A G-Fresnel Optical Device and Image Processing Based Miniature Spectrometer for Mechanoluminescence Sensor Applications

Abstract

:1. Introduction

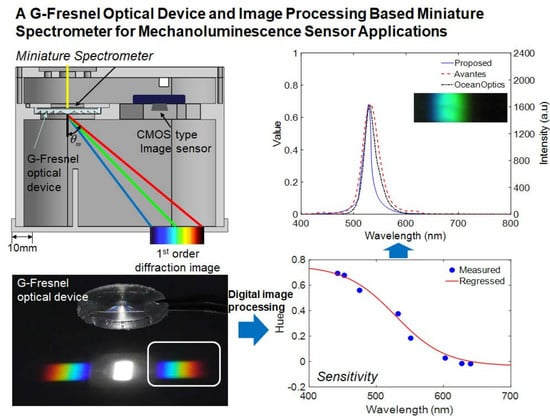

2. G-Fresnel Optical Device and Image Processing Based Miniature Spectrometer

2.1. PDMS-Based G-Fresnel Optical Device

2.2. Design of Miniature Spectrometer

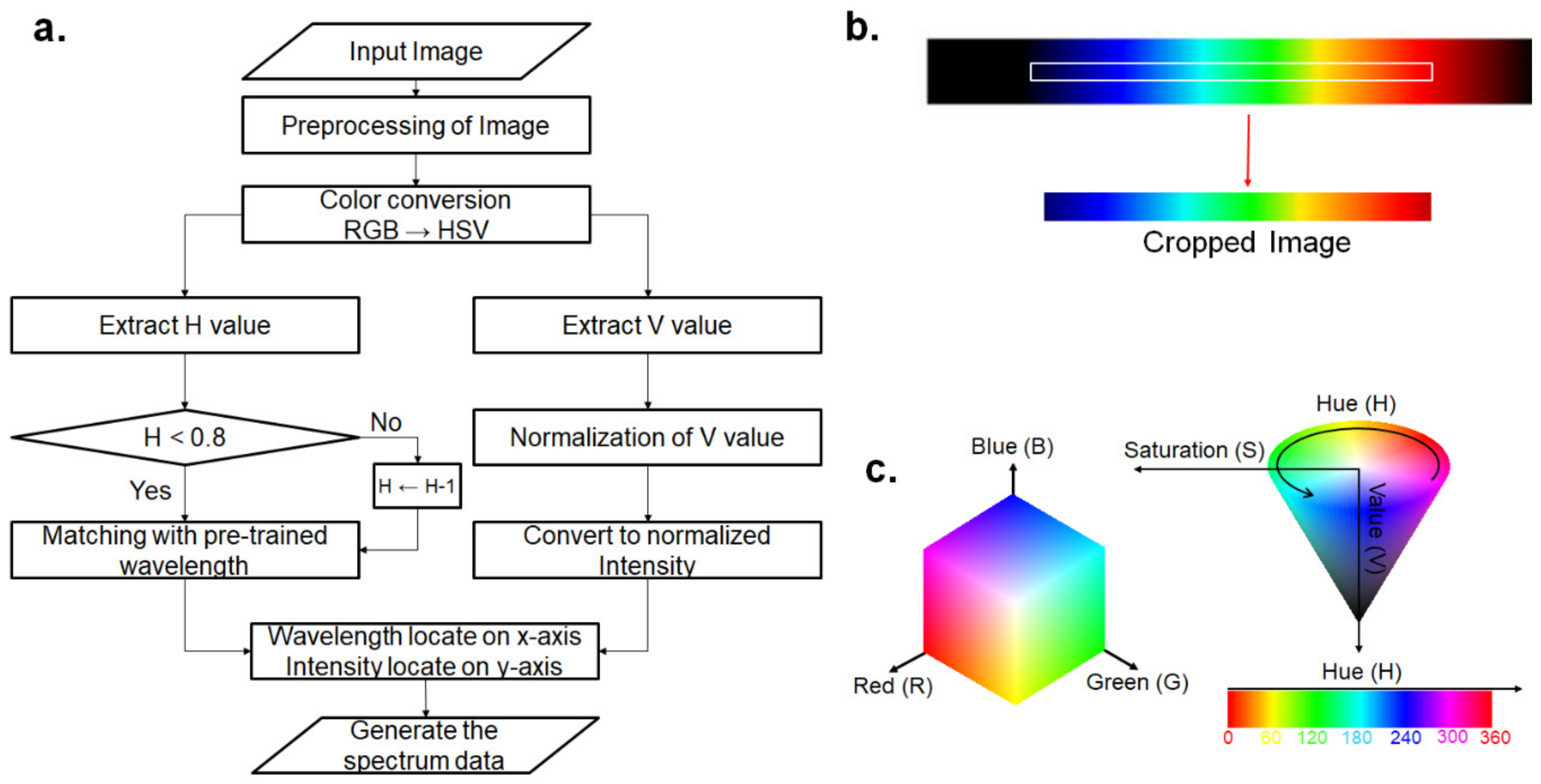

2.3. Digital Image Processing

2.4. Calibration Results

3. Application to Mechanoluminescent Optomechanical Sensors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bashford, C.L.; Harris, D.A. Spectrophotometry & Spectrofiuorimetry: A Practical Approach; IRL Press: Oxford, UK, 1987. [Google Scholar]

- Siegel, P.H. THz Instruments for Space. TAP 2007, 55, 2957–2965. [Google Scholar] [CrossRef]

- Hoper, J.; Gaab, M.R. Effect of Arterial PCO2 on Local HbO2 and Relative Hb Concentration in the Human Brain-a Study with the Erlangen Micro-Lightguide Spectrophotometer (EMPHO). Physiol. Meas. 1994, 15, 107–113. [Google Scholar] [CrossRef] [PubMed]

- Muthukumaran, S.; Gopalakrishnan, R. Structural, FTIR and Photoluminescence Studies of Cu Doped ZnO Nanopowders by Co-Precipitation Method. Opt. Mater. 2012, 34, 1946–1953. [Google Scholar] [CrossRef]

- Pilařová (Vávrů), K.; Kozubíková, P.; Šolc, J.; Spěváček, V. Characteristics of Polyacrylamide Gel with THPC and Turnbull Blue Gel Dosimeters Evaluated using Optical Tomography. Radiat. Phys. Chem. 2014, 104, 283–286. [Google Scholar] [CrossRef]

- Mayevsky, A.; Pewzner, E.; Deutsch, A.; Walden, R.; Heldenberg, E.; Lavee, J.; Tager, S.; Kachel, E.; Raanani, E.; Preisman, S.; et al. Mitochondrial Function and Tissue Vitality: Bench-to-Bedside Real-Time Optical Monitoring System. J. Biomed. Opt. 2011, 16, 067004. [Google Scholar] [CrossRef] [PubMed]

- Antony, S.J.; Sundeep, V.; Thomas, D.T.; Melody, M.A. Continuous pH Monitoring in a Perfused Bioreactor System using an Optical pH Sensor. Biotechnol. Bioeng. 2005, 80, 467–472. [Google Scholar]

- Wang, X.; Peng, D.; Huang, B.; Pan, C.; Wang, L.Z. Piezophotonic effect based on mechanoluminescent materials for advanced flexible optoelectronic applications. Nano Energy 2019, 55, 389–400. [Google Scholar] [CrossRef]

- Peng, D.; Chen, B.; Wang, P. Recent Advances in Doped Mechanoluminescent Phosphors. ChemPlusChem 2015, 80, 1209–1215. [Google Scholar] [CrossRef]

- Timilsina, S.; Kim, J.; Kim, J.; Kim, G. Review of State-of-the-Art Sensor Applications using Mechanoluminescence Microparticles. Int. J. Precis. Eng. Manuf. 2016, 17, 1237–1247. [Google Scholar] [CrossRef]

- Du, Y.; Jiang, Y.; Sun, T.; Zhao, J.; Huang, B.; Peng, D.; Wang, F. Mechanically Excited Multicolor Luminescence in Lanthanide Ions. Adv. Mater. 2019, 31, 1807062. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, J.; Kim, G.-W. A Novel Frequency Selectivity Approach Based on Travelling Wave Propagation in Mechanoluminescence Basilar Membrane for Artificial Cochlea. Sci. Rep. 2018, 8, 12023–12028. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Ma, Y.; Meng, X.; Ji, Y.; Li, A.; Qi, G.; Xu, W.; Zou, B.; Kuang, G.; Jia, X. Pressure Induced the Largest Emission Wavelength Change in a Single Crystal. Dyes Pigment 2019, 162, 136–144. [Google Scholar] [CrossRef]

- Patel, D.; Cohen, B.; Etgar, L.; Magdassi, S. Fully 2D and 3D printed anisotropic mechanoluminescent objects and their application for energy harvesting in the dark. Mater. Horiz. 2018, 5, 708–714. [Google Scholar] [CrossRef]

- Park, Y.; Koch, L.; Song, K.D.; Park, S.; King, G.; Choi, S. Miniaturization of a Fresnel Spectrometer. J. Opt. A Pure Appl. Opt. 2008, 10, 095301. [Google Scholar] [CrossRef]

- Park, Y.; Yoon, H.; Lee, U.; King, G.C.; Choi, S. Mathematical Simulation for Integrated Linear Fresnel Spectrometer Chip. In Nanosensors, Biosensors, and Info-Tech Sensors and Systems; International Society for Optics and Photonics: Bellingham, WA, USA, 2012; p. 8. [Google Scholar]

- Kurokawa, U.; Byung, I.C.; Cheng-Chun, C. Filter-Based Miniature Spectrometers: Spectrum Reconstruction using Adaptive Regularization. JSEN 2011, 11, 1556–1563. [Google Scholar] [CrossRef]

- Huang, E.; Ma, Q.; Liu, Z. Etalon Array Reconstructive Spectrometry. Sci. Rep. 2017, 7, 40693. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vanderveen, J.R.; Martin, B.; Ooms, K.J. Developing Tools for Undergraduate Spectroscopy: An Inexpensive Visible Light Spectrometer. J. Chem. Educ. 2013, 90, 894–899. [Google Scholar] [CrossRef]

- Zhang, C.; Cheng, G.; Edwards, P.; Zhou, M.; Zheng, S.; Liu, Z. G-Fresnel Smartphone Spectrometer. Lab Chip 2016, 16, 246–250. [Google Scholar] [CrossRef] [PubMed]

- Edwards, P.; Zhang, C.; Zhang, B.; Hong, X.; Nagarajan, V.K.; Yu, B.; Liu, Z. Smartphone Based Optical Spectrometer for Diffusive Reflectance Spectroscopic Measurement of Hemoglobin. Sci. Rep. 2017, 7, 12224–12227. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Shi, K.; Edwards, P.; Liu, Z. Demonstration of a PDMS Based Hybrid Grating and Fresnel Lens (G-Fresnel) Device. Opt. Express 2010, 18, 23529. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, X.; Geng, M.; Hu, H.; Ni, K.; Zhong, L.; Yan, P.; Wang, X. Economic Fabrication of a Novel Hybrid Planar Grating/Fresnel Lens for Miniature Spectrometers. Opt. Express 2018, 26, 6079. [Google Scholar] [CrossRef] [PubMed]

- Min, K.; Kang, S.; Kim, G.-W. Development of G-Fresnel lens-based microspectrometer. In Nano-, Bio-, Info-Tech Sensors and 3D Systems III; International Society for Optics and Photonics: Bellingham, WA, USA, 2019. [Google Scholar] [CrossRef]

- Kim, G.-W. Micro Spectrometer System and the Method of Spectroscopic Analysis. Korea Patent Pending No. 10-2019-0059465, 29 May 2019. [Google Scholar]

- Zhang, B.; Cui, M.; Cui, J.; Duan, J. A New Fabrication Method for Nano-Gratings Based on the High Flexibility of PDMS. Opt. Laser Technol. 2017, 92, 206–210. [Google Scholar] [CrossRef]

- Shih, T.; Chen, C.; Ho, J.; Chuang, F. Fabrication of PDMS (Polydimethylsiloxane) Microlens and Diffuser using Replica Molding. Microelectron. Eng. 2006, 83, 2499–2503. [Google Scholar] [CrossRef]

- Schneider, F.; Draheim, J.; Kamberger, R.; Wallrabe, U. Process and Material Properties of Polydimethylsiloxane (PDMS) for Optical MEMS. Sens. Actuators A. Phys. 2009, 151, 95–99. [Google Scholar] [CrossRef]

- Kim, S.; Lee, S.; Ahn, D.; Park, J.Y. PDMS Double Casting Method Enabled by Plasma Treatment and Alcohol Passivation. Sens. Actuators B Chem. 2019, 293, 115–121. [Google Scholar] [CrossRef]

- Yang, C.; Edwards, P.; Shi, K.; Liu, Z. Proposal and Demonstration of a Spectrometer using a Diffractive Optical Element with Dual Dispersion and Focusing Functionality. Opt. Lett. 2011, 36, 2023. [Google Scholar] [CrossRef] [PubMed]

- A Freely Licensed Media from Wikipedia Commons. Available online: https://en.wikipedia.org/wiki/Diffraction_grating (accessed on 1 April 2019).

- Min, K.-P.; Kim, G.-W. Photo-Rheological Fluid-based Colorimetric Ultraviolet Light Intensity Sensor. Sensors 2019, 19, 1128. [Google Scholar] [CrossRef] [PubMed]

- A Freely Licensed Media from Wikipedia Commons. Available online: https://en.wikipedia.org/wiki/Visible_spectrum (accessed on 1 April 2019).

- MathWorks. MATLAB/Image Processing ToolboxTM V7.4. In User’s Guide; The MathWorks: Natick, MA, USA, 2017. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, K.-P.; Kim, J.; Song, K.D.; Kim, G.-W. A G-Fresnel Optical Device and Image Processing Based Miniature Spectrometer for Mechanoluminescence Sensor Applications. Sensors 2019, 19, 3528. https://doi.org/10.3390/s19163528

Min K-P, Kim J, Song KD, Kim G-W. A G-Fresnel Optical Device and Image Processing Based Miniature Spectrometer for Mechanoluminescence Sensor Applications. Sensors. 2019; 19(16):3528. https://doi.org/10.3390/s19163528

Chicago/Turabian StyleMin, Kyung-Pyo, Jaehwan Kim, Kyo D. Song, and Gi-Woo Kim. 2019. "A G-Fresnel Optical Device and Image Processing Based Miniature Spectrometer for Mechanoluminescence Sensor Applications" Sensors 19, no. 16: 3528. https://doi.org/10.3390/s19163528

APA StyleMin, K.-P., Kim, J., Song, K. D., & Kim, G.-W. (2019). A G-Fresnel Optical Device and Image Processing Based Miniature Spectrometer for Mechanoluminescence Sensor Applications. Sensors, 19(16), 3528. https://doi.org/10.3390/s19163528