Modeling Indoor Relative Humidity and Wood Moisture Content as a Proxy for Wooden Home Fire Risk

Abstract

:1. Introduction

2. Theory and Model Description

2.1. Gas Phase Water Vapor Concentrations

2.2. Wood Equilibrium Moisture Content (EMC)

2.3. Transport of Humidity in Wood

2.4. The Overall Numerical Model

3. Results

3.1. Testing the Model for a 120 Year-Old Wooden Home

3.2. Testing the Model for a 100 Year-Old Wooden Home

3.3. Testing the Model for a 55 Year-Old Wooden Home

3.4. Testing the Model for a Balanced Ventilation Modern Wooden Home

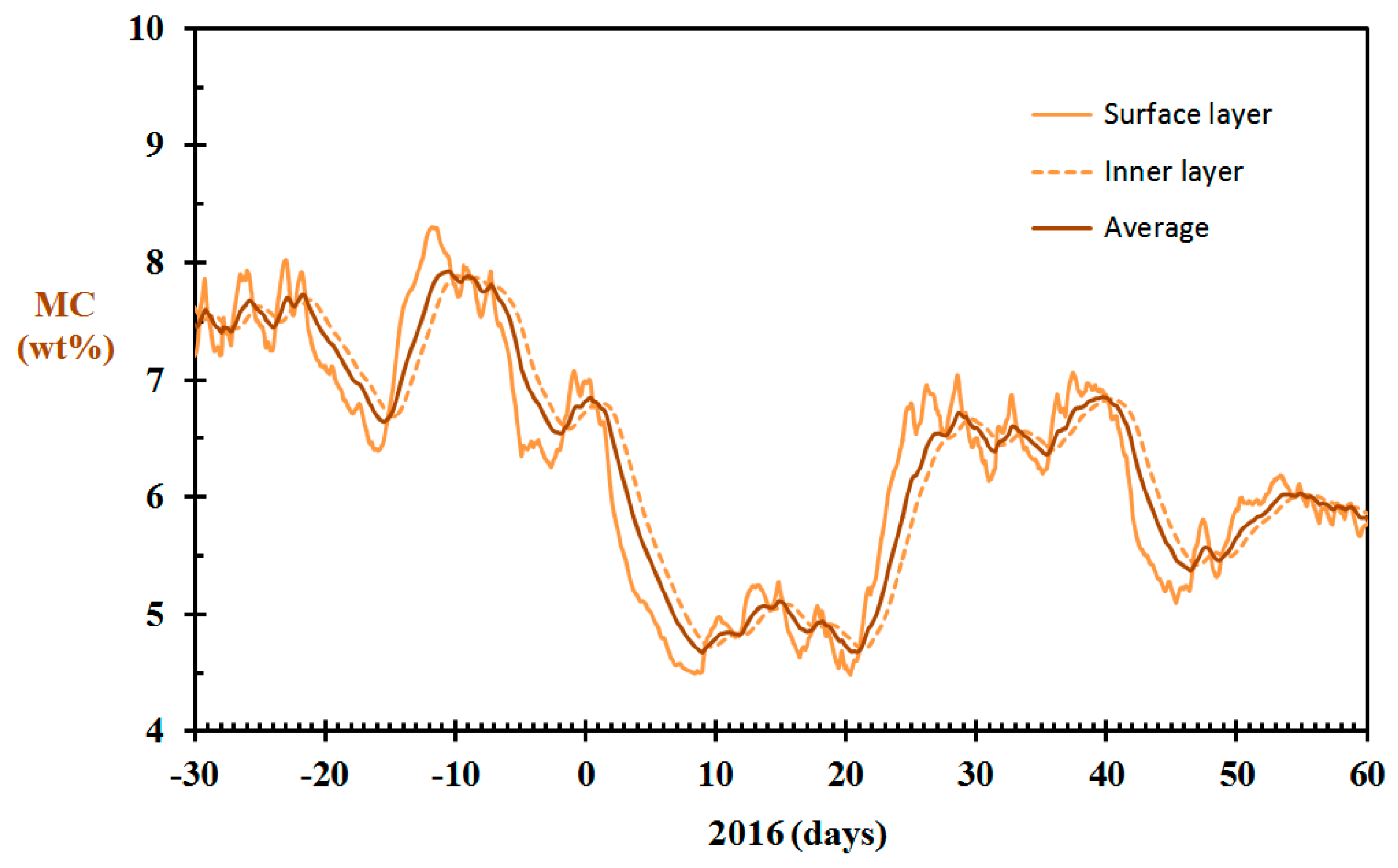

3.5. Indoor Wood Panels Moisture Content

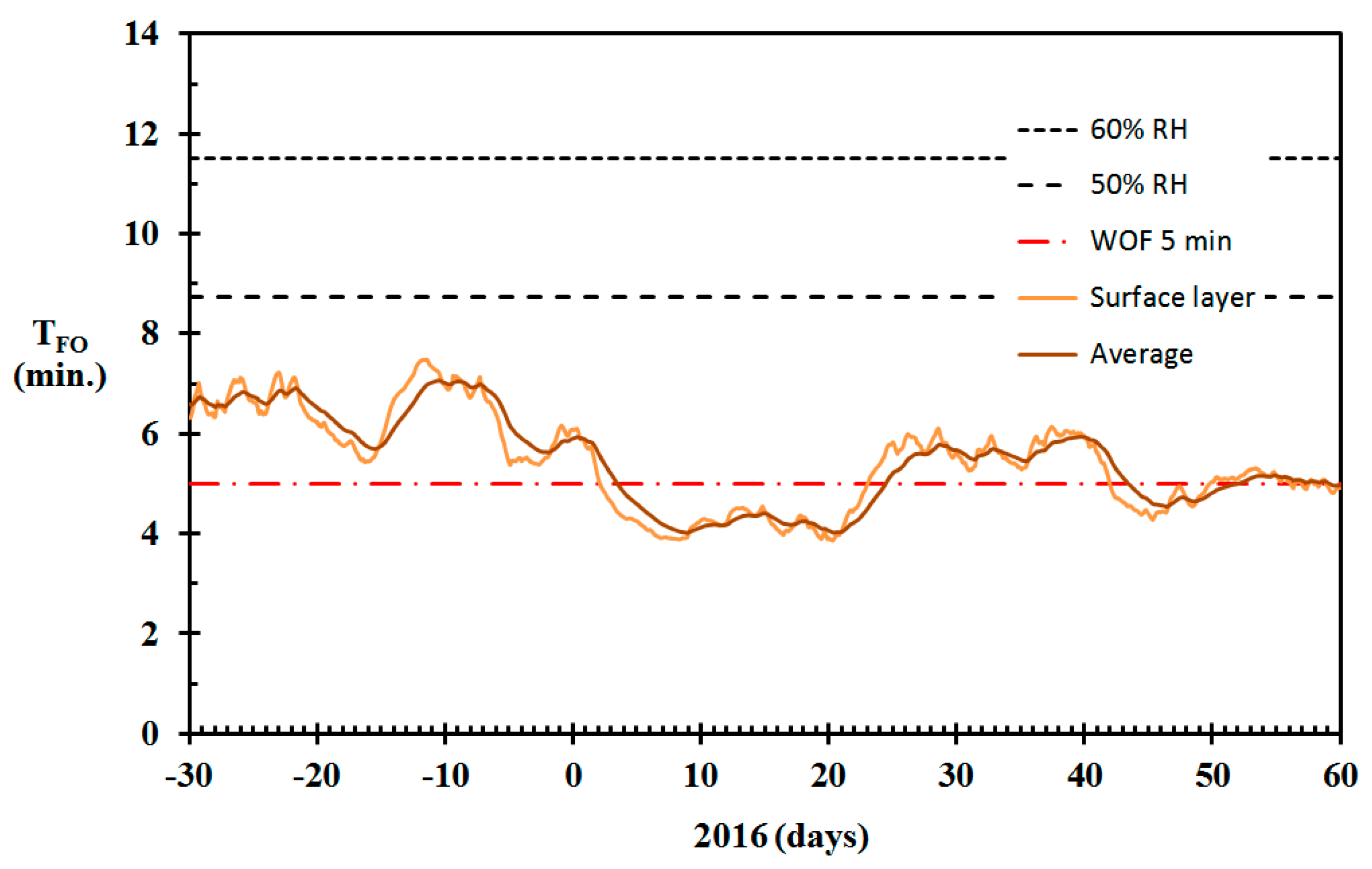

3.6. A Possible Wooden Home Cold Climate Fire Risk Proxy

- smoke layer temperatures approaching 500–600 °C,

- 20 kW/m2 heat flux to the floor level, and

- crumpled paper at the entrance of the compartment self-igniting.

3.7. Future Possibilities

4. Discussion

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Park, Y.; Ryu, J.; Ryou, H.S. Experimental Study on the Fire-Spreading Characteristics and Heat Release Rates of Burning Vehicles Using a Large-Scale Calorimeter. Energies 2019, 12, 1465. [Google Scholar] [CrossRef]

- Novozhilov, V. Fire Hazards of Some Modern Solid Fuels. Energies 2017, 10, 113. [Google Scholar] [CrossRef]

- Log, T.; Pedersen, W.B.; Moumets, H. Optical Gas Imaging (OGI) as a Moderator for Interdisciplinary Cooperation, Reduced Emissions and Increased Safety. Energies 2019, 128, 1454. [Google Scholar] [CrossRef]

- Huang, H.S.; Su, C.H.; Li, C.B.; Lin, C.Y.; Lin, C.C. Enhancement of Fire Safety of an Existing Green Building due to Natural Ventilation. Energies 2016, 9, 192. [Google Scholar] [CrossRef]

- Losnegård, G. Norske Ulykker og Katastrofar/Norwegian Accidents and Catastrophes; Skald: Leikanger, Norway, 2013; ISBN 978-82-7959-196-2. [Google Scholar]

- Log, T. Indoor relative humidity as a fire risk indicator. Build. Environ. 2017, 111, 238–248. [Google Scholar] [CrossRef]

- Pirsko, A.R.; Fons, W.L. Frequency of Urban Building Fires as Related to Daily Weather Conditions. Available online: https://www.fs.fed.us/psw/publications/documents/cfres_series/cfres_itr_afswp866.pdf (accessed on 11 February 2019).

- Babrauskas, V. Ignition Handbook; Fire Science Publishers: Issaquah, WA, USA, 2003; ISBN 0-9728111-3-3. [Google Scholar]

- Log, T. Cold Climate Fire Risk; A Case Study of the Lærdalsøyri Fire, January 2014. Fire Technol. 2016, 52, 1825–1843. [Google Scholar] [CrossRef]

- DSB Report (2014) “Brannene I Lærdal, Flatanger op på Frøya vinteren 2014, Lærepunkter og anbefalinger/The Fires in Lærdal, Flatanger and Frøya the Winter 2014, Learning Points and Recommendations”; Norwegian Directorate for Civil Protection: Tønsberg, Norway, 2014; p. 55. ISBN 978-82-7768-342-3. (In Norwegian)

- Steen-Hansen, A.; Bøe, G.A.; Hox, K.; Mikalsen, R.F.; Stensaas, J.P.; Storesund, K. Evaluation of Fire Spread in the Large Lærdal Fire, January 2014. In Proceedings of the 14th International Fire and Materials Conference and Exhibition, San Francisco, CA, USA, 2–4 February 2015; pp. 1014–1024. [Google Scholar]

- Delâge, C. Rapport du Commissaire Aux Incendies du Québec. Available online: https://www.coroner.gouv.qc.ca/fileadmin/Coroners/Rapport_d_enquete_-_L_Isle-Verte.pdf (accessed on 11 February 2019).

- Metallinou, M.M.; Log, T. Health Impacts of Climate Change-Induced Subzero Temperature Fires. Int. J. Environ. Res. Public Health 2017, 14, 814. [Google Scholar] [CrossRef]

- Manzello, S.L.; Blanchi, R.; Gollner, M.J.; Gorham, D.; McAllister, S.; Pastor, E.; Planas, E.; Reszka, P.; Suzuki, S. Summary of workshop large outdoor fires and the built environment. Fire Saf. J. 2018, 100, 76–92. [Google Scholar] [CrossRef]

- Manzello, S.L.; McAllister, S.; Suzuki, S. Large outdoor fires and the built environment: Objectives and goals of permanent IAFSS working group. Fire Saf. J. 2018, 98, 1–2. [Google Scholar] [CrossRef]

- Challands, N. The Relationships Between Fire Service Response Time and Fire Outcomes. Fire Technol. 2010, 46, 665–676. [Google Scholar] [CrossRef]

- Claridge, E.; Spearpoint, M. New Zealand fire service response times to structure fires. Procedia Eng. 2013, 62, 1063–1072. [Google Scholar] [CrossRef]

- Kraaijeveld, A.; Log, T. Vertical Flame Spread in Wooden Corners as a Function of Fuel Moisture Content. In Proceedings of the 15th International Conference Fire and Materials 2017, San Francisco, CA, USA, 6–8 February 2017; pp. 307–318. [Google Scholar]

- Kraaijeveld, A.; Gunnarshaug, A.; Schei, B.; Log, T. Burning Rate and Time to Flashover in Wooden ¼ scale Compartments as a Function of Fuel Moisture Content. In Proceedings of the 10th International Fire Science & Engineering Conference, Windsor, UK, 4–6 July 2016; pp. 553–558. [Google Scholar]

- Simpson, W.T. Equilibrium Moisture Content of Wood in Outdoor Locations in the United States and Worldwide; Research Note FPL-RN-0268; US Dep. of Agriculture: Washington, DC, USA, 1998; p. 14.

- Koo, E.; Pagni, P.J.; Weise, D.R.; Woycheese, J.P. Firebrands and spotting ignition in large-scale fires. Int. J. Wildland Fire 2010, 19, 818–843. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L. Characteristics of Firebrands Collected from Actual Urban Fires. Fire Technol. 2018, 54, 1533–1546. [Google Scholar] [CrossRef] [PubMed]

- Metallinou, M.M.; Log, T. Cold Climate Structural Fire Danger Rating System? Challenges 2018, 9, 12. [Google Scholar] [CrossRef]

- Pérez, J.; Maldonado, S.; López-Ospina, H. A fleet management model for the Santiago Fire Department. Fire Saf. J. 2016, 82, 1–11. [Google Scholar] [CrossRef]

- Pietrzyk, K. A systemic approach to moisture problems in buildings for mould safety modelling. Build. Environ. 2015, 86, 50–60. [Google Scholar] [CrossRef]

- Kalamees, T.; Vali, A.; Kurik, L.; Napp, M.; Arumagi, E.; Kallavus, U. The Influence of Indoor Climate Control on Risk for Damages in Naturally Ventilated Historic Churches in Cold Climate. Int. J. Archit. Herit. 2016, 10, 486–498. [Google Scholar] [CrossRef]

- Pisello, A.L.; Cotana, F.; Nicolini, A.; Buratti, C. Effect of dynamic characteristics of building envelope onthermal-energy performance in winter conditions: In field experiment. Energy Build. 2014, 80, 218–230. [Google Scholar] [CrossRef]

- Vinha, J.; Korpi, M.; Salminen, K.; Kurnitski, J.; Kiviste, M.; Laukkarinen, A. Airtightness of residential buildings in Finland. Build. Environ. 2015, 93, 128–140. [Google Scholar] [CrossRef]

- Kotol, M.; Rode, C.; Clausen, G.; Nilsen, T.R. Indoor environment in bedrooms in 79 Greenlandic households. Build. Environ. 2014, 81, 29–36. [Google Scholar] [CrossRef]

- Vardoulakis, S.; Dimitroulopoulou, C.; Thornes, J.; Lai, K.; Taylor, J.; Myers, I.; Heaviside, C.; Mavrogianni, A.; Shrubsole, C.; Chalabi, Z.; et al. Impact of climate change on the domestic indoor environment and associated health risks in the UK. Environ. Int. 2015, 85, 299–313. [Google Scholar] [CrossRef] [PubMed]

- Kalamees, T.; Korpi, M.; Vinha, J.; Kurnitski, J. The effects of ventilation systems and building fabric on the stability of indoor temperature and humidity in Finnish detached houses. Build. Environ. 2009, 44, 1643–1650. [Google Scholar] [CrossRef]

- Tetens, O. Uber einige meteorologische Begriffe. Z. Geophys. 1930, 6, 297. [Google Scholar]

- Jenssen, J.A.; Geving, S.; Johnsen, R. Assessments on Indoor air Humidity in Four Different Types of Dwelling Randomly Selected in Trondheim, Norway. In Proceedings of the 6th Symposium on Building Physics in the Nordic Countries, Trondheim, Norway, 17–19 June 2002; pp. 729–735. [Google Scholar]

- Kalamees, T.; Vinha, J.; Kurnitski, J. Indoor Humidity Loads and Moisture Production in Lightweight Timber-frame Detached Houses. J. Build. Phys. 2006, 29, 219–246. [Google Scholar] [CrossRef]

- Salin, J.G. Inclusion of the Sorption Hysteresis Phenomenon in Future Drying Models. Some Basic Considerations. Maderas. Cienc. Tecnol. 2011, 13, 173–182. [Google Scholar] [CrossRef]

- Funk, M. Hysteretic moisture properties of porous materials: Part I: Thermodynamics. J. Build. Phys. 2014, 38, 6–49. [Google Scholar] [CrossRef]

- Drysdale, D. An Introduction to Fire Dynamics, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; ISBN 978-0-470-31903-1. [Google Scholar]

- ISO Reaction to Fire Tests—Room Corner Test for Wall and Ceiling Lining Products—Part 1: Test Method for a Small Room Configuration; ISO 9705-1:2016; International Organization for Standardization: Geneva, Switzerland, 2016; p. 42.

- Mortensen, L.H. Hygrothermal Microclimate on Interior Surfaces of the Building Envelope. Ph.D. Thesis, Technical University of Denmark, Lyngby, Denmark, 2007; p. 166. [Google Scholar]

- Ramstad, T.Ø.; Hallquist, Å. Scandinavian timber frame house construction technical design and future trends. In Proceedings of the CIB World Building Congress, Oslo, Norway, 2–3 June 1980; pp. 410–415. Available online: http://www.irbnet.de/daten/iconda/CIB15170.pdf (accessed on 29 October 2019).

- Baronas, R.; Ivanauskasa, F.; Juodeikienėc, I.; Kajalavičiusc, A. Modelling of Moisture Movement in Wood during Outdoor Storage. Nonlinear Anal. Model. Control 2001, 6, 3–14. [Google Scholar]

- Log, T. Consumer Grade Weather Stations for Wooden Structure Fire Risk Assessment. Sensors 2018, 18, 3244. [Google Scholar] [CrossRef]

- Rong, L.; Liu, D.Z.; Pedersen, E.F.; Zhang, G.Q. Effect of climate parameters on air exchange rate and ammonia and methane emissions from a hybrid ventilated dairy cow building. Energy Build. 2014, 82, 632–643. [Google Scholar] [CrossRef]

- Mortensen, L.H.; Rode, C.; Peuhkuri, R. Full scale tests of moisture buffer capacity of wall materials. In Proceedings of the 7th Symposium on Building Physics in the Nordic Countries, Reykjavik, Iceland, 13–15 June 2005; Volume 2, pp. 662–669. [Google Scholar]

- Svennberg, K.; Harderup, L.E. Time-dependent moisture properties for plasterboard with surface coating. In Proceedings of the 9th International Conference on Indoor Air Quality and Climate–Indoor Airil 2002, Monterey, CA, USA, 30 June–5 July 2002; pp. 66–72. [Google Scholar]

- Rode, C.; Peuhkuri, R.; Mortensen, L.H.; Hansen, K.K.; Time, B.; Gustavsen, A.; Ojanen, T.; Ahonen, J.; Svennberg, K.; Harderup, L.E.; et al. Moisture Buffering of Building Materials; Report BYG-DTU R-126; Technical University of Denmark: Lyngby, Denmark, 2005; p. 46. ISBN 87-7877-195-1. [Google Scholar]

- Popper, P.; Niemz, P.; Croptier, S. Adsorption and desorption measurements on selected exotic wood species. Analysis with the Hailwood-Horrobin model to describe the sorption hysteresis. Wood Res. 2009, 54, 43–56. [Google Scholar]

- Xie, Y.J.; Hill, C.A.S.; Jalaludin, Z.; Curling, S.F.; Anandjiwala, R.D.; Norton, A.J.; Newman, G. The dynamic water vapour sorption behaviour of natural fibres and kinetic analysis using the parallel exponential kinetics model. J. Mater. Sci. 2011, 46, 479–489. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Keating, B.A.; Jalaludin, Z.; Mahrdt, E. A rheological description of the water vapour sorption kinetics behaviour of wood invoking a model using a canonical assembly of Kelvin-Voigt elements and a possible link with sorption hysteresis. Holzforschung 2012, 66, 35–47. [Google Scholar] [CrossRef]

- Babrauskas, V.; Peacock, R. Heat Release Rate: The Single Most Important Variable in Fire Hazard. Fire Saf. J. 1992, 18, 255–272. [Google Scholar] [CrossRef]

- Averill, J.D.; Moore-Merrell, L.; Barowy, A.; Santos, R.; Peacock, R.; Notarianni, K.A.; Wissoker, D. Report on Residential Fireground Field Experiments; NIST Technical Note 1661; Robinson, B., Ed.; National Institute of Standards and Technology: Gaithersburg, MD, USA, April 2010; p. 104.

- Reglen, D.; Scheller, D.S. Fire Department Turnout Times: A Contextual Analysis. J. Homel. Secur. Emerg. Manag. 2016, 13, 167–189. [Google Scholar] [CrossRef]

- Upson, R.; Notarianni, K. Quantitative Evaluation of Fire and EMS Mobilization Times; The Fire Protection Research Foundation: Quincy, MA, USA, 2010; p. 44. Available online: https://www.nfpa.org/-/media/Files/News-and-Research/Archived-reports/mobilizationpart1.ashx?la=en (accessed on 6 November 2018).

- Boudaden, J.; Steinmaßl, M.; Endres, H.E.; Drost, A.; Eisele, I.; Kutter, C.; Müller-Buschbaum, P. Polyimide-Based Capacitive Humidity Sensor. Sensors 2018, 18, 1516. [Google Scholar] [CrossRef] [Green Version]

- Sun, C.; Shi, Q.; Yazici, M.S.; Lee, C.; Liu, Y. Development of a Highly Sensitive Humidity Sensor Based on a Piezoelectric Micromachined Ultrasonic Transducer Array Functionalized with Graphene Oxide Thin Film. Sensors 2018, 18, 4352. [Google Scholar] [CrossRef] [Green Version]

- Leal-Junior, A.; Frizera-Neto, A.; Marques, C.; Pontes, M.J. Measurement of Temperature and Relative Humidity with Polymer Optical Fiber Sensors Based on the Induced Stress-Optic Effect. Sensors 2018, 18, 916. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Shi, J.; Yang, X.; Xu, D.; Rong, F.; Zhao, J.; Yao, J. Relative Humidity Sensor Based on No-Core Fiber Coated by Agarose-Gel Film. Sensors 2017, 17, 2353. [Google Scholar] [CrossRef] [Green Version]

- Gaspar, C.; Olkkonen, O.; Passoja, S.; Smolander, M. Paper as Active Layer in Inkjet-Printed Capacitive Humidity Sensors. Sensors 2017, 17, 1464. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Guo, J.; Xiong, H.; Liu, X.; Zhang, D. A Framework for an Intelligent and Personalized Fire Evacuation Management System. Sensors 2019, 19, 3128. [Google Scholar] [CrossRef] [Green Version]

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Log, T. Modeling Indoor Relative Humidity and Wood Moisture Content as a Proxy for Wooden Home Fire Risk. Sensors 2019, 19, 5050. https://doi.org/10.3390/s19225050

Log T. Modeling Indoor Relative Humidity and Wood Moisture Content as a Proxy for Wooden Home Fire Risk. Sensors. 2019; 19(22):5050. https://doi.org/10.3390/s19225050

Chicago/Turabian StyleLog, Torgrim. 2019. "Modeling Indoor Relative Humidity and Wood Moisture Content as a Proxy for Wooden Home Fire Risk" Sensors 19, no. 22: 5050. https://doi.org/10.3390/s19225050

APA StyleLog, T. (2019). Modeling Indoor Relative Humidity and Wood Moisture Content as a Proxy for Wooden Home Fire Risk. Sensors, 19(22), 5050. https://doi.org/10.3390/s19225050