Electrical and Thermal Properties of Heater-Sensor Microsystems Patterned in TCO Films for Wide-Range Temperature Applications from 15 K to 350 K

Abstract

:1. Introduction

- the heaters mostly covered large surface areas and were embedded directly on the surface of the heated object [2,19,20,21,22,24,25,26]. The heaters, with dimensions of less than a few millimeters, were made using complex technologies (masking, photolithography, or etching) [17,23,27,28,29,31,32,33,34];

2. Experiments

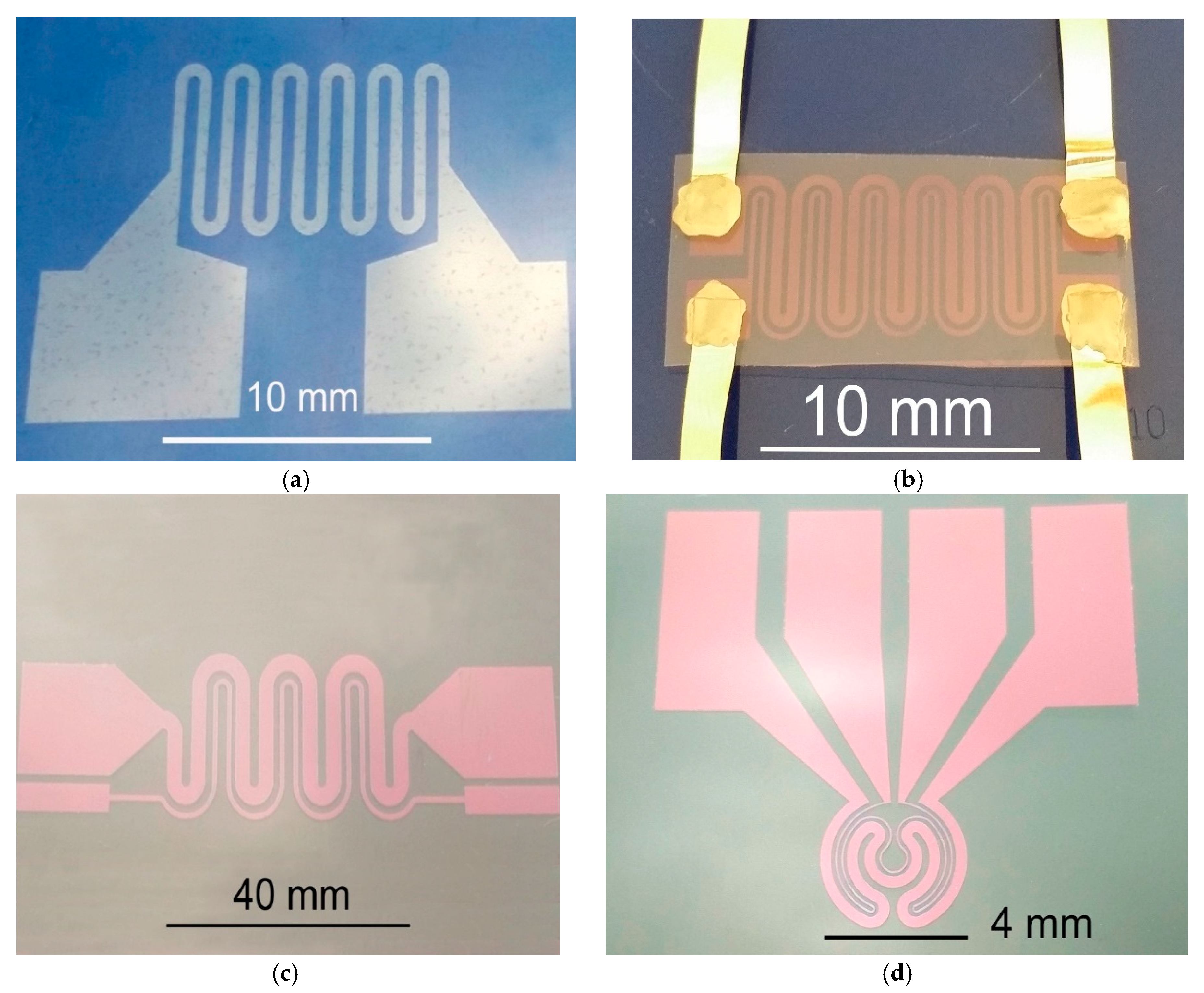

2.1. Materials and Structures

2.2. Experimental Procedures

- natural convection: the investigated structure was suspended under natural convection conditions at room temperature. Convection and radiation were observed. Microsystems with microchambers attached to the surface were also investigated. The microchambers were filled with liquid as an additional heat load for the heating structure;

- heat conduction at cryogenic temperatures (295–15 K). The structure was mounted on a copper heat exchanger in a cryogenic system. The investigation was conducted in a vacuum chamber equipped with a radiation shield.

3. Results and Discussion

3.1. Room Temperature

3.2. Cryogenic Temperature

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gupta, R.; Rao, K.D.M.; Kiruthika, S.; Kulkarni, G.U. Visibly transparent heaters. ACS Appl. Mater. Interfaces 2016, 8, 12559–12575. [Google Scholar] [CrossRef] [PubMed]

- Im, K.; Cho, K.; Kim, J.; Kim, S. Transparent heaters based on solution-processed indium tin oxide nanoparticles. Thin Solid Films 2010, 518, 3960–3963. [Google Scholar] [CrossRef]

- Yoon, Y.-H.; Song, J.-W.; Kim, D.; Kim, J.; Park, J.-K.; Oh, S.-K.; Han, C.-S. Transparent film heater using single-walled carbon nanotubes. Adv. Mater. 2007, 19, 4284–4287. [Google Scholar] [CrossRef]

- Jang, H.-S.; Jeon, S.K.; Nahm, S.H. The manufacture of a transparent film heater by spinning multi-walled carbon nanotubes. Carbon 2011, 49, 111–116. [Google Scholar] [CrossRef]

- Janas, D.; Koziol, K.K. Rapid electrothermal response of high-temperature carbon nanotube film heaters. Carbon 2013, 59, 457–463. [Google Scholar] [CrossRef]

- Sui, D.; Huang, Y.; Huang, L.; Liang, J.; Ma, Y.; Chen, Y. Flexible and transparent electrothermal film heaters based on graphene materials. Small 2011, 7, 3186–3192. [Google Scholar] [CrossRef] [PubMed]

- Zhang, T.-Y.; Zhao, H.-M.; Yang, Z.; Wang, Q.; Wang, D.-Y.; Deng, N.-Q.; Yang, Y.; Ren, T.-L. Improved electrothermal performance of custom-shaped micro heater based on anisotropic laser-reduced graphene oxide. Appl. Phys. Lett. 2016, 109, 151905. [Google Scholar] [CrossRef]

- Bae, J.J.; Lim, S.C.; Han, G.H.; Jo, Y.W.; Doung, D.L.; Kim, E.S.; Chae, S.J.; Huy, T.Q.; Van Luan, N.; Lee, Y.H. Heat dissipation of transparent graphene defoggers. Adv. Funct. Mater. 2012, 22, 4819–4826. [Google Scholar] [CrossRef]

- Kim, T.; Kim, Y.W.; Lee, H.S.; Kim, H.; Yang, W.S.; Suh, K.S. Uniformly interconnected silver-nanowire networks for transparent film heaters. Adv. Funct. Mater. 2013, 23, 4819–4826. [Google Scholar] [CrossRef]

- Celle, C.; Mayousse, C.; Moreau, E.; Basti, H.; Carella, A.; Simonato, J.-P. Highly flexible transparent film heaters based on random networks of silver nanowires. Nano Res. 2012, 5, 427–433. [Google Scholar] [CrossRef]

- Ye, S.; Rathmell, A.R.; Chen, Z.; Stewart, I.E.; Wiley, B.J. Metal nanowire networks: The next generation of transparent conductors. Adv. Mater. 2014, 26, 6670–6687. [Google Scholar] [CrossRef] [PubMed]

- Pyo, K.-H.; Kim, J.-W. Thermally stable and flexible transparent heaters based on silver nanowire-colorless polyimide composite electrode. Curr. Appl. Phys. 2016, 16, 1453–1458. [Google Scholar] [CrossRef]

- Kang, J.; Jang, Y.; Kim, Y.; Cho, S.-H.; Suhr, J.; Hong, B.H.; Choi, J.-B.; Byun, D. An Ag-grid/graphene hybrid structure for large-scale, transparent, flexible heaters. Nanoscale 2015, 7, 6567–6573. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Liang, J.; Jian, X.; Hu, W.; Li, J.; Pei, Q. A flexible and transparent thin film heater based on a silver nanowire/heat-resistant polymer composite. Macromol. Mater. Eng. 2014, 299, 1403–1409. [Google Scholar] [CrossRef]

- Ji, S.; He, W.; Wang, K.; Ran, Y.; Ye, C. Thermal response of transparent silver nanowire/PEDOT: PSS film heaters. Small 2014, 10, 4951–4960. [Google Scholar] [CrossRef] [PubMed]

- Toyotomi, S.; Momose, Y. Temperature-controlled perfusion apparatus for microscope using transparent conducting film heater. Am. J. Physiol.-Cell Physiol. 1989, 256, C214–C217. [Google Scholar] [CrossRef] [PubMed]

- Shivashankar, G.V.; Liu, S.; Libchaber, A. Control of the expression of anchored genes using micron scale heater. Appl. Phys. Lett. 2000, 76, 3638–3640. [Google Scholar] [CrossRef]

- Pascual, C.C.; Jeter, S.M.; Abdel-Khalik, S.I. Visualization of boiling bubble dynamics using a flat uniformly heated transparent surface. Int. J. Heat Mass Transf. 2001, 45, 691–696. [Google Scholar] [CrossRef]

- Sun, K.; Yamaguchi, A.; Ishida, Y.; Matsuo, S.; Misawa, H. A heater-integrated transparent microchannel chip for continuous-flow PCR. Sens. Actuators B 2002, 84, 283–289. [Google Scholar] [CrossRef]

- Yen, T.-H.; Shoji, M.; Takemura, F.; Suzuki, Y.; Kasagi, N. Visualization of convective boiling heat transfer in single microchannels with different shaped cross-sections. Int. J. Heat Mass Transf. 2006, 49, 3884–3894. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, P.; Huang, C.J.; Wang, R.Z. Bubble growth, departure and the following flow pattern evolution during flow boiling in a mini-tube. Int. J. Heat Mass Transf. 2010, 53, 4819–4831. [Google Scholar] [CrossRef]

- Dall’Olio, S.; Marengo, M. Boiling of R134a inside a glass minichannel. A new statistical approach of flow pattern characterization based on flow visualization. Int. J. Heat Mass Transf. 2012, 55, 1048–1065. [Google Scholar]

- Jha, S.K.; Chand, R.; Han, D.; Jang, Y.-C.; Ra, G.-S.; Kim, J.S.; Nahm, B.-H.; Kim, Y.-S. An integrated PCR microfluidic chip incorporating aseptic electrochemical cell lysis and capillary electrophoresis amperometric DNA detection for rapid and quantitative genetic analysis. Lab Chip 2012, 12, 4455–4464. [Google Scholar] [CrossRef] [PubMed]

- Chu, I.-C.; No, H.C.; Song, C.-H. Visualization of boiling structure and critical heat flux phenomenon for a narrow heating surface in a horizontal pool of saturated water. Int. J. Heat Mass Transf. 2013, 62, 142–152. [Google Scholar] [CrossRef]

- McGranaghan, G.J.; Robinson, A.J. The mechanisms of heat transfer during convective boiling under the influence of AC electric fields. Int. J. Heat Mass Transf. 2014, 73, 376–388. [Google Scholar] [CrossRef]

- Gao, M.; Cheng, P.; Quan, X. An experimental investigation on effects of an electric field on bubble growth on a small heater in pool boiling. Int. J. Heat Mass Transf. 2013, 67, 984–991. [Google Scholar] [CrossRef]

- Chen, X.; Qiu, H. Bubble dynamics and heat transfer on a wettability patterned surface. Int. J. Heat Mass Transf. 2015, 88, 544–551. [Google Scholar] [CrossRef]

- Çakır, M.C.; Çaliışkan, D.; Bütün, B.; Özbay, E. Planar indium tin oxide heater for improved thermal distribution for metal oxide micromachined gas sensors. Sensors 2016, 16, 1612. [Google Scholar] [CrossRef] [PubMed]

- Ahn, B.D.; Oh, S.H.; Hong, D.U.; Shin, D.H.; Moujoud, A.; Kim, H.J. Transparent Ga-doped zinc oxide-based window heaters fabricated by pulsed laser deposition. J. Cryst. Growth 2008, 310, 3303–3307. [Google Scholar] [CrossRef]

- Ko, E.; Kim, H.; Lee, S.; Lee, J.; Kim, H. Nano-sized Ag inserted into ITO films prepared by continuous roll-to-roll sputtering for high-performance, flexible, transparent film heaters. RSC Adv. 2016, 6, 46634–46642. [Google Scholar] [CrossRef]

- Kim, J.-H.; Na, K.-H.; Kang, C.J.; Jeon, D.; Kim, Y.-S. A disposable thermopneumatic-actuated microvalve stacked with PDMS layers and ITO-coated glass. Microelectron. Eng. 2004, 73–74, 864–869. [Google Scholar] [CrossRef]

- Kim, J.-H.; Na, K.-H.; Kang, C.J.; Kim, Y.-S. A disposable thermopneumatic-actuated micropump stacked with PDMS layers and ITO-coated glass. Sens. Actuators A 2005, 120, 365–369. [Google Scholar] [CrossRef]

- Yoo, J.-C.; Moon, M.-C.; Choi, Y.J.; Kang, C.J.; Kim, Y.-S. A high performance microfluidic system integrated with the micropump and microvalve on the same substrate. Microelectron. Eng. 2006, 83, 1684–1687. [Google Scholar] [CrossRef]

- Yoo, J.-C.; Choi, Y.J.; Kang, C.J.; Kim, Y.-S. A novel polydimethylsiloxane microfluidic system including thermopneumatic-actuated micropump and Paraffin-actuated microvalve. Sens. Actuators A 2007, 139, 216–220. [Google Scholar] [CrossRef]

- Saint-Gobain. Available online: https://www.saint-gobain-sekurit-transport.com (accessed on 10 April 2018).

- Vartech System Inc. Available online: http://www.vartechsystems.com/products/Transparent-Heaters.asp (accessed on 10 April 2018).

- Lebioda, M.; Pawlak, R. Influence of cryogenic temperatures on electrical properties of structures patterned by a laser in ITO/Ag/ITO layers. Phys. Status Solidi A 2016, 213, 1150–1156. [Google Scholar] [CrossRef]

- Pawlak, R.; Lebioda, M.; Rymaszewski, J.; Szymanski, W.; Kolodziejczyk, L.; Kula, P. A fully transparent flexible sensor for cryogenic temperatures based on high strength metallurgical grapheme. Sensors 2017, 17, 51. [Google Scholar] [CrossRef] [PubMed]

- Pawlak, R.; Tomczyk, M.; Walczak, M. Ablation of selected conducting layers by fiber laser. Proc. SPIE 2014, 9291, 92910P. [Google Scholar]

- Amepox Ltd. Available online: http://www.amepox-mc.com (accessed on 10 April 2018).

| No. | Heater Material; Thickness | Substrate | Shape of Heater; Preparation Method | Surface Area (mm2) | Surface Power (W/cm2) | Refs. |

|---|---|---|---|---|---|---|

| 1 | ITO; 100 nm | glass | rectangle; vacuum deposition | 72 | — * | [16] |

| 2 | ITO; — | glass | square; photolithography and etching | 0.01 | ≈133 | [17] |

| 3 | ITO; 300 nm | glass | square; vacuum deposition and etching | 255 ÷ 413 | 5 ÷ 11 | [18] |

| 4 | ITO; 500 nm | quartz glass | rectangle; lift-off technique deposition | ≈150 | — | [19] |

| 5 | ITO/Ag; 100 nm | glass | outer surface of tube; sputtering | 125 ÷ 565 | ≈4 | [20] |

| 6 | ITO; — | quartz glass tube | outer surface of tube; — | ≈628 | 2.18 | [21] |

| 7 | ITO; — | glass tube | outer surface of tube; vacuum deposition | 628 ÷ 12,000 | 0.2 ÷ 4 | [22] |

| 8 | ITO; — | glass | rectangle; patterned by photolithography | ≈6500 | — | [23] |

| 9 | ITO nanoparticle solution; 470 nm | glass | rectangle; spin coating and sintering | ≈350 | ≈0.6 | [2] |

| 10 | ITO; 350 nm | sapphire | rectangle; sputtering | 640 | 50–134 | [24] |

| 11 | ITO; — | sapphire tube | outer surface of tube; sputtering | 15,000 | — | [25] |

| 12 | ITO; 180 nm | pyrex glass | square; — | 25 | 5.89 | [26] |

| 13 | ITO; — | pyrex glass | square; etching | 1 | 300 | [27] |

| 14 | ITO; 140 nm | Si3N4 | square; photolithography and etching | ~0.67 | 17.8 | [28] |

| 15 | Ga-doped ZnO; 400 nm | glass | rectangle; photolithography and etching | 110 | ≈1.32 | [29] |

| 16 | ITO/Ag/ITO; 40/6 ÷ 12/40 nm | PET | rectangle; cutting of large area film | 2500 | 0.28 ÷ 0.33 | [30] |

| 17 | ITO; 170 nm | glass | square; photolithography and etching | 4 | 1.9 ÷ 6.25 | [31,32] |

| 18 | ITO; 170 nm | glass | square; photolithography and etching | 5.52 | 4.55 ÷ 10 | [33] |

| 19 | ITO; 170 nm | glass | square/meander; photolithography and etching | 5.52 | 10 | [34] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pawlak, R.; Lebioda, M. Electrical and Thermal Properties of Heater-Sensor Microsystems Patterned in TCO Films for Wide-Range Temperature Applications from 15 K to 350 K. Sensors 2018, 18, 1831. https://doi.org/10.3390/s18061831

Pawlak R, Lebioda M. Electrical and Thermal Properties of Heater-Sensor Microsystems Patterned in TCO Films for Wide-Range Temperature Applications from 15 K to 350 K. Sensors. 2018; 18(6):1831. https://doi.org/10.3390/s18061831

Chicago/Turabian StylePawlak, Ryszard, and Marcin Lebioda. 2018. "Electrical and Thermal Properties of Heater-Sensor Microsystems Patterned in TCO Films for Wide-Range Temperature Applications from 15 K to 350 K" Sensors 18, no. 6: 1831. https://doi.org/10.3390/s18061831

APA StylePawlak, R., & Lebioda, M. (2018). Electrical and Thermal Properties of Heater-Sensor Microsystems Patterned in TCO Films for Wide-Range Temperature Applications from 15 K to 350 K. Sensors, 18(6), 1831. https://doi.org/10.3390/s18061831