, L.; Prudhomme, C.; Roussel, N.; Giuseffi, M.; Maguis, S. Optical Fiber Sensors from laboratory to field trials: Applications and trends at CEA LIST. Fiber Integr. Opt. 2009, 28, 81–107. [Google Scholar] [CrossRef]

- Laffont, G. Study and Development of Tilted FBG-Based Transducers and Measurement Systems in Single Mode Optical Fiber. Ph.D. Thesis, University of Lille, Lille, France, 2001. [Google Scholar]

- Roussel, N.; Ferdinand, P.; Maurin, L. Long term stability of spectral measurement systems for fiber Bragg grating sensors. In Proceedings of the 4th Asia Pacific Optical Sensors Conference (APOS), Wuhan, China, 15–18 October 2013. [Google Scholar] [CrossRef]

- Westbrook, P.S.; Kremp, T.; Feder, K.S.; Ko, W.; Monberg, E.M.; Wu, H.; Simoff, D.A.; Taunay, T.F.; Ortiz, R.M. Continuous multicore optical fiber grating arrays for distributed sensing applications. J. Lightwave Technol. 2017, 35, 1248. [Google Scholar] [CrossRef]

- Cusano, A.; Cutolo, A.; Albert, J. Fiber Bragg Grating Sensors: Recent Advancements, Industrial Applications and Market Exploitation; Bentham Science Publisher: Oak Park, IL, USA, 2011; ISBN 160805084X, 9781608050840. [Google Scholar]

- Laffont, G.; Ferdinand, P. Tilted short-period fibre Bragg grating induced coupling to cladding modes for accurate refractometry. Meas. Sci. Technol. 2001, 12, 765. [Google Scholar] [CrossRef]

- Maguis, S.; Laffont, G.; Ferdinand, P.; Carbonnier, B.; Kham, K.; Mekhalif, T.; Millot, M.-C. Biofunctionalized tilted fiber Bragg gratings for label-free immunosensing. Opt. Express 2008, 16, 19049. [Google Scholar] [CrossRef] [PubMed]

- Lepinay, S.; Laffont, G.; Volet, G.; Wintgens, V.; Ferdinand, P.; Millot, M.-C.; Carbonnier, B. Cyclodextrin-based supramolecular multilayer assemblies for the design of biological optical sensors using tilted fiber Bragg gratings. Key Eng. Mater. 2012, 495, 45. [Google Scholar] [CrossRef]

- Guo, T.; Guan, B.-O.; Albert, J. Tilted fiber grating mechanical and biochemical sensors. Opt. Laser Technol. 2016, 78, 19. [Google Scholar] [CrossRef]

- Gusarov, A.; Hoeffgen, S.K. Radiation effects on fiber gratings. IEEE Trans. Nucl. Sci. 2013, 60, 2037–2053. [Google Scholar] [CrossRef]

- Girard, S.; Kuhnhenn, J.; Gusarov, A.; Brichard, B.; Van Uffelen, M.; Ouerdane, Y.; Boukenter, A.; Marcandella, C. Radiation Effects on Silica-Based Optical Fibers: Recent Advances and Future Challenges. IEEE Trans. Nucl. Sci. 2013, 60, 2015–2036. [Google Scholar] [CrossRef]

- Morana, A.; Girard, S.; Marin, E.; Marcandella, C.; Rizzolo, S.; Perisse, J.; Mace, J.R.; Taouri, A.; Boukenter, A.; Cannas, M.; et al. Radiation Vulnerability of Fiber Bragg Gratings in Harsh Environments. J. Lightwave Technol. 2015, 33, 2646–2651. [Google Scholar] [CrossRef]

- Blanchet, T.; Morana, A.; Laffont, G.; Cotillard, R.; Marin, E.; Boukenter, A.; Ouerdane, Y.; Girard, S. Radiation effects on Type I Fiber Bragg Gratings: Influence of Recoating and Irradiation Conditions. J. Lightwave Technol. 2018, 36, 998–1004. [Google Scholar] [CrossRef]

- Petrie, C.M.; Hawn, D.P.; Windl, W.; Blue, T.E. Reactor radiation-induced attenuation in fused silica optical fibers heated up to 1000 °C. J. Non-Cryst. Solids 2015, 409, 88–94. [Google Scholar] [CrossRef] [Green Version]

- Ramsey, A.T.; Tighe, W.; Bartolick, J.; Morgan, P.D. Radiation effects on heated optical fibers. Rev. Sci. Instrum. 1997, 68, 632–635. [Google Scholar] [CrossRef]

- Marshall, G.D.; Williams, R.J.; Jovanovic, N.; Steel, M.J.; Withford, M.J. Point-by-point written fiber-Bragg gratings and their application in complex grating designs. Opt. Express 2010, 18, 19844–19859. [Google Scholar] [CrossRef] [PubMed]

- Canning, J. Regeneration, regenerated gratings and composite glass properties: The implications for high temperature micro and nano milling and optical sensing. Measurement 2016, 79, 236–249. [Google Scholar] [CrossRef]

- Bueno, A.; Kinet, D.; Mégret, P.; Caucheteur, C. Fast thermal regeneration of fiber Bragg gratings. Opt. Lett. 2013, 38, 4178–4181. [Google Scholar] [CrossRef] [PubMed]

- Lai, M.-H.; Gunawardena, D.S.; Lim, K.-S.; Yang, H.-Z.; Ahmad, H. Observation of grating regeneration by direct CO2 laser annealing. Opt. Express 2015, 23, 452–463. [Google Scholar] [CrossRef] [PubMed]

- Laffont, G.; Cotillard, R.; Ferdinand, P. 9000 hours-long high temperature annealing of regenerated Fiber Bragg Gratings. In Proceedings of the 5th European Workshop on Optical Fibre Sensors, Krakow, Poland, 19–22 May 2013. [Google Scholar] [CrossRef]

- Holmberg, P.; Fokine, M. Thermometric study of CO2-laser heated optical fibers in excess of 1700 °C using fiber Bragg gratings. J. Opt. Soc. Am. B 2013, 30, 1835–1842. [Google Scholar] [CrossRef]

- Bellouard, Y.; Hongler, M.-O. Femtosecond-laser generation of self-organized bubble patterns in fused silica. Opt. Express 2011, 19, 6807. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mathew, J.; MacPherson, W.N.; Hand, D.P.; Maier, R.R. Stainless steel component with compressed fiber Bragg grating for high temperature sensing applications. In Proceedings of the SPIE—Sixth European Workshop on Optical Fibre Sensors, Limerick, Ireland, 31 May–3 June 2016; Volume 9916. [Google Scholar] [CrossRef]

- Tu, Y.; Ye, L.; Zhou, S.-P.; Tu, S.-T. An improved metal-packaged strain sensor based on a regenerated Fiber Bragg Grating in hydrogen-loaded boron-germanium co-doped photosensitive fiber for high-temperature applications. Sensors 2017, 17, 431. [Google Scholar] [CrossRef] [PubMed]

| Temperature (°C) | Bragg Wavelength Sensitivity to Temperature (pm/°C) (Extracted from [3]) | Temperature Measurement Error of A Regenerated-FBG After Receiving A 33 Kgy Dose |

|---|---|---|

| Room temperature | 9.5 | 4.0 °C |

| 200 °C | 12.7 | 2.5 °C |

| 400 °C | 14.6 | 1.3 °C |

| 600 °C | 15.7 | 0.3 °C |

| 800 °C | 16.4 | 0.3 °C |

| λBragg_start (nm) | R_Start (%) | T_Annealing (°C) | ΔλBragg (nm) | ΔR/R (%) |

|---|---|---|---|---|

| 1530 | 12% | 950 °C | −0.52 nm | −43% |

| 1540 | 16% | 945 °C | −0.43 nm | −5% |

| 1560 | 25% | 940 °C | −0.41 nm | −39% |

| 1570 | 8% | 925 °C | −0.18 nm | +5% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Laffont, G.; Cotillard, R.; Roussel, N.; Desmarchelier, R.; Rougeault, S. Temperature Resistant Fiber Bragg Gratings for On-Line and Structural Health Monitoring of the Next-Generation of Nuclear Reactors. Sensors 2018, 18, 1791. https://doi.org/10.3390/s18061791

Laffont G, Cotillard R, Roussel N, Desmarchelier R, Rougeault S. Temperature Resistant Fiber Bragg Gratings for On-Line and Structural Health Monitoring of the Next-Generation of Nuclear Reactors. Sensors. 2018; 18(6):1791. https://doi.org/10.3390/s18061791

Chicago/Turabian StyleLaffont, Guillaume, Romain Cotillard, Nicolas Roussel, Rudy Desmarchelier, and Stéphane Rougeault. 2018. "Temperature Resistant Fiber Bragg Gratings for On-Line and Structural Health Monitoring of the Next-Generation of Nuclear Reactors" Sensors 18, no. 6: 1791. https://doi.org/10.3390/s18061791

APA StyleLaffont, G., Cotillard, R., Roussel, N., Desmarchelier, R., & Rougeault, S. (2018). Temperature Resistant Fiber Bragg Gratings for On-Line and Structural Health Monitoring of the Next-Generation of Nuclear Reactors. Sensors, 18(6), 1791. https://doi.org/10.3390/s18061791