Analysis of Graphene Antenna Properties for 5G Applications

Abstract

:1. Introduction

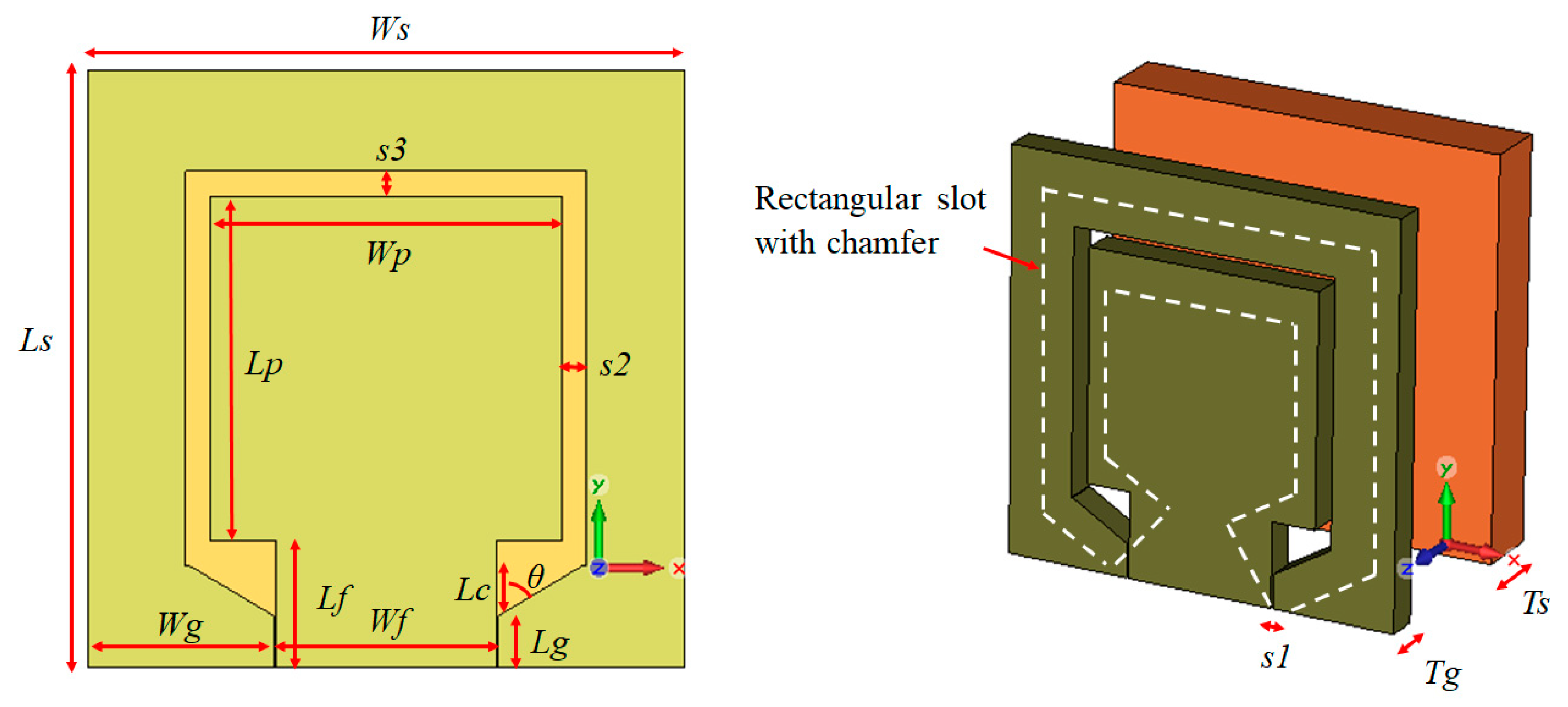

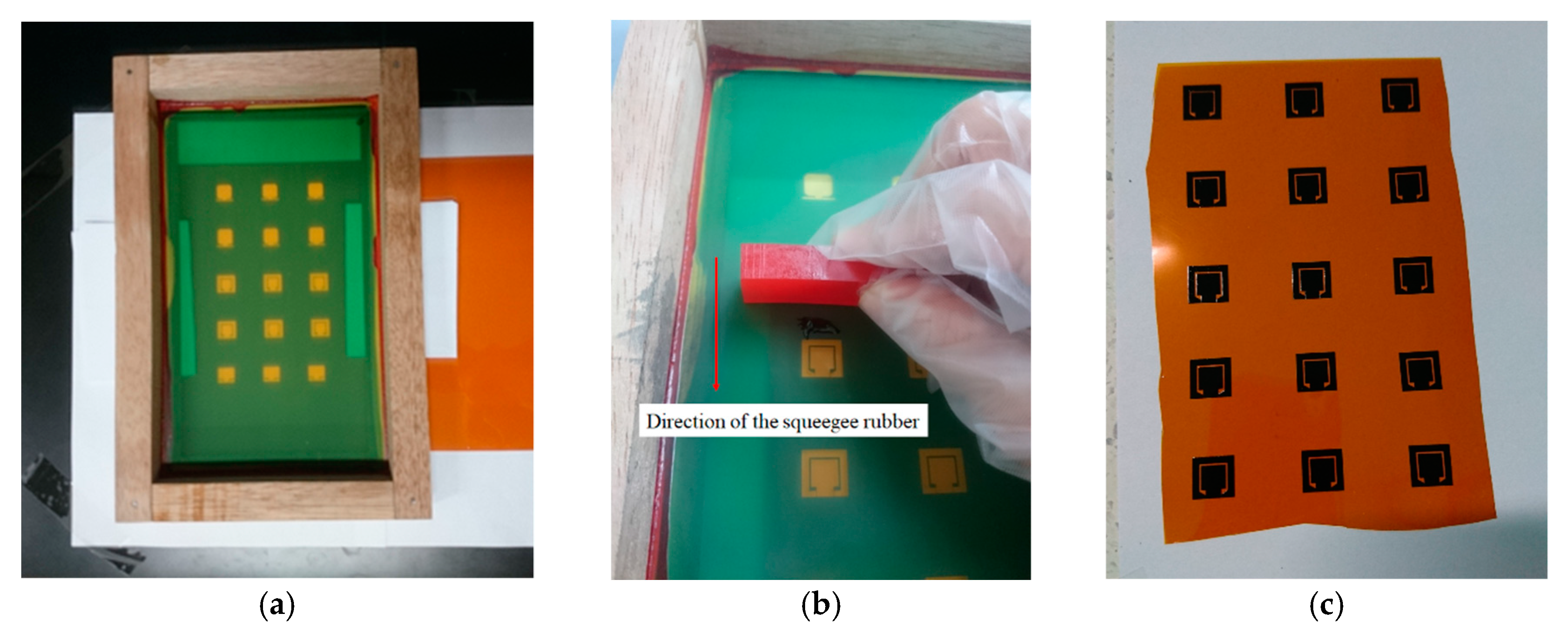

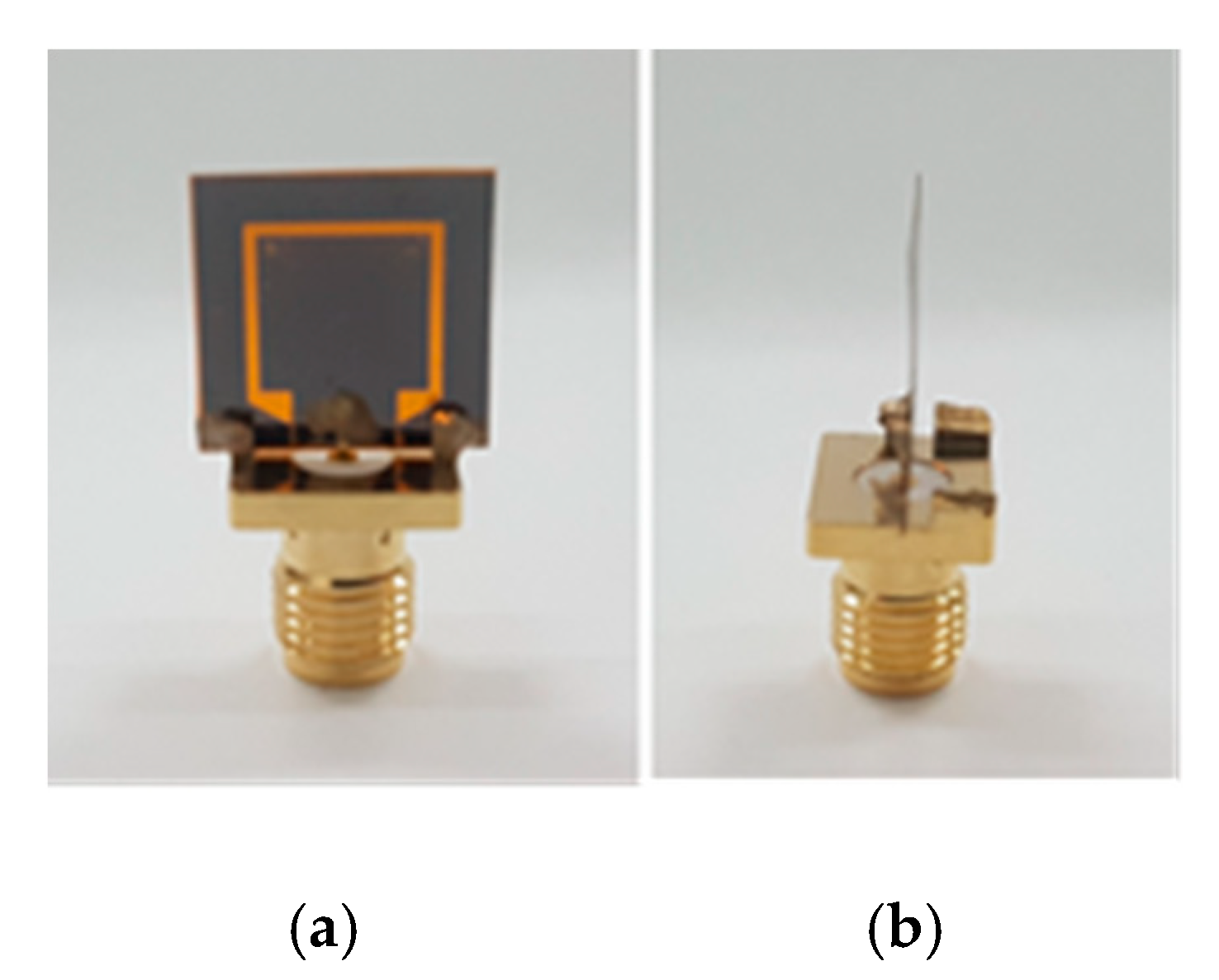

2. Single Graphene Antenna

2.1. Antenna Design

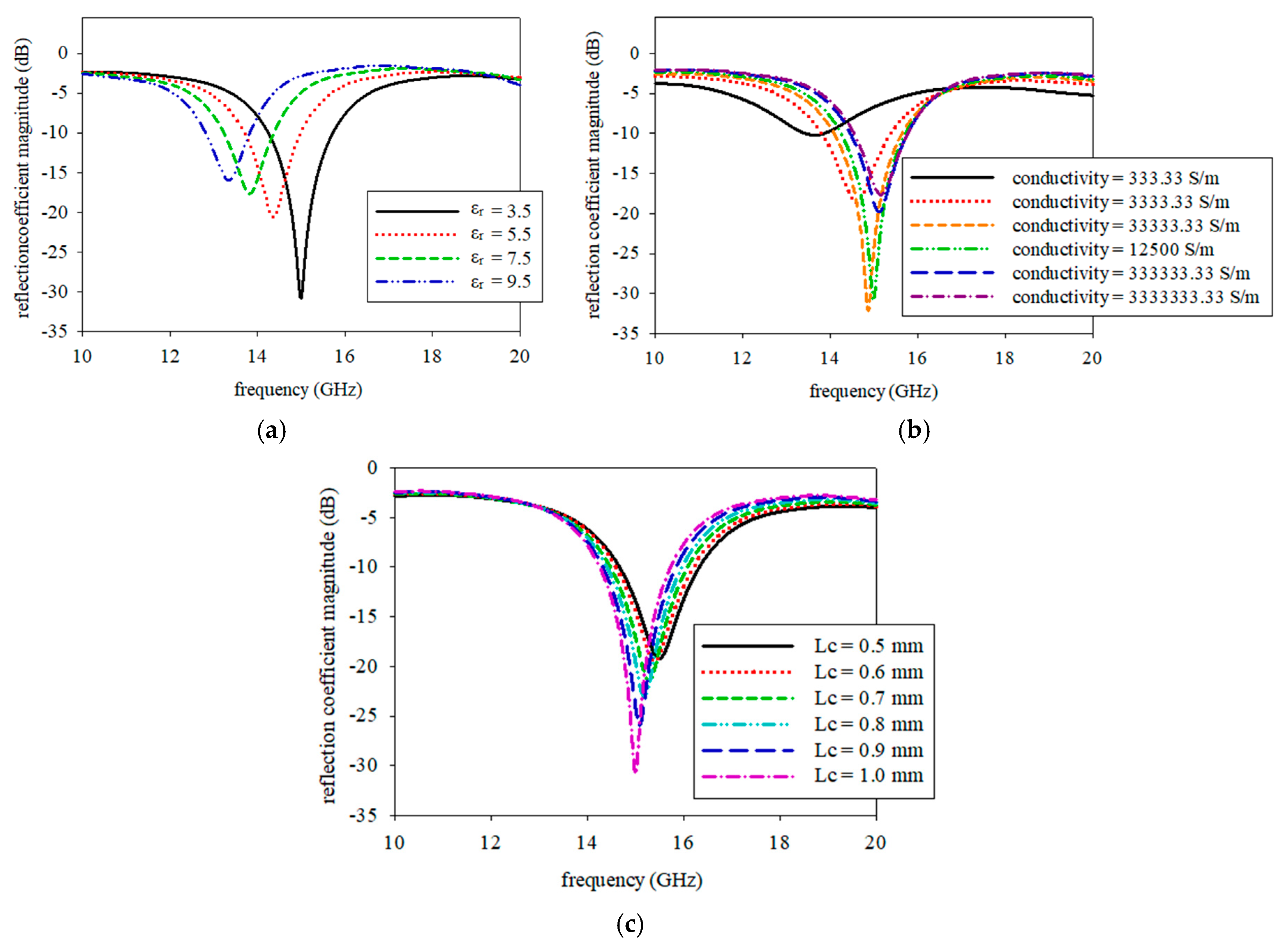

2.2. Parametric Studies

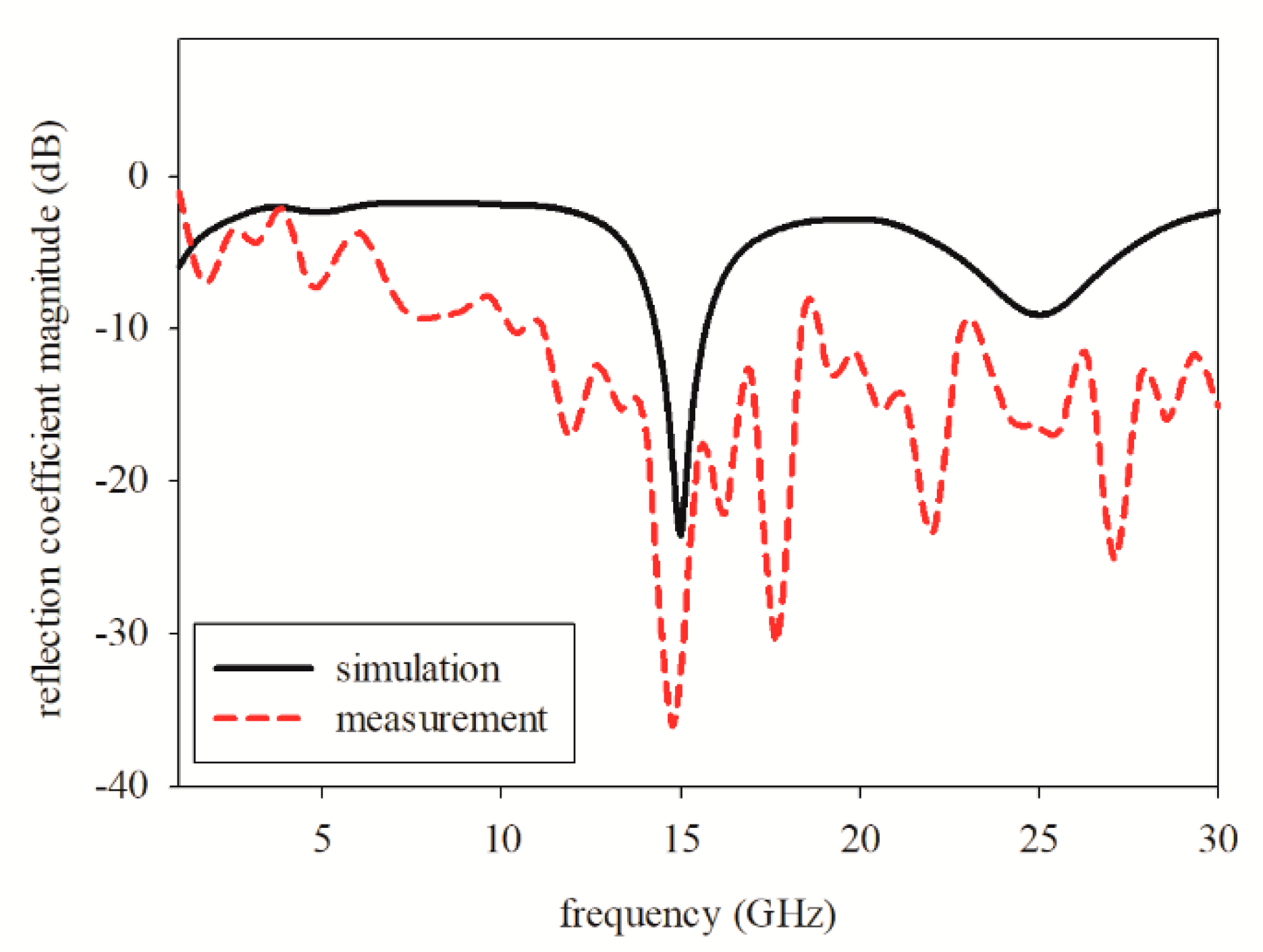

2.3. Results

3. Antenna Array

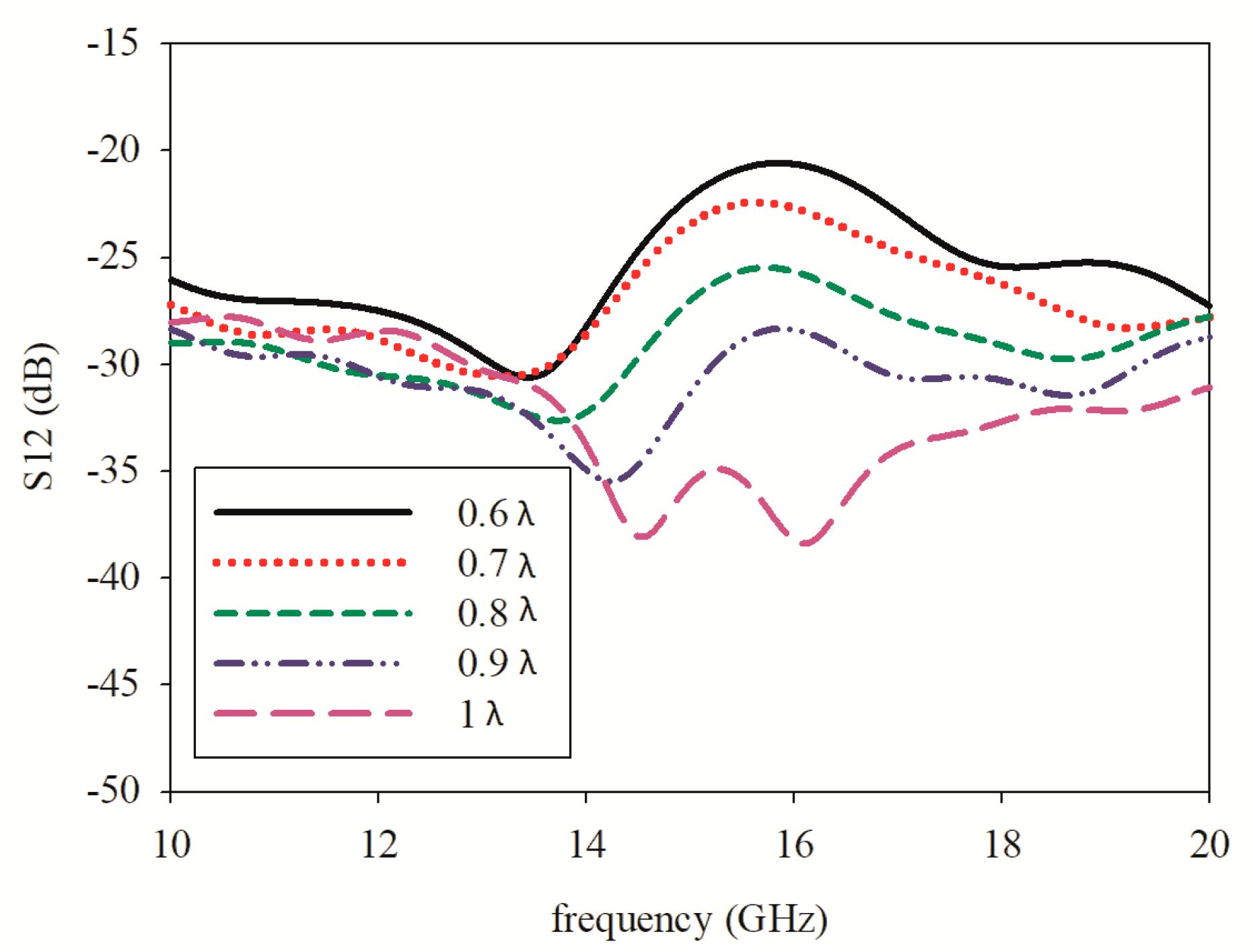

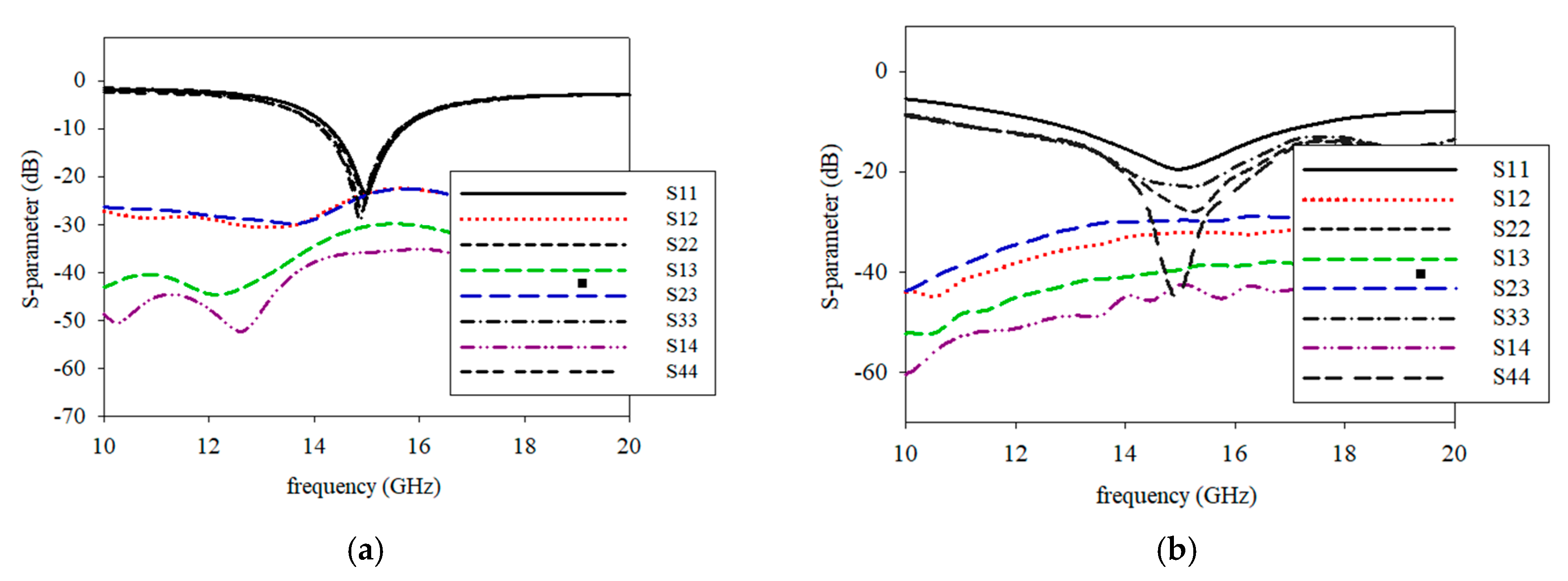

3.1. Mutual Coupling Reduction

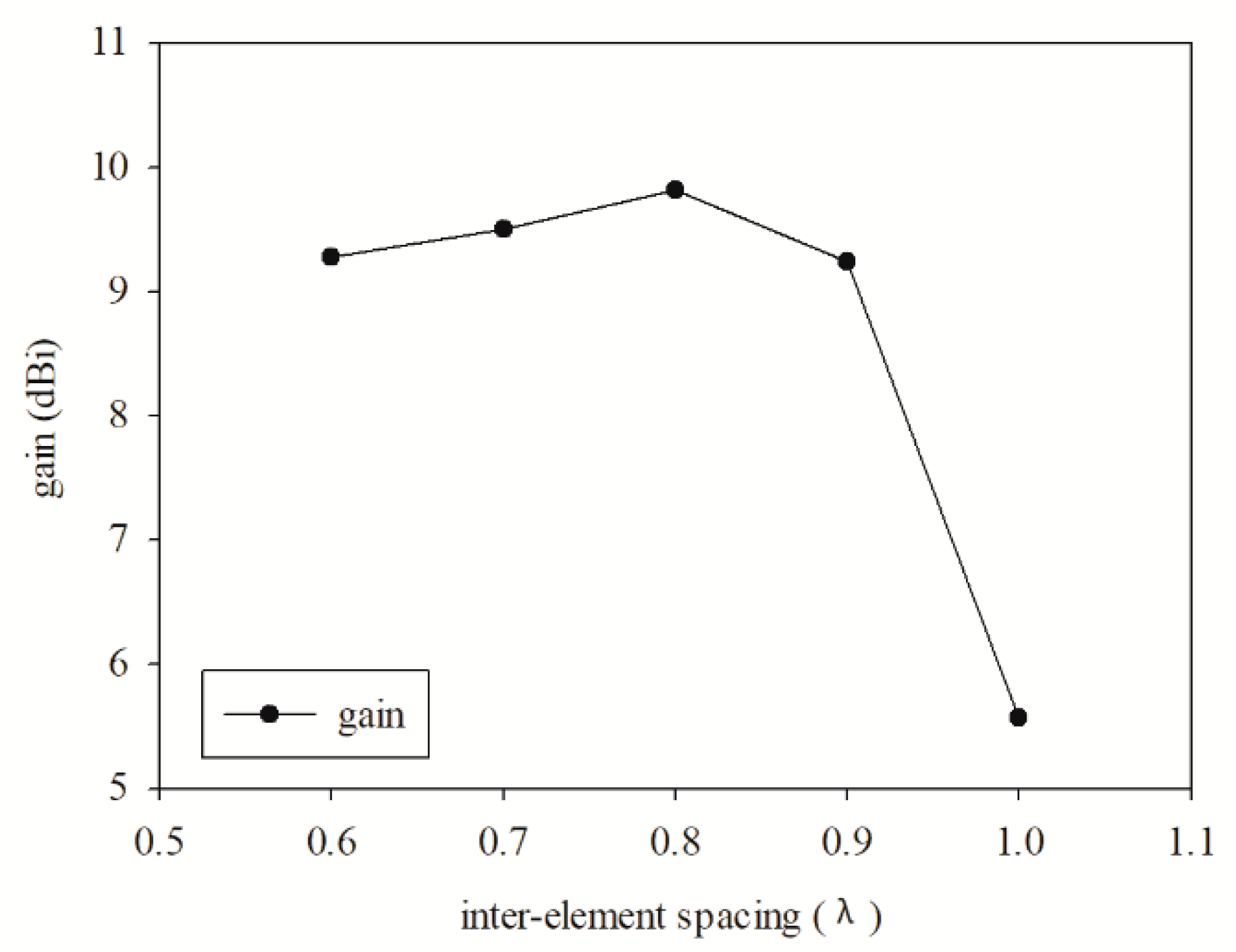

3.2. Inter-Element Spacing

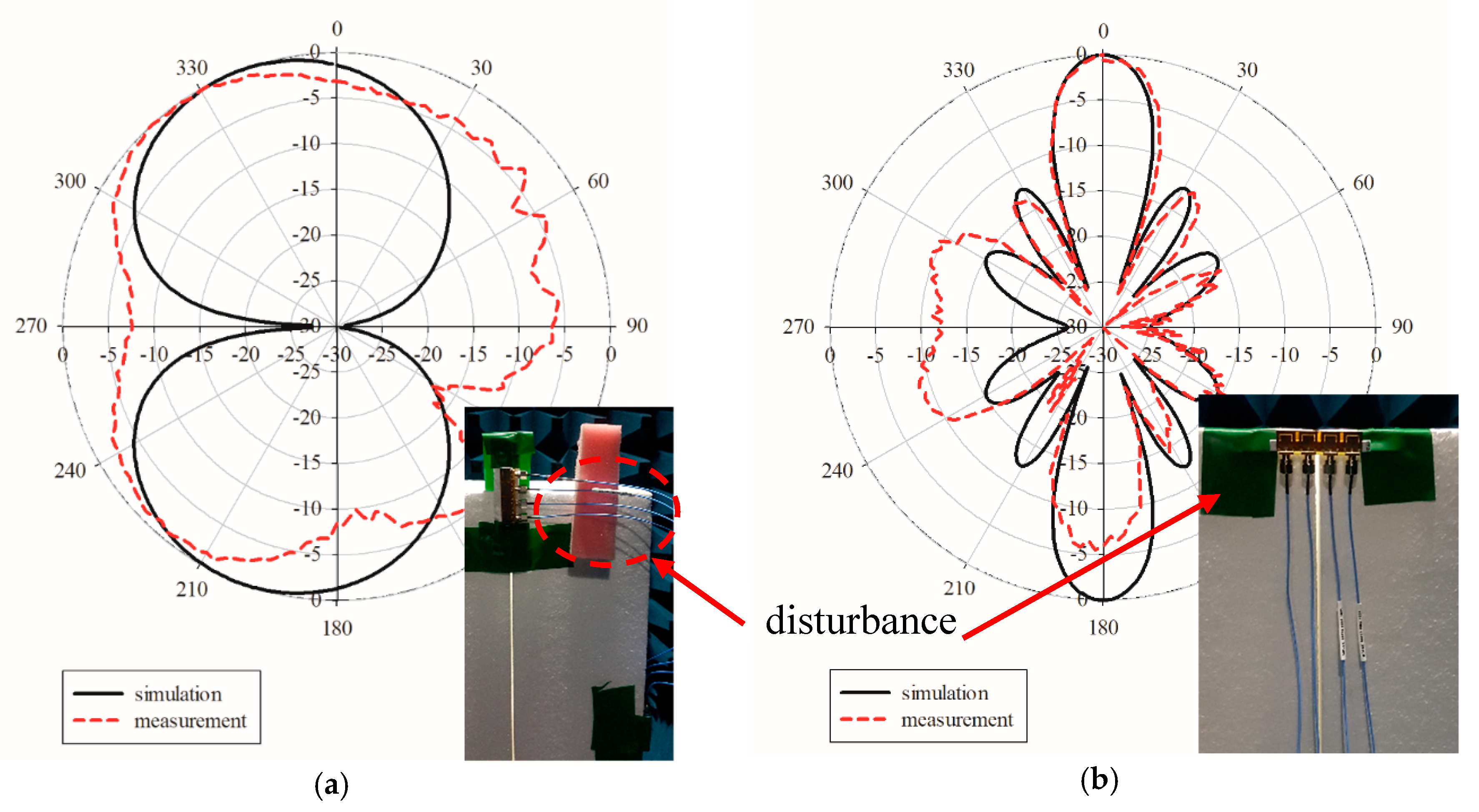

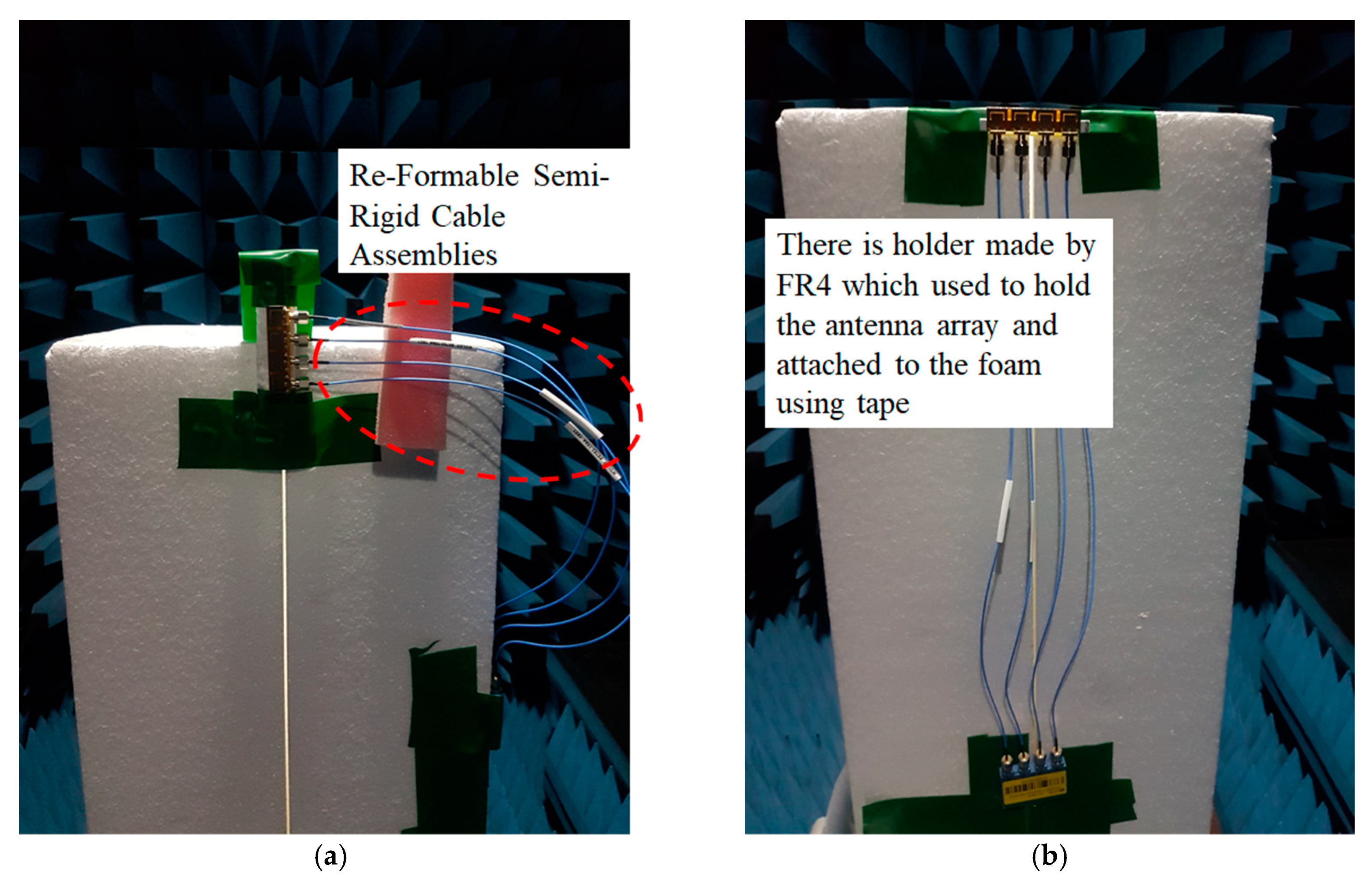

3.3. Results

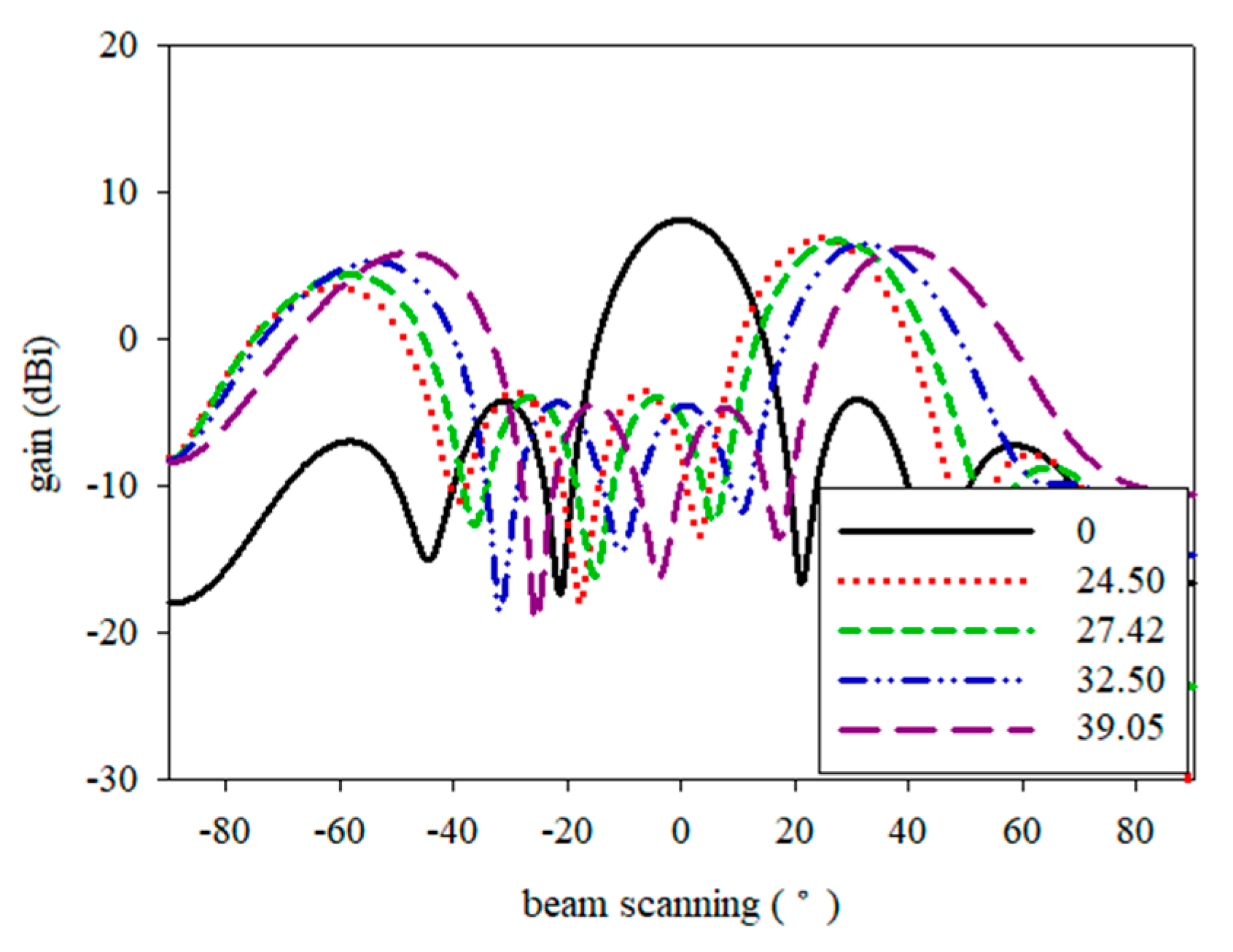

3.4. Scanning Performance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Shafi, M.; Molisch, A.F.; Smith, P.J.; Haustein, T.; Zhu, P.; De Silva, P.; Tufvesson, F.; Benjebbour, A.; Wunder, G. 5G: A Tutorial Overview of Standards, Trials, Challenges, Deployment, and Practice. IEEE J. Sel. Areas Commun. 2017, 35, 1201–1221. [Google Scholar] [CrossRef]

- Wang, C.-X.; Haider, F.; Gao, X.; You, X.-H.; Yang, Y.; Yuan, D.; Aggoune, H.; Haas, H.; Fletcher, S.; Hepsaydir, E. Cellular architecture and key technologies for 5G wireless communication networks. IEEE Commun. Mag. 2014, 52, 122–130. [Google Scholar] [CrossRef]

- Chen, S.; Zhao, J. The requirements, challenges, and technologies for 5G of terrestrial mobile telecommunication. IEEE Commun. Mag. 2014, 52, 36–43. [Google Scholar] [CrossRef]

- Rappaport, T.S.; Sun, S.; Mayzus, R.; Zhao, H.; Azar, Y.; Wang, K.; Wong, G.N.; Schulz, J.K.; Samimi, M.; Gutierrez, F. Millimeter Wave Mobile Communications for 5G Cellular: It Will Work! IEEE Access 2013, 1, 335–349. [Google Scholar] [CrossRef]

- Boccardi, F.; Heath, R.W.; Lozano, A.; Marzetta, T.L.; Popovski, P. Five disruptive technology directions for 5G. IEEE Commun. Mag. 2014, 52, 74–80. [Google Scholar] [CrossRef] [Green Version]

- Haraz, O.M. Broadband and 28/38-GHz Dual-Band Printed Monopole/Elliptical Slot Ring Antennas for the Future 5G Cellular Communications. J. Infrared Millim. Terahertz Waves 2016, 37, 308–317. [Google Scholar] [CrossRef]

- Li, Y.; Wang, C.; Yuan, H.; Liu, N.; Zhao, H.; Li, X. A 5G MIMO Antenna Manufactured by 3-D Printing Method. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 657–660. [Google Scholar] [CrossRef]

- Syrytsin, I.; Zhang, S.; Pedersen, G.F. User Impact on Phased and Switch Diversity Arrays in 5G Mobile Terminals. IEEE Access 2017, 6, 1616–1623. [Google Scholar] [CrossRef]

- Jilani, S.F.; Munoz, M.O.; Abbasi, Q.H.; Alomainy, A. Millimeter-Wave Liquid Crystal Polymer Based Conformal Antenna Array for 5G Applications. IEEE Antennas Wirel. Propag. Lett. 2019, 18, 84–88. [Google Scholar] [CrossRef]

- Ofcom. Spectrum Above 6 GHz for Future Mobile Communications. 2015. Available online: https://www.ofcom.org.uk/consultations-and-statements/category-2/above-6ghz (accessed on 3 June 2015).

- Mattisson, S. An Overview of 5G Requirements and Future Wireless Networks: Accommodating Scaling Technology. IEEE Solid State Circuits Mag. 2018, 10, 54–60. [Google Scholar] [CrossRef]

- Bleicher, A. The 5G phone future [News]. IEEE Spectr. 2013, 50, 15–16. [Google Scholar] [CrossRef]

- Dehos, C.; González, J.L.; De Domenico, A.; Kténas, D.; Dussopt, L. Millimeter-wave access and backhauling: The solution to the exponential data traffic increase in 5G mobile communications systems? IEEE Commun. Mag. 2014, 52, 88–95. [Google Scholar] [CrossRef]

- Gupta, A.; Jha, R.K. A Survey of 5G Network: Architecture and Emerging Technologies. IEEE Access 2015, 3, 1206–1232. [Google Scholar] [CrossRef]

- Chandrasekhar, V.; Andrews, J.; Gatherer, A. Femtocell networks: A survey. IEEE Commun. Mag. 2008, 46, 59–67. [Google Scholar] [CrossRef]

- Hong, W.; Baek, K.-H.; Lee, Y.; Kim, Y.; Ko, S.-T. Study and prototyping of practically large-scale mmWave antenna systems for 5G cellular devices. IEEE Commun. Mag. 2014, 52, 63–69. [Google Scholar] [CrossRef]

- Liao, L.; Duan, X. Graphene for radio frequency electronics. Mater. Today 2012, 15, 328–338. [Google Scholar] [CrossRef]

- Ta, S.X.; Choo, H.; Park, I. Broadband Printed-Dipole Antenna and Its Arrays for 5G Applications. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 2183–2186. [Google Scholar] [CrossRef]

- Mao, C.-X.; Gao, S.; Wang, Y. Broadband High-Gain Beam-Scanning Antenna Array for Millimeter-Wave Applications. IEEE Trans. Antennas Propag. 2017, 65, 4864–4868. [Google Scholar] [CrossRef]

- Dadgarpour, A.; Sorkherizi, M.S.; Kishk, A.A. Wideband, Low-loss Magneto-Electric Dipole Antenna for 5G Wireless Network with Gain Enhancement Using Meta Lens and Gap Waveguide Technology Feeding. IEEE Trans. Antennas Propag. 2016, 64, 5094–5101. [Google Scholar] [CrossRef]

- Abu Diawuo, H.; Jung, Y.-B. Broadband Proximity-Coupled Microstrip Planar Antenna Array for 5G Cellular Applications. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 1286–1290. [Google Scholar] [CrossRef]

- Li, X.; Xiao, J.; Qi, Z.; Zhu, H. Broadband and High-Gain SIW-Fed Antenna Array for 5G Applications. IEEE Access 2018, 6, 56282–56289. [Google Scholar] [CrossRef]

- Array, L.P.; With, A.; Stacked, C. Wideband, Low-Profile Patch Array Antenna with Corporate Stacked Microstrip and Substrate Integrated Waveguide Feeding Structure. IEEE Trans. Antennas Propag. 2019, 67, 1368–1373. [Google Scholar]

- Chu, Q.-X.; Li, X.-R.; Ye, M. High-Gain Printed Log-Periodic Dipole Array Antenna with Parasitic Cell for 5G Communication. IEEE Trans. Antennas Propag. 2017, 65, 6338–6344. [Google Scholar] [CrossRef]

- Kim, E.; Ko, S.-T.; Lee, Y.J.; Oh, J. Millimeter-Wave Tiny Lens Antenna Employing U-Shaped Filter Arrays for 5G. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 845–848. [Google Scholar] [CrossRef]

- Liu, H.; Yang, W.; Zhang, A.; Zhu, S.; Wang, Z.; Huang, T. A Miniaturized Gain-Enhanced Antipodal Vivaldi Antenna and Its Array for 5G Communication Applications. IEEE Access 2018, 6, 76282–76288. [Google Scholar] [CrossRef]

- Haraz, O.M.; Elboushi, A.; Alshebeili, S.A.; Sebak, A.-R. Dense Dielectric Patch Array Antenna with Improved Radiation Characteristics Using EBG Ground Structure and Dielectric Superstrate for Future 5G Cellular Networks. IEEE Access 2014, 2, 909–913. [Google Scholar] [CrossRef]

- Zhu, S.; Liu, H.; Chen, Z.; Wen, P. A Compact Gain-Enhanced Vivaldi Antenna Array with Suppressed Mutual Coupling for 5G mmWave Application. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 776–779. [Google Scholar] [CrossRef]

- Selvaraju, R.; Jamaluddin, M.H.; Kamarudin, M.R.; Nasir, J.; Dahri, M.H. Mutual Coupling Reduction and Pattern Error Correction in a 5G Beamforming Linear Array Using CSRR. IEEE Access 2018, 6, 65922–65934. [Google Scholar] [CrossRef]

- Yang, B. Compact Tapered Slot Antenna Array for 5G. IEEE Trans. Antennas Propag. 2017, 65, 6721–6727. [Google Scholar] [CrossRef]

- Yashchyshyn, Y.; Derzakowski, K.; Bogdan, G.; Godziszewski, K.; Nyzovets, D.; Kim, C.H.; Park, B. 28 GHz Switched-Beam Antenna Based on S-PIN Diodes for 5G Mobile Communications. IEEE Antennas Wirel. Propag. Lett. 2018, 17, 225–228. [Google Scholar] [CrossRef]

- Zhang, S.; Syrytsin, I.; Pedersen, G.F. Compact Beam-Steerable Antenna Array with Two Passive Parasitic Elements for 5G Mobile Terminals at 28 GHz. IEEE Trans. Antennas Propag. 2018, 66, 5193–5203. [Google Scholar] [CrossRef]

- Lee, H.J.; Kim, E.; Yook, J.G.; Jung, J. Intrinsic characteristics of transmission line of graphenes at microwave frequencies Intrinsic characteristics of transmission line of graphenes at microwave frequencies. Appl. Phys. Lett. 2012, 100, 223102. [Google Scholar] [CrossRef]

- Dragoman, M.; Necolui, D.; Dragoman, D.; Deligeorgis, G.; Konstantinidis, G.; Cismaru, A.; Coccetti, F.; Plana, R. Graphene for microwaves. IEEE Microw. Mag. 2010, 11, 81–86. [Google Scholar] [CrossRef]

- Moon, J.-S.; Gaskill, D.K. Graphene: Its Fundamentals to Future Applications. IEEE Trans. Microw. Theory Tech. 2011, 59, 2702–2708. [Google Scholar] [CrossRef]

- Palacios, T.; Hsu, A.; Wang, H. Applications of graphene devices in RF communications. IEEE Commun. Mag. 2010, 48, 122–128. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Y.; Zhang, T.; Chang, H.; Xiao, P.; Chen, H.; Huang, Z.; Chen, Y. Broadband and Tunable High-Performance Microwave Absorption of an Ultralight and Highly Compressible Graphene Foam. Adv. Mater. 2015, 27, 2049–2053. [Google Scholar] [CrossRef]

- Katsounaros, A.; Cole, M.T.; Tuncer, H.M.; Milne, W.I.; Hao, Y. Near-field characterization of chemical vapor deposition graphene in the microwave regime. Appl. Phys. Lett. 2013, 102, 233104. [Google Scholar] [CrossRef] [Green Version]

- Tamagnone, M.; Gómez-Díaz, J.S.; Mosig, J.R.; Perruisseau-Carrier, J. Analysis and design of terahertz antennas based on plasmonic resonant graphene sheets. J. Appl. Phys. 2012, 112, 114915. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.Y.; Argyropoulos, C.; Alu, A. Terahertz antenna phase shifters using integrally-gated graphene transmission-lines. IEEE Trans. Antennas Propag. 2013, 61, 1528–1537. [Google Scholar] [CrossRef]

- Aloia, A.G.D.; Amore, M.D.; Sarto, M.S. Adaptive Broadband Radar Absorber Based on Tunable Graphene. IEEE Trans. Antennas Propag. 2016, 64, 2527–2531. [Google Scholar] [CrossRef]

- Na, K.; Ma, H.; Park, J.; Yeo, J.; Park, J.-U.; Bien, F. Graphene-Based Wireless Environmental Gas Sensor on PET Substrate. IEEE Sens. J. 2016, 16, 5003–5009. [Google Scholar] [CrossRef]

- Li, L.; Guo, Y.; Zhang, X.; Song, Y. Inkjet-printed highly conductive transparent patterns with water based Ag-doped graphene. J. Mater. Chem. A 2014, 2, 19095–19101. [Google Scholar] [CrossRef]

- Fuscaldo, W.; Burghignoli, P.; Baccarelli, P.; Galli, A. A Reconfigurable Substrate—Superstrate. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1545–1548. [Google Scholar] [CrossRef]

- Dragoman, M.; Neculoiu, D.; Bunea, A.-C.; Deligeorgis, G.; Aldrigo, M.; Vasilache, D.; Dinescu, A.; Konstantinidis, G.; Mencarelli, D.; Pierantoni, L.; et al. A tunable microwave slot antenna based on graphene. Appl. Phys. Lett. 2015, 106, 153101. [Google Scholar] [CrossRef] [Green Version]

- Carrasco, E.; Perruisseau-Carrier, J. Reflectarray Antenna at Terahertz Using Graphene. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 253–256. [Google Scholar] [CrossRef]

- Dong, Y.; Liu, P.; Yu, D.; Li, G.; Tao, F. Dual-Band Reconfigurable Terahertz Patch Antenna with Graphene-Stack-Based Backing Cavity. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1541–1544. [Google Scholar] [CrossRef]

- Kazemi, A.H.; Mokhtari, A. Graphene-based patch antenna tunable in the three atmospheric windows. Optik 2017, 142, 475–482. [Google Scholar] [CrossRef]

- Materials, M.; Liang, F.; Yang, Z.; Xie, Y.; Li, H.; Zhao, D. Beam-Scanning Microstrip Quasi-Yagi—Uda Antenna Based on Hybrid. IEEE Photonics Technol. Lett. 2018, 30, 1127–1130. [Google Scholar]

- Huang, X.; Leng, T.; Zhu, M.; Zhang, X.; Chen, J.; Chang, K.; Aqeeli, M.; Geim, A.K.; Novoselov, K.S.; Hu, Z. Highly Flexible and Conductive Printed Graphene for Wireless Wearable Communications Applications. Sci. Rep. 2015, 5, 18298. [Google Scholar] [CrossRef] [Green Version]

- Leng, T.; Huang, X.; Chang, K.; Chen, J.; Abdalla, M.A.; Hu, Z. Graphene Nanoflakes Printed Flexible Meandered-Line Dipole Antenna on Paper Substrate for Low-Cost RFID and Sensing Applications. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 1565–1568. [Google Scholar] [CrossRef]

- Akbari, M.; Khan, M.W.A.; Hasani, M.; Björninen, T.; Sydanheimo, L.; Ukkonen, L.; Khan, M.W.A. Fabrication and Characterization of Graphene Antenna for Low-Cost and Environmentally Friendly RFID Tags. IEEE Antennas Wirel. Propag. Lett. 2015, 15, 1569–1572. [Google Scholar] [CrossRef]

- Tang, D.; Wang, Q.; Wang, Z.; Liu, Q.; Zhang, B.; He, D.; Wu, Z.; Mu, S. Highly sensitive wearable sensor based on a flexible multi-layer graphene film antenna. Sci. Bull. 2018, 63, 574–579. [Google Scholar] [CrossRef]

- Fan, C.; Wu, B.; Song, R.; Zhao, Y.; Zhang, Y.; He, D. Electromagnetic shielding and multi-beam radiation with high conductivity multilayer graphene film. Carbon 2019, 155, 506–513. [Google Scholar] [CrossRef]

- Tian, W.; Li, W.; Yu, W.; Liu, X. A Review on Lattice Defects in Graphene: Types, Generation, Effects and Regulation. Micromachines 2017, 8, 163. [Google Scholar] [CrossRef]

- Tanyer-Tigrek, F.M.; Lager, I.E.; Ligthart, L.P. A CPW-Fed Printed Loop Antenna for Ultra-Wideband Applications, and its Linear-Array Performance. IEEE Antennas Propag. Mag. 2010, 52, 31–40. [Google Scholar] [CrossRef]

- Simons, R.N. Coplanar Waveguide Circuits, Components, and Systems; John Wiley & Sons, Inc.: New York, NY, USA, 2001; Volume 7. [Google Scholar]

- Ji, T.; Yoon, H.; Abraham, J.; Varadan, V. Ku-band antenna array feed distribution network with ferroelectric phase shifters on silicon. IEEE Trans. Microw. Theory Tech. 2006, 54, 1131–1138. [Google Scholar]

- Pardo, D.A.; Jabbour, G.E.; Peyghambarian, N. Application of Screen Printing in the Fabrication of Organic Light-Emitting Devices. Adv. Mater. 2000, 12, 1249–1252. [Google Scholar] [CrossRef]

- Cao, X.; Chen, H.; Gu, X.; Liu, B.; Wang, W.; Cao, Y.; Wu, F.; Zhou, C. Screen Printing as a Scalable and Low-Cost Approach for Rigid and Flexible Thin-Film Transistors Using Separated Carbon Nanotubes. ACS Nano 2014, 8, 12769–12776. [Google Scholar] [CrossRef]

- Shin, K.-Y.; Kim, M.; Lee, J.S.; Jang, J. Highly Omnidirectional and Frequency Controllable Carbon/Polyaniline-based 2D and 3D Monopole Antenna. Sci. Rep. 2015, 5, 13615. [Google Scholar] [CrossRef]

- Hyun, W.J.; Secor, E.B.; Hersam, M.C.; Frisbie, C.D.; Francis, L.F. High-resolution patterning of graphene by screen printing with a silicon stencil for highly flexible printed electronics. Adv. Mater. 2015, 27, 109–115. [Google Scholar] [CrossRef]

- Arapov, K.; Jaakkola, K.; Ermolov, V.; Bex, G.; Rubingh, E.; Haque, S.; Sandberg, H.; Abbel, R.; De With, G.; Friedrich, H. Graphene screen-printed radio-frequency identification devices on flexible substrates. Phys. Status Solidi Rapid Res. Lett. 2016, 10, 812–818. [Google Scholar] [CrossRef] [Green Version]

- Suikkola, J.; Bjorninen, T.; Mosallaei, M.; Kankkunen, T.; Iso-Ketola, P.; Ukkonen, L.; Vanhala, J.; Mäntysalo, M. Screen-Printing Fabrication and Characterization of Stretchable Electronics. Sci. Rep. 2016, 6, 25784. [Google Scholar] [CrossRef] [PubMed]

- Xiao, G.; Aflaki, P.; Lang, S.; Zhang, Z.; Tao, Y.; Py, C.; Lu, P.; Martin, C.; Change, S. Printed UHF RFID Reader Antennas for Potential Retail Applications. IEEE J. Radio Freq. Identif. 2018, 2, 31–37. [Google Scholar] [CrossRef]

- Sa’don, S.N.H.; Jamaluddin, M.H.; Kamarudin, M.R.; Ahmad, F.; Dahlan, S.H. A 5G graphene antenna produced by screen printing method. Indones. J. Electr. Eng. Comput. Sci. 2019, 15, 950–1055. [Google Scholar]

- RS Online. Kapton HN Thermal Insulating Film, 304mm × 200mm × 0.075mm. 2018. Available online: https://my.rs-online.com/web/p/thermal-insulating-films/5363968/ (accessed on 3 September 2019 ).

- Huang, X.; Leng, T.; Zhang, X.; Chen, J.C.; Chang, K.H.; Geim, A.K.; Novoselov, K.S.; Hu, Z. Binder-free highly conductive graphene laminate for low cost printed radio frequency applications. Appl. Phys. Lett. 2015, 106, 203105. [Google Scholar] [CrossRef]

- Balanis, C.A. Antenna Theory: Analysis and Design, 3rd ed.; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

| References | Antenna Design | Operating Frequency (GHz) | Bandwidth (GHz) | Gain (dBi) | Total Efficiency (%) | Applications |

|---|---|---|---|---|---|---|

| [38] | CPW-fed wideband quasi dipole antenna | 1.7–5 | 3.3% or 98.51% | 0.6–2.3 | 60 | Low cost wireless |

| [50] | CPW fed slot antenna | 1.73–3.77 | 2.04 %or 74.18% | −1–0.2 | - | On-body wearable communication |

| [51] | Meandered line antenna | 0.984–1.052 | 0.068% or 6.67% | −4 | - | Low cost RFID and sensing |

| [52] | Dipole antenna | 0.8–0.965 | 0.165% or 18.70% | −2.18 | 40 | Low-cost and environmentally friendly RFID tags |

| [53] | Rectangular microstrip patch antenna | 1.63 | - | - | - | Wearable sensor |

| [54] | Microstrip antenna array | 29–31 | - | 15.07 | - | Electromagnetic shielding and radiation |

| Proposed antenna | CPW-fed rectangular slot with chamfer | 15 | (single element) | 2.87 | 67.44 | Mobile terminal for Fifth Generation (5G) |

| 6.63% or 48.63% | ||||||

| (array) | ||||||

| 7.2% or 48.98% | 8.41 | 72.98 |

| Parameter | Description | Length | Parameter | Description | Length |

|---|---|---|---|---|---|

| Ws | Substrate width | 12.2 mm | s1 | The slot between CPW and feedline | 0.08 mm |

| Ls | Substrate length | 11.8 mm | s2 | Top slot | 2.5 mm |

| Wp | Patch width | 7.2 mm | s3 | Side slot | 2.5 mm |

| Lp | Patch length | 6.8 mm | Tg | Graphene thickness | 100 nm |

| Wf | Feedline width | 4.5 mm | Ts | Substrate thickness | 76 µm |

| Lf | Feedline length | 2.5 mm | Lc | Cut length | 1 mm |

| Wg | Ground plane width between slot and feedline | 3.77 mm | θ | Cutting degree | 60° |

| Lg | CPW length | 1 mm |

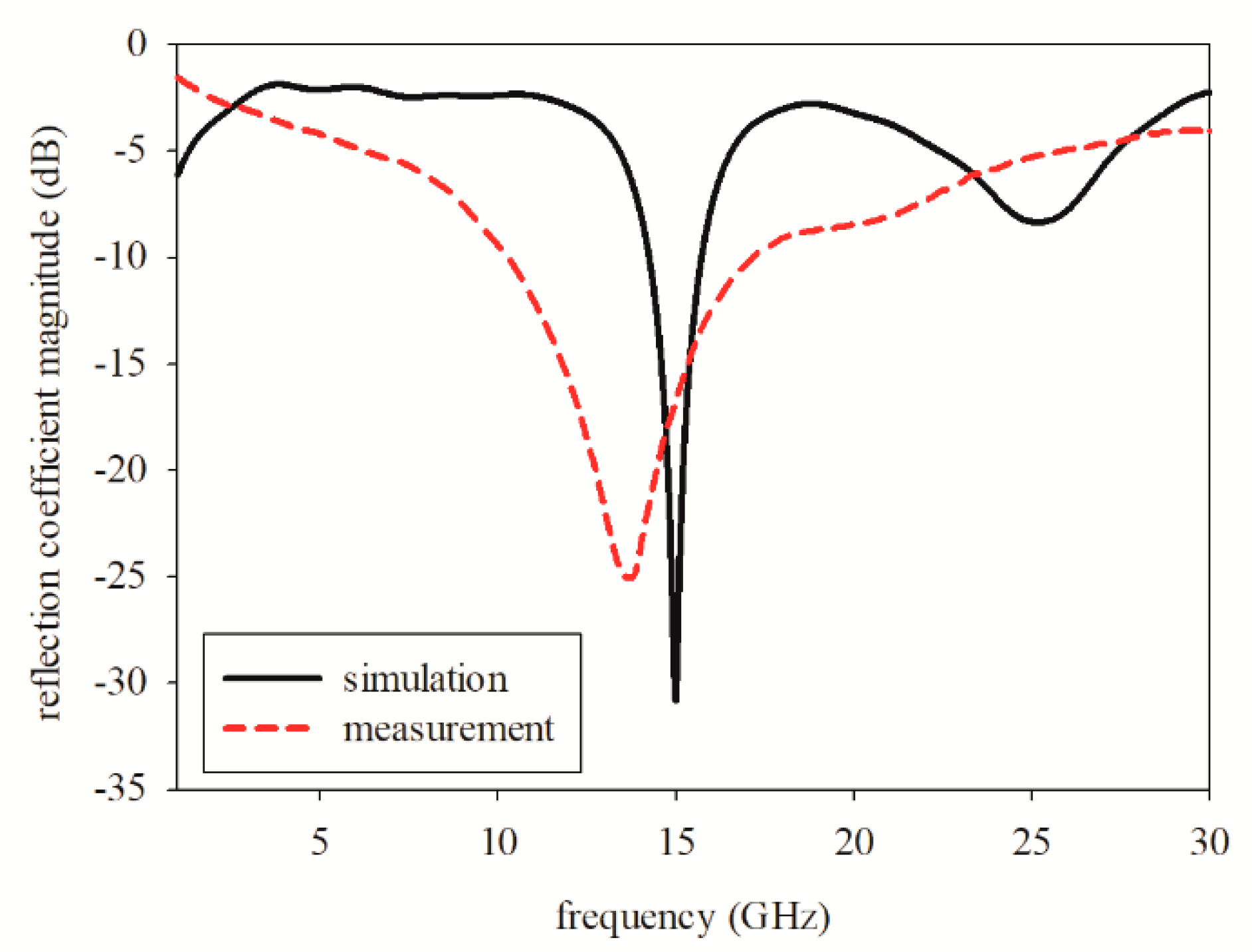

| Antenna Properties | Simulation | Measurement |

|---|---|---|

| Resonance frequency | 15 GHz | 13.8 GHz |

| Reflection coefficient magnitude | −30.82 dB | −25.26 dB |

| Frequency range at −10 dB level | 14.25–15.73 GHz | 10.35–17.0 GHz |

| Bandwidth | 1.48 GHz | 6.65 GHz |

| Percentage of impedance bandwidth | 9.87% | 48.63% |

| Gain | 2.39 dBi | 2.87 dBi |

| Total efficiency | 65.25% | 67.44% |

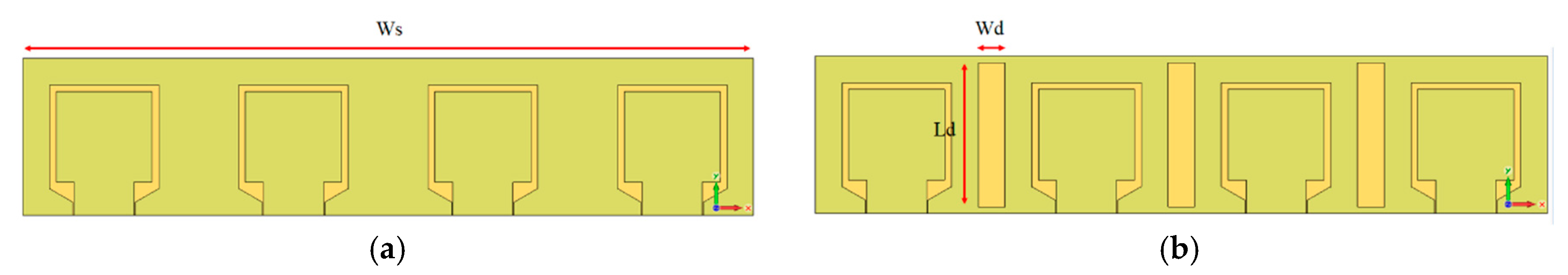

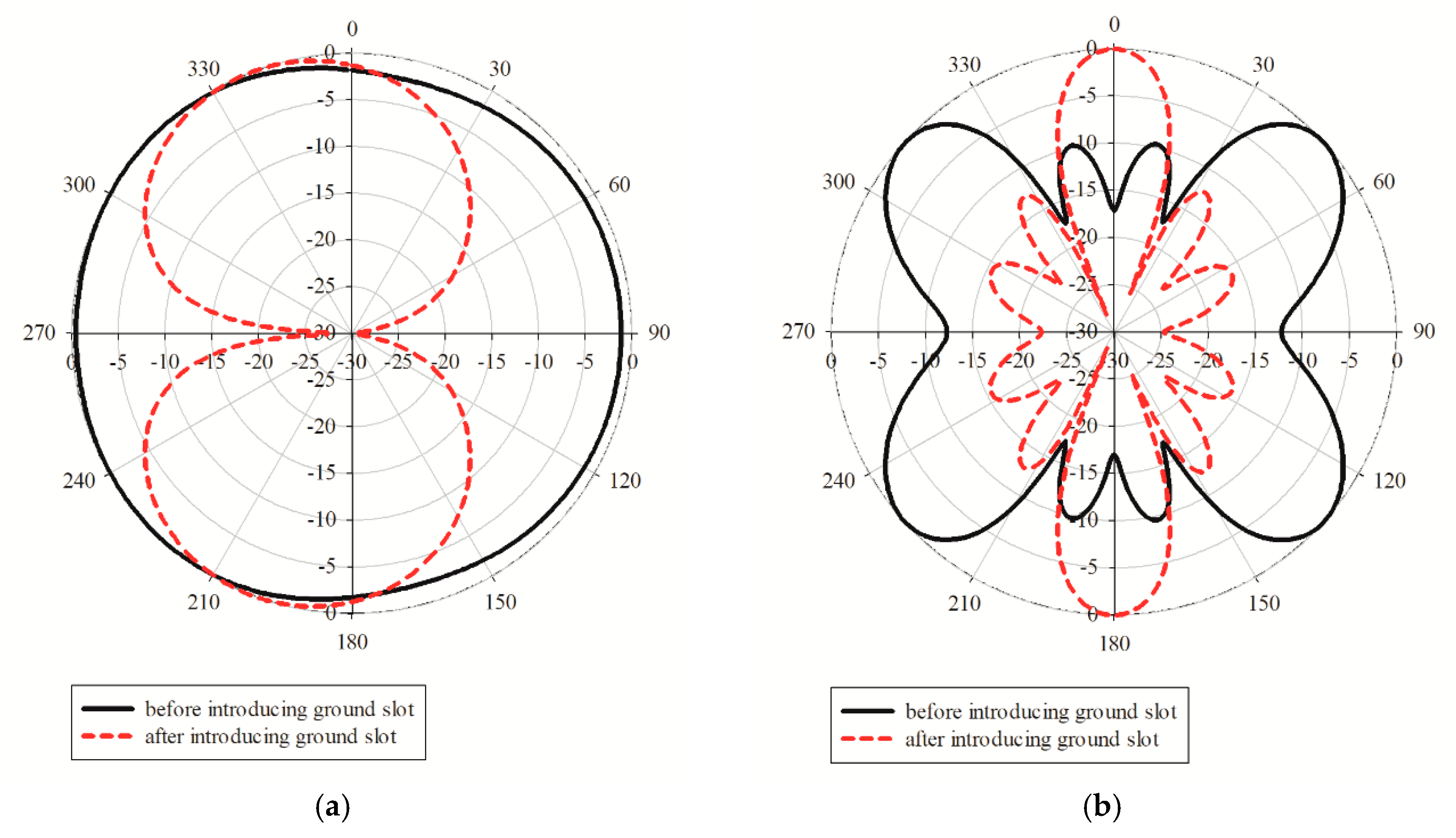

| Before Rectangular Slot | After Rectangular Slot | |

|---|---|---|

| Resonance frequency | 15.09 GHz | 15 GHz |

| S11 | −37.57 dB | −25.13 dB |

| S12 | −17.47 dB | −22.13 dB |

| Frequency range at −10 dB level | 14.32–15.87 GHz | 14.30–15.71 GHz |

| Bandwidth | 1.55 GHz | 1.41 GHz |

| Percentage of impedance bandwidth | 10.27% | 9.40% |

| Gain | 5.63 dBi | 9.28 dBi |

| Side lobe level | −9.6 dB | −12.4 dB |

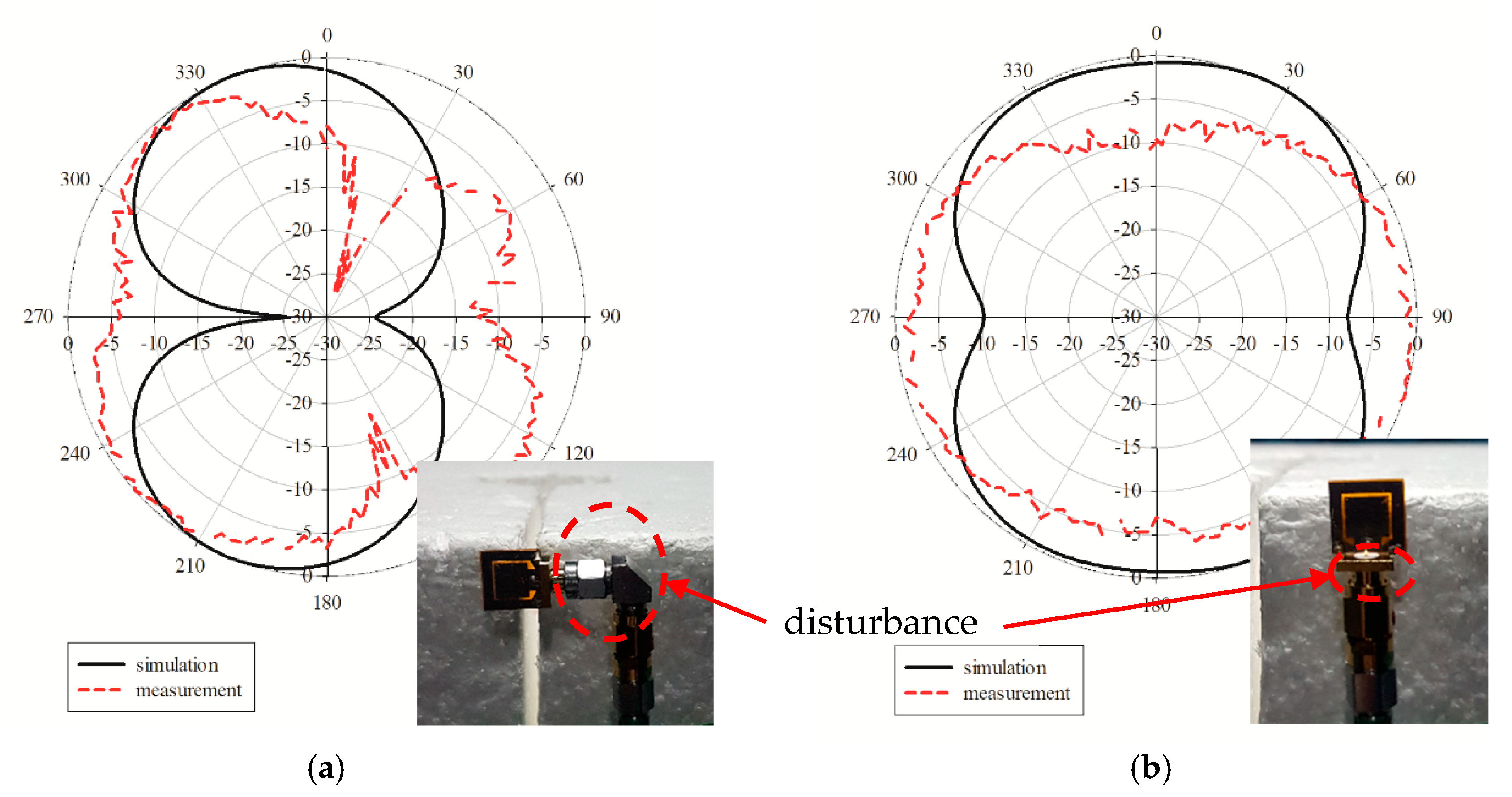

| Antenna Properties | Simulation | Measurement |

|---|---|---|

| Resonance frequency | 15.0 GHz | 14.78 GHz |

| Reflection coefficient magnitude/S11 | −23.50 dB | −36.02 dB |

| S12 | −23.41 dB | −32.40 dB |

| Frequency range at −10 dB level | 14.30–15.70 GHz | 11.10–18.30 GHz |

| Bandwidth | 1.4 GHz | 7.2 GHz |

| Percentage of impedance bandwidth | 9.33% | 48.98% |

| Gain | 9.50 dBi | 8.41 dBi |

| Side lobe level | −12.3 dB | −13.0 dB |

| Half power beam width | 18.9° | 21.1° |

| Total efficiency | 62.47% | 72.98% |

| Phase Shift, β | Beam Steering, θ° |

|---|---|

| 0 | 0° |

| −251.72° | 24.50° |

| −240.19° | 27.42° |

| −221.36° | 32.50° |

| −195.80° | 39.05° |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sa’don, S.N.H.; Jamaluddin, M.H.; Kamarudin, M.R.; Ahmad, F.; Yamada, Y.; Kamardin, K.; Idris, I.H. Analysis of Graphene Antenna Properties for 5G Applications. Sensors 2019, 19, 4835. https://doi.org/10.3390/s19224835

Sa’don SNH, Jamaluddin MH, Kamarudin MR, Ahmad F, Yamada Y, Kamardin K, Idris IH. Analysis of Graphene Antenna Properties for 5G Applications. Sensors. 2019; 19(22):4835. https://doi.org/10.3390/s19224835

Chicago/Turabian StyleSa’don, Siti Nor Hafizah, Mohd Haizal Jamaluddin, Muhammad Ramlee Kamarudin, Fauzan Ahmad, Yoshihide Yamada, Kamilia Kamardin, and Izni Husna Idris. 2019. "Analysis of Graphene Antenna Properties for 5G Applications" Sensors 19, no. 22: 4835. https://doi.org/10.3390/s19224835

APA StyleSa’don, S. N. H., Jamaluddin, M. H., Kamarudin, M. R., Ahmad, F., Yamada, Y., Kamardin, K., & Idris, I. H. (2019). Analysis of Graphene Antenna Properties for 5G Applications. Sensors, 19(22), 4835. https://doi.org/10.3390/s19224835