Application of GNSS/INS and an Optical Sensor for Determining Airplane Takeoff and Landing Performance on a Grassy Airfield †

Abstract

:1. Introduction

1.1. Grassy Airfields

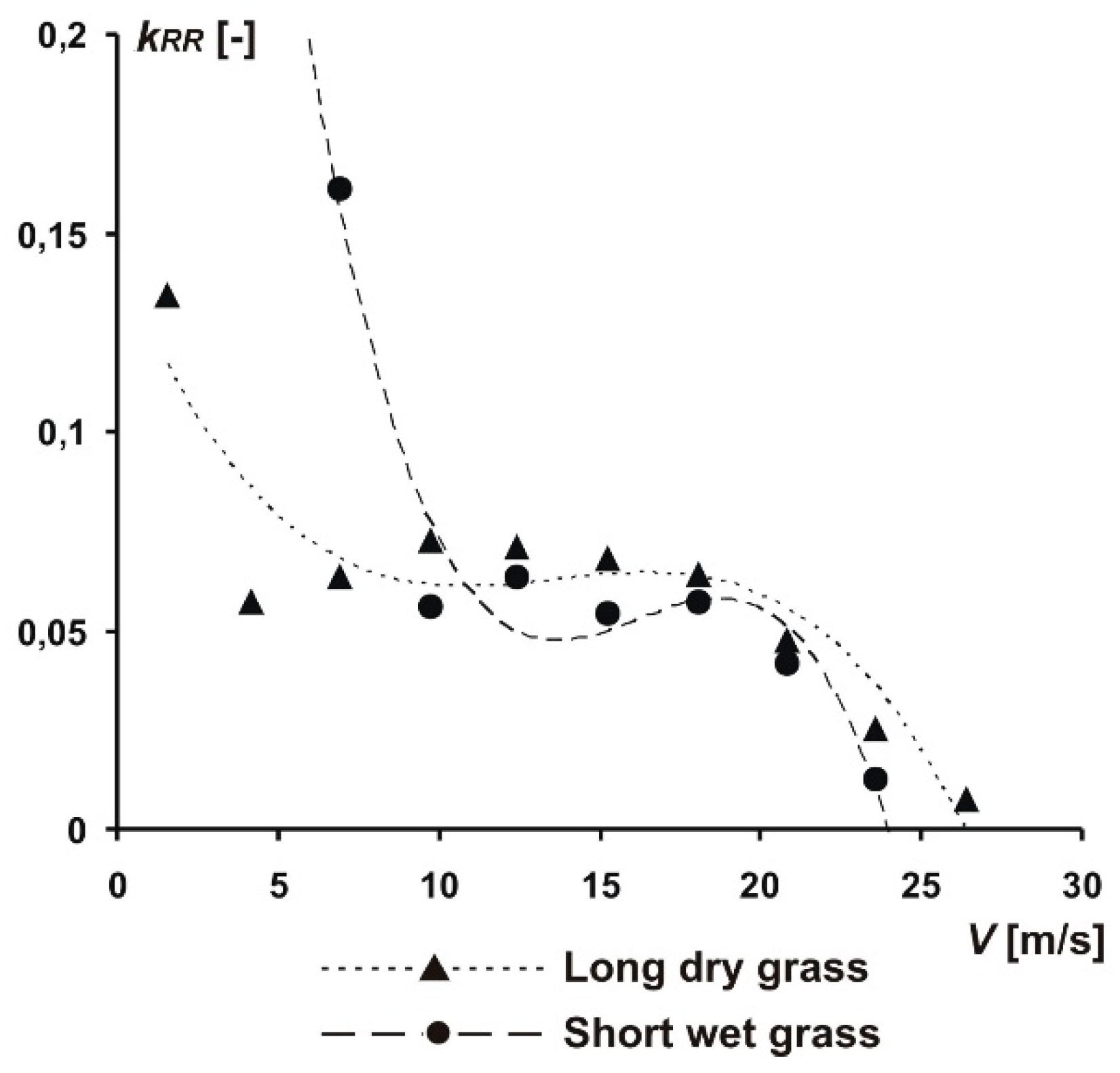

1.2. Methods for Determination of Rolling Resistance for Aircraft Tires: A Review

1.3. Takeoff and Landing Ground Roll Distance Determination Methods

2. Materials and Methods

2.1. GNSS/INS Sensor

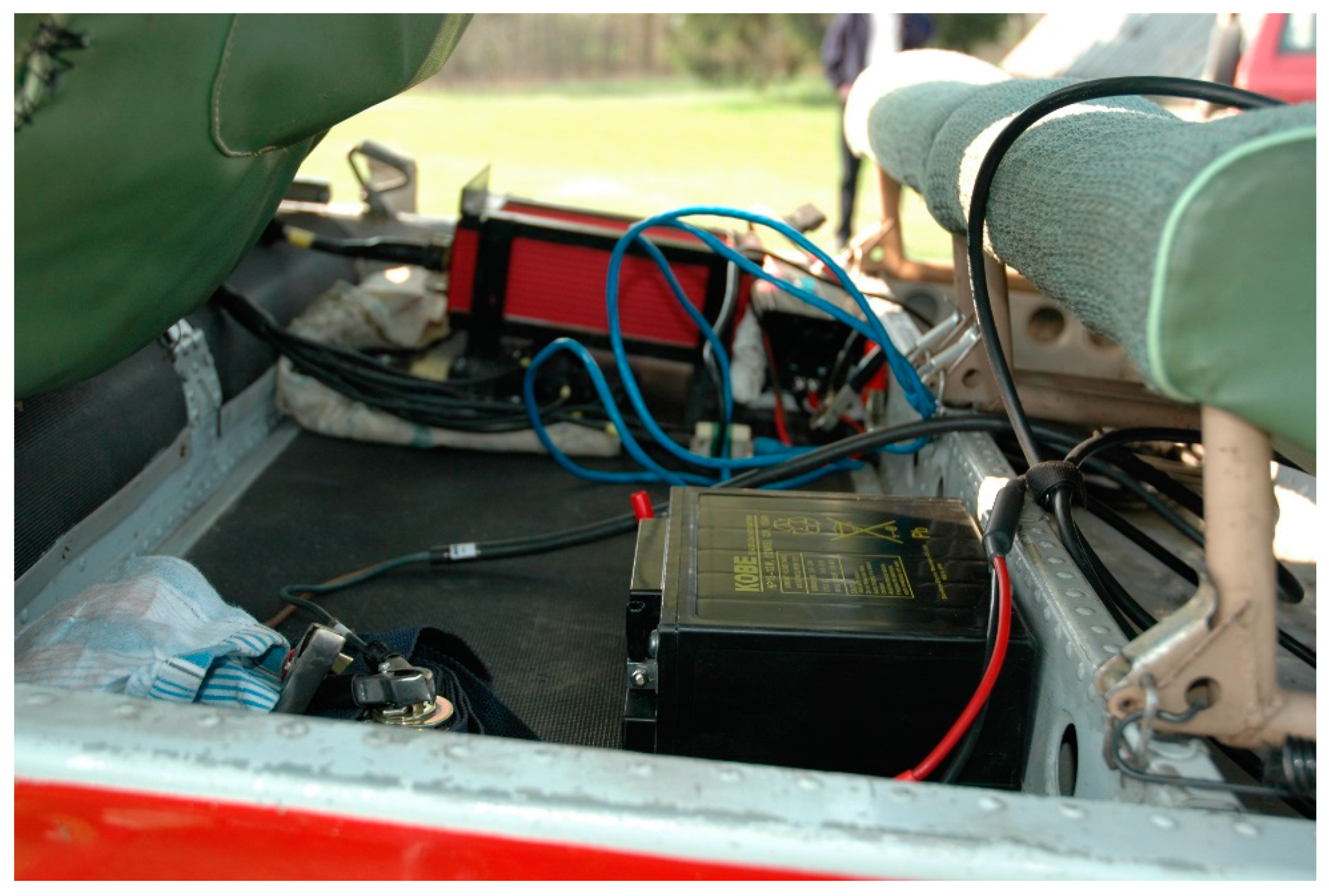

2.2. The CORREVIT L400 Optical Sensor

2.3. The Test Airplane

2.4. Airfield Conditions and Procedures

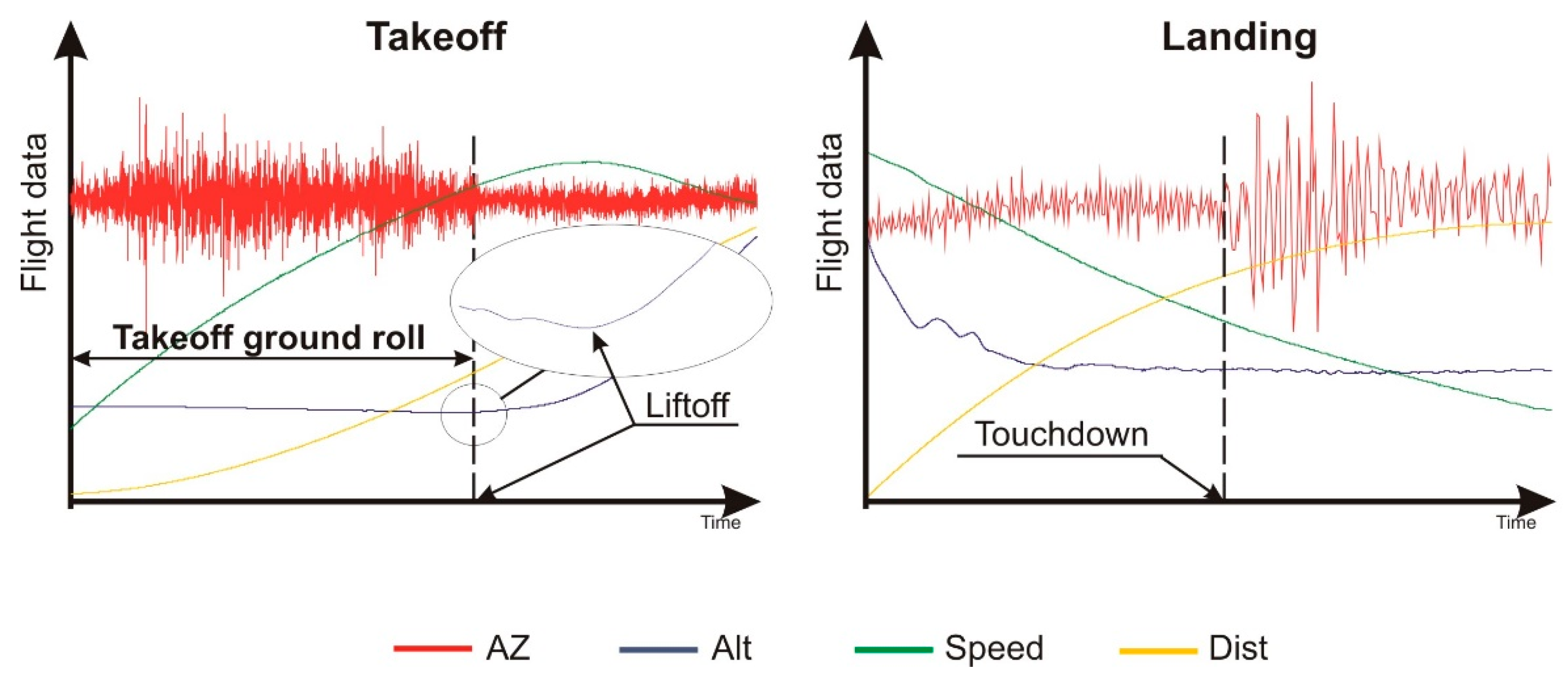

2.5. Data Reduction Methods

- Manually given by a test engineer who was observing the undercarriage wheel of the test airplane. This input was given by simply clicking the microphone, connected to the DAT recorder, and marking the time point when the airplane lifted off;

- Instrumentally obtained by analyzing the outgoing signal when it vanished due to increasing altitude.

3. Results

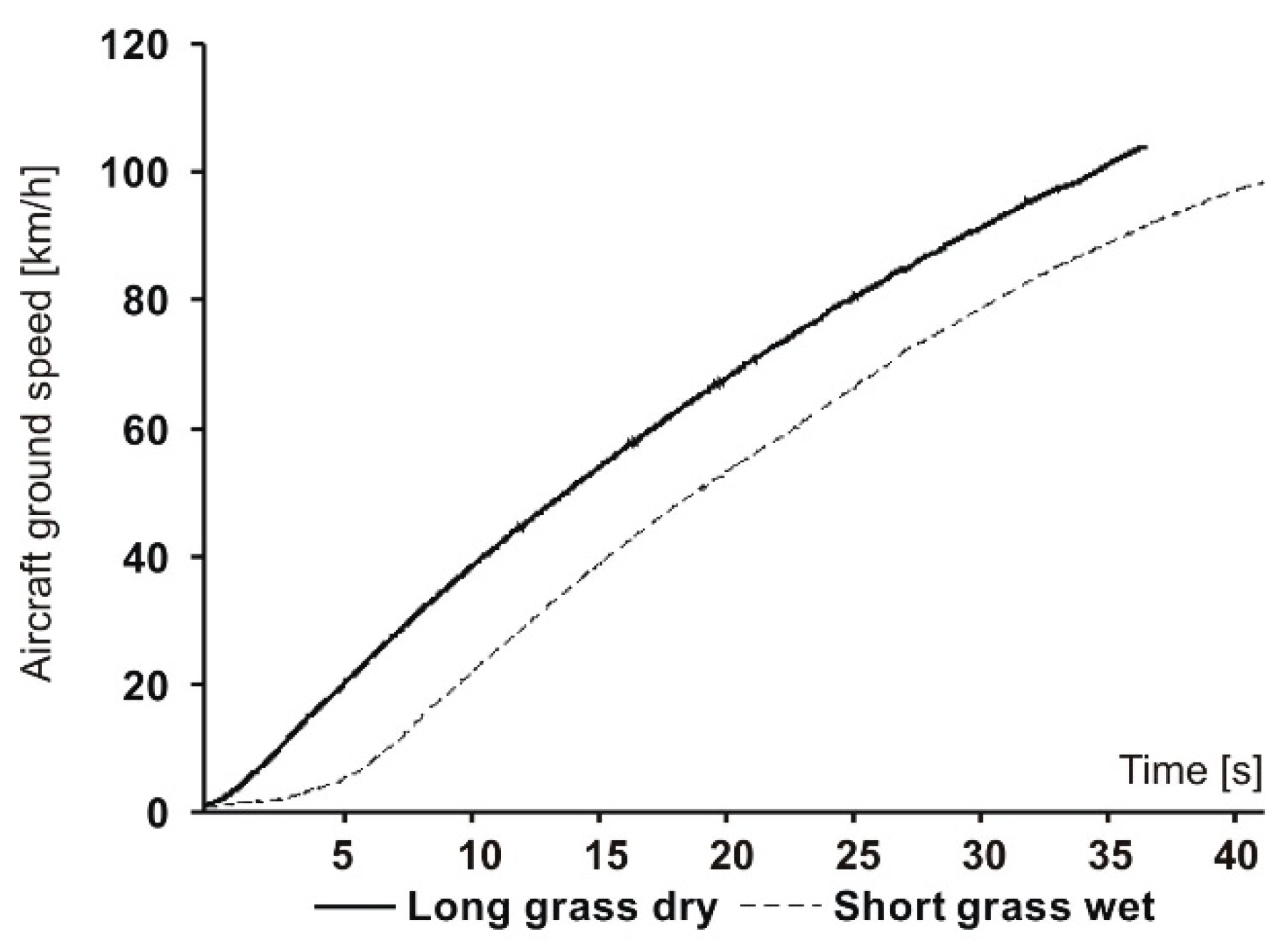

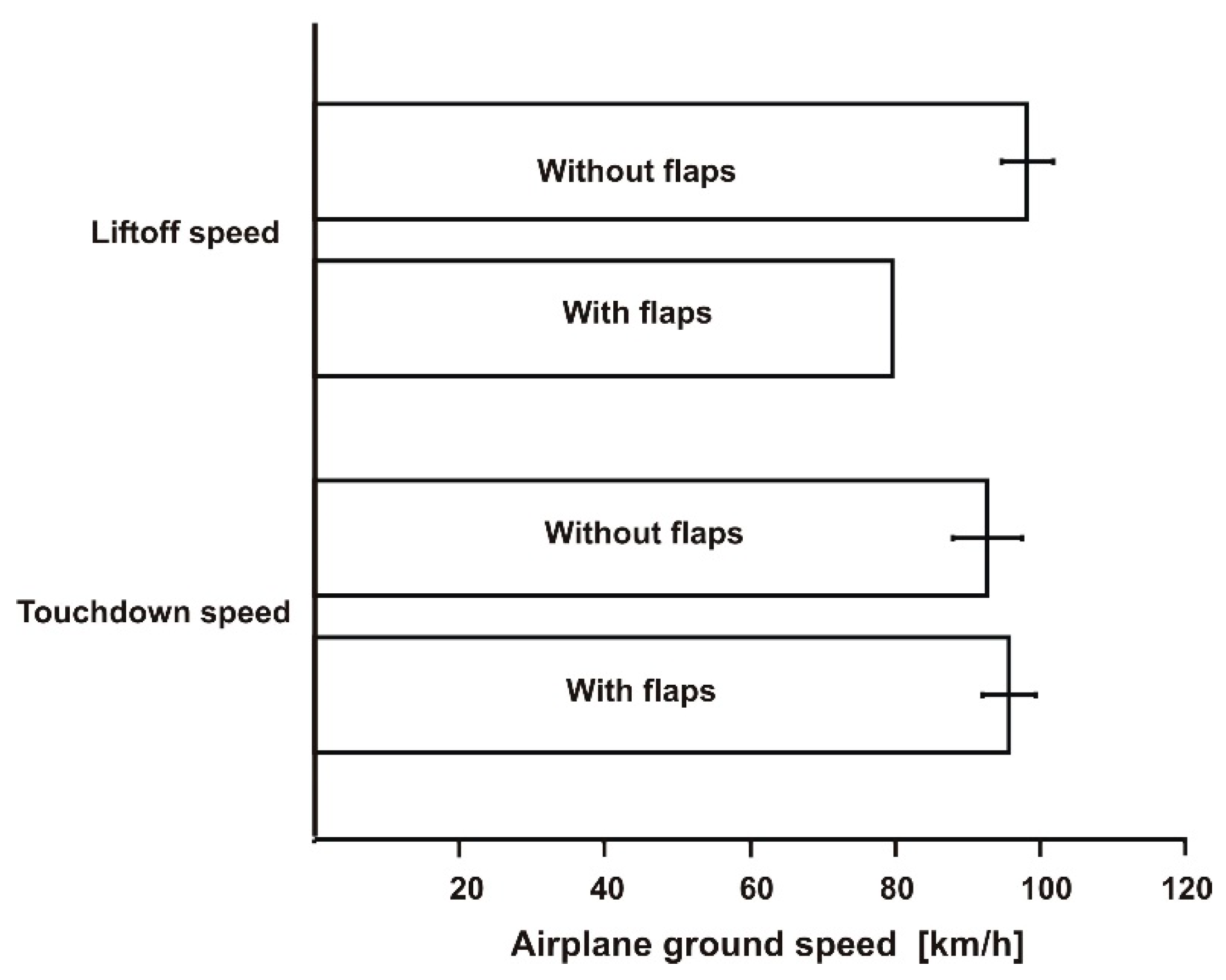

3.1. Airplane Ground Speed Profiles

- in the after-liftoff flare, the aerodynamic lift force is equal to aircraft’s weight with respect to climb angle:

- the aerodynamic drag is equal to the propeller thrust force minus the longitudinal acceleration of the entire aircraft (determined from speed data for the after-liftoff flare):where CD, CL = aerodynamic coefficients, S = reference area, and ρ = air density.

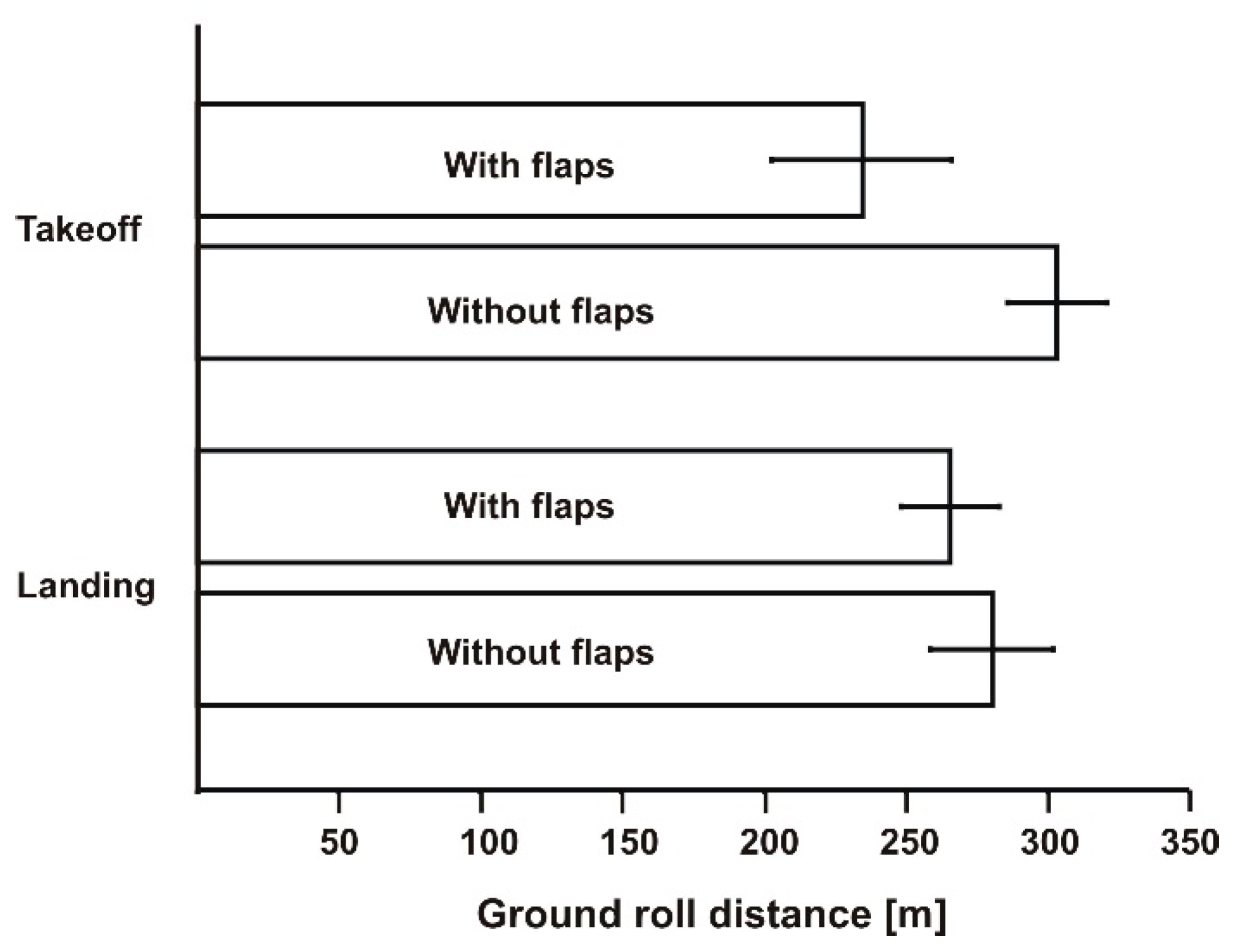

3.2. Distances of Takeoff and Landing of the Wilga Airplane on a Grassy Runway

4. Comparison of the Two Sensors

4.1. Accuracy and Functionality

- Accuracy of measurement of the basic parameter;

- Human factor—manual determination of the lift off or touchdown.

4.2. Installation and Operation

4.3. Cost and Other Issues

5. Verification of Measurements with Calculated Values of Takeoff Ground Roll Distances

5.1. Homebuilt Designer Equation

5.2. Filippone Equation

5.3. Rapid Takeoff Distance Equation

5.4. Results Comparison

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Pytka, J.; Józwik, J.; Łyszczyk, T.; Budzyński, P.; Laskowski, J. Gnapowski Measurement of Takeoff and Landing Ground Roll of Airplane on Grassy Runway. In Proceedings of the 2019 IEEE 5th International Workshop on Metrology for AeroSpace (MetroAeroSpace), Torino, Italy, 19–21 June 2019. [Google Scholar]

- Dąbrowski, J.; Pytka, J.; Tarkowski, P.; Zając, M. Advantages of all-season versus snow tyres for off-road traction and soil stresses. J. Terramech. 2006, 43, 163–175. [Google Scholar] [CrossRef]

- Pytka, J. A semiempirical model of a wheel-soil system. Int. J. Automot. Techn. 2010, 11, 681–690. [Google Scholar] [CrossRef]

- Pytka, J.; Józwik, J.; Budzyński, P.; Łyszczyk, T.; Tofil, A.; Gnapowski, E.; Laskowski, J. Wheel dynamometer system for aircraft landing gear testing. Measurement 2019, 148. [Google Scholar] [CrossRef]

- Pytka, J.; Budzyński, P.; Kamiński, M.; Łyszczyk, T.; Józwik, J. Application of the TDR Moisture Sensor for Terramechanical Research. Sensors 2019, 19, 2116. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shoop, S.A.; Diemand, D.; Wieder, W.L.; Mason, G.L.; Seman, P.M. Predicting California Bearing Ratio from Trafficability Cone Index Values; CRREL Techn Rep TR-08-17; Engineer Research and Development Center Hanover Nh Cold Regions Research and Engineering Lab: Hanover, NH, USA, 2008. [Google Scholar]

- van Es, G.W.H. Method for predicting the rolling resistance of aircraft tires in dry snow. J. Aircr. 1999, 36, 762–768. [Google Scholar] [CrossRef]

- Pytka, J. Identification of Rolling Resistance Coefficients for Aircraft Tires on Unsurfaced Airfields. J. Aircr. 2014, 51, 353–360. [Google Scholar] [CrossRef]

- Shoop, S.A. Estimating rolling friction of loose till for aircraft takeoff on dirt runways. In Proceedings of the 13th International Conference of the ISTVS, Munich, Germany, 14–17 September 1999; pp. 421–427. [Google Scholar]

- Rowe, R.S.; Hegedus, E. Drag Coefficients of Locomotion over Viscous Soil; Report No.54; Department of the Army, Ordnance Tank—Automotive Command, Land Locomotion Laboratory: Centerline, MI, USA, July 1959. [Google Scholar]

- Crenshaw, B. Soil—Wheel interaction at high speed. J. Terramech. 1972, 8, 71–88. [Google Scholar] [CrossRef]

- Howland, H.J. Soil inertia in wheel-soil interaction. J. Terramech. 1973, 10, 47–65. [Google Scholar] [CrossRef]

- Gibbesch, A. Reifen-Boden Interaktion von Flugzeugen auf Nachgeibigen Landebahnen beihohen Geschwindigkeiten. In Proceedings of the Luft-Und Raumfahrt Kongress DLR-Deutsches Zentrum Fur Luft- undRaumfahrt, München, Germany, 17–20 November 2003; pp. 2079–2085. [Google Scholar]

- Pytka, J.; Józwik, J.; Łyszczyk, T.; Gnapowski, E. Method for Determination of Airplane Takeoff and Landing Distance. In Proceedings of the 2018 5th IEEE International Workshop on Metrology for AeroSpace (MetroAeroSpace), Rome, Italy, 20–22 June 2018. [Google Scholar]

- Albéri, M.; Baldoncini, M.; Bottardi, C.; Chiarelli, E.; Fiorentini, G.; Raptis, K.; Strati, V. Accuracy of flight altitude measured with low-cost GNSS, radar and barometer sensors: Implications for airborne radiometric surveys. Sensors 2017, 17, 1889. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Raymer, D. Aircraft Design. A Conceptual Approach; American Institute of Aeronautics and Astronautics, Inc.: Washington, DC, USA, 1992. [Google Scholar]

- Stinton, D. Flying Qualities and Flight Testing of the Aeroplane; Blackwell Science: Oxford, UK, 1998. [Google Scholar]

- Jarząb, K. Obliczanie zdolności startowej. Skrzyd. Pol. 1986, 1808, 12. [Google Scholar]

- Filippone, A. Flight Performance of Fixed and Rotary Wing Aircraft; AIAA Education Series; AIAA: Washington, DC, USA, 2006. [Google Scholar]

- Gudmundsson, S. General Aviation Aircraft Design. Applied Methods and Procedures; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

| Functionality | Accuracy * | Installation and Operation | Data Handling ** | Cost |

|---|---|---|---|---|

| CORREVITR Optical Sensor | ||||

| Full functionality in the described research | 0.0027 m | Difficult and time consuming | Easy and reliable | High |

| GNSS/INS Sensor | ||||

| Full functionality in the described research | 0.001 m | Easy and quick installation, but difficult data gathering | Difficult, the data can be missed | High |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pytka, J.; Budzyński, P.; Józwik, J.; Michałowska, J.; Tofil, A.; Łyszczyk, T.; Błażejczak, D. Application of GNSS/INS and an Optical Sensor for Determining Airplane Takeoff and Landing Performance on a Grassy Airfield. Sensors 2019, 19, 5492. https://doi.org/10.3390/s19245492

Pytka J, Budzyński P, Józwik J, Michałowska J, Tofil A, Łyszczyk T, Błażejczak D. Application of GNSS/INS and an Optical Sensor for Determining Airplane Takeoff and Landing Performance on a Grassy Airfield. Sensors. 2019; 19(24):5492. https://doi.org/10.3390/s19245492

Chicago/Turabian StylePytka, Jaroslaw, Piotr Budzyński, Jerzy Józwik, Joanna Michałowska, Arkadiusz Tofil, Tomasz Łyszczyk, and Dariusz Błażejczak. 2019. "Application of GNSS/INS and an Optical Sensor for Determining Airplane Takeoff and Landing Performance on a Grassy Airfield" Sensors 19, no. 24: 5492. https://doi.org/10.3390/s19245492

APA StylePytka, J., Budzyński, P., Józwik, J., Michałowska, J., Tofil, A., Łyszczyk, T., & Błażejczak, D. (2019). Application of GNSS/INS and an Optical Sensor for Determining Airplane Takeoff and Landing Performance on a Grassy Airfield. Sensors, 19(24), 5492. https://doi.org/10.3390/s19245492