1. Introducing Key Performance Indexes (KPI) for Suspension Systems

Semi-active suspension systems are part of the natural mechatronic evolution of cars. However, many contributions come from other suspension-related field. In fact, their use presents advantages in several different fields ranging from motor vehicle suspension control [

1,

2,

3], to rail vehicles [

4], from airplane landing [

5], to marine vehicles [

6,

7], from vibration control of structures [

8,

9], and in general to any shock absorber process [

10]. Comfort is a primary goal in that controllable damping makes more effective the suspension filtering of the road roughness. It is known that noise and vibrations on board can be substantially reduced by acting on the suspension parameters, such as damping and stiffness. At the same time, when making better comfort performance, something is lost in terms of handling. Softening the suspension has, in fact, potentially negative effects on the tire-road contact forces and on car rolling response. An optimal balance of these opposite performance requirements, needs deep analysis and definition of suitable key performance indicators, as discussed ahead.

This paper considers the solution to the previous technical problem through a semi-active technology, installing on board of a real car, a new integrated sensors-controller-actuators device. The system acquires information on the car response through the deployment of a network of sensors, that produces in this way a primary source of data. These are elaborated by an electronic controller that is based on a very new control algorithm, variational feedback control (VFC), recently proposed theoretically by the authors, and for the first time experimentally implemented as illustrated in the present paper. The controller drives a set of semi-active actuators of magneto-rheological type [

11,

12,

13].

Semi-active control based on VFC was firstly reviewed in [

8,

14,

15,

16,

17] and was introduced in order to increase handling and comfort performance in car suspension. Their control logics were mainly derived by numerical simulations, which optimized some key parameters related to comfort and handling, in order to reduce the acceleration of the car body and increase the contact force exchanged from the tire and the road. In the light of these results, it is the authors’ opinion that VFC control logic is able to provide an excellent tradeoff between antithetical requirements for car dynamics, such as having a comfortable car that is also characterized by a sharp handling: these are almost unique features of the VFC, in respect to others’ control logic [

18,

19,

20].

Concerning the design of a new suspension, its final performances are influenced by several parameters: as an example, in order to maximize comfort, the goal is to limit vertical accelerations transmitted to the car seats, while to enhance the drivability, the tire adhesion to the road should be maximized by the suspension system, guaranteeing, as much as possible, a constant load on the contact patch, minimizing load drops due to road irregularities. In this regard, the suspension stroke is one of the most important parameters to design: the car body acceleration can be indeed easily controlled if large movements of the car body, i.e., of the elastic elements of the suspension, are allowed. By contrast, if the movements of the car body are strictly constrained, for instance by exterior design requirements (limited space requirement from tire and fender), limiting the vertical acceleration becomes a task much more difficult to obtain. Another important parameter of the suspension setup that deserves to be properly designed is the settling time, which however is not explicitly linked to the handling or comfort performances.

In order to deliver a general optimal control of the suspension system, a number of key performance indexes (KPI) are here introduced. Considering pairs of these KPI to be associated with the x and y-axes, they can define special performance planes, where some special regions can be linked to the different existing suspension’s control logic. In this regard, the performance of a new control method can be evaluated by the capability of reaching zones not accessible to the conventional controllers. The introduction of VFC theory and its application to car dynamics is here presented, highlighting how the control law is able to sneak into problematic regions of the performance planes because they are characterized by different and antithetic features of the suspension.

The VFC control logic is suitably tuned through numerical models that emulate both the behavior of the car and the response of variable damping actuators. In the sections below it will be shown how the VFC is carefully tuned with nonlinear dynamic models of half-car, rather than the more usual quarter-car model. This choice is motivated by the fact that the vehicle wants to be studied by observing both, its behavior during longitudinal motion on long road routes and how it behaves during the crossing of bumps or holes. The coupled heave and pitch dynamics allow indeed a more realistic check of the performance of the controlled response and, therefore, permits an in-depth study of the performance of the proposed suspension system. The suspension is indeed required not only to avoid relevant accelerations at the point that is attached to the car body, a task that can be carried out, for example, considering a simpler quarter-car model, but also the quality of control should be evaluated monitoring the motion of the passengers seats, that is influenced by pitch and heave motion of the car body and that is driven by the suspension system of the half-car. In addition, several abilities of the suspension should be taken into account to be confronted with different kinds of excitations: one kind of excitation is the random force induced by a rough road and the capability to filter this kind of excitation is surely a good indicator to classify the job done by the suspension, however this capability of the suspension is also confronted with the bump response, which generally is obtained acting on a completely different type of setting.

In this regard, a number of different parameters (KPI) are identified to be monitored for analyzing the comfort and handling of the vehicle, such as the settling time and maximum acceleration after a speed bump crossing or rather the mean vertical body acceleration and wheel displacement on extra-urban driving cycle. The goal of this publication is indeed the application of the VFC to a real car, i.e., the BMW 1 series, where all the KPI are evaluated. The KPI analyzed are grouped into two categories: time step-response and statistical analysis of which only the most relevant are listed ahead.

A crossing bump simulation is employed to calculate to the former set of indexes:

the largest vertical body acceleration reached by the vehicle;

the variance of the stroke reached by the front and rear suspension, representing the analysis index of the handling of the vehicle;

the settling time required to the suspension for dissipating the involved mechanical energy, which brings the oscillation of the suspension below the threshold value ε.

The second set of indexes are evaluated for extra-urban driving cycle:

the variance of the vertical body acceleration defines the comfort index;

the variance of the stroke reached by the front and rear suspension, representing the analysis index of the handling of the vehicle;

KPI evaluated in the frequency domain are typically filtered within a suitable band-pass, for instance, the KPI related to comfort is generally analyzed between 0–20 Hz, while the KPI related to handling and is analyzed between 0–30 Hz.

The

Figure 1,

Figure 2 and

Figure 3 show some pairs of KPI computed via experimental test: five different simulation benchmarks are analyzed, i.e., the original passive suspension vs, four different control strategies, the Skyhook [

21], and three VFC tuning [

14]. Furthermore, in all planes, there is a dashed curve which represents the technological limit of a passive damper in which the damping factor is constant. This curve was found through a rough interpolation of experimental tests in which the damping coefficient was kept constant between a minimum damping factor

and the maximum

. In this respect, the passive and Skyhook suspensions are generally used as a reference in order to benchmark the performances of other semi-active controls. The indexes-plane is organized to compare two

indexes at once: in each plan, the markers represent the index values reached by each considered control law or by the passive suspension setting, the origin of the axes represents the optimal minimum

. All the quality evaluation diagrams of the different tests in comparison are normalized with appropriate coefficients to present the results at best. In the forthcoming chapter, it is explained how the proposed control logic is fine-tuned to obtain the best KPI explaining the hardware and sensor used and the experimental campaign conducted.

Figure 1 shows the plane for assessing comfort and handling for an extra-urban route, i.e., the

and

plane (the smaller the index, the better the performance). Three different VFC control tunings are compared. The first one called

which is tuned specifically to improve comfort minimizing the vertical accelerations, then we have

which aims to improve road holding and finally an intermediate performance between the previous two,

. These results concern experimental tests on extra-urban routes with average travel speeds between 70–110 km/h. The skyhook has excellent results in optimizing comfort even if the

has the best performance ever. This last setting, however, is very far from the best handling achieved by the

which has handling performance comparable to the original BMW suspension setup slightly improving comfort. The

presents as expected a compromise between the two extremal control logics, being as good as Skyhook concerning comfort, while outperforming it for handling.

Figure 2 and

Figure 3 show the results regarding the passage of the vehicle on the various shapes of a bump at different speeds, as shown below. The plane related to the maximum handling,

, vs. the minimum peak acceleration monitored by the car body,

, is shown in

Figure 2. It is worth pointing out the technological limitation shown by all the control logics that are arranged parallel to the dashed line found with different passive designs. All four controls and in particular the

,

and Skyhook are able to minimize the maximum acceleration very effectively at the cost, however, of worsening the handling, which is comparable to that of the standard setup.

Figure 3 shows the results of the handling versus the settling time of the vertical displacement after crossing the bump. This last diagram is very useful for the comfort analysis because it evaluates, at once, the instantaneous vertical acceleration and also the coupled pitch and heave behavior of the vehicle. As expected,

has the best performance, followed by

. It is worthwhile stressing the separation between the performance provided by the Skyhook setup and

, both exhibit a comparable Handling, while the settling time is much shorter for VFC.

In conclusion, the the strategy represents an excellent compromise of performance and comfort both in terms of an extra-urban road cycle and in mitigating the accelerations and settling times of the vehicle in the presence of road bumps.

2. The Control System and the Sensor Network

The proposed VFC is developed on an experimental platform which is based on Arduino with interfaced commercial sensors and is employed to control magneto-rheological suspensions. The choice to use Arduino is due to two main reasons, the first is the possibility of working on an open source and inexpensive platform to test different control strategies. The second reason is due to the flexibility of the Arduino system, which gives the possibility to expand the number of sensors and their type: the use of redundant sensors can indeed improve the estimation accuracy of the measurement of a vehicle’s dynamic motion, especially in the presence of many sources of disturbance that generally are involved with a car vehicle. The first architecture tested consists of four different types of sensors, i.e., accelerometers, gyroscopes, magnetometers, and potentiometers, linked by an ethernet network employed to connect them to a central control unit. Ethernet communication is important because it guarantees the modularity of the architecture: individual control units can be indeed connected or disconnected without disturbing the transmission speed of the data, thanks to a suitable hardware shield of the communication protocol, which is attainable by the Arduino architecture. An internet protocol (IP) address is assigned to each unit, which is able to communicate with other control platforms in a simple, yet robust, way.

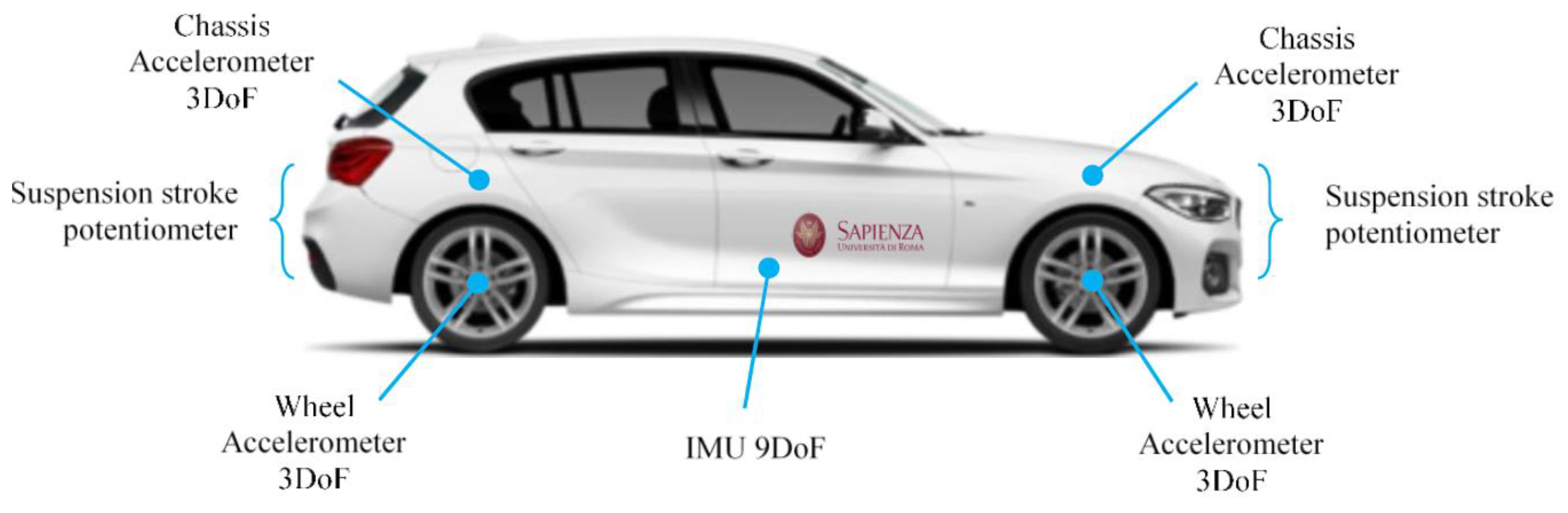

Concerning this architecture, with reference to

Figure 4, four linear potentiometers are employed, one is mounted on each suspension, together with a set of eight triaxial MEMS accelerometers, four of them installed on the wheels and the other four on the car body frame, near the joint of the suspension. The inertial measurement unit (IMU) with nine degrees of freedom, which consists of a three-axis accelerometer, a three-axis gyroscope and a three-axis magnetometer, is installed nearby the center of gravity of the car. The four sensors positioned on the frame have a twofold task, measuring the vertical accelerations near the suspensive attacks, and assisting the estimation of the overall vehicle attitude. In fact, the four 3-D accelerations acquired from the four corners are shared with the IMU to better estimate the pitch and roll of the vehicle.

With reference to

Figure 4 and

Figure 5, the control hardware consists of five platforms of the type “Arduino Due”, which are linked to the mentioned sensors. Four Arduino boards are located at the four sides of the car and they are linked to two accelerometers, placed on the body and on the wheel of the car, and to a potentiometer, in order to record the stroke of the suspension. The fifth Arduino board is integral to the 9DOF (Degrees of Freedom) inertial platform, which makes it rigidly connected the car’s vehicle body. The four controllers arranged on the four sides of the vehicle, measure the data of the accelerometric and potentiometer sensors, have also the task of actively controlling the characteristics of the suspensions and are connected to current generators (see

Figure 6 for more details). The set of Arduino boards, connected by ethernet modules and their switches, are connected to a dedicated PC, which is employed to impart control rules or strategies or simply for the real-time acquisition of the data.

3. Optimal Control Strategy

Recently the Mechatronics and Vehicle Dynamics research group of Sapienza university is working on the autonomous vehicle project and is developing different control strategies deriving from the principle of the optimum [

22,

23,

24]. The VFC is a dynamic compensator that is obtained by the solution of Pontryagin’s minimum principle for nonlinear dynamical systems [

25,

26]. Through the calculation of the variations and with certain assumptions, the Pontryagin open-loop optimum problem can be roughly solved according to the local minimum principle with the possibility of generating a category of purely feedback controls. The novelty of the proposed mathematical model is based on the introduction of a special objective function, together with on certain, weak, assumptions on the form of the dynamic equation of the controlled system.

As a brief resume on optimal control theory, it can be summarized as, given non-linear dynamic system characterized by

, the optimal control

is an algorithm that optimizes, minimizing or maximizing, a certain objective function, which may depend on the state variables

such as on the input

. In symbols, it holds:

on

, which sets the physical constraints of the control variables

. In the maximum case, the Pontryagin solution

specifies the condition:

To fulfill the constraint condition

, the cost function is generally completed employing the Lagrangian multiplier

, which leads to:

The direct application of the Pontryagin technique produces the Euler-Lagrange equations in terms of

,

,

, where

is used for the initial conditions and

for extremal conditions:

For a particular class of objective functions

, where

is the external sources and considering an affine non-linear dynamic system in the state

while is linear in the control

:

the optimal solution (4) leads the explicit feedback control:

The matrices and are the gains of the control to choose which state variable has to be minimized, and are the non-linear component of the dynamic system that has to be controlled, the exponent means a pseudo-inverse matrix.

Using this approach, a new class of variational controls is found, which can be proficiently applied for semi-active and active control systems, as it is discussed in the forthcoming section.

5. Fine Regulations of the Variational Feedback Control (VFC)

The four Arduino boards that govern the four suspensions are used to implement and perform the fine tuning of the VFC control law. With reference to Equation (11), gains within the control equation pay the role of tuning parameters and are not selected a priori, since VFC is employed to control nonlinear systems, therefore a closed form relation between gains and the system response is not generally attainable. In fact, the particular objective function used in the variation method (5) requires minimizing the entire dynamic function in a quadratic form. This request means that the control has a strong coupling between the coefficients of the gain matrices and the dynamics itself. Therefore, a direct correlation between handling/comfort and the gains of the control is not assured and a tuning procedure to regulate the feedback control is needed.

Concerning the tuning of the gains, the vehicle is numerically modeled in order to implement and test the proposed control logic the gains are identified employing a genetic algorithm (GA), that is, a heuristic method of optimizing problems [

35]. Solutions provided by GA to the optimization problems are based on techniques inspired by natural evolution, such as inheritance, mutation, selection, and crossover: the technique employed to find the best values of the gains minimizes an objective function, which are the ideal indicators as introduced at the beginning of the paper. As an example, once the best comfort is required, the control evaluation function that provides the optimal gains is defined ahead:

Thanks to the use of GA, they randomly produce a starting guess for the gains and then runs the simulation of the VFC-controlled model, so that the time history of the acceleration is computed, its variance is evaluated and, finally,

is known. At this point, GA generates a new set of gains, according to how much the

improves or worsens, with specific techniques of the algorithm, as shown in

Figure 14. Convergence or the reaching of the absolute minimum are not guaranteed for GAs, however, they are among the best methods that can proficiently deal with non-linear systems. The control values selected by the GA algorithm are of three types as seen in

Section 1: i) gains are selected to optimize handling in general, ii) gains are selected to improve comfort and iii) an intermediate gain selection which is a compromise between the previous two. The selection of gains has been performed on two types of tracks, a rough road of an extra-urban profile, as per regulation [

36], and a bump speed profile.

Results of the application of GA algorithm are obtained from the simulation of a dynamic half-car model, where the stroke-end of the suspension was also considered since it is a fundamental feature of the suspension behavior that is very important to consider for optimal results in real life applications. The dynamic equations of motion for the half-car model are stated ahead:

where the subscripts,

are for the front and, rear wheel, front and rear tire, body, tire, front and rear, respectively, the coordinate

are for the displacement and its first and second derivatives,

is the weight of the car,

are the wheels masses,

is the momentum of inertia;

is the distance between the centrum gravity and the suspension link;

is the pitch coordinate and

is the road surface;

is the stiffness elastic element and finally

is the variable damping. The last equation

is an algebraic constraint representing the stiffness increase due to the suspension stroke end.

The optimization of the VFC is then followed by the process of identifying the correlation map that exists between the desired damping factor and the actual current injected into the

Magneride suspension. It is interesting to mention that there are studies, such as in [

11], that through the use of sophisticated laboratory equipment, are able to estimate the damping force of the damper through combined feed forward and feedback techniques to estimate the MR damper current for a given desired control force. With this information a mixed feedback-forward control system can be developed. However, in our case, parametric maps of the BWI dampers are not available, and the damping coefficient was estimated in an approximate way using a feed forward method by directly exploiting the experimental vehicle.

Figure 15 shows the block graph related to

map identification technique, where a genetic algorithm identifies the forward and rear damping value by minimizing the difference between simulated and experimental suspensive strokes

. Experimental activities were carried out concerning the crossing of a speed bump at different constant speeds keeping the current of

Magneride constant.

Figure 16 shows how the GA identifies the best damping factor associated with the injected constant current. The experiments led to a linear interpolation between the current and the damping and their ratio increases as the bump crossing speed increases. The higher the maximum compression speed

of the suspension and the greater the damping capacity of the damper for the same current. The map provides the relation between current and damping in function of the compression and rebound speed of the suspension, which in this case is linearly interpolated from the tests carried out in

Figure 16.

6. Experimental Results

The experimental activity is aimed at showing how different gains for the VFC control logic can produce different results both in terms of power spectral density and time domain transient signals of the response. Correspondently, two different suspension responses are analysed in the experimental campaign: (i) statistical evaluation of comfort and handling on extra-urban tracks; (ii) transient response to bump crossing. The results shown are acquired directly acquired from the on-board instrumentation via a central computer.

Figure 17 shows the layout of the control boards for the rear suspension with the wiring, the Ethernet network, and the controlled current amplifiers details.

With reference to the extra-urban road test, the results are summarized in

Figure 1. They summarize several maneuvers, with different road-input, such as bumps, bents, braking, accelerations, random paths on fast roads.

Figure 18 shows the power spectra densities (PSDs) of the vertical acceleration of the car body

obtained for three different control settings of the VFC and for the skyhook control. The purpose of the suspension in this context is to minimize the discomfort of the passengers, which obviously involves a minimization of some measure of the vehicle body motion, by the damping control. The assessment of the best comfort is a subjective opinion as it depends very much on the response of each individual. There are numerous studies in this regard that analyze the response of human subjected to excitations with constant frequencies and are studied how the amplitude and duration of oscillation determines a state of discomfort or not [

37]. As far as the vertical accelerations linked to land transport are concerned, the study of comfort is analyzed in three frequency bandwidths: (i) the low frequency band <1 Hz in which mainly the human suffers from nausea, stomach pain and vomiting; (ii) the band between 1–2 Hz which is generally not associated with motion sickness problems although they may cause impaired skilled performance, inefficiency and fatigue; (iii) and the bandwidth between 2–20 Hz which is associated to fatigue discomfort and bad feeling of the passengers about the car insulation from the road. The latter bandwidth is associated to many natural frequencies of the human internal organs with the exception of the stomach.

Now, analyzing

Figure 18, we can focus on the evaluation of the different controller’s behaviors. The

VFC-comfort setting reduces the vertical accelerations of the vehicle more effectively than the skyhook. The

VFC-mix produces a lower response in the 2–20 Hz frequency bandwidth. Instead, around the first natural frequency of the vehicle, i.e., 2 Hz, the skyhook control shows its lowest value. As far as

VFC handling is concerned, the comfort indicator worsens and decays in the 12–18 Hz bandwidth set by the natural frequency of the wheel, while the

VFC mix has an intermediate trend between the other two.

In order to globally evaluate comfort, it is usual to compare the standard deviations of vertical accelerations in the 0–20 Hz frequency band of the different controllers [

18]. The quality index

evaluated in

Figure 1 is associated with the standard deviation

so calculated:

where

is the PSD of the vehicle vertical acceleration.

Figure 19a shows, in brief, the results of

obtained for the four controls.

Vice versa, the integral of the PSD’s curves shown in

Figure 20, are associated to the statistics of the handling level response. The road holding, i.e., the quality index

, is calculated through the integral of the PSD of the suspension stroke

between 0 and 30 Hz, and the result is summarized in the bar graph shown in

Figure 19b.

Figure 20 shows how the

VFC handling curve is the lowest in absolute terms, which confirms that the

VFC-handling is the lowest

standard deviation. The latter mitigates both the vertical response at the vehicle first natural frequency and at that of the wheel. However, an increase of the

VFC-handling, in the higher frequency response (after 18 Hz) is observed. Vice versa, the

VFC-comfort has the worst trend in the range of the vehicle’s first natural frequency. The remaining two control logics have almost similar trends, and both show the highest oscillation in the 2 Hz frequency range.

The two bar graphs of

Figure 19 summarize the results of

Figure 1 and the

Table 2 shows the gains used by the control logics used in the experimental setup.

The second analysis concerns the passage of the vehicle on speed bump at different speeds (see

Figure 21) to verify the behavior of the suspensions subjected to strong shocks. Many tests were performed with different bump profiles and at different speeds, results are summarized in

Figure 2 and

Figure 3 and in

Figure 22 where the acquired trend of the potentiometers during a passage is reproduced. The subplot on top in

Figure 22 shows the front potentiometer, while the rear one is shown in the subplot on the bottom. Among all four controls, both

VFC handling control and the

VFC mix exhibit good damping and limited settling times, the excursion is indeed the lowest with the

VFC mix followed by

VFC handling, while the

VFC comfort and the

skyhook have the largest excursions. Moreover, the amplified input current in the rear damper is shown in

Figure 23, with a comparison of the different control strategies.