Fiber Bragg Gratings Sensors for Aircraft Wing Shape Measurement: Recent Applications and Technical Analysis

Abstract

1. Introduction

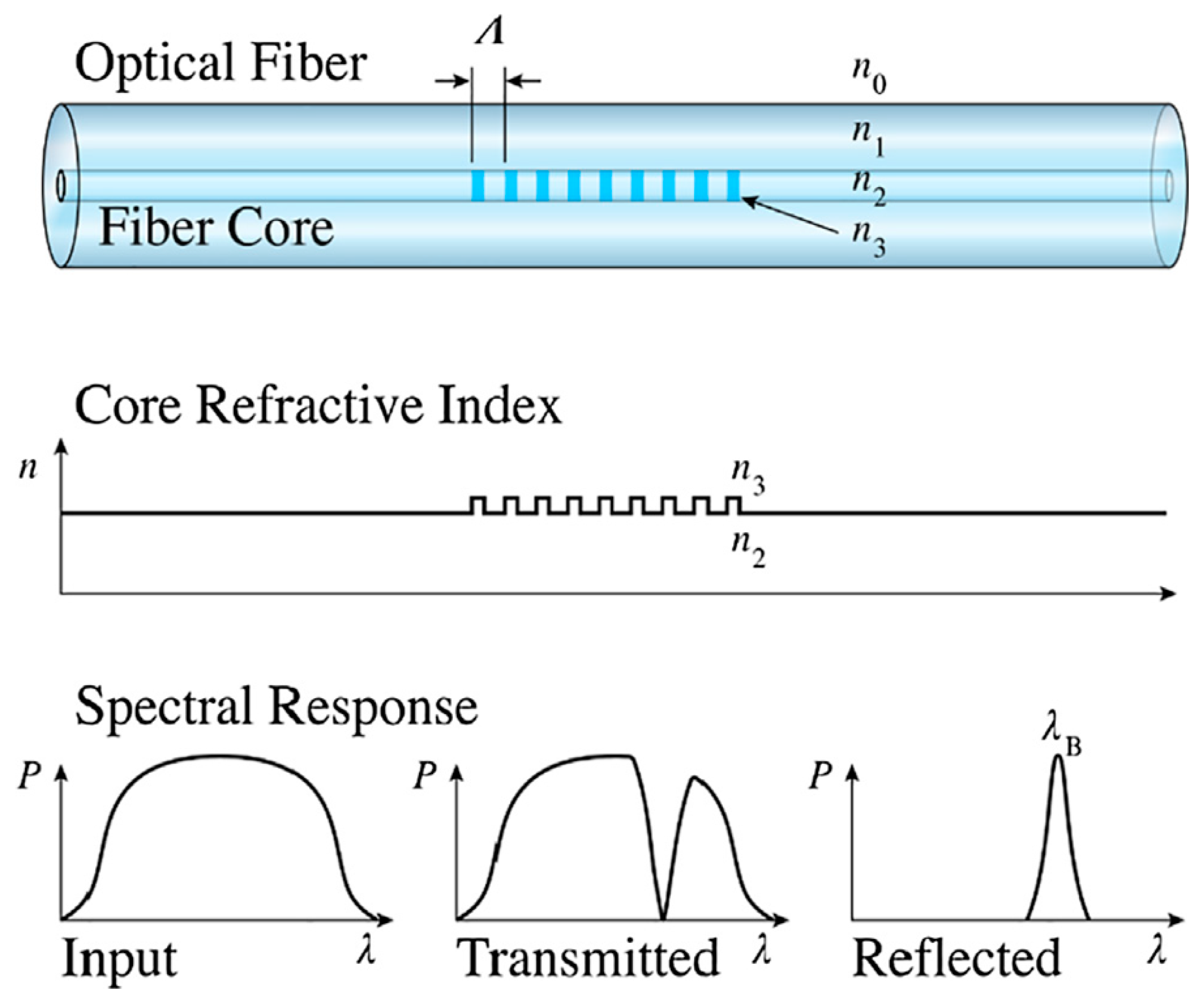

2. Working Principle and Technical Characteristics

2.1. Structure Principle of Fiber Optic

2.2. Working Principle of FBG Sensor

2.3. FBG Multiplexing Technology

2.3.1. Wavelength Division Multiplexing Technology

2.3.2. Spatial Division Multiplexing Technology

3. Influence Factors of FBGs Strain Transfer Efficiency

3.1. FBGs Strain Transfer Coefficient

3.2. Influencing Factors of Strain Transfer Rate

4. Comparative Analysis of Other Measurement Methods

4.1. Measuring Deformation with Strain Gages

4.2. Measuring Deformation with Laser

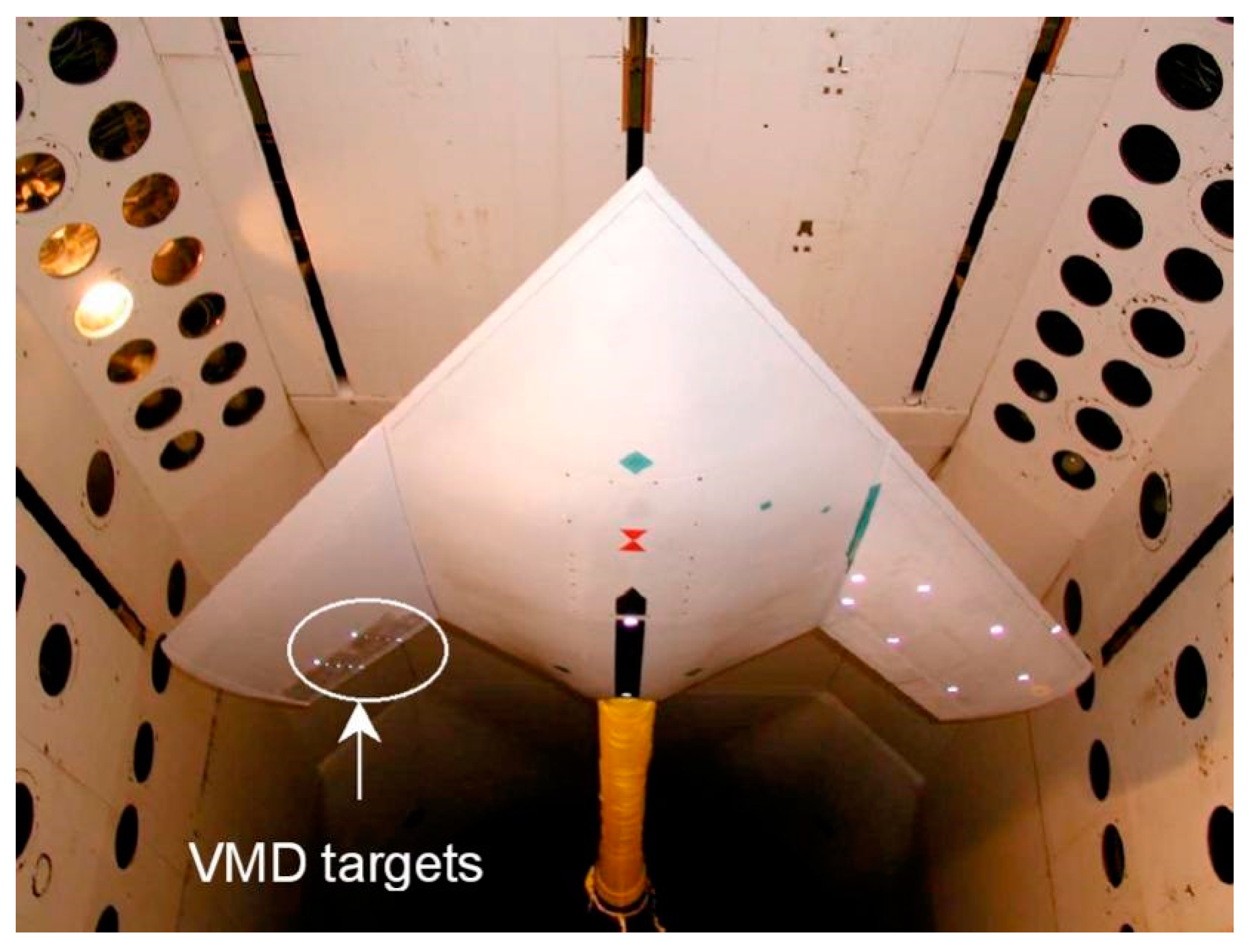

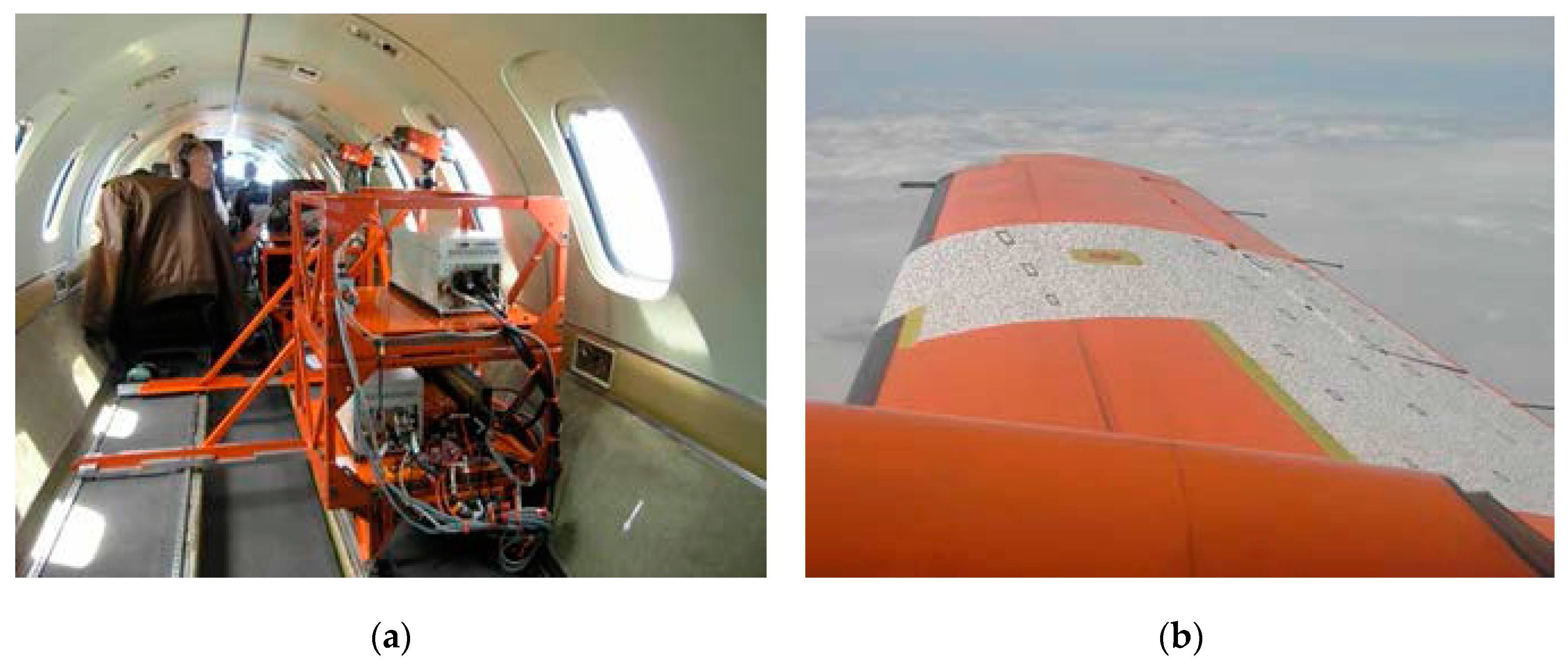

4.3. Visual Deformation Measurement

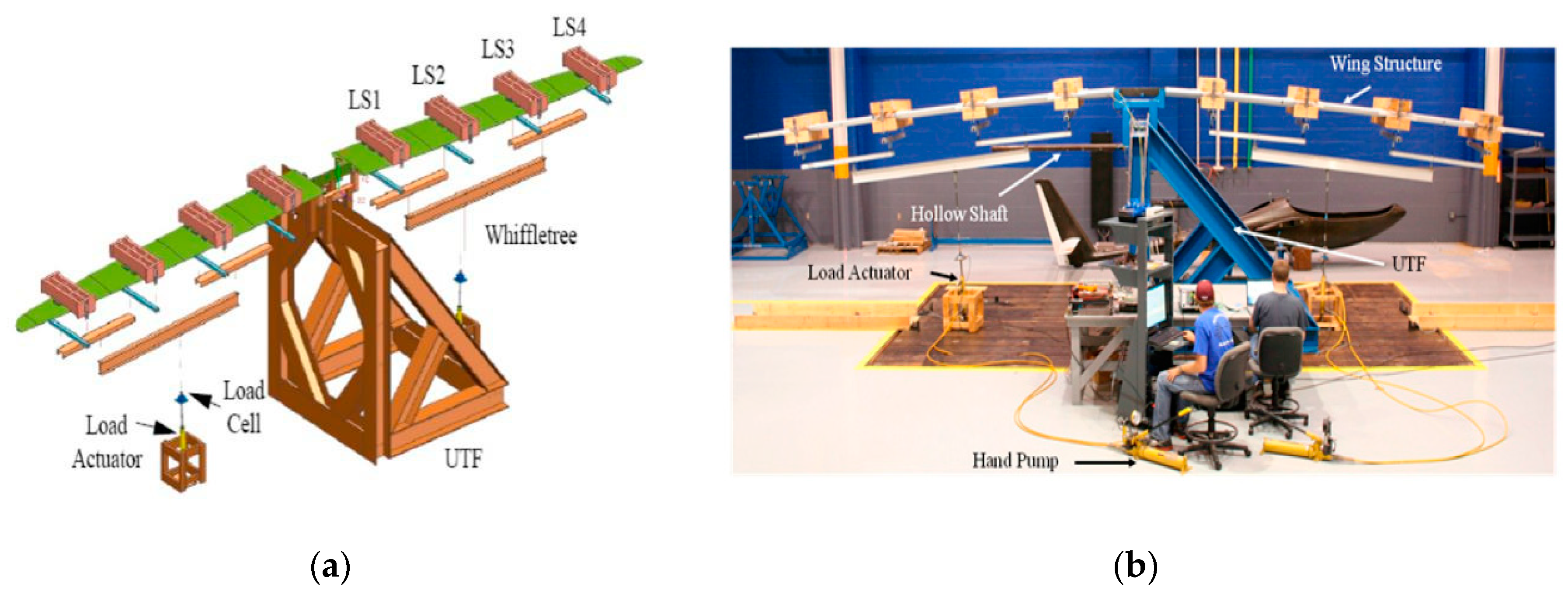

5. Research Status of Aircraft Wing Shape Technology by FBGs

6. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Ko, W.; Richards, W.; Tran, V. Displacement Theories for In-flight Deformed Shape Predictions of Aerospace Structures; Report 214612; NASA Dryden Flight Research Center: Hampton, VA, USA, 2007.

- Ko, W.; Richards, W.U.S. Patent Application for Method for Real-Time Structure Shape-Sensing. U.S. Patent No. 7520176, 21 April 2009. [Google Scholar]

- Pena, F.; Richards, L.; Parker, A.R., Jr.; Piazza, A.; Chan, P.; Hamory, P. Fiber Optic Sensing System (FOSS) Technology-A New Sensor Paradigm for Comprehensive Structural Monitoring and Model Validation throughout the Vehicle Life-Cycle. 2015. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20180007391.pdf (accessed on 27 October 2018).

- Military Airspace. Available online: https://www.militaryaerospace.com/articles/2015/04/ av8b-airplane-blog.html (accessed on 27 October 2018).

- Kinet, D.; Guerra, B.; Garray, D.; Caucheteur, C.; Mgret, P. Weakly intrusive optical fibre connector for composite materials applications: Vibration and temperature validation tests. In Proceedings of the 5th European Workshop on Optical Fibre Sensors, Krakow, Poland, 19–22 May 2013. [Google Scholar]

- Goshal, A.; Ayers, J.; Gurvich, M.; Urban, M.; Bordick, N. Experimental investigations in embedded sensing of composite components in aerospace vehicles. Compos. Part B 2015, 71, 52–62. [Google Scholar] [CrossRef]

- Childers, B.A.; Froggatt, M.E.; Allison, S.G.; Moore, T.C.S.; Hare, D.A.; Batten, C.F.; Jegley, D.C. Use of 3000 Bragg grating strain sensors distributed on four eight-meter optical fibers during static load tests of a composite structure. In Proceedings of the Smart Structures and Materials 2001: Industrial and Commercial Applications of Smart Structures Technologies, Newport Beach, CA, USA, 4–8 March 2001; pp. 133–142. [Google Scholar]

- Kahandawa, G.C.; Epaarachchi, J.; Wang, H.; Lau, K.T. Use of FBG sensors for SHM in aerospace structures. Photonic Sens. 2012, 2, 203–214. [Google Scholar] [CrossRef]

- Guo, H.; Xiao, G.; Mrad, N.; Yao, J. Fiber optic sensors for structural health monitoring of air platforms. Sensors 2011, 11, 3687–3705. [Google Scholar] [CrossRef] [PubMed]

- Hong, C.Y.; Zhang, Y.F.; Zhang, M.X.; Leung, L.M.; Liu, L.Q. Application of FBG sensors for geotechnical monitoring, a review of sensor design, implementation methods and packaging techniques. Sens. Actuators A Phys. 2016, 244, 184–197. [Google Scholar] [CrossRef]

- Di Sante, R. Fiber optic sensors for structural health monitoring of aircraft composite structures: Recent advances and applications. Sensors 2015, 15, 18666–18713. [Google Scholar] [CrossRef] [PubMed]

- Vorathin, E.; Hafizi, Z.M.; Ghani, S.C.; Lim, K.S. Real-time monitoring system of composite aircraft wings utilizing Fibre Bragg Grating Sensor. Innov. Aerosp. Eng. Technol. 2016, 152, 012024. [Google Scholar] [CrossRef]

- Amanzadeh, M.; Aminossadati, S.M.; Kizil, M.S.; Raki’c, A.D. Recent Developments in Fiber Optic Shape Sensing. Measurement 2018, 128, 119–137. [Google Scholar] [CrossRef]

- Hill, K.O.; Fujii, Y.; Johnson, D.C.; Kawasaki, B.S. Photo sensitivity in optical fiber waveguides: Application to reflection filter fabrication. Appl. Phys. Lett. 1978, 32, 647. [Google Scholar] [CrossRef]

- Dunphy, J.R.; Meltz, G. Optical Fiber Sensors for Composite Structures. Opt. Fiber Sens. 1988. [CrossRef]

- Malo, B.; Hill, K.O.; Bilodeau, F. Point-by-point fabrication of micro-Bragg gratings in photosensitive fibre using single excimer pulse refractive index modification techniques. Electron. Lett. 1993, 29, 1668–1669. [Google Scholar] [CrossRef]

- Lally, E.M.; Reaves, M.; Horrell, E. Fiber optic shape sensing for monitoring of flexible structures. Proc. SPIE 2012, 8345, 80. [Google Scholar]

- Rao, Y.J. Review Article: In-fibre Bragg grating sensors. Meas. Sci. Technol. 1997, 8, 355–375. [Google Scholar] [CrossRef]

- Chen, J.; Liu, B.; Zhang, H. Review of fiber Bragg grating sensor technology. Front. Optoelectron. 2011, 4, 204–212. [Google Scholar] [CrossRef]

- Chuang, S.L. Physics of Photonic Devices; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

- Masoudi, A.; Newson, T.P. Contributed review: Distributed optical fibre dynamic strain sensing. Rev. Sci. Instrum. 2016, 87, 011501. [Google Scholar] [CrossRef] [PubMed]

- Hill, K.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Lightw. Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Xiong, W.; Cai, C.S.; Kong, X. Instrumentation design for bridge scour monitoring using fiber Bragg grating sensors. Appl. Opt. 2012, 51, 547–557. [Google Scholar] [CrossRef]

- Davis, M.A.; Kersey, A.D.; Sirkis, J.; Friebele, E.J. Shape and vibration mode sensing using a fiber optic Bragg grating array. Smart Mater. Struct. 1996, 5, 759–765. [Google Scholar] [CrossRef]

- Richardson, D.J.; Fini, J.M.; Nelson, L.E. Space Division Multiplexing in Optical Fibres. Nat. Photonics 2013, 7, 354–362. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Williams, J.A.R.; Bennion, I. Enhanced FBG strain sensing multiplexing capacity using combination of intensity and wavelength dual-coding technique. IEEE Photonics Technol. Lett. 1999, 11, 1638–1640. [Google Scholar] [CrossRef]

- Peng, P.C.; Lin, J.H.; Tseng, H.Y.; Chi, S. Intensity and wavelength-division multiplexing FBG sensor system using a tunable multiport fiber ring laser. IEEE Photonics Technol. Lett. 2004, 16, 230–232. [Google Scholar] [CrossRef]

- Yeh, C.H.; Zhuang, Y.H.; Tsai, N.; Chow, C.W. Capacity and capability enhancements of FBG sensor system by utilizing intensity and WDM detection technique. Smart Mater. Struct. 2017, 26, 035026. [Google Scholar] [CrossRef]

- Rao, Y.J.; Kalli, K.; Brady, G.; Webb, D.J.; Jackson, D.A.; Zhang, L.; Bennion, I. Spatially-multiplexed fiber-optic Bragg grating strain and temperature sensor system based on interferometric wavelength-shift detection. Electron. Lett. 1995, 31, 1009. [Google Scholar] [CrossRef]

- Yu, Y.L.; Tan, H.Y. Active spatial/wavelength-division multiplexed fiber Bragg grating. Chin. J. Lasers 2002, 29, 131–134. [Google Scholar]

- Hartog, L.; Lin, Y.C. Research on the spatial division multiplexing technique of fber Bragg grating sensors. Opt. Precis. Genineering 2007, 15, 473–477. [Google Scholar]

- Richardson, D.J.; Fini, J.M.; Nelson, L.E. Space-division multiplexing in optical fibres. Nat. Photonics 2013, 7, 354–362. [Google Scholar] [CrossRef]

- Yaman, F.; Bai, N.; Zhu, B.; Wang, T.; Li, G. Long distance transmission in few-mode fibers. Opt. Express 2010, 18, 13250–13257. [Google Scholar] [CrossRef]

- Uden, R.G.H.; Correa, R.A.; Lopez, E.A.; Huijskens, F.M.; Xia, C.; Li, G.; Schülzgen, A.; Waardt, H.D.; Koonen, A.M.J.; Okonkwo, C.M. Ultra-high-density spatial division multiplexing with a few-mode multicore fibre. Nat. Photonics 2014, 8, 865–870. [Google Scholar] [CrossRef]

- Abdelwahab, M.M.; Ashcroft, I.A.; Crocombe, A.D.; Shaw, S.J. Prediction of fatigue thresholds in adhesively bonded joints using damage mechanics and fracture mechanics. J. Adhes. Sci. Technol. 2001, 15, 763–781. [Google Scholar]

- Ansari, F.; Libo, Y. Mechanics of bond and interface shear transfer in optical fiber sensors. J. Eng. Mech. 1998, 124, 385–394. [Google Scholar] [CrossRef]

- Lau, K.T.; Yuan, L.M.; Zhou, L.; Wu, J.; Woo, C.H. Strain monitoring in FRP laminates and concrete beams using FBG sensors. Compos. Struct. 2001, 51, 9–20. [Google Scholar] [CrossRef]

- Zhou, G.; Li, H.; Ren, L.; Li, D. Influencing parameters analysis of strain transfer in optic fiber bragg grating sensors. SPIE Proc. 2006, 6179, 61790R1–61790R9. [Google Scholar]

- Ren, L.; Song, G. Strain transferring analysis of fiber Bragg grating sensors. Opt. Eng. 2006, 45, 409–411. [Google Scholar]

- Xiong, L.; Jiang, G.; Guo, Y.; Liu, H. A three-dimensional fiber Bragg grating force sensor for robot. IEEE Sens. J. 2018, 18, 3632–3639. [Google Scholar] [CrossRef]

- Li, D.S.; Li, H.N. Strain transferring of embedded fiber Bragg grating sensors. Acta Mech. Sin. 2005, 5765, 1085–1094. [Google Scholar]

- Shiuh-Chuan, H.; Huang, C.Y. Effect of Coating on the Strain Transfer of Optical Fiber Sensors. Sensors 2011, 11, 6926–6941. [Google Scholar]

- Wan, K.T.; Leung, C.K.Y.; Olson, N.G. Investigation of the strain transfer for surface-attached optical fiber strain sensors. Smart Mater. Struct. 2008, 17. [Google Scholar] [CrossRef]

- Her, S.C.; Tsai, C.Y. Strain measurement of fiber optic sensor surface bonding on host material. Trans. Nonferr. Met. Soc. China 2009, 19, s143–s149. [Google Scholar] [CrossRef]

- Garrick, I.E.; Iii, W.H.R. Historical Development of Aircraft Flutter. J. Aircr. 1981, 18, 897–912. [Google Scholar] [CrossRef]

- Little, E.G. Strain Gauge Measurement; Chapman & Hall: London, UK, 1992. [Google Scholar]

- Shen, G.L. New developments of strain gauge measurement and transducer technique and applications in all kinds of engineers and domains. China Meas. Test 2011, 2, 025. [Google Scholar]

- Ajovalasit, A. Advances in Strain Gauge Measurement on Composite Materials. Strain 2011, 47, 313–325. [Google Scholar] [CrossRef]

- Pallek, D.; Butefisch, K.A.; Quest, J.; Strudthoff, W. Model deformation measurement in ETW using the Moire technique. In Proceedings of the International Congress on Instrumentation in Aerospace Simulation Facilities, Gottingen, Germany, 25–29 August 2003; pp. 110–114. [Google Scholar]

- Bakunowicz, J.; Meyer, R. In-flight wing deformation measurements on a glider. Aeronaut. J. 2016, 120, 1917–1931. [Google Scholar] [CrossRef]

- Boden, F.; Jentink, H.; Petit, C. IPCT Wing Deformation Measurements on a Large Transport Aircraft. In Advanced In-Flight Measurement Techniques; Springer: Berlin/Heidelberg, Germany, 2013; pp. 93–115. [Google Scholar]

- Klinge, F. Cross Correlation Based Optical Measurement Techniques for Fluid Dynamics and Structure Analysis BOS, IPCT; Tampere University of Technology: Tampere, Finland, 2004. [Google Scholar]

- Kompenhans, J.; Schroder, A.; Engler, R.; Klinge, F.; Stasicki, B. Development and application of image based measurements techniques for aerodynamic investigation in wind tunnels. In Proceedings of the International Conference High Speed Flow: Fundamental Problems, Zhukovsky, Russia, 2–24 September 2004. [Google Scholar]

- AIAA. Contributions of the NASA Langley Research Center to the DARPA/AFRL/NASA/Northrop Grumman Smart Wing Program; American Inst Aeronautics & Astronautics Inc.: Reston, VA, USA, 2003; pp. 3–14. [Google Scholar]

- Langley Research Center Advertisement. Available online: https://slideplayer.com/slide/7353157/ (accessed on 27 October 2018).

- Burner, A.W.; Wahls, R.A.; Goad, W.K. Wing Twist Measurements at the National Transonic Facility. Available online: https://ntrs.nasa.gov/search.jsp?R=19960016773 (accessed on 23 December 2018).

- Hooker, J.R.; Burner, A.W.; Valla, R. Static Aeroelastic Analysis of Transonic Wind Tunnel Models using Finite Element Methods. In Proceedings of the 15th Applied Aerodynamics Conference, Atlanta, GA, USA, 23–25 June 1997. [Google Scholar]

- Burner, A.W. Model deformation measurements at NASA Langley Research Center, AGARD Conference Proceedings CP-601: Advanced Aerodynamic Measurement Technology. In Proceedings of the 81st Meeting and Symposium of the Fluid Dynamics Panel, Seattle, WA, USA, 22–25 September 1997; pp. 34-1–34-9. [Google Scholar]

- Burner, A.W.; Liu, T. Videogrammetric Model Deformation Measurement Technique. J. Aircr. 2001, 38, 745–754. [Google Scholar] [CrossRef]

- Buener, A.W.; Fleming, G.A.; Hoppe, J.C. Comparison of Three Optical Methods for Measuring Model Deformation. NASA Langley Technical Report Server, American Institute of Aeronautics and Astronautics: Hampton, VA, USA, 2000.

- Fleming, G.A.; Gorton, S.A. Measurement of rotorcraft blade deformation using Projection Moiré Interferometry. J. Shock Vib. 2000, 7, 149–165. [Google Scholar] [CrossRef]

- Wilbur, M.L.; Mirick, P.H.; Yeager, W.T.; Langston, C.W.; Cesnik, C.E.; Shin, S. Vibratory loads reduction testing of the NASA/ARMY/MIT Active Twist Rotor. Presented at the American Helicopter Society 57th Annual Forum, Washington, DC, USA, 9–11 May 2001. [Google Scholar]

- Fleming, G.A.; Soto, H.L.; South, B.W.; Bartram, S.M. Advances in Projection Moiré Interferometry Development for Large Wind Tunnel Applications, SAE Paper No. 1999-01-5598. Presented at the SAE World Aviation Congress, San Francisco, CA, USA, 19–21 October 1999. [Google Scholar]

- Fleming, G.A.; Bartram, S.M.; Waszak, M.R.; Jenkins, L.N. Projection Moiré Interferometry Measurements of Micro Air Vehicle Wings. Proc. SPIE Int. Soc. Opt. Eng. 2001, 4448, 90–101. [Google Scholar]

- AIM² Newsletter No. 3 available NOW. Available online: http://aim2.dlr.de/project/index.html (accessed on 27 October 2018).

- Chen, T.; Du, X.; Jia, M.; Song, G. Application of Optical Inspection and Metrology in Quality Control for Aircraft Components. Inst. Electr. Electron. Eng. 2010, 5, 294–298. [Google Scholar]

- Chung, S.; Ley, O.; Godinez, V.; Bandos, B. Line Scanning Thermography for Rapid Nondestructive Inspection of Large Scale Composites. Rev. Prog. Quant. Nondestruct. Eval. 2011, 30, 1029–1036. [Google Scholar]

- Erchart, D.; Ostrom, L.T.; Wilhelmsen, C.A. Visual Detectibility of dents on a Composite Aircraft Inspection Specimen: An Initial Study. Int. J. Appl. Aviat. Stud. 2004, 4, 111–122. [Google Scholar]

- Habermehl, J.; Lamarre, A.; Roach, D. Ultrasonic Phased Array Tools for Large Area composite Inspection During Maintenance and Manufacturing. Rev. Quant. Nondestruct. Eval. 2009, 28, 832–839. [Google Scholar]

- Kersten, T.P.; Mechelke, K.; Lindstaedt, M.; Sternberg, H. Methods for Geometric Accuracy Investigations of Terrestrial Laser Scanning Systems. Photogramm. Fernerkundung Geoinf. 2009, 301–314. [Google Scholar] [CrossRef]

- Ostrom, L.T.; Wilhemsen, C.A.; Scott, R.L. Use of Three Dimensional Imaging to Perform Aircraft Composite Inspection: Proof of the concept. IEEE Comput. Soc. 2012, 18, 53–58. [Google Scholar]

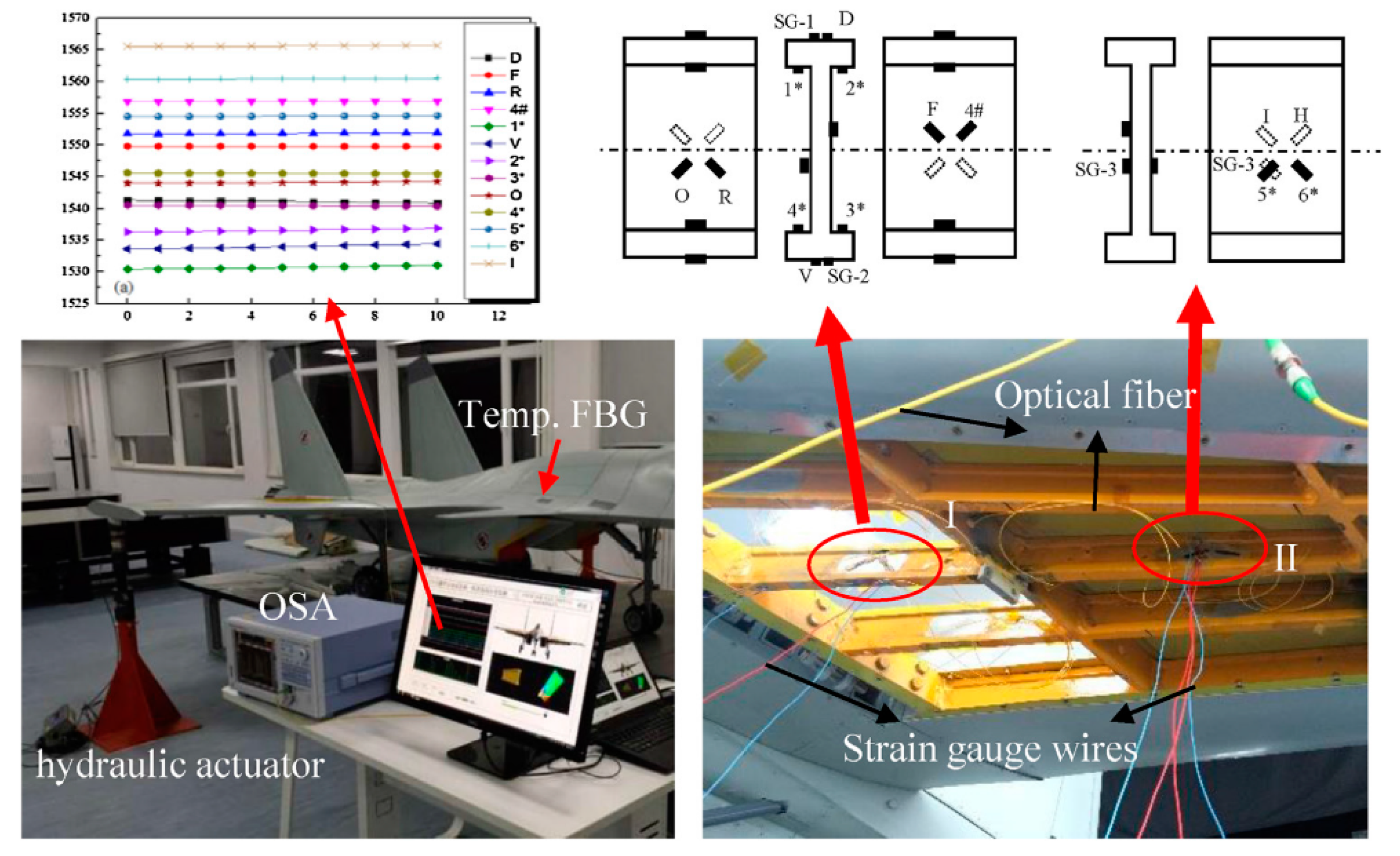

- Ryu, C.Y.; Lee, J.R.; Kim, C.G.; Hong, C.S. Buckling behaviour monitoring of a composite wing box using multiplexed and multi-channeled built-in fiber Bragg grating strain sensors. NDT&E Int. 2008, 41, 534–543. [Google Scholar]

- Kosters, E.; van Els, T.J. Structural health monitoring and impact detection for primary aircraft structures. In Proceedings of the SPIE-The International Society for Optical Engineering, Fiber Optic Sensors and Applications VII, Orlando, FL, USA, 5 April 2010; Volume 7677. [Google Scholar]

- Mieloszyk, M.; Skarbek, L.; Krawczuk, M.; Ostachowicz, W.; Zak, A. Application of fibre Bragg grating sensors for structural health monitoring of an adaptive wing. Smart Mater. Struct. 2011, 20, 125014. [Google Scholar] [CrossRef]

- Gherlone, M.; Cerracchio, P.; Mattone, M.; di Sciuva, M.D.; Tessler, A. Shape sensing of 3D frame structures using an inverse finite element method. Int. J. Solids Struct. 2012, 49, 3100–3112. [Google Scholar] [CrossRef]

- Minakuchi, S.; Umehara, T.; Takagaki, K.; Ito, Y.; Takeda, N. Life cycle monitoring and advanced quality assurance of L-shaped composite corner part using embedded fiber-optic sensor. Compos. Part A 2013, 48, 153–161. [Google Scholar] [CrossRef]

- Lee, J.R.; Ryu, C.Y.; Koo, B.Y.; Kang, S.G.; Hong, C.S. In-flight health monitoring of a subscale wing using a fiber Bragg grating sensor system. Smart Mater. Struct. 2003, 12, 147. [Google Scholar] [CrossRef]

- Duncan, P.G.; Jones, M.E.; Shinpaugh, K.A.; Poland, S.H.; Murphy, K.A.; Claus, R.O. Optical fiber pressure sensors for adaptive wings. Proc. SPIE 1997, 3042, 320–332. [Google Scholar]

- NASA. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20050185211.pdf (accessed on 27 October 2018).

- Ko, W.L.; Richards, W.L.; Fleischer, V.T. Applications of the Ko displacement theory to the deformed shape predictions of the doubly-tapered Ikhana wing. In NASA/TP-2009-214652; NASN Dryden Flight Research Center: Edwards, CA, USA, 2009. [Google Scholar]

- Jutte, C.V.; Ko, W.L.; Stephens, C.A.; Bakalyar, J.A.; Richards, W.L. Deformed Shape Calculation of a Full-ScaleWing Using Fiber Optic Strain Data from a Ground Loads Test. In NASA Langley Research Center, Rept, TP-215975; NASA Research Center: Hampton, VA, USA, 2011. [Google Scholar]

- Derkevorkian, A.; Masri, S.F.; Alvarenga, J.; Boussalis, H.; Bakalyar, J.; Richards, W.L. Strain-based deformation estimating algorithm for control and monitoring applications. AIAA J. 2013, 51, 2231–2240. [Google Scholar] [CrossRef]

- Quach, C.; Vazquez, S.; Tessler, A.; Moore, J.; Cooper, E.; Spangler, J. Structural anomaly detection using fiber optic sensors and inverse finite element method. In Proceedings of the AIAA Guidance, Navigation, and Control Conference and Exhibit, San Francisco, CA, USA, 15–18 August 2005. [Google Scholar]

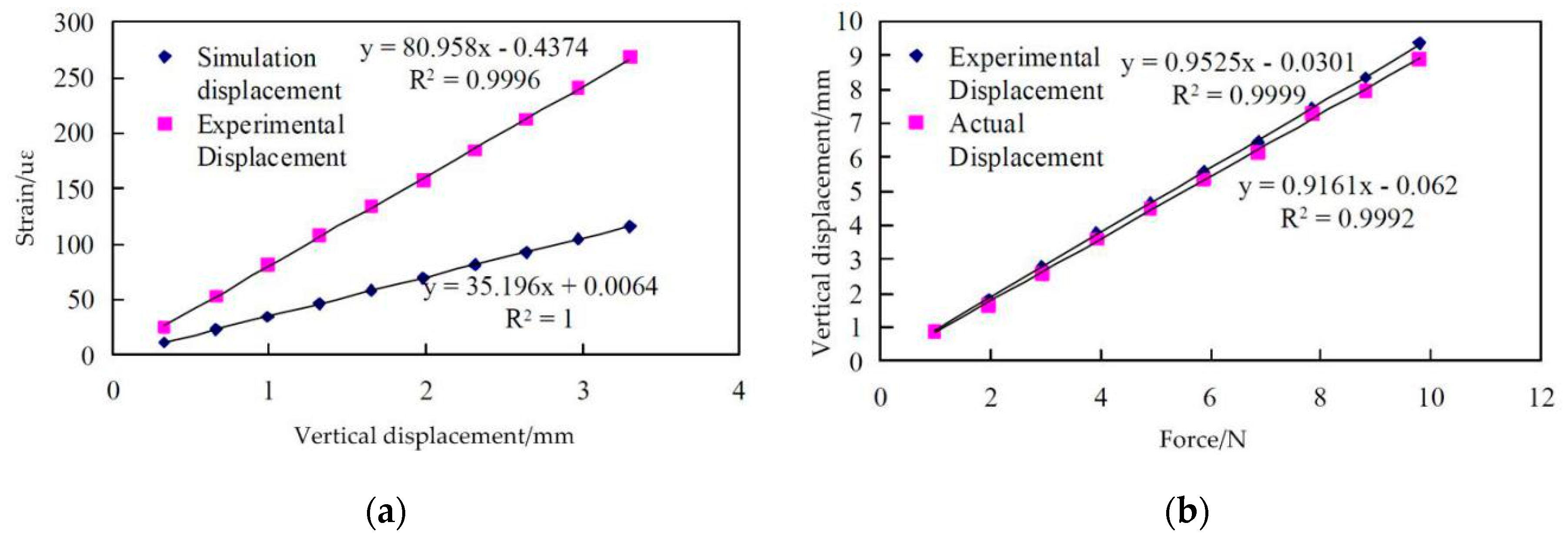

- Song, X.; Liang, D. Dynamic displacement prediction of beam structures using fiber bragg grating sensors. Optik 2018, 158, 1410–1416. [Google Scholar] [CrossRef]

- Cusano, A.; Capoluongo, P.; Campopiano, S.; Cutolo, A.; Giordano, M. Experimental modal analysis of an aircraft model wing by embedded fiber Bragg grating sensors. IEEE Sens. J. 2006, 6, 67–77. [Google Scholar] [CrossRef]

- Murayama, H.; Hirano, Y.; Igawa, H.; Kageyama, K.; Nakamura, T. Distributed strain and load monitoring of 6 m composite wing structure by FBG arrays and long-length FBGs, International Conference on Optical Fiber Sensors. Int. Soc. Opt. Photonics 2012, 8421, 84212D–84212D-4. [Google Scholar]

- Yi., J.; Zhang, H.; Qiao, X.; Zhu, X. Shape monitoring for wing structure using fiber Bragg grating sensors. In Proceedings of the IEEE Fifth International Conference on Advanced Computational Intelligence, Nanjing, China, 18–20 October 2012; pp. 1032–1036. [Google Scholar]

- Diamanti, K.; Soutis, C. Structural health monitoring techniques for aircraft composite structures. Prog. Aerosp. Sci. 2010, 46, 342–352. [Google Scholar] [CrossRef]

- Zhu, M. Comparison of Shape Reconstruction Strategies in a Complex Flexible Structure. Master’s Thesis, University of California, San Diego, CA, USA, 2008. [Google Scholar]

- Matthew, J.N.; Rani, W.S.; Richards, W.L. Large Scale Applications Using FBG Sensors: Determination of In-Flight Loads and Shape of a Composite AircraftWing. Aerospace 2016, 3, 8. [Google Scholar]

- Nicolas, M.J.; Sullivan, R.W.; Richards, W.L. Fiber Bragg grating strains to obtain structural response of a carbon composite wing. In Proceedings of the ASME 2013 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, Snowbird, UT, USA, 16–18 September 2013. [Google Scholar]

- Sullivan, R.; Hwang, Y.; Rais-Rohani, M.; Lacy, T. Structural Analysis and Testing of an Ultralight Unmanned-Aerial-Vehicle Carbon-Composite Wing. J. Aircr. 2009, 46, 814–820. [Google Scholar] [CrossRef]

- Richards, W.L.; Parker, A.R., Jr.; Ko, W.L.; Piazza, A.; Chan, P. RTO AGARDograph 160: Application of Fiber Optic Instrumentation; NASA Center for AeroSpace Information: Hanover, MD, USA, 2012; Volume 22.

- Bakalyar, J.A.; Jutte, C. Validation tests of fiber optic strain-based operational shape and load measurements. In Proceedings of the AIAA (SDM) Structures, Structural Dynamics and Materials Conference, Honolulu, HI, USA, 23–26 April 2012. [Google Scholar]

- Cui, P.; Zhang, W.; Wang, Z.; Song, Y.; Li, F. Measurement of aircraft wing deformation using fiber Bragg gratings. In Proceedings of the International Conference on Optical Communications and Networks, Wuzhen, China, 7–10 August 2017; pp. 1–3. [Google Scholar]

- Li, H.; Zhu, L.Q.; Sun, G. Deflection Monitoring of Thin-walled wing Spar Subjected to Bending Load Using Multi-element FBG Sensors. Optik 2018, 164, 691–700. [Google Scholar] [CrossRef]

| Influencing factors | Relation |

|---|---|

| Adhesive layer | Inverse ratio |

| Length of sensor grating area | Direct ratio |

| Elastic modulus of adhesive layer | Direct ratio |

| Method category | Advantages | Disadvantages | Whether it Suitable for Full field Measurement | Whether it Suitable for High Altitude Flight | |

|---|---|---|---|---|---|

| Measuring deformation with strain gages | -Long life -Good frequency response characteristics | -Long time installation -Large volume -Additional load - High cost | No | No | |

| Measuring deformation with laser | -High precision -Good real-time property | -Complex device -Poor stability, -Partial area measurement | No | No | |

| Visual deformation measurement | VMD measurement system | -Easy to implement, -High precision | -Insufficient measuring points | No | No |

| PMI measurement system | -High precision, -Full field measurement | -Susceptible to light -Limited to specific ground deformation measurements | Yes | No | |

| IPCT measurement system | -High precision, -Flexible grating division -Full field measurement | -Influenced by noise and complex weather conditions | Yes | No | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Z.; Chen, X. Fiber Bragg Gratings Sensors for Aircraft Wing Shape Measurement: Recent Applications and Technical Analysis. Sensors 2019, 19, 55. https://doi.org/10.3390/s19010055

Ma Z, Chen X. Fiber Bragg Gratings Sensors for Aircraft Wing Shape Measurement: Recent Applications and Technical Analysis. Sensors. 2019; 19(1):55. https://doi.org/10.3390/s19010055

Chicago/Turabian StyleMa, Zhen, and Xiyuan Chen. 2019. "Fiber Bragg Gratings Sensors for Aircraft Wing Shape Measurement: Recent Applications and Technical Analysis" Sensors 19, no. 1: 55. https://doi.org/10.3390/s19010055

APA StyleMa, Z., & Chen, X. (2019). Fiber Bragg Gratings Sensors for Aircraft Wing Shape Measurement: Recent Applications and Technical Analysis. Sensors, 19(1), 55. https://doi.org/10.3390/s19010055