A Framework for Evaluating Field-Based, High-Throughput Phenotyping Systems: A Meta-Analysis

Abstract

:1. Introduction

2. The Framework and Evaluation Approach

2.1. Defining the System Boundary

2.2. Defining the Elements

2.2.1. Project

2.2.2. Platform

2.2.3. Environment

2.2.4. Data

3. Applying the Framework

3.1. Selection of Case Studies

3.2. Applying the Framework and Results

3.3. Results of Framework Application

3.3.1. Complexity Scoring

3.3.2. Utility Scoring

3.3.3. Total Complexity and Utility Scores

4. Discussion

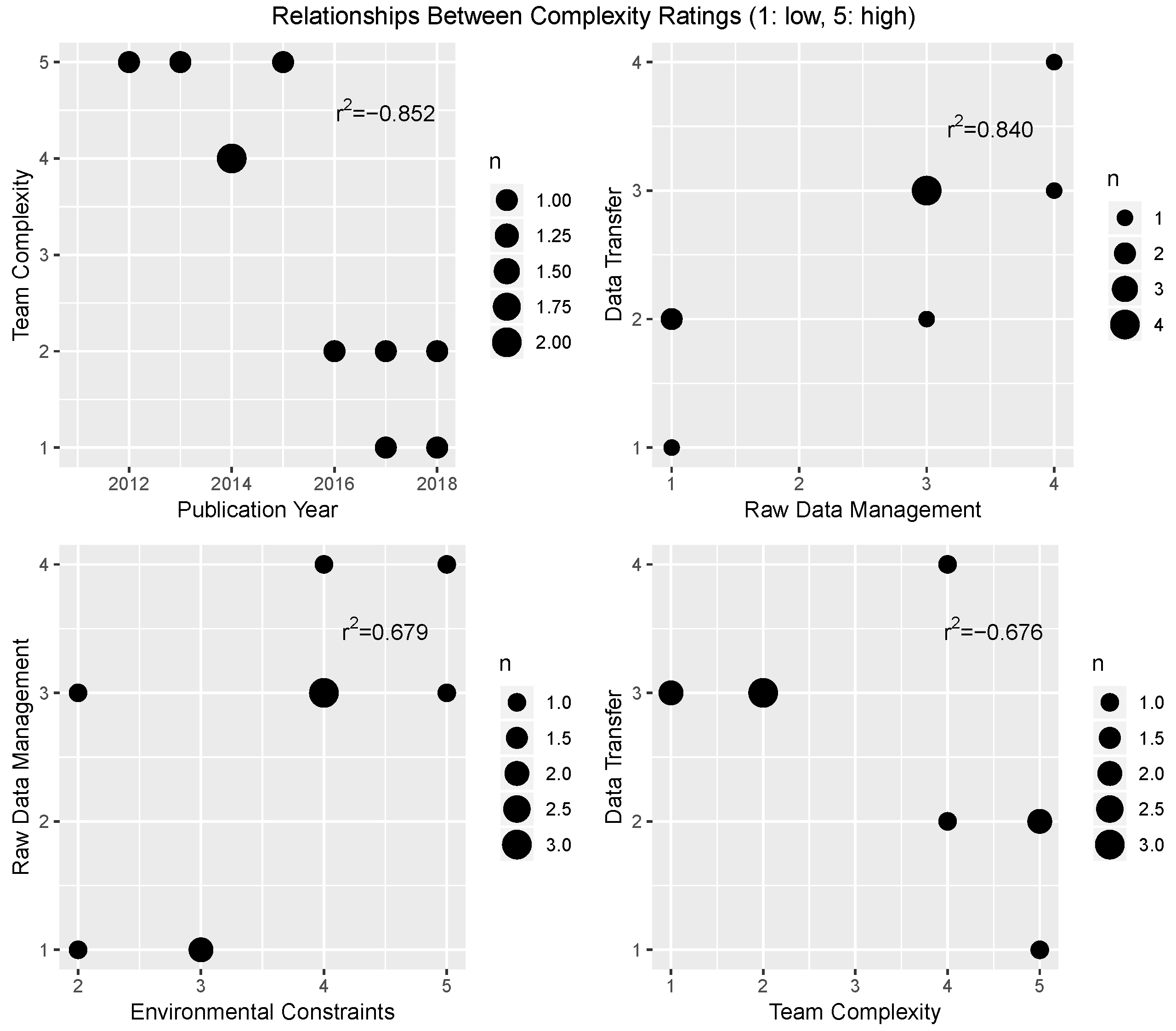

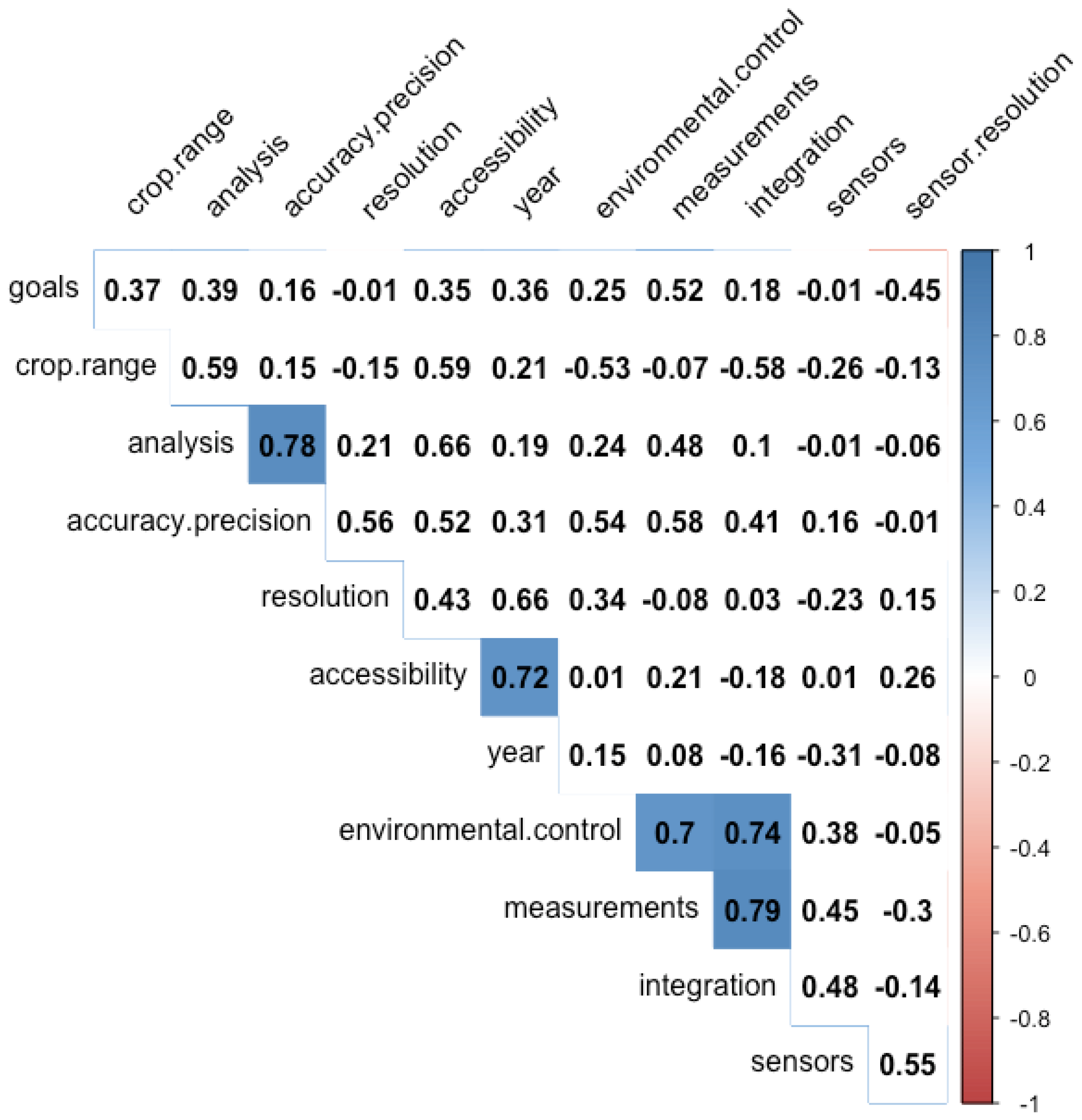

4.1. Observations from Complexity and Utility Rating Data

4.1.1. Observation 1: Lack of Included Information Related to the Data Subsystem

- Large scale. Datasets are on the order of thousands, millions, or even billions of items.

- Unstructured. The data are often heterogeneous and lack coherent structure.

- Multiple sources. The data must be combined and synthesized from several different sources, each with their own data format and possibly without explicit relations.

4.1.2. Observation 2: Inadequate Human-Machine Interaction Technology

4.1.3. Observation 3: Competing Drivers of System Complexity and Utility

5. Conclusions and Future Directions

Future Directions: Shifting Focus from Subsystems and Factors to Their Interfaces

Supplementary Materials

Funding

Acknowledgments

Conflicts of Interest

References

- Roitsch, T.; Cabrera-Bosquet, L.; Fournier, A.; Ghamkhar, K.; Jiménez-Berni, J.; Pinto, F.; Ober, E.S. Review: New sensors and data-driven approaches—A path to next generation phenomics. Plant Sci. 2019, 282, 2–10. [Google Scholar] [CrossRef] [PubMed]

- Araus, J.L.; Kefauver, S.C.; Zaman-Allah, M.; Olsen, M.S.; Cairns, J.E. Translating high-throughput phenotyping into genetic gain. Trends Plant Sci. 2018, 23, 451–466. [Google Scholar] [CrossRef] [PubMed]

- Pauli, D.; Chapman, S.C.; Bart, R.; Topp, C.N.; Lawrence-Dill, C.J.; Poland, J.; Gore, M.A. The quest for understanding phenotypic variation via integrated approaches in the field environment. Plant Physiol. 2016, 172, 622. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Pumphrey, M.O.; Zhou, J.; Zhang, Q.; Sankaran, S. Development of an automated high-throughput phenotyping system for wheat evaluation in a controlled environment. Trans. Am. Soc. Agric. Biol. Eng. 2019, 62, 61–74. [Google Scholar] [CrossRef]

- Boloix, G.; Robillard, P.N. A software system evaluation framework. Computer 1995, 28, 17–26. [Google Scholar] [CrossRef]

- Shackel, B. Usability—Context, framework, definition, design and evaluation. Interact. Comput. 2009, 21, 339–346. [Google Scholar] [CrossRef]

- Moraga, C.; Moraga, M.A.; Calero, C.; Caro, A. SQuaRE-Aligned Data Quality Model for Web Portals. In Proceedings of the 2009 Ninth International Conference on Quality Software, Jeju, Korea, 24–25 August 2009; Volume 84, pp. 117–122. [Google Scholar]

- Parasuraman, A.; Zeithaml, V.A.; Malhotra, A. E-S-QUAL: A Multiple-Item Scale for Assessing Electronic Service Quality. J. Serv. Res. 2005, 7, 213–233. [Google Scholar] [CrossRef]

- Checkland, P. Systems thinking. In Rethinking Management Information Systems; Oxford University Press: London, UK, 1999; pp. 45–56. [Google Scholar]

- Browning, T.R. Applying the design structure matrix to system decomposition and integration problems: A review and new directions. IEEE Trans. Eng. Manag. 2001, 48, 292–306. [Google Scholar] [CrossRef]

- GAPPS. A Framework for Performance Based Competency Standards for Global Level 1 and 2 Project Managers; Report Ver 1.7a; Global Alliance for Project Performance Standards (GAPPS): Sydney, Australia, 2007. [Google Scholar]

- Crawford, L.; Pollack, J. Developing a basis for global reciprocity: Negotiating between the many standards for project management. Int. J. IT Stand. Stand. Res. 2008, 6, 70–84. [Google Scholar] [CrossRef]

- Caldiera, V.R.B.G.; Rombach, H.D. The goal question metric approach. In Encyclopedia of Software Engineering; John Wiley & Sons: DeKalb, IL, USA, 1994; pp. 528–532. [Google Scholar]

- Busemeyer, L.; Mentrup, D.; Möller, K.; Wunder, E.; Alheit, K.; Hahn, V.; Maurer, H.P.; Reif, J.C.; Würschum, T.; Müller, J.; et al. BreedVision—A multi-sensor platform for non-destructive field-based phenotyping in plant breeding. Sensors 2013, 13, 2830–2847. [Google Scholar] [CrossRef]

- Kicherer, A.; Herzog, K.; Pflanz, M.; Wieland, M.; Rüger, P.; Kecke, S.; Kuhlmann, H.; Töpfer, R. An automated field phenotyping pipeline for application in grapevine research. Sensors 2015, 15, 4823–4836. [Google Scholar] [CrossRef]

- Ruckelshausen, A.; Biber, P.; Dorna, M.; Gremmes, H.; Klose, R.; Linz, A.; Rahe, F.; Resch, R.; Theil, M.; Trautz, D.; et al. BoniRob-An autonomous field robot platform for individual plant phenotyping. Precis. Agric. 2009, 9, 841–847. [Google Scholar]

- Bangert, W.; Kielhorn, A.; Rahe, F.; Albert, A.; Biber, P.; Grzonka, S.; Huag, S.; Michaels, A.; Mentrup, D.; Hansel, M.; et al. Field-Robot-Based Agriculture: “RemoteFarming.1” and “BoniRob-Apps”. VDI-Berichte 2013, 2193, 439–446. [Google Scholar]

- Wunder, E.; Kielhorn, A.; Klose, R.; Thiel, M.; Ruckelshausen, A. GIS-and sensor-based technologies for individual plant agriculture. Landtechnik 2012, 67, 37–41. [Google Scholar]

- Chapman, S.C.; Merz, T.; Chan, A.; Jackway, P.; Hrabar, S.; Dreccer, M.F.; Holland, E.; Zheng, B.; Ling, T.J.; Jimenez-Berni, J. Pheno-Copter: A low-altitude, autonomous remote-sensing robotic helicopter for high-throughput field-based phenotyping. Agronomy 2014, 4, 279–301. [Google Scholar] [CrossRef]

- Young, S.N.; Kayacan, E.; Peschel, J.M. Design and field evaluation of a ground robot for high-throughput phenotyping of energy sorghum. Precis. Agric. 2019, 20, 697–722. [Google Scholar] [CrossRef]

- Salas Fernandez, M.G.; Bao, Y.; Tang, L.; Schnable, P.S. A high-throughput, field-based phenotyping technology for tall biomass crops. Plant Physiol. 2017, 174, 2008–2022. [Google Scholar] [CrossRef]

- Andrade-Sanchez, P.; Gore, M.A.; Heun, J.T.; Thorp, K.R.; Carmo-Silva, A.E.; French, A.N.; Salvucci, M.E.; White, J.W. Development and evaluation of a field-based highthroughput phenotyping platform. Funct. Plant Biol. 2014, 41, 68–79. [Google Scholar] [CrossRef]

- Bai, G.; Ge, Y.; Hussain, W.; Baenziger, P.S.; Graef, G. A multi-sensor system for high throughput field phenotyping in soybean and wheat breeding. Comput. Electron. Agric. 2016, 128, 181–192. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Li, C.; Robertson, J.S.; Sun, S.; Xu, R.; Paterson, A.H. GPhenoVision: A ground mobile system with multi-modal imaging for field-based high throughput phenotyping of cotton. Sci. Rep. 2018, 8, 1213. [Google Scholar] [CrossRef]

- Shafiekhani, A.; Kadam, S.; Fritschi, F.B.; DeSouza, G.N. Vinobot and Vinoculer: Two robotic platforms for high-throughput field phenotyping. Sensors 2017, 17, 214. [Google Scholar] [CrossRef]

- Baharav, T.; Bariya, M.; Zakhor, A. Computing height and width of in situ sorghum plants using 2.5d infrared images. In Proceedings of the IS&T International Symposium on Electronic Imaging 2017 Computational Imaging XV, Burlingame, CA, USA, 29 January–2 February 2017; pp. 1–14. [Google Scholar]

- Krajewski, P.; Chen, D.; Cwiek, H.; van Dijk, A.D.; Fiorani, F.; Kersey, P.; Klukas, C.; Lange, M.; Markiewicz, A.; Nap, J.P.; et al. Towards recommendations for metadata and data handling in plant phenotyping. J. Exp. Bot. 2015, 66, 5417–5427. [Google Scholar] [CrossRef] [Green Version]

- Elmqvist, N. Embodied human-data interaction. In Proceedings of the CHI Workshop on Embodied Interaction: Theory and Practice in HCI, Vancouver, BC, Canada, 7–12 May 2011; pp. 104–107. [Google Scholar]

- Salvucci, D.D. Multitasking. In The Oxford Handbook of Cognitive Engineering; Lee, J.D., Kirlik, A., Eds.; Oxford University Press: Oxford, UK, 2013. [Google Scholar]

- Harris, W.C.; Hancock, P.A.; Arthur, E.J.; Caird, J.K. Performance, workload, and fatigue changes associated with automation. Int. J. Aviat. Psychol. 1995, 5, 169–185. [Google Scholar] [CrossRef]

- Parasuraman, R.; Wickens, C.D. Humans: Still vital after all these years of automation. Hum. Factors 2008, 50, 511–520. [Google Scholar] [CrossRef]

- Parasuraman, R.; Sheridan, T.B.; Wickens, C.D. A model for types and levels of human interaction with automation. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2000, 30, 286–297. [Google Scholar] [CrossRef] [Green Version]

- Pimmler, T.U.; Eppinger, S.D. Integration analysis of product decompositions. In Proceedings of the ASME Design Theory and Methodology Conference, Minneapolis, MN, USA, 11–14 September 1994; Sloan, A.P., Ed.; School of Management, Massachusetts Institute of Technology: Minneapolis, MN, USA, 1994. [Google Scholar]

| Factor | Description | Category | ||

|---|---|---|---|---|

| Basic | Intermediate | Advanced | ||

| Complexity | ||||

| Team | The personnel, institutions, and expertise that comprise the team members | Few team members; single-institution; same or related disciplines | Multiple team members; one to two institutions; multidisciplinary teams | Many team members (>10), multiple institutions; diverse teams across many factors (geography, country, discipline) |

| Resources | The equipment (sensors and platforms), land, budget, and human resources available for use in the project | Small plots; minimal equipment; few team members actively participating in data collection | Mid-sized field trails; on-site equipment available; some team members dedicated for phenotyping | Large-scale plots; technically advanced sensors and equipment; many team members involved with data collection operations |

| Utility | ||||

| Goals | The high-level goal of the phenotyping project as stated in the introduction or motivation sections | One-dimensional, highly specific goal | Multi-dimensional, high-level goal(s) | Highly complex, multi-dimensional goal; multiple stated goals |

| Factor | Description | Category | ||

|---|---|---|---|---|

| Basic | Intermediate | Advanced | ||

| Complexity | ||||

| Navigation | The navigation system capabilities of the phenotyping platform | Fully autonomous; little to no human interaction required; human as system monitor | Some autonomous functions; some level of human interaction required | Manual operation; no autonomy; continuous human input required for operation |

| Requirements | Operational requirements that must be met for the system to properly function | Highly flexible operational environments; few to none strict requirements | Moderate operational requirements; some strict, some flexible | Strict set of operating conditions and requirements |

| Basic | Intermediate | Advanced | ||

| Interface | The user interface that controls the system during operation | Expert knowledge of the syste is required to operate using interface, for example, command line or hardware interfacing | Interface is operable with some training, requires some domain knowledge. | Visual Graphic User Interface (GUI) that enables operation by a non-expert |

| Constraints | The environmental and physical constraints for system operation | Can operate in a wide range of environments and settings | Can operate in a few environments and settings | Strict operating constraints and environments |

| Utility | ||||

| Sensors | The number and type of sensors on board used for phenotyping | Few or one sensor on board; independent sensor operation | Few sensors on board; integration of sensors begins to occur | Many sensors on board; full system integration and synchronization required |

| Measurements | The types of phenotypic measurements that the system enables during data collection | One to few measurement types; multiple measurements can come from one sensor | Multiple traits of interest; data from a few sensors may be combined of synthesized | Complex traits of different types (e.g., physical, spectral); measurements are integrated to produce additional metrics |

| Resolution | The resolution of the sensor(s) included in the system | Low-resolution data; point data only; or sensors only capable of collecting plot-level data | Sensors are capable of producing reasonably high resolution data at the plant level | Multiple high-resolution sensors |

| Integration | The ability to add additional sensors to the platform for custom configurations | System was constructed specifically for one or few types of individual sensors; highly application specific | System is not ready for integration with any sensor type, but new sensors can be added with some effort | System was constructed in a modular fashion with flexibility and sensor integration in mind |

| Factor | Description | Category | ||

|---|---|---|---|---|

| Basic | Intermediate | Advanced | ||

| Complexity | ||||

| Configuration | The planting configuration of the crop system, including row spacing, plant height, and field layout | Wide row spacing; low crop density; symmetric and ordered layout | Narrower row spacing; taller crops; more complex layout | Tallest crop height; dense planting; narrow row spacing; complex field layout |

| Structure | The physical characteristics of plant architecture, including aspects that impact measurement | Simple plant morphological structure; few occlusions; high visibility | More complex morphological structure; some occlusions | Complex morphological structure; many occlusions |

| Utility | ||||

| Resolution Range | The range environmental resolution of the phenotypic data | Coarse, plot-level data | Row-level data; aggregate plant-level data | Plant or plant organ data; single plant per genotype |

| Crop Range | The range of crop systems that the platform is capable of operating in | Platform built for and operates in one specific crop | Platform is moderately flexible and can operate in a broad category of crop | System is highly flexible and can operate in a wide range of crops |

| Factor | Description | Category | ||

|---|---|---|---|---|

| Basic | Intermediate | Advanced | ||

| Complexity | ||||

| Raw Data | The methods for storing and organizing the raw data collected from the sensors | Data automatically organized according to date, time, and location | Some organization or metadata recorded automatically, but some manual processing needed | All organization and metadata handling manually required post-data collection |

| Data Transfer | How the data are handled throughout the processing pipeline | Processing on-board with automatic transfer for storage; little to no manual handling | Some manual data handling required; most of the process is automated | Complete manual data transfers required for each step of the pipeline |

| Basic | Intermediate | Advanced | ||

| Processing Automation | The level of autonomy in the data post-processing pipeline, after data transfer from the platform | Fully autonomous post-processing software or techniques used to extract the trait data | Semi-automated or semi-supervised post-processing techniques used for trait extraction | Trait extraction methods were fully manual or required continuous human input |

| Trait Data | The methods for storing and organizing the trait data after computation | Data automatically organized, usually into a database, with accompanying metadata | Some automatic organization and metadata recording, but some manual processing needed | All organization and storage handled manually after computation |

| Utility | ||||

| Analysis | The type of analytical solutions that are made available with the system for post-processing of the data | Basic analysis of traits; raw trait data used without analysis | Some post-processing techniques made for trait extraction; Some detail provided about the analysis methods with reference to softwares used | Ability to extract a wide range of phenotypic traits; Details explanation provided |

| Accessibility | The accessibility and availability of the data processing methods | No code or scripts made available; no reference to software used, or proprietary software used only; no details about the methods provided | Open source software used; methods are standard or available, but specific code used was not provided | Open source software used, and code or scripts used for analysis made available for use |

| Accuracy & Precision | The accuracy and precision of the resulting processed phenotypic data | Relatively low accuracy and precision; no ground-truth procedures performed | Moderate agreement between system measurements and ground truth data | Ground-truth results presented for phenotypic trait analysis, resulting in high accuracy (> 90%) |

| Variability | How the system handles variability in environmental conditions in the resulting data | Environmental variability was not controlled for or measured | Variability in environmental conditions was measured with each sensor measurement | Attempts were made to control environmental variability for all sensor measurements |

| Ref(s) | Author Institutions | Goals | Platform | Crop |

|---|---|---|---|---|

| [14] | Univ. of Applied Sciences Osnabrück (Competence Centre of Applied Agricultural Eng.); Universität Hohenheim (State Plant Breeding Institute, Institute of Agricultural Engineering); AMAZONEN-WERKE H.Dreyer GmbH & Co. KG | To develop a tractor-pulled multi-sensor phenotyping platform for small grain cereals | Tractor-pulled sensor trailer | Small grains and cereals (tested in triticale) |

| [15] | Julius Kühn-Institut, Federal Research Centre of Cultivated Plants; Liebniz Institute for Agricultural Engineering Potsdam-Bornim; University of Bonn, Department of Geodesy; Geisenheim Uni., Dept. of Viticultural Engineering | To develop an automated phenotyping platform to screen for phenotypic traits on a single-plant level in a reasonable time | Autonomous chain vehicle | Grapevines |

| [16,17,18] | Robert Bosch GmbH; University of Applied Sciences Osnabrück; AMAZONEN-WERKE H.Dreyer GmbH & Co. KG | To develop an autonomous field scout robot for phenotyping at the single plant level | Autonomous four-legged rover | A wide range of row crops, including maize |

| [19] | CSIRO Plant Industry and Climate Adaptation Flagship, Computational Informatics, and High Resolution Plant Phenomics Centre | To develop an autonomous platform and a software workflow solution for plot-based data | Autonomous unmanned aerial vehicle | Row crops that require plot-level data (e.g., sorghum, sugarcane) |

| [20] | University of Illinois at Urbana-Champaign (Civil and Environmental Engineering); Iowa State University (Agricultural and Biosystems Engineering); Massachusetts Institute of Technology | To image the plant from both the side and above and enable phenotyping throughout the entire growing season | Portable between-row robot | Energy sorghum |

| [21] | Iowa State University (Agronomy, Agricultural and Biosystems Engineering) | To create a self-propelled platform adaptable to tall crops | Modified tractor system | Tall biomass crops (e.g., sorghum) |

| [22] | University of Arizona (Agricultural and Biosystems Eng.); US Department of Agriculture, Arid-Land Agricultural Research Center; Cornell University (Plant Breeding and Genetics); Rothamsted Research (Plant Biology and Crop Science) | To develop a system that records multiple types of data in a single pass to increase throughput and enable more accurate and comprehensive specification of phenotypes | Proximal sensing cart | Cotton |

| [23] | University of Nebraska-Lincoln (Biological Systems Engineering; Agronomy and Horticulture) | To develop a multi-sensor system to collect high throughput, plot-level trait measurements for plant breeding | Proximal sensing cart | Soybean and wheat |

| [24] | University of Georgia (Electrical and Computer Engineering, Agricultural and Environmental Sciences, Arts and Sciences) | To develop and evaluate a FB-HTP system accommodating high-resolution imagers | Sensing system integrated into a high-clearance tractor | Cotton |

| [25] | University of Missouri (Electrical Engineering and Computer Science, Division of Plant Sciences) | To develop a ground vehicle that measures individual plants coupled with an observation tower that oversees an entire field | Autonomous mobile platform and stationary tower | Maize and sorghum |

| Refs. | [14] | [15] | [16,17,18] | [19] | [20,26] | [21] | [22] | [23] | [24] | [25] |

|---|---|---|---|---|---|---|---|---|---|---|

| Project | ||||||||||

| Team Members | 5 | 5 | 5 | 4 | 1 | 2 | 4 | 2 | 2 | 1 |

| Resources | 4 | 2 | 4 | 4 | 2 | 3 | 3 | 2 | 4 | 5 |

| System | ||||||||||

| System Navigation | 4 | 2 | 2 | 1 | 2 | 2 | 4 | 5 | 4 | 3 |

| Operation Requirements | 3 | 2 | 1 | 4 | 3 | 4 | 2 | 1 | 1 | 2 |

| User Interface | 2 | 1 | 4 | 4 | 5 | 2 | 5 | 1 | 1 | 5 |

| Operation Constraints | 3 | 3 | 2 | 5 | 4 | 4 | 4 | 5 | 2 | 4 |

| Environment | ||||||||||

| Field Configuration | 3 | 2 | 2 | 1 | 4 | 2 | 3 | 2 | 1 | 2 |

| Crop Structure | 3 | 2 | 3 | 2 | 4 | 4 | 1 | 1 | 2 | 3 |

| Data | ||||||||||

| Raw Data Management | 1 | 1 | 1 | 3 | 3 | 3 | 4 | 4 | 3 | 3 |

| Data Handling | 2 | 1 | 2 | 2 | 3 | 3 | 4 | 3 | 3 | 3 |

| Data Processing Automation | 1 | 2 | 3 | 3 | 2 | 3 | 5 | 5 | 1 | 2 |

| Trait Data Management | 2 | 2 | 1 | NA | 1 | NA | NA | 4 | NA | NA |

| Refs. | [14] | [15] | [16,17,18] | [19] | [20,26] | [21] | [22] | [23] | [24] | [25] |

|---|---|---|---|---|---|---|---|---|---|---|

| Project | ||||||||||

| Project Goal | 2 | 1 | 4 | 3 | 3 | 1 | 1 | 4 | 3 | 5 |

| System | ||||||||||

| Sensors | 5 | 2 | 5 | 3 | 2 | 1 | 2 | 2 | 5 | 1 |

| Phenotype Measurements | 4 | 1 | 5 | 2 | 2 | 2 | 2 | 3 | 4 | 3 |

| Sensor Resolution | 3 | 4 | NA | 4 | 3 | 3 | 3 | 2 | 4 | 2 |

| Sensor Integration | 5 | 3 | 5 | 2 | 2 | 2 | 4 | 4 | 5 | 4 |

| Environment | ||||||||||

| Environmental Resolution | 3 | 5 | 5 | 1 | 5 | 4 | 3 | 1 | 5 | 5 |

| Crop Deployment Range | 3 | 1 | 3 | 5 | 4 | 4 | 3 | 3 | 3 | 4 |

| Data | ||||||||||

| Types of Analyses | 4 | 2 | 3 | 4 | 3 | 4 | 2 | 2 | 4 | 5 |

| Analysis and Data Accessibility | 2 | 2 | 1 | 3 | 3 | 3 | 2 | 2 | 4 | 3 |

| Accuracy and Precision | 5 | 3 | NA | 3 | 4 | 4 | 3 | 2 | 5 | 5 |

| Environmental Variability | 5 | 4 | 1 | 1 | 3 | 3 | 1 | 4 | 5 | 4 |

| Type | Description |

|---|---|

| Spatial | Associations of physical space and alignment; needs for adjacency or orientation between two elements |

| Energy | Needs for energy transfer/exchange between two elements |

| Information | Needs for data or signal exchange between two elements |

| Material | Needs for material exchange between two elements |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Young, S.N. A Framework for Evaluating Field-Based, High-Throughput Phenotyping Systems: A Meta-Analysis. Sensors 2019, 19, 3582. https://doi.org/10.3390/s19163582

Young SN. A Framework for Evaluating Field-Based, High-Throughput Phenotyping Systems: A Meta-Analysis. Sensors. 2019; 19(16):3582. https://doi.org/10.3390/s19163582

Chicago/Turabian StyleYoung, Sierra N. 2019. "A Framework for Evaluating Field-Based, High-Throughput Phenotyping Systems: A Meta-Analysis" Sensors 19, no. 16: 3582. https://doi.org/10.3390/s19163582

APA StyleYoung, S. N. (2019). A Framework for Evaluating Field-Based, High-Throughput Phenotyping Systems: A Meta-Analysis. Sensors, 19(16), 3582. https://doi.org/10.3390/s19163582