On the Lateral Instability Analysis of MEMS Comb-Drive Electrostatic Transducers

Abstract

:1. Introduction

2. Analytical Model of a Single Transducer with Translational and Rotational Misalignments

2.1. Device Modeling

2.2. Potential Energy

2.3. Rotational Instability

2.4. Translational Instability

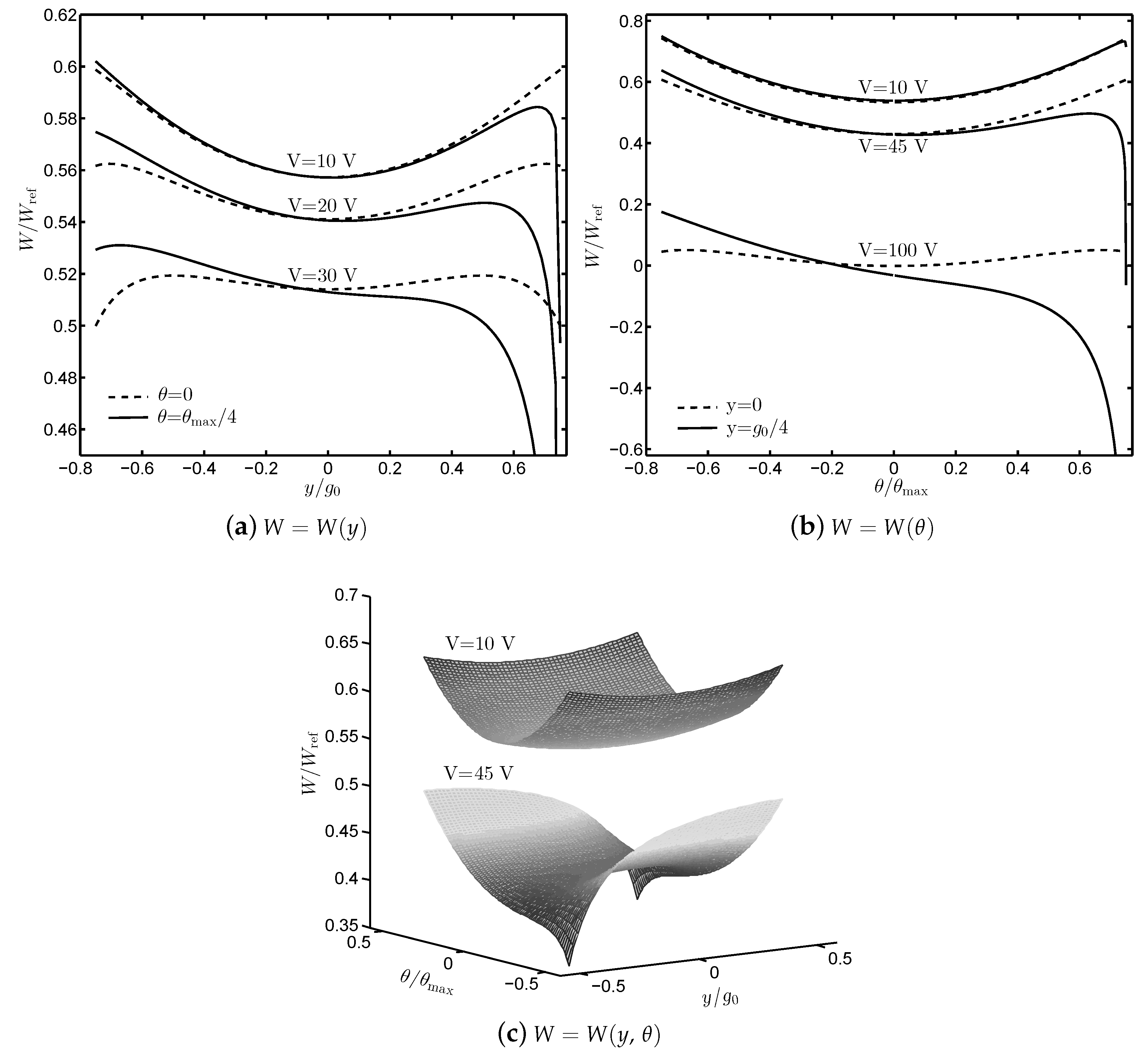

2.5. Lateral Instability Due to a Combination of Translation and Rotation

2.6. Critical Voltage with Translational and Rotational Offsets

3. Analysis of a Comb-Drive Harvesters with Two Anti-Phase Capacitors

3.1. Differential Common Modes

3.2. Bennet’s Doubler Configuration

3.3. Numerical Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. Anti-Phase Operation Mode

Appendix B. Bennet’s Doubler Configuration

References

- Meninger, S.; Mur-Miranda, J.; Amirtharajah, R.; Chandrakasan, A.; Lang, J. Vibration-to-electric energy conversion. IEEE Trans. Very Large Scale Integr. (VLSI) Syst. 2001, 9, 64–76. [Google Scholar] [CrossRef]

- Roundy, S.; Pister, K.S.J.; Wright, P.K. Micro-electrostatic vibration-to-electricity converters. In Proceedings of the IMECE2002, ASME International Mechanical Engineering Congress & Exposition, New Orleans, LA, USA, 17–22 November 2002. [Google Scholar]

- Tang, W.C.; Nguyen, T.-C.H.; Judy, M.W.; Howe, R.T. Electrostatic-comb drive of lateral polysilicon resonators. Sens. Actuators A Phys. 1990, 21, 328–331. [Google Scholar] [CrossRef]

- Adams, S.G.; Bertsch, F.M.; Shaw, K.A.; Hartwell, P.G.; Moon, F.C.; MacDonald, N.C. Capacitance based tunable resonators. J. Micromech. Microeng. 1998, 8, 15. [Google Scholar] [CrossRef]

- Hirano, T.; Furuhata, T.; Gabriel, K.J.; Fujita, H. Design, fabrication, and operation of submicron gap comb-drive microactuators. J. Microelectromech. Syst. 1992, 1, 52–59. [Google Scholar] [CrossRef]

- Jaecklin, V.P.; Linder, C.; de Rooij, N.F.; Moret, J.M. Micromechanical comb actuators with low driving voltage. J. Micromech. Microeng. 1992, 2, 250. [Google Scholar] [CrossRef]

- Truong, B.D.; Le, C.P.; Halvorsen, E. Analysis of electrostatic energy harvesters electrically configured as Bennet’s doublers. IEEE Sens. J. 2017, 17, 5180–5191. [Google Scholar] [CrossRef]

- Truong, B.D.; Le, C.P.; Halvorsen, E. Analysis of MEMS electrostatic energy harvesters electrically configured as voltage multipliers. AEU Int. J. Electron. Commun. 2019, 107, 125–136. [Google Scholar] [CrossRef] [Green Version]

- Nathanson, H.C.; Newell, W.E.; Wickstrom, R.A.; Davis, J.R. The resonant gate transistor. IEEE Trans. Electr. Devices 1967, 14, 117–133. [Google Scholar] [CrossRef]

- Legtenberg, R.; Groeneveld, A.W.; Elwenspoek, M. Comb-drive actuators for large displacements. J. Micromech. Microeng. 1996, 6, 320. [Google Scholar] [CrossRef]

- Zhou, G.; Dowd, P. Tilted folded-beam suspension for extending the stable travel range of comb-drive actuators. J. Micromech. Microeng. 2003, 13, 178. [Google Scholar] [CrossRef]

- Avdeev, I.V.; Lovell, M.R.; Onipede, O., Jr. Modeling in-plane misalignments in lateral combdrive transducers. J. Micromech. Microeng. 2003, 13, 809. [Google Scholar] [CrossRef]

- Huang, W.; Lu, G. Analysis of lateral instability of in-plane comb drive MEMS actuators based on a two-dimensional model. Sens. Actuators A Phys. 2004, 113, 78–85. [Google Scholar] [CrossRef]

- Grade, J.D.; Jerman, H.; Kenny, T.W. Design of large deflection electrostatic actuators. J. Microelectromech. Syst. 2003, 12, 335–343. [Google Scholar] [CrossRef]

- Chen, C.; Lee, C. Design and modeling for comb drive actuator with enlarged static displacement. Sens. Actuators A Phys. 2004, 115, 530–539. [Google Scholar] [CrossRef]

- Olfatnia, M.; Sood, S.; Gorman, J.J.; Awtar, S. Large stroke electrostatic comb-drive actuators enabled by a novel flexure mechanism. J. Microelectromech. Syst. 2013, 22, 483–494. [Google Scholar] [CrossRef]

- Jorge Nocedal, S.W. Numerical Optimization, 2nd ed.; Springer Series in Operations Research; Springer: New York, NY, USA, 2006. [Google Scholar]

- Yu, Y.; Yuan, W.; Sun, R.; Qiao, D.; Yan, B. A strategy to efficiently extend the change rate of period for comb-drive micromechanical pitch-tunable gratings. J. Microelectromech. Syst. 2010, 19, 1180–1185. [Google Scholar] [CrossRef]

- Chang, C.-M.; Wang, S.-Y.; Chen, R.; Yeh, J.A.; Hou, M.T. A comb-drive actuator driven by capacitively- coupled-power. Sensors 2012, 12, 10881–10889. [Google Scholar] [CrossRef] [PubMed]

- Hou, M.T.; Huang, M.-X.; Chang, C.-M. Nested folded-beam suspensions with low longitudinal stiffness for comb-drive actuators. J. Micromech. Microeng. 2014, 24, 125022. [Google Scholar] [CrossRef]

- Truong, B.D.; Le, C.P.; Halvorsen, E. Theoretical analysis of electrostatic energy harvester configured as Bennet’s doubler based on Q-V cycles. arXiv 2017, arXiv:1709.08754. [Google Scholar]

- Younis, M.I. Introduction to Nonlinear Dynamics; Springer: Boston, MA, USA, 2011; pp. 155–249. [Google Scholar]

- Elata, D.; Bamberger, H. On the dynamic pull-in of electrostatic actuators with multiple degrees of freedom and multiple voltage sources. J. Microelectromech. Syst. 2006, 15, 131–140. [Google Scholar] [CrossRef]

- De Queiroz, A.C.M.; Domingues, M. Electrostatic energy harvesting using doublers of electricity. In Proceedings of the 2011 IEEE 54th International Midwest Symposium on Circuits and Systems (MWSCAS), Seoul, Korea, 7–10 August 2011; pp. 1–4. [Google Scholar]

| Parameters | Value |

|---|---|

| Nominal capacitance, | 12.27 pF |

| Device thickness, t | 25 m |

| Finger length, L | 222 m |

| Initial gap, | 2 m |

| Nominal overlap, | 110 m |

| Spring length, | 1500 m |

| Spring width, | 16 m |

| Beam distance, () | 200 (90) m |

| Maximum displacement, | 110 m |

| Young’s modulus, E | 169 GPa |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Truong, B.D.; Le, C.P.; Halvorsen, E. On the Lateral Instability Analysis of MEMS Comb-Drive Electrostatic Transducers. Sensors 2019, 19, 3770. https://doi.org/10.3390/s19173770

Truong BD, Le CP, Halvorsen E. On the Lateral Instability Analysis of MEMS Comb-Drive Electrostatic Transducers. Sensors. 2019; 19(17):3770. https://doi.org/10.3390/s19173770

Chicago/Turabian StyleTruong, Binh Duc, Cuong Phu Le, and Einar Halvorsen. 2019. "On the Lateral Instability Analysis of MEMS Comb-Drive Electrostatic Transducers" Sensors 19, no. 17: 3770. https://doi.org/10.3390/s19173770

APA StyleTruong, B. D., Le, C. P., & Halvorsen, E. (2019). On the Lateral Instability Analysis of MEMS Comb-Drive Electrostatic Transducers. Sensors, 19(17), 3770. https://doi.org/10.3390/s19173770