Bragg-Grating-Based Photonic Strain and Temperature Sensor Foils Realized Using Imprinting and Operating at Very Near Infrared Wavelengths

Abstract

:1. Introduction

2. Sensor Design

2.1. Concept and Layout of the Multi-Axial Photonic Strain Sensor

2.2. Waveguide Design for Single Mode Operation around λ = 850 nm

2.3. Bragg Grating Sensor Design

3. Methods

3.1. Sensor Fabrication

3.2. Sensor Characterization Methods

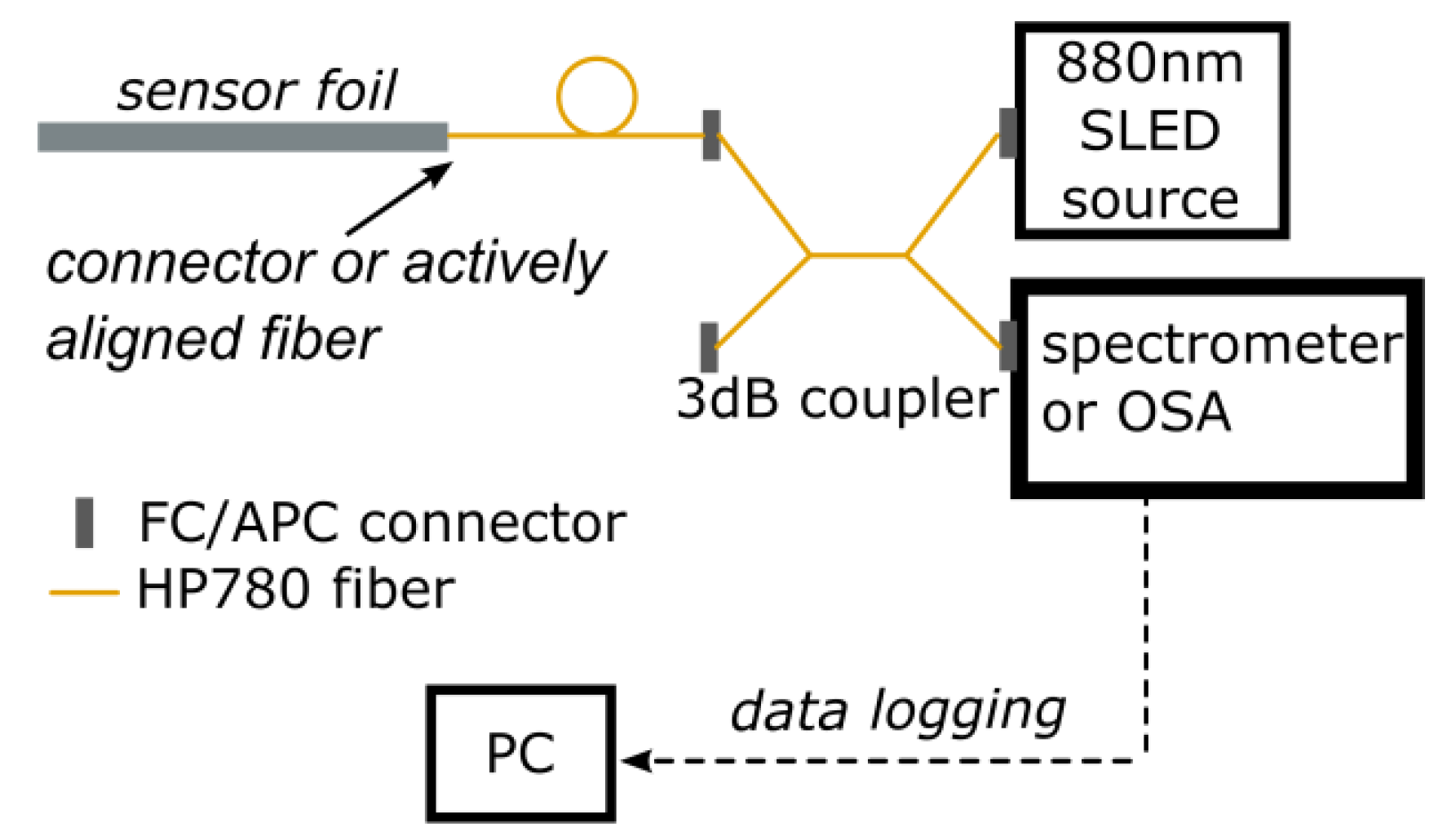

3.2.1. Readout System

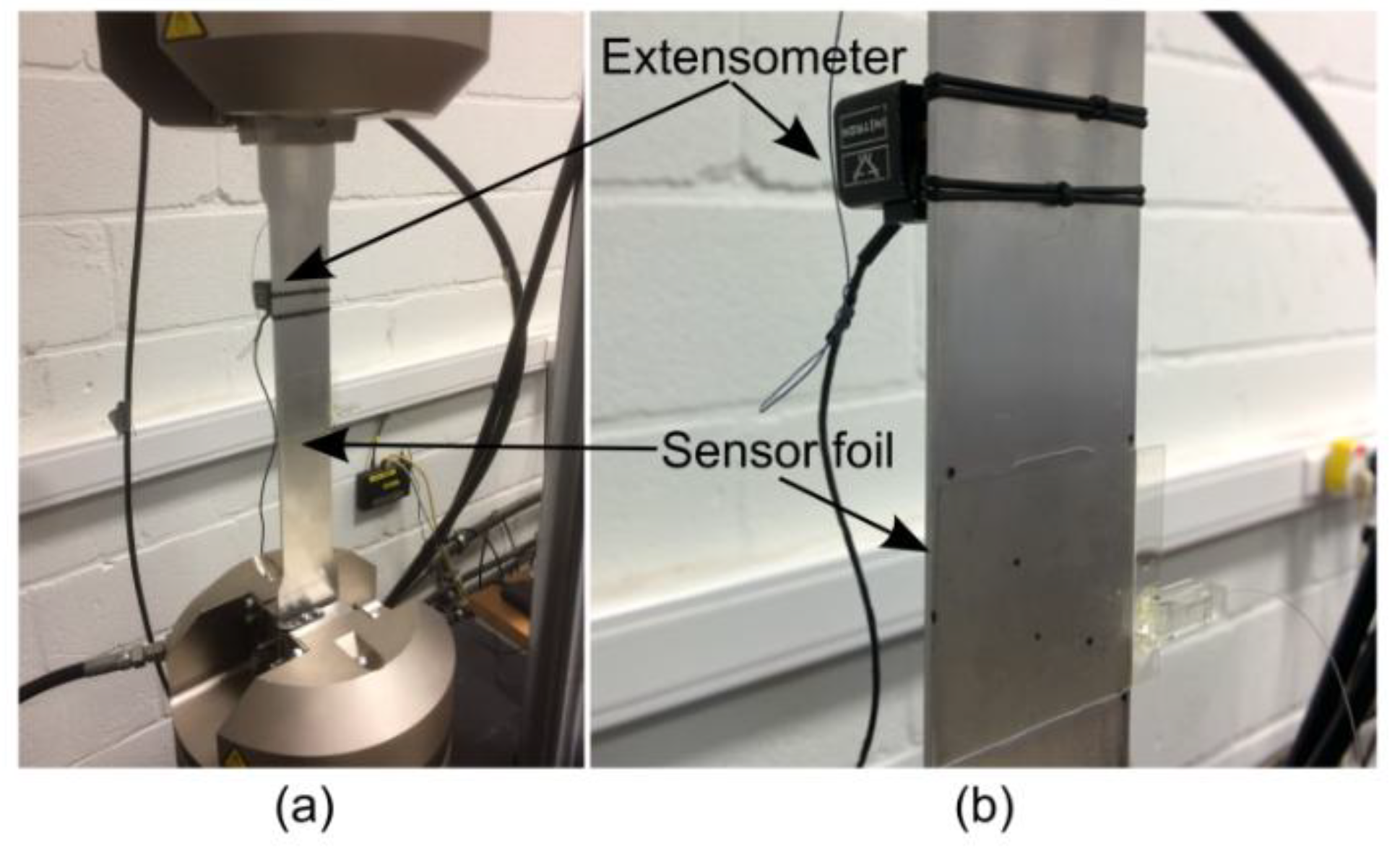

3.2.2. Methods for Characterizing Strain Sensitivity

3.2.3. Methods for Characterizing Temperature Sensitivity

4. Results and Discussion

4.1. Imprinted Waveguides

4.2. Imprinted Bragg Grating Sensors

4.3. Strain Sensitivity

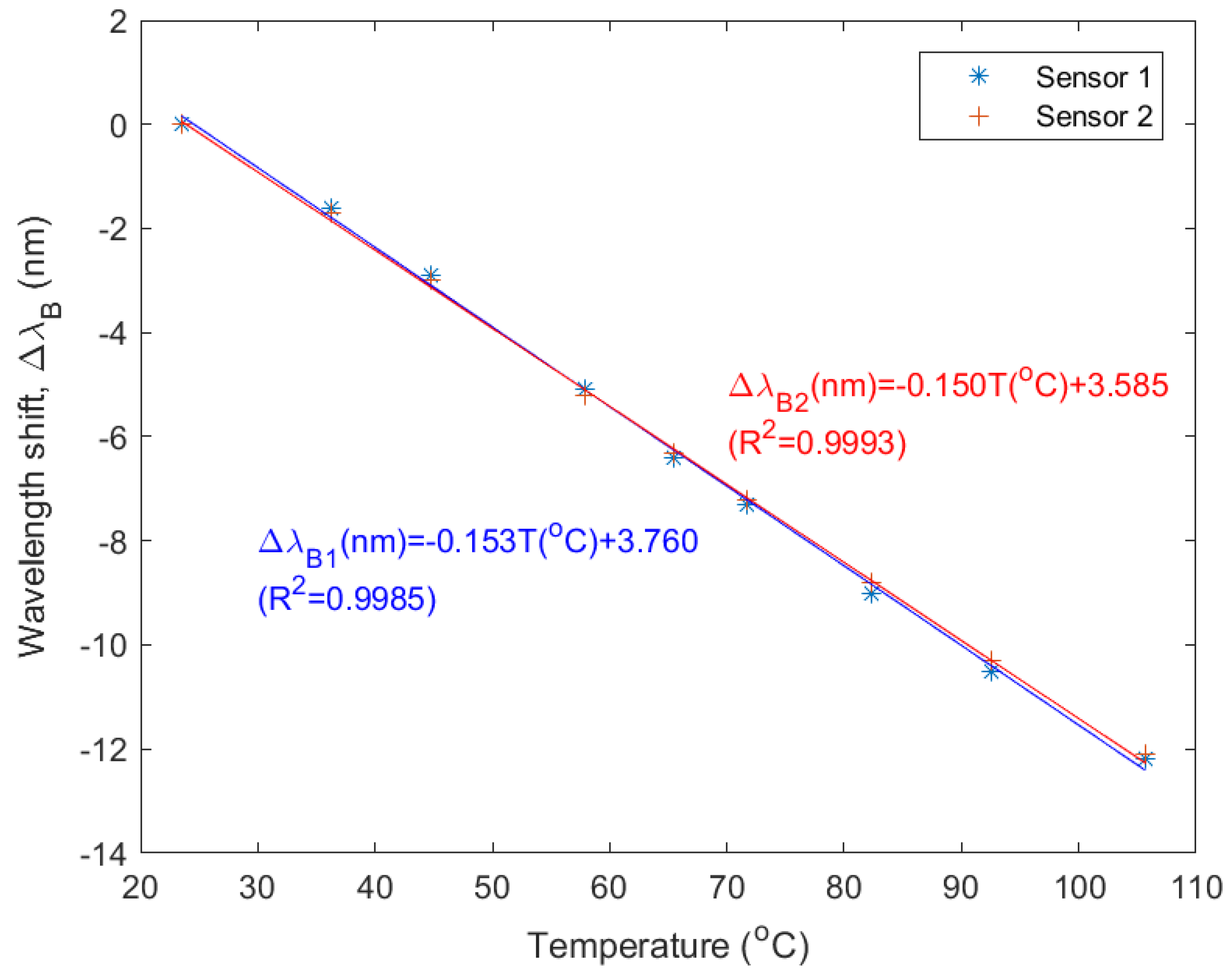

4.4. Temperature Sensitivity

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Davis, K.M.; Miura, K.; Sugimoto, N.; Hirao, K. Writing waveguides in glass with a femtosecond laser. Opt. Lett. 1996, 21, 1729–1731. [Google Scholar] [CrossRef] [PubMed]

- Dietrich, P.I.; Blaicher, M.; Reuter, I.; Billah, M.; Hoose, T.; Hofmann, A.; Caer, C.; Dangel, R.; Offrein, B.; Troppenz, U.; et al. In situ 3d nanoprinting of free-form coupling elements for hybrid photonic integration. Nat. Photonics 2018, 12, 241–247. [Google Scholar] [CrossRef]

- Saeidpourazar, R.; Li, R.; Li, Y.; Sangid, M.D.; Lu, C.; Huang, Y.; Rogers, J.A.; Ferreira, P.M. Laser-driven micro transfer placement of prefabricated microstructures. J. Microelectromech. Syst. 2012, 21, 1049–1058. [Google Scholar] [CrossRef]

- Kaur, K.S.; Missinne, J.; Steenberge, G.V. Flip-chip bonding of vertical-cavity surface-emitting lasers using laser-induced forward transfer. Appl. Phys. Lett. 2014, 104, 061102. [Google Scholar] [CrossRef]

- Elmogi, A.; Soenen, W.; Ramon, H.; Yin, X.; Missinne, J.; Spiga, S.; Amann, M.C.; Srinivasan, S.A.; Heyn, P.D.; Campenhout, J.V.; et al. Aerosol-jet printed interconnects for 2.5d electronic and photonic integration. J. Lightwave Technol. 2018, 36, 3528–3533. [Google Scholar] [CrossRef]

- Zhang, C.; Zou, C.-L.; Zhao, Y.; Dong, C.-H.; Wei, C.; Wang, H.; Liu, Y.; Guo, G.-C.; Yao, J.; Zhao, Y.S. Organic printed photonics: From microring lasers to integrated circuits. Sci. Adv. 2015, 1. [Google Scholar] [CrossRef] [PubMed]

- Stumpel, J.E.; Wouters, C.; Herzer, N.; Ziegler, J.; Broer, D.J.; Bastiaansen, C.W.M.; Schenning, A.P.H.J. An optical sensor for volatile amines based on an inkjet-printed, hydrogen-bonded, cholesteric liquid crystalline film. Adv. Opt. Mater. 2014, 2, 459–464. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Nanoimprint lithography. J. Vac. Sci. Technol., B 1996, 14, 4129–4133. [Google Scholar] [CrossRef]

- Ji, R.; Hornung, M.; Verschuuren, M.A.; van de Laar, R.; van Eekelen, J.; Plachetka, U.; Moeller, M.; Moormann, C. UV enhanced substrate conformal imprint lithography (uv-scil) technique for photonic crystals patterning in led manufacturing. Microelectron. Eng. 2010, 87, 963–967. [Google Scholar] [CrossRef]

- Hyun, A.S.; Jay, G.L. High-speed roll-to-roll nanoimprint lithography on flexible plastic substrates. Adv. Mater. 2008, 20, 2044–2049. [Google Scholar] [CrossRef]

- Kooy, N.; Mohamed, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale Res. Lett. 2014, 9, 320. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahn, S.H.; Guo, L.J. Large-area roll-to-roll and roll-to-plate nanoimprint lithography: A step toward high-throughput application of continuous nanoimprinting. ACS Nano 2009, 3, 2304–2310. [Google Scholar] [CrossRef] [PubMed]

- Verschuuren, M.A.; Gerlach, P.; Sprang, H.A.v.; Polman, A. Improved performance of polarization-stable vcsels by monolithic sub-wavelength gratings produced by soft nano-imprint lithography. Nanotechnology 2011, 22, 505201. [Google Scholar] [CrossRef] [PubMed]

- Morarescu, R.; Pal, P.K.; Beneitez, N.T.; Missinne, J.; Steenberge, G.V.; Bienstman, P.; Morthier, G. Fabrication and characterization of high-optical-quality-factor hybrid polymer microring resonators operating at very near infrared wavelengths. IEEE Photonics J. 2016, 8, 1–9. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, S.L.; Ling, T.; Guo, L.J. Review of imprinted polymer microrings as ultrasound detectors: Design, fabrication, and characterization. IEEE Sensors J. 2015, 15, 3241–3248. [Google Scholar] [CrossRef]

- Aikio, S.; Hiltunen, J.; Hiitola-Keinänen, J.; Hiltunen, M.; Kontturi, V.; Siitonen, S.; Puustinen, J.; Karioja, P. Disposable photonic integrated circuits for evanescent wave sensors by ultra-high volume roll-to-roll method. Opt. Express 2016, 24, 2527–2541. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.U.; Justice, J.; Petäjä, J.; Korhonen, T.; Boersma, A.; Wiegersma, S.; Karppinen, M.; Corbett, B. Multi-level single mode 2d polymer waveguide optical interconnects using nano-imprint lithography. Opt. Express 2015, 23, 14630–14639. [Google Scholar] [CrossRef] [PubMed]

- Hill, K.O.; Meltz, G. Fiber bragg grating technology fundamentals and overview. J. Lightwave Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Missinne, J.; Benéitez, N.; Lamberti, A.; Chiesura, G.; Luyckx, G.; Mattelin, M.A.; Paepegem, W.V.; Steenberge, G.V. Thin and flexible polymer photonic sensor foils for monitoring composite structures. Adv. Eng. Mater. 2018, 1701127. [Google Scholar] [CrossRef]

- Van Hoe, B.; Lee, G.; Bosman, E.; Missinne, J.; Kalathimekkad, S.; Maskery, O.; Webb, D.J.; Sugden, K.; Van Daele, P.; Van Steenberge, G. Ultra small integrated optical fiber sensing system. Sensors 2012, 12. [Google Scholar] [CrossRef] [Green Version]

- Gabrielli, L.H.; Liu, D.; Johnson, S.G.; Lipson, M. On-chip transformation optics for multimode waveguide bends. Nat. Commun. 2012, 3, 1217. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yariv, A. Coupled-mode theory for guided-wave optics. IEEE J. Quantum Electron. 1973, 9, 919–933. [Google Scholar] [CrossRef] [Green Version]

- FBGS-International. Available online: https://www.fbgs.com/index/be-en/30/ (accessed on 7 August 2018).

- Benéitez, N.T.; Missinne, J.; Shi, Y.; Chiesura, G.; Luyckx, G.; Degrieck, J.; Steenberge, G.V. Highly sensitive waveguide bragg grating temperature sensor using hybrid polymers. IEEE Photonics Technol. Lett. 2016, 28, 1150–1153. [Google Scholar] [CrossRef]

| Grating Pitch (nm) | Bragg Wavelength (nm) | 3dB Bandwidth (nm) | |

|---|---|---|---|

| Sensor 3 | 280 | 859.6 | 0.220 |

| Sensor 2 | 285 | 874.95 | 0.231 |

| Sensor 1 | 290 | 890.3 | 0.242 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Missinne, J.; Teigell Benéitez, N.; Mattelin, M.-A.; Lamberti, A.; Luyckx, G.; Van Paepegem, W.; Van Steenberge, G. Bragg-Grating-Based Photonic Strain and Temperature Sensor Foils Realized Using Imprinting and Operating at Very Near Infrared Wavelengths. Sensors 2018, 18, 2717. https://doi.org/10.3390/s18082717

Missinne J, Teigell Benéitez N, Mattelin M-A, Lamberti A, Luyckx G, Van Paepegem W, Van Steenberge G. Bragg-Grating-Based Photonic Strain and Temperature Sensor Foils Realized Using Imprinting and Operating at Very Near Infrared Wavelengths. Sensors. 2018; 18(8):2717. https://doi.org/10.3390/s18082717

Chicago/Turabian StyleMissinne, Jeroen, Nuria Teigell Benéitez, Marie-Aline Mattelin, Alfredo Lamberti, Geert Luyckx, Wim Van Paepegem, and Geert Van Steenberge. 2018. "Bragg-Grating-Based Photonic Strain and Temperature Sensor Foils Realized Using Imprinting and Operating at Very Near Infrared Wavelengths" Sensors 18, no. 8: 2717. https://doi.org/10.3390/s18082717

APA StyleMissinne, J., Teigell Benéitez, N., Mattelin, M.-A., Lamberti, A., Luyckx, G., Van Paepegem, W., & Van Steenberge, G. (2018). Bragg-Grating-Based Photonic Strain and Temperature Sensor Foils Realized Using Imprinting and Operating at Very Near Infrared Wavelengths. Sensors, 18(8), 2717. https://doi.org/10.3390/s18082717