Recent Advances in Pipeline Monitoring and Oil Leakage Detection Technologies: Principles and Approaches

Abstract

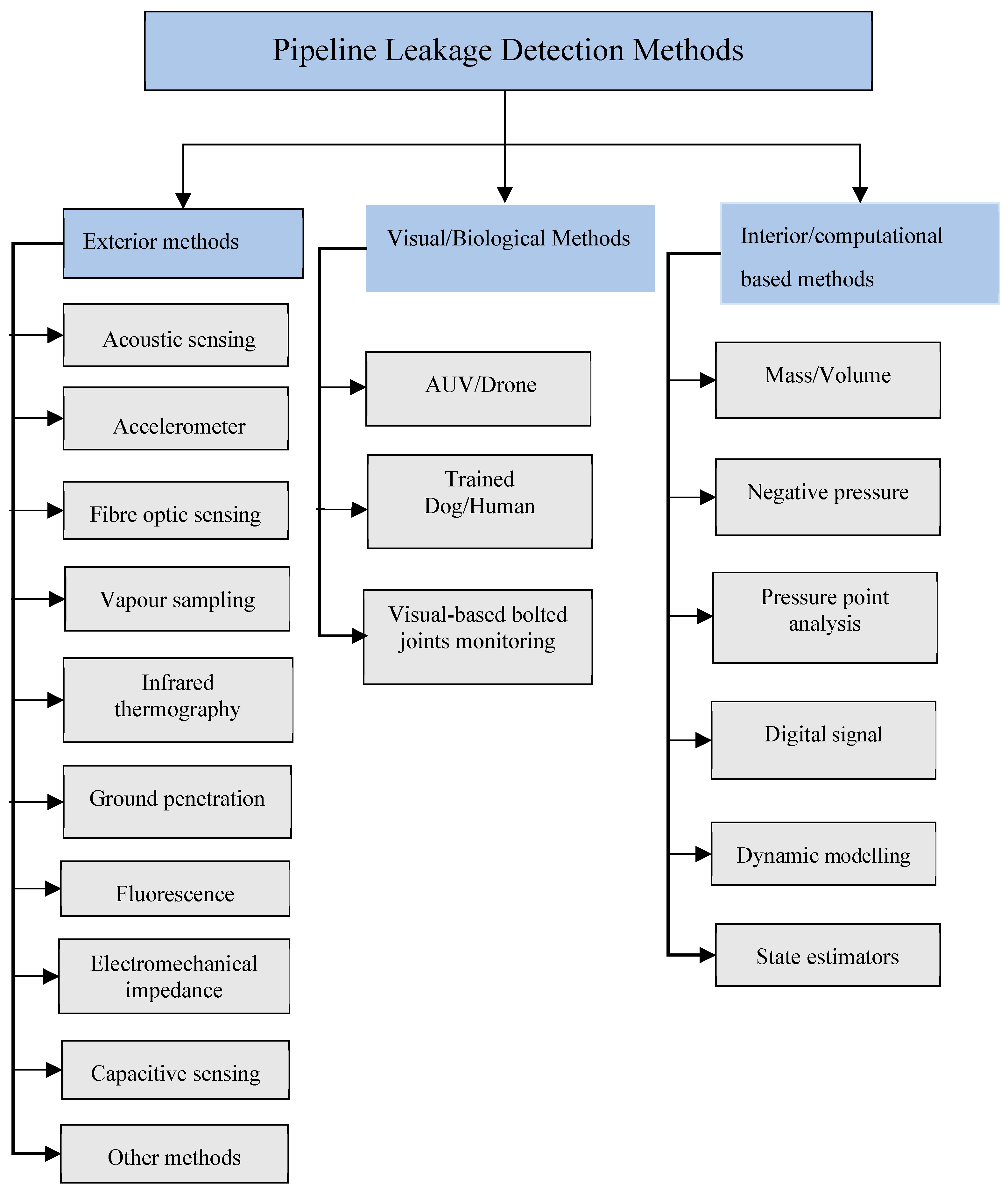

:1. Introduction

2. Exterior Based Leak Detection Methods

2.1. Acoustic Emission Sensors

2.2. Accelerometers

2.3. Fibre Optic Method

2.4. Vapour Sampling Method

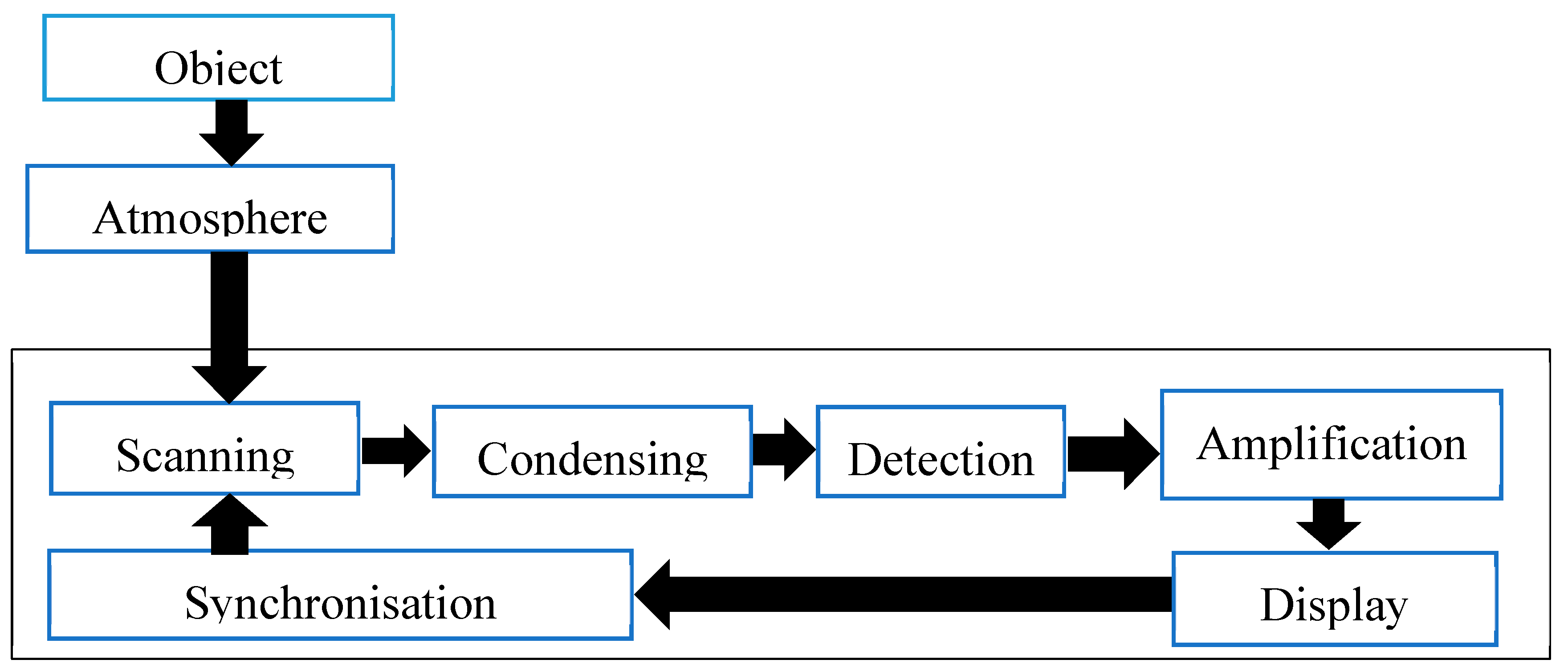

2.5. Infrared Thermography

2.6. Ground Penetration Radar

2.7. Fluorescence Method

2.8. Capacitive Sensing

2.9. Electromechanical Impedance-Based Methods

2.10. Other Methods

3. Visual/ Biological Leak Detection Methods

4. Interior/Computational Methods

4.1. Mass-Volume Balance

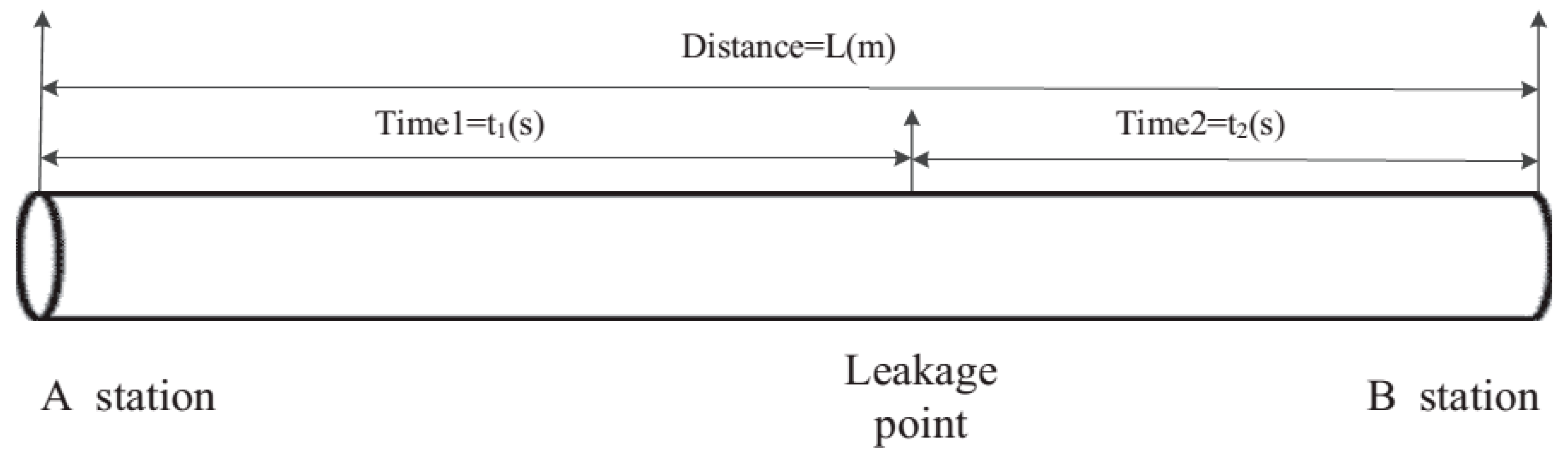

4.2. Negative Pressure Wave

4.3. Pressure Point Analysis

4.4. Digital Signal Processing

4.5. Dynamic Modelling

4.6. State Estimators/Observers Method

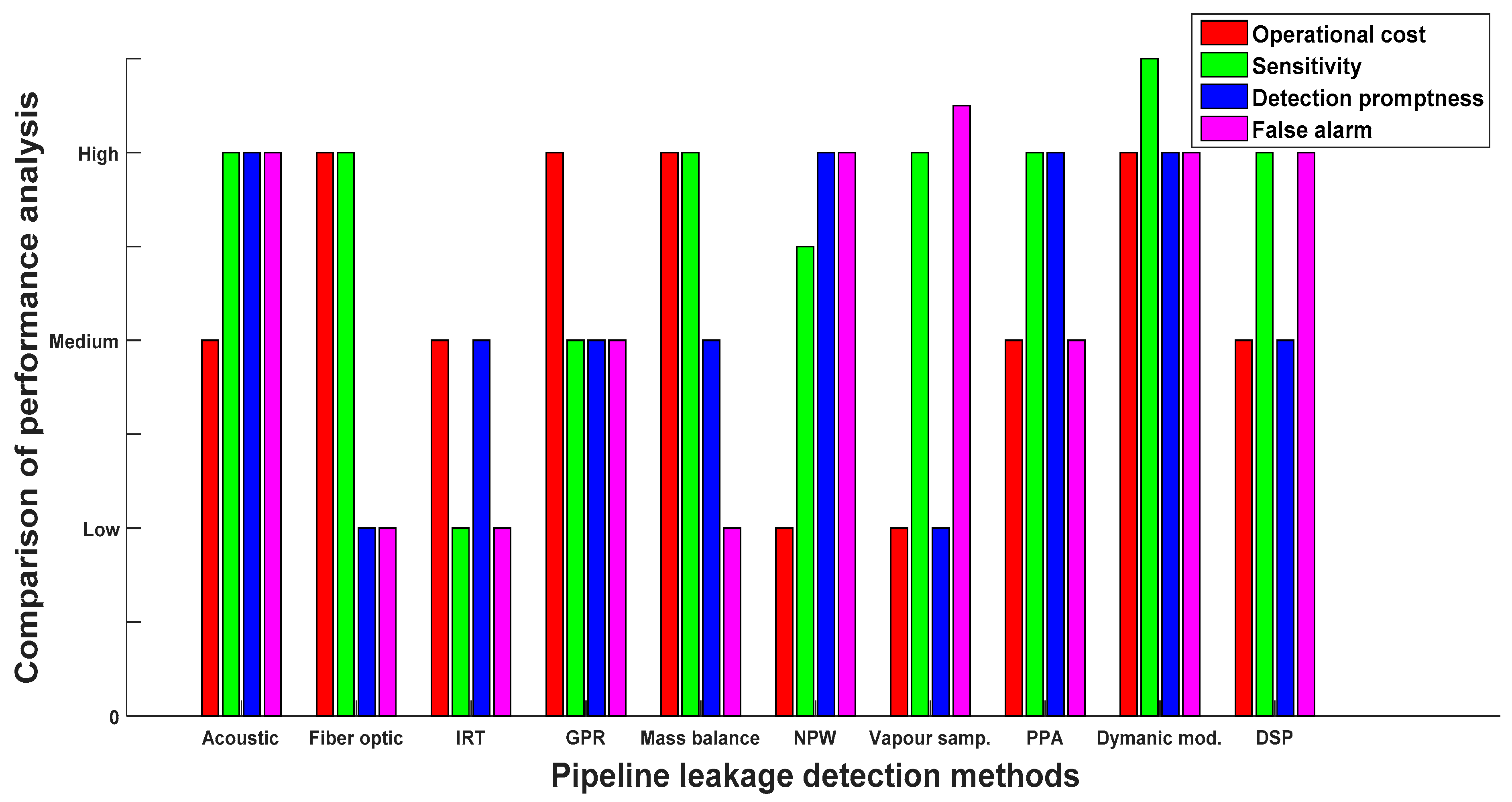

5. Performance Comparison of Leak Detection Technologies

6. Guideline for Pipeline Leakage Detection Method Selection

7. Research Gaps and Open Issues

8. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rehman, K.; Nawaz, F. Remote pipeline monitoring using Wireless Sensor Networks. In Proceedings of the International Conference on Communication, Computing and Digital Systems (C-CODE), Islandbad, Pakistan, 8–9 March 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Boaz, L.; Kaijage, S.; Sinde, R. An overview of pipeline leak detection and location systems. In Proceedings of the 2nd Pan African International Conference on Science, Computing and Telecommunications (PACT 2014), Arusha, Tanzania, 14–18 July 2014; IEEE: Piscataway, NJ, USA, 2014. [Google Scholar] [CrossRef]

- Xiao, Q.; Li, J.; Sun, J.; Feng, H.; Jin, S. Natural-gas pipeline leak location using variational mode decomposition analysis and cross-time–frequency spectrum. Measurement 2018, 124, 163–172. [Google Scholar] [CrossRef]

- Cramer, R.; Shaw, D.; Tulalian, R.; Angelo, P.; Van Stuijvenberg, M. Detecting and correcting pipeline leaks before they become a big problem. Mar. Technol. Soc. J. 2015, 49, 31–46. [Google Scholar] [CrossRef]

- Jia, Z.; Wang, Z.; Sun, W.; Li, Z. Pipeline leakage localization based on distributed FBG hoop strain measurements and support vector machine. Optik 2019, 176, 1–13. [Google Scholar] [CrossRef]

- Ajao, L.A.; Adedokun, E.A.; Nwishieyi, C.P.; Adegboye, M.A.; Agajo, J.; Kolo, J.G. An Anti-Theft Oil Pipeline Vandalism Detection: Embedded System Development. Int. J. Eng. Sci. Appl. 2018, 2, 55–64. [Google Scholar]

- White, B.; Kreuz, T.; Simons, S. Midstream. In Compression Machinery for Oil and Gas; Klaus, B., Rainer, K., Eds.; Gulf Professional Publishing: Houston, TX, USA, 2019; pp. 387–400. [Google Scholar] [CrossRef]

- Arifin, B.; Li, Z.; Shah, S.L.; Meyer, G.A.; Colin, A. A novel data-driven leak detection and localization algorithm using the Kantorovich distance. Comput. Chem. Eng. 2018, 108, 300–313. [Google Scholar] [CrossRef]

- Mokhatab, S.; Poe, W.A.; Mak, J.Y. Raw Gas Transmission. In Handbook of Natural Gas Transmission and Processing, 2nd ed.; Gulf Professional Publishing: Waltham, MA, USA, 2012; pp. 103–176. [Google Scholar]

- Liu, J.; Yao, J.; Gallaher, M.; Coburn, J.; Fernandez, R. Study on Methane Emission Reduction Potential in China’s Oil and Natural Gas Industry (Technical Report); RTI International: Research Triangle Park, NC, USA, 2008. [Google Scholar]

- Lena, V.G. Pipelines Explained: How Save Are American’s 2.5 Million Miles of Pipelines. 15 November 2012. Available online: https://www.propublica.org/article/pipelines-explained-how-safe-are-americas-2.5-million-miles-of-pipelines (accessed on 28 February 2019).

- Bolotina, I.; Borikov, V.; Ivanova, V.; Mertins, K.; Uchaikin, S. Application of phased antenna arrays for pipeline leak detection. J. Pet. Sci. Eng. 2018, 161, 497–505. [Google Scholar] [CrossRef]

- Meng, L.; Yuxing, L.; Wuchang, W.; Juntao, F. Experimental study on leak detection and location for gas pipeline based on acoustic method. J. Loss Prev. Process Ind. 2012, 25, 90–102. [Google Scholar] [CrossRef]

- Jin, H.; Zhang, L.; Liang, W.; Ding, Q. Integrated leakage detection and localization model for gas pipelines based on the acoustic wave method. J. Loss Prev. Process Ind. 2014, 27, 74–88. [Google Scholar] [CrossRef]

- Mahmutoglu, Y.; Turk, K. A passive acoustic based system to locate leak hole in underwater natural gas pipelines. Digit. Signal Process. 2018, 76, 59–65. [Google Scholar] [CrossRef]

- Lim, K.; Wong, L.; Chiu, W.K.; Kodikara, J. Distributed fibre optic sensors for monitoring pressure and stiffness changes in out-of-round pipes. Struct. Control Health Monit. 2016, 23, 303–314. [Google Scholar] [CrossRef]

- Jia, Z.; Ren, L.; Li, H.; Sun, W. Pipeline Leak Localization Based on FBG Hoop Strain Sensors Combined with BP Neural Network. Appl. Sci. 2018, 8, 146. [Google Scholar] [CrossRef]

- Png, W.H.; Lin, H.S.; Pua, C.H.; Rahman, F.A. Pipeline monitoring and leak detection using Loop integrated Mach Zehnder Interferometer optical fibre sensor. Opt. Fibre Technol. 2018, 46, 221–225. [Google Scholar] [CrossRef]

- Ni, S.; Huang, Y.; Lo, K.; Lin, D. Buried pipe detection by ground penetrating radar using the discrete wavelet transform. Comput. Geotech. 2010, 37, 440–448. [Google Scholar] [CrossRef]

- Hoarau, Q.; Ginolhac, G.; Atto, A.M.; Nicolas, J. Robust adaptive detection of buried pipes using GPR. Signal Process. 2017, 132, 293–305. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Xiao, D.; Zhao, X. Morphological filtering assisted field-pipeline small leakage detection. In Proceedings of the 2009 IEEE International Conference on System, Man and Cybernetics, SMC 2009, San Antonio, TX, USA, 11–14 October 2009; pp. 3769–3774. [Google Scholar] [CrossRef]

- Delgado, M.R.; Mendoza, O.B. A comparison between leak location methods based on the negative pressure wave. In Proceedings of the 14th International Conference on Electrical Engineering, Computing Science and Automatic Control (CCE), Mexico City, Mexico, 20–22 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–6. [Google Scholar] [CrossRef]

- Chen, Q.; Shen, G.; Jiang, J.; Diao, X.; Wang, Z.; Ni, L. Effect of rubber washers on leak location for assembled pressurized liquid pipeline based on negative pressure wave method. Process Saf. Environ. Prot. 2018, 119, 181–190. [Google Scholar] [CrossRef]

- Kam, S.I. Mechanistic modeling of pipeline leak detection at fixed inlet rate. J. Pet. Sci. Eng. 2010, 70, 145–156. [Google Scholar] [CrossRef]

- Tian, S.; Du, J.; Shao, S.; Xu, H.; Tian, C. A study on a real-time leak detection method for pressurized liquid refrigerant pipeline based on pressure and flow rate. Appl. Therm. Eng. 2016, 95, 462–470. [Google Scholar] [CrossRef]

- He, G.; Liang, Y.; Li, Y.; Wu, M.; Sun, L.; Xie, C.; Li, F. A method for simulating the entire leaking process and calculating the liquid leakage volume of a damaged pressurized pipeline. J. Hazard. Mater. 2017, 332, 19–32. [Google Scholar] [CrossRef]

- Yang, Z.; Fan, S.; Xiong, T. Simulation and Numerical Calculation on Pipeline Leakage Process. In Proceedings of the 2010 2nd International Symposium on Information Engineering and Electronic Commerce (IEEC), Ternopil, Ukraine, 23–25 July 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Li, X.; Chen, G.; Zhang, R.; Zhu, H.; Fu, J. Simulation and assessment of underwater gas release and dispersion from subsea gas pipelines leak. Process Saf. Environ. Prot. 2018, 119, 46–57. [Google Scholar]

- Wan, J.; Yu, Y.; Wu, Y.; Feng, R.; Yu, N. Hierarchical leak detection and localization method in natural gas pipeline monitoring sensor networks. Sensors 2012, 12, 189–214. [Google Scholar] [CrossRef]

- Manekiya, M.H.; Arulmozhivarman, P. Leakage detection and estimation using IR thermography. In Proceedings of the 2016 International Conference on Communication and Signal Processing (ICCSP), Melmaruvathur, India, 6–8 April 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1516–1519. [Google Scholar] [CrossRef]

- Sun, J.; Peng, Z.; Wen, J. Leakage aperture recognition based on ensemble local mean decomposition and sparse representation for classification of natural gas pipeline. Measurement 2017, 108, 91–100. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, Y.; Ma, Y.; Cheng, X.; Yang, J. Application of the differentiation process into the correlation-based leak detection in urban pipeline networks. Mech. Syst. Signal Process. 2018, 112, 251–264. [Google Scholar] [CrossRef]

- Yin, S.; Weng, Y.; Song, Z.; Cheng, B.; Gu, H.; Wang, H.; Yao, J. Mass transfer characteristics of pipeline leak-before-break in a nuclear power station. Appl. Therm. Eng. 2018, 142, 194–202. [Google Scholar] [CrossRef]

- Turner, N. Hardware and software techniques for pipeline integrity and leak detection monitoring. Soc. Pet. Eng. 1991, 139–148. [Google Scholar] [CrossRef]

- Murvay, P.; Silea, I. A survey on gas leak detection and localization techniques. J. Loss Prev. Process Ind. 2012, 25, 966–973. [Google Scholar] [CrossRef]

- Zhang, J. Designing a cost-effective and reliable pipeline leak-detection system. Pipes Pipelines Int. 1997, 42, 20–26. [Google Scholar]

- Geiger, G.; Vogt, D.; Tetzner, R. State-of-the-art in leak detection and localization. Oil Gas Eur. Mag. 2006, 32, 1–26. [Google Scholar]

- Golmohamadi, M. Pipeline Leak Detection. Master’s Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2015. [Google Scholar]

- Scott, S.L.; Barrufet, M.A. Worldwide Assessment of Industry Leak Detection Capabilities for Single & Multiphase Pipelines. Offshore Technology Research Center College Station. 2003. Available online: http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.118.6455&rep=rep1&type=pdf (accessed on 17 December 2018).

- Matos, S.; Powell, D.; Davies, R.; Zhang, X.; Moore, P. A Guideline Framework for the Integrity Assessment of Offshore Pipelines. 2006. Available online: https://www.bsee.gov/sites/bsee.gov/files/research-reports//565aa.pdf (accessed on 25 January 2019).

- Folga, S.M. Natural Gas Pipeline Technology Overview; Argonne National Lab. (ANL): Argonee, IL, USA, 2007. Available online: http://corridoreis.anl.gov/documents/docs/technical/apt_61034_evs_tm_08_5.pdf (accessed on 25 January 2019).

- Wang, X.; Lambert, M.F.; Simpson, A.R.; Vitkovsky, J.P. Leak detection in pipelines and pipe networks: A review. In Conference on Hydraulics in Civil Engineering, Proceedings of the 6th Conference on Hydraulics in Civil Engineering: The State of Hydraulics, Hobart, Australia, 28–30 November 2001; Institution of Engineers: Barton, Australia, 2001; pp. 391–400. [Google Scholar]

- ASTME1316-16a. Standard Terminology for Nondestructive Examinations; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Martini, A.; Troncossi, M.; Rivola, A. Leak Detection in Water-Filled Small-Diameter Polyethylene Pipes by Means of Acoustic Emission Measurements. Appl. Sci. 2017, 7, 2. [Google Scholar] [CrossRef]

- Li, S.; Wen, Y.; Li, P.; Yang, J.; Yang, L. Leak detection and location for gas pipelines using acoustic emission sensors. In Proceedings of the 2012 IEEE International Ultrasonics Symposium (IUS), Dresden, Germany, 7–10 October 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 957–960. [Google Scholar] [CrossRef]

- Recommended, Practice. DNVL-RP-F302—Edition April 2016. Available online: https://rules.dnvgl.com/docs/pdf/DNVGL/RP/2016-04/DNVGL-RP-F302.pdf (accessed on 15 February 2019).

- Naranjo, E.D.; Baliga, S.H. Expanding the use of ultrasonic gas leak detector: A review of gas release characteristics for adequate detection. Int. Gases Instrum. 2009, 3, 24–29. [Google Scholar]

- Chatzigeorgiou, D.; Youcef-Toumi, K.; Ben-Mansour, R. Design of a novel in-pipe reliable leak detector. IEEE/ASME Trans. Mechatron. 2015, 20, 824–833. [Google Scholar] [CrossRef]

- Fuchs, H.; Riehle, R. Ten years of experience with leak detection by acoustic signal analysis. Appl. Acoust. 1991, 33, 1–19. [Google Scholar] [CrossRef]

- Davoodi, S.; Mostafapour, A. Theoretical Analysis of Leakage in High Pressure Pipe Using Acoustic Emission Method. Adv. Mater. Res. Trans Tech. Publ. 2012, 445, 917–922. [Google Scholar]

- Datta, S.; Sarkar, S. A review on different pipeline fault detection methods. J. Loss Prev. Process Ind. 2016, 41, 97–106. [Google Scholar] [CrossRef]

- Oh, S.W.; Yoon, D.; Kim, G.J.; Bae, J.; Kim, H.S. Acoustic data condensation to enhance pipeline leak detection. Nucl. Eng. Des. 2018, 327, 198–211. [Google Scholar] [CrossRef]

- Miller, R.; Pollock, A.; Watts, D.; Carlyle, J.; Tafuri, A.; Yezzi, J.J. A reference standard for the development of acoustic emission pipeline leak detection techniques. NDT E Int. 1999, 32, 1–8. [Google Scholar] [CrossRef]

- Li, S.; Song, Y.; Zhou, G. Leak detection of water distribution pipeline subject to failure of socket joint based on acoustic emission and pattern recognition. Measurement 2018, 115, 39–44. [Google Scholar] [CrossRef]

- Ai, C.; Zhao, H.; Ma, R.; Dong, X. Pipeline damage and leak detection based on sound spectrum LPCC and HMM. In Proceedings of the Sixth International Conference on Intelligent Systems Design and Applications (ISDA’06), Jinan, China, 16–18 October 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 829–833. [Google Scholar] [CrossRef]

- Ahadi, M.; Bakhtiar, M.S. Leak detection in water-filled plastic pipes through the application of tuned wavelet transforms to acoustic emission signals. Appl. Acoust. 2010, 71, 634–639. [Google Scholar] [CrossRef]

- Elandalibe, K.; Jbari, A.; Bourouhou, A. Application of cross-correlation technique for multi leakage detection. In Proceedings of the 2015 Third World Conference on Complex Systems (WCCS), Marrakech, Morocco, 23–25 November 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–4. [Google Scholar] [CrossRef]

- Chen, Z.; Xie, Y.; Yuan, M.; Xu, Z. Weak feature signal extraction for small leakage in pipelines based on wavelet. In Proceedings of the IET International Conference on Information Science and Control Engineering 2012 (ICISCE 2012), Shenzhen, China, 7–9 December 2012. [Google Scholar] [CrossRef]

- Yazdekhasti, S.; Piratla, K.R.; Atamturktur, S.; Khan, A. Novel vibration-based technique for detection of water pipeline leakage. Struct. Infrastruct. Eng. 2017, 13, 731–742. [Google Scholar] [CrossRef]

- El-Zahab, S.; Mohammed Abdelkader, E.; Zayed, T. An accelerometer-based leak detection system. Mech. Syst. Signal Process. 2018, 108, 58–72. [Google Scholar] [CrossRef]

- Yazdekhasti, S.; Piratla, K.R.; Atamturktur, S.; Khan, A. Experimental evaluation of a vibration-based leak detection technique for water pipelines. Struct. Infrastruct. Eng. 2018, 14, 46–55. [Google Scholar] [CrossRef]

- Martini, A.; Troncossi, M.; Rivola, A. Vibroacoustic Measurements for Detecting Water Leaks in Buried Small-Diameter Plastic Pipes. J. Pipeline Syst. Eng. Pract. 2017, 8, 1–10. [Google Scholar] [CrossRef]

- Martini, A.; Rivola, A.; Troncossi, M. Autocorrelation Analysis of Vibro-Acoustic Signals Measured in a Test Field for Water Leak Detection. Appl. Sci. 2018, 8, 2450. [Google Scholar] [CrossRef]

- Tanimola, F.; Hill, D. Distributed fibre optic sensors for pipeline protection. J. Nat. Gas Sci. Eng. 2009, 1, 134–143. [Google Scholar] [CrossRef]

- Wang, L.; Narasimman, S.C.; Ravula, S.R.; Ukil, A. Water ingress detection in low-pressure gas pipelines using distributed temperature sensing system. IEEE Sens. J. 2017, 17, 3165–3173. [Google Scholar] [CrossRef]

- Selker, J.S.; Thévenaz, L.; Huwald, H.; Mallet, A.; Luxemburg, W.; Van De Giesen, N. Distributed fibre-optic temperature sensing for hydrologic systems. Water Resour. Res. 2006, 42, 1–8. [Google Scholar] [CrossRef]

- Bao, X.; Chen, L. Recent progress in distributed fibre optic sensors. Sensors 2012, 12, 8601–8639. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.A.; Vrabie, V.; Mars, J.I.; Girard, A.; D’Urso, G. A source separation technique for processing of thermometric data from fibre-optic DTS measurements for water leakage identification in dikes. IEEE Sens. J. 2008, 8, 1118–1129. [Google Scholar] [CrossRef]

- Kroll, A.; Baetz, W.; Peretzki, D. On autonomous detection of pressured air and gas leaks using passive IR-thermography for mobile robot application. In Proceedings of the IEEE International Conference on Robotics and Automation, 2009 (ICRA’09), Kobe, Japan, 12–17 May 2012; IEEE: Piscataway, NJ, USA, 2009; pp. 921–926. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, B.; He, J. Pipeline deformation monitoring using distributed fibre optical sensor. Measurement 2019, 133, 208–213. [Google Scholar] [CrossRef]

- Du, J.; Wang, L.; Cai, C.; Yin, C.; Zhao, G. Study on distributed optical fibre heating pipeline network leak detection system. In Proceedings of the 2017 IEEE 2nd Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chegdu, China, 15–17 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 137–140. [Google Scholar] [CrossRef]

- Ong, K.S.; Png, W.H.; Lin, H.S.; Pua, C.H.; Rahman, F.A. Acoustic vibration sensor based on macro-bend coated fibre for pipeline leakage detection. In Proceedings of the 17th International Conference on Control, Automation and Systems (ICCAS20), Jeju, South Korea, 18–21 October 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 167–171. [Google Scholar] [CrossRef]

- Hatton, G.J.; Pulici, M.; Curti, G.; Mansueto, M.; Kruka, V.R. Deepwater Natural Gas Pipeline Hydrate Blockage Caused by a Seawater Leak Test. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002. [Google Scholar] [CrossRef]

- Ahmed, M.; Shama, A.; Mohamed, E.; Mohamed, K. Review of leakage detection methods for subsea pipeline. Arab Acad. Sci. Technol. Marit. Transp. 2017, 1, 1–9. [Google Scholar]

- Cosham, A.; Hopkins, P. The pipeline defect assessment manual. In Proceedings of the 2002 4th International Pipeline Conference, Calgary, AB, Canada, 29 September–3 October 2002; pp. 1565–1581. [Google Scholar]

- Bagavathiappan, S.; Lahiri, B.; Saravanan, T.; Philip, J.; Jayakumar, T. Infrared thermography for condition monitoring—A review. Infrared Phys. Technol. 2013, 60, 35–55. [Google Scholar] [CrossRef]

- Shakmak, B.; Al-Habaibeh, A. Detection of water leakage in buried pipes using infrared technology; a comparative study of using high and low resolution infrared cameras for evaluating distant remote detection. In Proceedings of the 2015 IEEE Jordan Conference on Applied Electrical Engineering and Computing Technologies (AEECT), Amman, Jordan, 3–5 November 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–7. [Google Scholar] [CrossRef]

- Rodgers, P.; Eveloy, V.; Lohan, J.; Fager, C.; Tiilikka, P.; Rantala, J. Experimental validation of numerical heat transfer predictions for single and multi-component printed circuit boards in natural convection environments. In Proceedings of the Fifteenth Annual IEEE Semiconductor Thermal Measurement and Management Symposium (Cat. No 99CH36306), San Diego, CA, USA, 9–11 March 1999; IEEE: Piscataway, NJ, USA, 1999; pp. 54–64. [Google Scholar] [CrossRef]

- Venkatraman, B.; Mukhophadyay, C.; Raj, B. Prediction of tensile failure of 316 stainless steel using infrared thermography. Exp. Tech. 2004, 28, 35–38. [Google Scholar] [CrossRef]

- Hu, J.; Tang, Q.; Twumasi, J.O.; Yu, T. Characterization of steel rebar spacing using synthetic aperture radar imaging. In International Society for Optics and Photonics, Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, Civil Infrastructure, and Transportation, Denver, CO, USA, 27 March 2018; SPIE: Bellingham, WA, USA, 2018; Volume 10599. [Google Scholar] [CrossRef]

- Meola, C. Origin and theory of infrared thermography. In Infrared Thermography Recent Advances and Future Trends; Meola, C., Ed.; Bentham eBooks: Perugia, Italy, 2012; pp. 3–28. [Google Scholar]

- Shen, G.; Li, T. Infrared thermography for high-temperature pressure pipe. Insight-Non-Destr. Test. Cond. Monit. 2007, 49, 151–153. [Google Scholar] [CrossRef]

- Flores-Bolarin, J.; Royo-Pastor, R. Infrared thermography: A good tool for nondestructive testing of plastic materials. In Proceedings of the 5th European Thermal-Sciences Conference, Eindhoven, The Netherlands, 18–22 May 2008; pp. 1–8. [Google Scholar]

- Jadin, M.S.; Ghazali, K.H. Gas leakage detection using thermal imaging technique. In Proceedings of the 2014 UKSim-AMSS 16th International Conference on Computer Modelling and Simulation, Cambridge, UK, 26–28 March 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 302–306. [Google Scholar] [CrossRef]

- Meola, C.; Giovanni, M.; Carlomagn, O. Recent advances in the use of infrared thermography. Meas. Sci. Technol. 2004, 15, 171–183. [Google Scholar] [CrossRef]

- Jadin, M.S.; Taib, S. Recent progress in diagnosing the reliability of electrical equipment by using infrared thermography. Infrared Phys. Technol. 2012, 55, 236–245. [Google Scholar] [CrossRef] [Green Version]

- Dudić, S.; Ignjatović, I.; Šešlija, D.; Blagojević, V.; Stojiljković, M. Leakage quantification of compressed air using ultrasound and infrared thermography. Measurement 2012, 45, 1689–1694. [Google Scholar] [CrossRef]

- Adefila, K.; Yan, Y.; Wang, T. Leakage detection of gaseous CO 2 through thermal imaging. In Proceedings of the 2015 IEEE International Instrumentation and Measurement Technology Conference (I2MTC) Proceedings, Pisa, Italy, 11–14 May 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 261–265. [Google Scholar] [CrossRef]

- Peters, L.; Daniels, J.J.; Young, J.D. Ground penetrating radar as a subsurface environmental sensing tool. Proc. IEEE 1994, 82, 1802–1822. [Google Scholar] [CrossRef]

- Bimpas, M.; Amditis, A.; Uzunoglu, N. Detection of water leaks in supply pipes using continuous wave sensor operating at 2.45 GHz. J. Appl. Geophys. 2010, 70, 226–236. [Google Scholar] [CrossRef]

- Adedeji, K.B.; Hamam, Y.; Abe, B.T.; Abu-Mahfouz, A.M. Towards achieving a reliable leakage detection and localization algorithm for application in water piping networks: An overview. IEEE Access 2017, 5, 20272–20285. [Google Scholar] [CrossRef]

- Cowdrick, D.H. Oblique Scanning Ground Penetrating Radar. U.S. Patent 609157, 25 July 2000. [Google Scholar]

- Benson, A.K. Applications of ground penetrating radar in assessing some geological hazards: Examples of groundwater contamination, faults, cavities. J. Appl. Geophys. 1995, 33, 177–193. [Google Scholar] [CrossRef]

- Moffatt, D.L.; Puskar, R. A subsurface electromagnetic pulse radar. Geophysics 1976, 41, 506–518. [Google Scholar] [CrossRef]

- Eyuboglu, S.; Mahdi, H.; Al-Shukri, H.; Rock, L. Detection of water leaks using ground penetrating radar. In Proceedings of the Third International Conference on Applied Geophysics, Orlando, FL, USA, 8–12 December 2003; pp. 8–12. Available online: https://scholar.google.co.uk/scholar?cluster=11125688841441489403&hl=en&as_sdt=0,5 (accessed on 15 February 2019).

- Maas, C.; Schmalzl, J. Using pattern recognition to automatically localize reflection hyperbolas in data from ground penetrating radar. Comput. Geosci. 2013, 58, 116–125. [Google Scholar] [CrossRef]

- Patterson, J.E.; Cook, F.A. Successful application of ground-penetrating radar in the exploration of gem tourmaline pegmatites of southern California. Geophys. Prospect. 2002, 50, 107–117. [Google Scholar] [CrossRef]

- Simi, A.; Manacorda, G.; Miniati, M.; Bracciali, S.; Buonaccorsi, A. Underground asset mapping with dual-frequency dual-polarized GPR massive array. In Proceedings of the XIII Internarional Conference on Ground Penetrating Radar, Lecce, Italy, 21–25 June 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1–5. [Google Scholar] [CrossRef]

- Zoubir, A.M.; Chant, I.J.; Brown, C.L.; Barkat, B.; Abeynayake, C. Signal processing techniques for landmine detection using impulse ground penetrating radar. IEEE Sens. J. 2002, 2, 41–51. [Google Scholar] [CrossRef] [Green Version]

- Ng, W.; Chan, T.C.; So, H.; Ho, K.C. Particle filtering based approach for landmine detection using ground penetrating radar. IEEE Trans. Geosci. Remote Sens. 2008, 46, 3739–3755. [Google Scholar] [CrossRef]

- Kovalenko, V.; Yarovoy, A.G.; Ligthart, L.P. A novel clutter suppression algorithm for landmine detection with GPR. IEEE Trans. Geosci. Remote Sens. 2007, 45, 3740–3751. [Google Scholar] [CrossRef]

- Bradford, J.H.; Dickins, D.F.; Brandvik, P.J. Assessing the potential to detect oil spills in and under snow using airborne ground-penetrating radar. Geophysics 2010, 75, 1–12. [Google Scholar] [CrossRef]

- Jasper, A. Oil/Gas Pipeline Leak Inspection and Repair in Underwater Poor Visibility Conditions: Challenges and Perspectives. J. Environ. Prot. 2012, 3, 394–399. [Google Scholar] [CrossRef] [Green Version]

- Chris, T. Subsea Leak Detection; Neptune Oceanographics Ltd.: Carlbury, UK, 2007. [Google Scholar]

- Recommended Practice, DNV-RP-F302. Selection and Use of Subsea Leak Detection Systems. April 2010. Available online: https://rules.dnvgl.com/docs/pdf/DNV/codes/docs/2010-04/RP-F302.pdf (accessed on 20 February 2019).

- Dario, C. A method to obtain precise determinations of relative humidity using thin film capacitive sensors under normal or extreme humidity conditions. J. Cult. Herit. 2019, 37, 166–169. [Google Scholar] [CrossRef]

- Park, G.; Cudney, H.H.; Inman, D.J. Feasibility of using impedance-based damage assessment for pipeline structures. Earthq. Eng. Struct. Dyn. 2001, 30, 1463–1474. [Google Scholar] [CrossRef]

- Zuo, C.; Feng, X.; Zhang, Y.; Lu, L.; Zhou, J. Crack detection in pipelines using multiple electromechanical impedance sensors. Smart Mater. Struct. 2017, 26, 104004. [Google Scholar] [CrossRef]

- Yang, X.U.; Luo, M.; Liu, Q.; Du, G.; Song, G. PZT transducer array enabled pipeline defect locating based on time-reversal method and matching pursuit de-noising. Smart Mater. Struct. 2019, 28. [Google Scholar] [CrossRef]

- Na, W.S.; Lee, H. Experimental investigation for an isolation technique on conducting the electromechanical impedance method in high-temperature pipeline facilities. J. Sound Vib. 2016, 383, 210–220. [Google Scholar] [CrossRef]

- Vision System Design. Infrared Camera Sports Gas Leaks. 1 March 2003. Available online: https://www.vision-systems.com/articles/print/volume-8/issue-3/technology-trends/industrial/infrared-camera-spots-gas-leaks.html (accessed on 25 January 2019).

- Sivathanu, Y. Technology Status Report on Natural Gas Leak Detection in Pipeline. 2005. Available online: https://www.academia.edu/5732928/Technology_Status_Report_on_Natural_Gas_Leak_Detection_in_Pipelines (accessed on 15 January 2019).

- Quaife, L.; Acker, D. Pipeline leak location technique using a novel test fluid and trained dogs. In Proceedings of the 5th International Conference and Exhibition on Pipeline Pigging and Integrity Monitoring Conference, Houston, TX, USA, 1–4 February 1993. [Google Scholar]

- Mandal, P.C. Gas leak detection in pipelines & repairing system of titas gas. J. Appl. Eng. 2014, 2, 23–34. [Google Scholar]

- Garner, K.J.; Busbee, L.; Cornwell, P.; Edmonds, J.; Mullins, K.; Rader, K.; Johnston, J.M.; Willian, J.M. Duty Cycle of the Detector Dog: A Baseline Study; Institute for Biological Detection Systems, Auburn University: Aubuern, AL, USA, 2001. [Google Scholar]

- Shukla, A.; Karki, H. Application of robotics in onshore oil and gas industry—A review Part II. Robot. Auton. Syst. 2016, 75, 508–524. [Google Scholar] [CrossRef]

- Costa, M.J.; Goncalves, P.; Martins, A.; Silva, E. Vision-based assisted teleoperation for inspection tasks with a small ROV. Oceans 2012, 2012, 1–8. [Google Scholar]

- Anisi, D.A.; Skourup, C. A step-wise approach to oil and gas robotics. In Proceeding of the 2012 IFAC workshop on Automatic Contral in offshore oil and gas production, Trondheim, Norway, 31 May–1 June 2012; Volume 45, pp. 47–52. [Google Scholar]

- Gómez, C.; Green, D.R. Small unmanned airborne systems to support oil and gas pipeline monitoring and mapping. Arab. J. Geosci. 2017, 10, 202–209. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, Y. Sense and avoid technologies with applications to unmanned aircraft systems: Review and prospects. Prog. Aerosp. Sci. 2015, 74, 152–166. [Google Scholar] [CrossRef]

- Mcfadyen, A.; Mejias, L. A survey of autonomous vision-based see and avoid for unmanned aircraft systems. Prog. Aerosp. Sci. 2016, 80, 1–17. [Google Scholar] [CrossRef]

- Hongjian, Z.; Ping, H.; Xudong, Y. Fault Detection of Train Center Plate Bolts Loss Using Modified LBP and Optimization Algorithm. Open Autom. Control Syst. J. 2015, 7, 1916–1921. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Zhou, F.; He, Y. Automated status inspection of fastening bolts on freight trains using a machine vision approach. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 1629–1641. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, Z. Potential fault region detection in TFDS images based on convolutional neural network. In Proceedings of the Infrared Technology and Applications, and Robot Sensing and Advanced Control, International Society for Optics and Photonics, Beijing, China, 25 October 2016; Volume 10157, p. 101571L. [Google Scholar] [CrossRef]

- Nguyen, T.C.; Huynh, T.C.; Ryu, J.Y.; Park, J.H.; Kim, J.T. Bolt-loosening identification of bolt connections by vision image-based technique. In Proceedings of the SPIE 9804, Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure, Las Vegas, NV, USA, 8 April 2016. [Google Scholar] [CrossRef]

- Park, J.H.; Huynh, T.C.; Choi, S.H.; Kim, J.-T. Vision-based technique for bolt-loosening detection in wind turbine tower. Wind Struct. 2015, 21, 709–726. [Google Scholar] [CrossRef]

- Wang, C.; Wang, N.; Ho, M.; Chen, X.; Song, G. Design of a New Vision-based Method for the Bolts Looseness Detection in Flange Connections. IEEE Trans. Ind. Electron. 2019, in press. [Google Scholar] [CrossRef]

- Ostapkowicz, P. Leak detection in liquid transmission pipelines using simplified pressure analysis techniques employing a minimum of standard and non-standard measuring devices. Eng. Struct. 2016, 113, 194–205. [Google Scholar] [CrossRef]

- Sheltami, T.R.; Bala, A.; Shakshuki, E.M. Wireless sensor networks for leak detection in pipelines: A survey. J. Ambient Intell. Humaniz. Comput. 2016, 7, 347–356. [Google Scholar] [CrossRef]

- Martins, J.C.; Seleghim, P. Assessment of the performance of acoustic and mass balance methods for leak detection in pipelines for transporting liquids. J. Fluids Eng. 2010, 132, 011401–011413. [Google Scholar] [CrossRef]

- Wylie, E.B.; Streeter, V.L. Fluid Transients in Systems; Prentice-Hall: Englewood Cliffs, NJ, USA, 1993; p. 463. [Google Scholar]

- Karim, M.Z.A.; Alrasheedy, A.; Gaafar, A.A. Compensated mass balance method for oil pipeline leakage detection using SCADA. Int. J. Comput. Sci. Secur. (IJCSS) 2015, 9, 293–302. [Google Scholar]

- Rougier, J. Probabilistic leak detection in pipelines using the mass imbalance approach. J. Hydraul. Res. 2005, 43, 556–566. [Google Scholar] [CrossRef]

- Sang, Y.; Zhang, J.; Lu, X.; Fan, Y. Signal processing based on wavelet transform in pipeline leakage detection and location. In Proceedings of the Sixth International Conference on Intelligent Systems Design and Applications (ISDA’06), Jinan, China, 16–18 October 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 734–739. [Google Scholar] [CrossRef]

- Yu, Z.; Jian, L.; Zhoumo, Z.; Jin, S. A combined kalman filter-Discrete wavelet transform method for leakage detection of crude oil pipelines. In Proceedings of the 9th International Conference on Electronic Measurement & Instruments (ICEMI’09), Beijing, China, 16–19 August 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 3-1086–3-1090. [Google Scholar] [CrossRef]

- Chen, H.; Ye, H.; Chen, L.; Su, H. Application of support vector machine learning to leak detection and location in pipelines. In Proceedings of the 21st IEEE Instrumentation and Measurement Technology Conference (IEEE Cat. No. 04CH37510), Como, Italy, 18–20 May 2004; IEEE: Piscataway, NJ, USA, 2004; pp. 2273–2277. [Google Scholar] [CrossRef]

- Ferrante, M.; Brunone, B.; Meniconi, S. Wavelets for the analysis of transient pressure signals for leak detection. J. Hydraul. Eng. 2007, 133, 1274–1282. [Google Scholar] [CrossRef]

- Hou, C.X.; Zhang, E.H. Pipeline leak detection based on double sensor negative pressure wave. Appl. Mech. Mater. 2013, 313–314, 1225–1228. [Google Scholar] [CrossRef]

- Wang, H.; Ye, H.; Wang, G. Oil pipeline leakage detection based on wavelet algorithm. Inf. Control-Shenyang 2002, 31, 456–460. [Google Scholar]

- Zhu, A.-H.; Jin, S.-J.; Zeng, Z.-M. Application of Kalman Filter in Pipeline Leak Detection. Control Instrum. Chem. Ind. 2005, 32, 57–60. [Google Scholar]

- Peng, Z.; Wang, J.; Han, X. A study of negative pressure wave method based on HAAR wavelet transform in ship piping leakage detection system. In Proceedings of the 2011 IEEE 2nd International Conference on Computing, Control and Industrial Engineering (CCIE), Wuhan, China, 20–21 August 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 111–113. [Google Scholar] [CrossRef]

- Yonghong, S.; Zhenhua, W. Detection of small leakage from pipeline based on improved harmonic wavelet. In Proceedings of the 2012 7th International Conference on Computer Science & Education (ICCSE), Melbourne, VIC, Australia, 14–17 July 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 45–49. [Google Scholar] [CrossRef]

- Chen, Z.; Lian, X.; Yu, Z. Leakage detection for oil pipelines based on Independent Component Analysis. In Proceedings of the 29th Chinese Control Conference (CCC), Beijing, China, 29–31 July 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 4009–4013. [Google Scholar]

- Li, Q.; Li, M.; Zhang, X.; Ba, W. Research on mixed signal separation method for pipeline leakage based on RobustICA. In Proceedings of the 2016 International Conference on Robotics and Automation Engineering (ICRAE), Jeju, South Korea, 27–29 August 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 70–74. [Google Scholar]

- Zhang, G.; Zhu, J.; Song, Y.; Peng, C.; Song, G. A Time Reversal Based Pipeline Leakage Localization Method with the Adjustable Resolution. IEEE Access 2018, 6, 26993–27000. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Y.; Li, Y.; Xu, M. Experimental study on new leak location methods for natural gas pipelines based on dynamic pressure waves. J. Nat. Gas Sci. Eng. 2018, 54, 83–91. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Du, X.; Zhang, H.; Li, M.; Ba, W. Liquid pipeline leakage detection based on moving windows LS-SVM algorithm. In Proceedings of the 2018 33rd Youth Academic Annual Conference of Chinese Association of Automation (YAC), Nanjing, China, 18–20 May 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 701–705. [Google Scholar] [CrossRef]

- Bin Md Akib, A.; Bin Saad, N.; Asirvadam, V. Pressure point analysis for early detection system. In Proceedings of the 2011 IEEE 7th International Colloquium on Signal Processing and its Applications (CSPA), Penang, Malaysia, 4–6 March 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 103–107. [Google Scholar] [CrossRef]

- Mpesha, W.; HanifChaudhry, M.; Gassman, S.L. Leak detection in pipes by frequency response method using a step excitation. J. Hydraul. Res. 2002, 40, 55–62. [Google Scholar] [CrossRef]

- Kim, M.; Lee, S. Detection of leak acoustic signal in buried gas pipe based on the time–frequency analysis. J. Loss Prev. Process Ind. 2009, 22, 990–994. [Google Scholar] [CrossRef]

- Lay-Ekuakille, A.; Vergallo, P.; Trotta, A. Impedance method for leak detection in zigzag pipelines. Meas. Sci. Rev. 2010, 10, 209–213. [Google Scholar] [CrossRef]

- Shibata, A.; Konishi, M.; Abe, Y.; Hasegawa, R.; Watanabe, M.; Kamijo, H. Neuro based classification of gas leakage sounds in pipeline. In Proceedings of the 2009 International Conference on Networking, Sensing and Control, Okayama, Japan, 26–29 March 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 298–302. [Google Scholar] [CrossRef]

- Lay-Ekuakille, A.; Vendramin, G.; Trotta, A. Spectral analysis of leak detection in a zigzag pipeline: A filter diagonalization method-based algorithm application. Measurement 2009, 42, 358–367. [Google Scholar] [CrossRef]

- Santos-Ruiz, I.; Bermúdez, J.; López-Estrada, F.; Puig, V.; Torres, L.; Delgado-Aguiñaga, J. Online leak diagnosis in pipelines using an EKF-based and steady-state mixed approach. Control Eng. Pract. 2018, 81, 55–64. [Google Scholar] [CrossRef]

- Sun, J.; Xiao, Q.; Wen, J.; Wang, F. Natural gas pipeline small leakage feature extraction and recognition based on LMD envelope spectrum entropy and SVM. Measurement 2014, 55, 434–443. [Google Scholar] [CrossRef]

- Liu, C.; Li, Y.; Fang, L.; Xu, M. New leak-localization approaches for gas pipelines using acoustic waves. Measurement 2019, 134, 54–65. [Google Scholar] [CrossRef]

- Kay, S.M. Fundamentals of Statistical Signal Processing, Vol. III: Practical Algorithm Development; Prentice Hall: Upper Saddle River, NJ, USA, 2013; pp. 1–496. [Google Scholar]

- Alaska Department of Environmental Conservation. Technical Review of Leak Detection Technologies. 1999. Available online: https://dec.alaska.gov/spar/ppr/response-resources/puplications-conferences.aspx (accessed on 15 January 2019).

- Vítkovský, J.P.; Lambert, M.F.; Simpson, A.R.; Liggett, J.A. Experimental observation and analysis of inverse transients for pipeline leak detection. J. Water Resour. Plan. Manag. 2007, 133, 519–530. [Google Scholar] [CrossRef]

- Giustolisi, O.; Savic, D.; Kapelan, Z. Pressure-driven demand and leakage simulation for water distribution networks. J. Hydraul. Eng. 2008, 134, 626–635. [Google Scholar] [CrossRef]

- Berardi, L.; Giustolisi, O.; Savic, D.; Kapelan, Z. An effective multi-objective approach to prioritisation of sewer pipe inspection. Water Sci. Technol. 2009, 60, 841–850. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Kuo, T.; Kao, W.; Tsai, J.; Chen, W.; Fan, K. An improved method of soil-gas sampling for pipeline leak detection: Flow model analysis and laboratory test. J. Nat. Gas Sci. Eng. 2017, 42, 226–231. [Google Scholar] [CrossRef]

- INTSOK. Russian–Norwegian Oil & Gas Industry Cooperation in the High North; Logistics and Transport-Report; INTSOK: Oslo, Norway, 2013. [Google Scholar]

- Besançon, G. Observer tools for pipeline monitoring. In Modeling and Monitoring of Pipelines and Networks; Springer: Cham, Switzerland, 2017; pp. 83–97. [Google Scholar] [CrossRef]

- Ali, J.M.; Hoang, N.H.; Hussain, M.A.; Dochain, D. Review and classification of recent observers applied in chemical process systems. Comput. Chem. Eng. 2015, 76, 27–41. [Google Scholar] [Green Version]

- Jiménez Cabas, J.A. Liquid Transport Pipeline Monitoring Architecture Based on State Estimators for Leak Detection and Location. Master’s Thesis, Universidad del Norte, Barranquilla, Colombia, March 2018. [Google Scholar]

- Navarro, A.; Begovich, O.; Besançon, G.; Dulhoste, J. Real-time leak isolation based on state estimation in a plastic pipeline. In Proceedings of the IEEE International Conference on Control Applications (CCA), Denver, CO, USA, 28–30 September 2011; pp. 953–957. [Google Scholar]

- Besançon, G.; Georges, D.; Begovich, O.; Verde, C.; Aldana, C. Direct observer design for leak detection and estimation in pipelines. In Proceedings of the 2007 European Control Conference (ECC), Kos, Greece, 2–5 July 2007; IEEE: Piscataway, NJ, USA, 2007; pp. 5666–5670. [Google Scholar] [CrossRef]

- Modisette, J.P. State estimation of pipeline models using the ensemble Kalman filter. In Proceedings of the PSIG Annual Meeting, Prague, Czech Republic, 16–19 April 2013; Pipeline Simulation Interest Group: Houston, TX, USA, 2013. [Google Scholar]

- Delgado-Aguiñaga, J.; Besançon, G.; Begovich, O.; Carvajal, J. Multi-leak diagnosis in pipelines based on extended Kalman filter. Control Eng. Pract. 2016, 49, 139–148. [Google Scholar] [CrossRef]

- Navarro, A.; Begovich, O.; Sánchez, J.; Besançon, G. Real-time leak isolation based on state estimation with fitting loss coefficient calibration in a plastic pipeline. Asian J. Control 2017, 19, 255–265. [Google Scholar] [CrossRef]

- Durgut, I.; Leblebicioğlu, M.K. State estimation of transient flow in gas pipelines by a Kalman filter-based estimator. J. Nat. Gas Sci. Eng. 2016, 35, 189–196. [Google Scholar] [CrossRef]

- Gong, J.; Cai, J.; Li, X.; Song, S. Research on state estimation of oil pipeline considering adaptive extended Kalman filtering. In Proceedings of the International Conference on Mechatronics and Automation, ICMA 2007, Harbin, China, 5–8 August 2007; pp. 1294–1298. [Google Scholar]

- Emara-Shabaik, H.; Khulief, Y.; Hussaini, I. A non-linear multiple-model state estimation scheme for pipeline leak detection and isolation, Proceedings of the Institution of Mechanical Engineers, Part I. J. Syst. Control Eng. 2002, 216, 497–512. [Google Scholar]

- Dos Santos, P.L.; Azevedo-Perdico’ulis, T.; Jank, G.; Ramos, J.; De Carvalho, J.M. Leakage detection and location in gas pipelines through an LPV identification approach. Commun. Nonlinear Sci. Numer. Simul. 2011, 16, 4657–4665. [Google Scholar] [CrossRef]

- Torres, L.; Besançon, G.; Navarro, A.; Begovich, O.; Georges, D. Examples of pipeline monitoring with nonlinear observers and real-data validation. In Proceedings of the 8th International Multi-Conference on Systems, Signals and Devices, Sousse, Tunisia, 22–25 March 2011. [Google Scholar]

- Torres, L.; Verde, C.; Besançon, G.; Gonzalez, O. High-gain observers for leak location in subterranean pipelines of liquefied petroleum gas. Int. J. Robust Nonlinear Control 2014, 24, 1127–1141. [Google Scholar] [CrossRef]

- Negrete, M.A.; Verde, C. Multi-leak reconstruction in pipelines by sliding mode observers. IFAC Proc. Vol. 2012, 45, 934–939. [Google Scholar] [CrossRef]

- Navarro, A.; Begovich, O.; Sanchez-Torres, J.D.; Besançon, G.; Murillo, J.A.P. Leak detection and isolation using an observer based on robust sliding mode differentiators. In Proceedings of the 2012 World Automation Congress (WAC), Puerto Vallarta, Mexico, 24–28 June 2012. [Google Scholar]

- Espinoza-Moreno, G.; Begovich, O.; Sanchez-Torres, J. Real time leak detection and isolation in pipelines: A comparison between sliding mode observer and algebraic steady state method. In Proceedings of the 2014 World Automation Congress (WAC), Waikoloa, HI, USA, 3–7 August 2014. [Google Scholar]

- Carvajal-Rubio, J.; Begovich, O.; Sanchez-Torres, J.D. Real-time leak detection and isolation in plastic pipelines with equivalent control based observers. In Proceedings of the 2015 12th International Conference on Electrical Engineering, Computing Science and Automatic Control (CCE), Mexico City, Mexico, 28–30 October 2015. [Google Scholar]

- Delgado-Aguinaga, J.; Begovich, O.; Besançon, G. Varying-parameter modelling and extended Kalman filtering for reliable leak diagnosis under temperature variations. In Proceedings of the 2016 20th International Conference on System Theory, Control and Computing (ICSTCC), Sinaia, Romania, 13–15 October 2016. [Google Scholar]

- Begovich, O.; Pizano-Moreno, A.; Garc´ıa-Malacara, E.; Besanc, G. How can the temperature affect the performance of a classical pipeline model when plastic pipes are used? In Proceedings of the 2011 8th International Conference on Electrical Engineering Computing Science and Automatic Control (CCE), Merida City, Mexico, 26–28 October 2011. [Google Scholar]

- Dhillon, S.S.; Chakrabarty, K. Sensor placement for effective coverage and surveillance in distributed sensor networks. In Proceedings of the 2003 IEEE Wireless Communications and Networking (WCNC2003), New Orleans, LA, USA, 16–20 March 2003; Volume 3, pp. 1609–1614. [Google Scholar]

- Agajo, J.; Kolo, J.G.; Adegboye, M.; Nuhu, B.; Ajao, L.; Aliyu, I. Experimental performance evaluation and feasibility study of 6lowpan based internet of things. Acta Electrotech. Inform. 2017, 17, 16–22. [Google Scholar] [CrossRef]

- Li, J.; Andrew, L.; Foh, C.; Zukerman, M.; Chen, H.H. Connectivity, coverage and placement in wireless sensor networks. Sensors 2009, 9, 7664–7693. [Google Scholar] [CrossRef] [PubMed]

- Fan, G.; Jin, S. Coverage problem in wireless sensor network: A survey. J. Netw. 2010, 5, 1033–1042. [Google Scholar] [CrossRef]

- Yan-Li, W.A.; Shi-Qan, A.N. Research on the Coverage of Wireless Sensor Network. J. Transcluction Technol. 2005, 2, 25–37. [Google Scholar]

- Boudriga, N.; Hamdi, M.; Iyengar, S. Coverage assessment and target tracking in 3D domains. Sensors 2011, 11, 9904–9927. [Google Scholar] [CrossRef] [PubMed]

- Ammari, H.M.; Das, S.K. Integrated coverage and connectivity in wireless sensor networks: A two-dimensional percolation problem. IEEE Trans. Comput. 2008, 57, 1423–1434. [Google Scholar] [CrossRef]

- Fan, G.; Wang, R.; Huang, H.; Sun, L.; Sha, C. Coverage-guaranteed sensor node deployment strategies for wireless sensor networks. Sensors 2010, 10, 2064–2087. [Google Scholar] [CrossRef] [PubMed]

- Coskun, V. Relocating sensor nodes to maximize cumulative connected coverage in wireless sensor networks. Sensors 2008, 8, 2792–2817. [Google Scholar] [CrossRef]

- Pashazadeh, S.; Sharifi, M. Determining the best sensing coverage for 2-dimensional acoustic target tracking. Sensors 2009, 9, 3405–3436. [Google Scholar] [CrossRef] [PubMed]

- Ab Aziz, N.A.; Mohemmed, A.W.; Alias, M.Y. A wireless sensor network coverage optimization algorithm based on particle swarm optimization and Voronoi diagram. In Proceedings of the 2009 International Conference on Networking, Sensing and Control, Okayama, Japan, 26–29 March 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 602–607. [Google Scholar] [CrossRef]

- Prabhu, S.B.; Sophia, S. A review of energy efficient clustering algorithm for connecting wireless sensor network fields. Int. J. Eng. Res. Technol. 2013, 2, 477–481. [Google Scholar]

- Tian, Y.; Ekici, E. Cross-layer collaborative in-network processing in multihop wireless sensor networks. IEEE Trans. Mob. Comput. 2007, 6, 297–310. [Google Scholar] [CrossRef]

- Anastasi, G.; Conti, M.; Di Francesco, M.; Passarella, A. Energy conservation in wireless sensor networks: A survey. Ad hoc Netw. 2009, 7, 537–568. [Google Scholar] [CrossRef]

- Sabat, A. Remote Monitoring of Pipeline Using Wireless Sensor Network. U.S. Patent 7526994B2, May 2009. [Google Scholar]

- Pullin, R.; Holfod, K.M.; Baxter, M.G. Modal analysis of acoustic emission signals from artificial and fatigue crack sources in aerospace grade steel. Key Eng. Mater. 2005, 293, 217–226. [Google Scholar] [CrossRef]

- Maroti, M.; Kusy, B.; Balogh, G.; Volgyesi, P.; Nadas, A.; Molnar, K.; Dora, S.; Ledezi, A. Radio interferometric geolocation. In Proceedings of the Third International Conference on Embedded Networked Sensor System, Sam Diego, CA, USA, 2–4 November 2005; pp. 1–12. [Google Scholar]

- Himonides, E. Mapping a beautiful voice: The continuous response measurement apparatus (CReMA). J. Music. Educ. 2011, 4, 5–25. [Google Scholar] [CrossRef]

- Henrie, M.; Carpenter, P.; Nicholas, R.E. Pipeline Leak Detection Handbook; Joe Hayton: Chennai, India, 2016; pp. 1–317. [Google Scholar]

- Thor Christian Andvik. Ru-NO Barents Project, Pipelines and Subsea Installations-Report. Available online: https://www.norwep.com/index.php/content/download/21473/141531/version/3/file/Pipelines+&+Subsea+Installations-Report,+20.06.14.pdf (accessed on 12 December 2018).

- Austine, K. Oil and Gas Pipeline Leak Detection Industry—A Growing Business and What This Means to Survey. 22 February 2017. Available online: https://www.hydrographicsociaty.org/documents/hyrographicsociety.org/downloads/ifhs_news_n_o_-_oil_and_gas_pipeline_leak_detection_industry pdf (accessed on 28 February 2019).

| Methods | Principle of Operation | Strengths | Weaknesses |

|---|---|---|---|

| Acoustic Emission | Detect leaks by picking up intrinsic signals escaping from a perforated pipeline. | Easy to install and suitable for early detection, portable and cost-effective. | Sensitive to random and environmental noise, prone to false alarms and not suitable for small leaks. |

| Fibre Optics Sensing | Detect leaks through the identification of temperature changes in the optical property of the cable induced by the presence of leakage. | Insensitive to electromagnetic noise and the optical fibre can act both as sensor and data transmission medium. | The cost of implementation is high, not durable and not applicable for pipelines protected by cathodic protection systems. |

| Vapour Sampling | Utilise hydrocarbon vapour diffused into the sensor tube to detect trace concentrations of specific hydrocarbon compounds. | Suitable for detecting small concentrations of diffused gas. | Time taken to detect a leak is long, not really effective for subsea pipelines. |

| Infrared Thermography | Detect leaks using infrared image techniques for detecting temperature variations in the pipeline environment. | Highly efficient power for transforming detected objects into visual images, easy to use and fast response time. | Quantifying leak orifices smaller than 1.0 mm using IRT-based systems is difficult. |

| Ground Penetration Radar | Utilise electromagnetic waves transmitted into the monitoring object by means of moving an antenna along a surface. | Timely detection of leakage in underground pipelines, reliable and leak information is comprehensive. | GPR signals can easily be distorted in a clay soil environment, costly and require highly skilled operator. |

| Fluorescence | Proportionality between the amount of fluid discharged and rate of light emitted at a different wavelength. | High spatial coverage, quick and easy scanning for leaks. | Medium to be detected must be naturally fluorescent. |

| Electromechanical Impedance | Utilise mechanical impedance changes deduced by the incident of pipeline defect. | A single piezoelectric transducer can serve as both sensor and actuator. | It is only applicable for metal pipelines, operational limitations in high temperature environments. |

| Capacitive Sensing | Measuring changes in the dielectric constant of the medium surrounding the sensor. | It can be employed for detection in non-metallic targets. | Requires direct contact with the leaking medium. |

| Spectral Scanners | Comparing spectral signature against normal background. | Capable of identification of oil type (light/crude) and thickness of the oil slick. | The amount of data generated by a spectral scanner is large which limited its ability to operate in nearly real-time. |

| Lidar Systems | Employed pulsed laser as the illumination source for methane detection. | Able to detect leaks in the absence of temperature variation between the gas and the surroundings. | High cost of execution and false alarm rate. |

| Electromagnetic Reflection | Measure emitted energy at different wavelengths. | It can indicate leak location | It can be affected by severe weather. |

| Methods | Principle of Operation | Strength | Weakness |

|---|---|---|---|

| Mass-volume Balance | Utilises discrepancy between upstream and downstream fluid mass-volume for determining the leakage. | Low cost, portable, straightforward and insensitive to noise interference. | Leak size dependent, not applicable for leak localisation. |

| Negative Pressure Wave | Utilises negative pressure waves propagated due to pressure drops as a result of leakage. | Fast response time and suitable for leak localisation. | Only effective for large instantaneous leaks. |

| Pressure Point Analysis | Monitor pressure variation at different points within the pipeline system. | Appropriate for underwater environments, cold climates and adequately functioning under diverse flow conditions. | Leak detection is challenging in batch processes where valves are opened and closed simultaneously. |

| Digital Signal Processing | Utilises extracted signal features such as amplitude, frequency wavelet transform coefficients, etc. from acquired data. | Good performance, suitable for detecting and locating leak positions. | Easily prone to false alarms, and can be masked by noise. |

| Dynamic Modelling | Detects leaks using the discrepancy between measured data and simulated values based on conservation equations and the equation of state for the fluid. | Applicable for leak detection and localisation, fast and a large amount of data can be handled. | High computational complexity, expensive and labour intensive. |

| State Estimation | Estimates the missing variables using a set of algebraic equations that relates a set of input, output and state variables. | Suitable for reconstruction of the state vector and estimating the missing variable. | The limitations vary based on estimator classes such as poor convergence factors, computational complexity, discarding of uncertainties during simulation etc. |

| Methods | Performance Comparison Metric | |||||

|---|---|---|---|---|---|---|

| System Accuracy | Leak Localisation | Leak Size Estimation | Ease of Usage | Ease of Retrofitting | Operational Mode | |

| Acoustic Emission | High, but sensitive to random noise | Yes | No | Yes | Yes | - |

| Fibre Optic Sensing | High | Yes | Yes | Yes | No | - |

| Vapour Sampling | Depends on sensing tube closeness to spilled gas | No | No | Yes | Yes | - |

| Infrared Thermography | High | Yes | No | Yes | Yes | - |

| Ground Penetration Radar | Low | Yes | No | Yes | Yes | - |

| Fluorescence | Low | No | No | No | Yes | - |

| Capacitive Sensing | Low | No | N | Yes | Yes | - |

| Mass-volume Balance | Low, depends on instrument calibration and leak size | No | Yes | Yes | Yes | Steady state |

| Negative Pressure Wave | Low | Yes | No | Yes | Yes | Steady state |

| Pressure Point Analysis | Low | Yes | Yes | Yes | Yes | Steady state |

| Digital Signal Processing | Depends on leakage size and sensor used | Yes | No | Yes | Yes | Stead state |

| Dynamic Modelling | High, depends on pipeline stability and mathematical model | Yes | Yes | No | Yes | Both steady and transient state |

| Methods | Operating Environment | Sensor Coverage | Hydrocarbon Fluids |

|---|---|---|---|

| Acoustic sensing | All | Local | All |

| Fibre optic sensing | All | Local | All |

| Vapour sampling | Subsea | Local | All |

| Infrared thermography | All | Local | Oil and gas |

| Ground penetration radar | Underground | Local | Water and gas |

| Fluorescence | All | Local | Oil |

| Capacitive sensing | Subsea | Local | All |

| Spectral scanner | Surface | Local | Oil |

| Lidar system | Subsea | Local | All |

| Electromagnetic reflection | Surface | Local | Oil |

| Biological methods | Subsea | Local | All |

| Interior methods | All | Area | All |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adegboye, M.A.; Fung, W.-K.; Karnik, A. Recent Advances in Pipeline Monitoring and Oil Leakage Detection Technologies: Principles and Approaches. Sensors 2019, 19, 2548. https://doi.org/10.3390/s19112548

Adegboye MA, Fung W-K, Karnik A. Recent Advances in Pipeline Monitoring and Oil Leakage Detection Technologies: Principles and Approaches. Sensors. 2019; 19(11):2548. https://doi.org/10.3390/s19112548

Chicago/Turabian StyleAdegboye, Mutiu Adesina, Wai-Keung Fung, and Aditya Karnik. 2019. "Recent Advances in Pipeline Monitoring and Oil Leakage Detection Technologies: Principles and Approaches" Sensors 19, no. 11: 2548. https://doi.org/10.3390/s19112548

APA StyleAdegboye, M. A., Fung, W.-K., & Karnik, A. (2019). Recent Advances in Pipeline Monitoring and Oil Leakage Detection Technologies: Principles and Approaches. Sensors, 19(11), 2548. https://doi.org/10.3390/s19112548