Damage Detection Performance of the Electromechanical Impedance (EMI) Technique with Various Attachment Methods on Glass Fibre Composite Plates

Abstract

:1. Introduction

2. Electromechanical Impedance (EMI) Technique

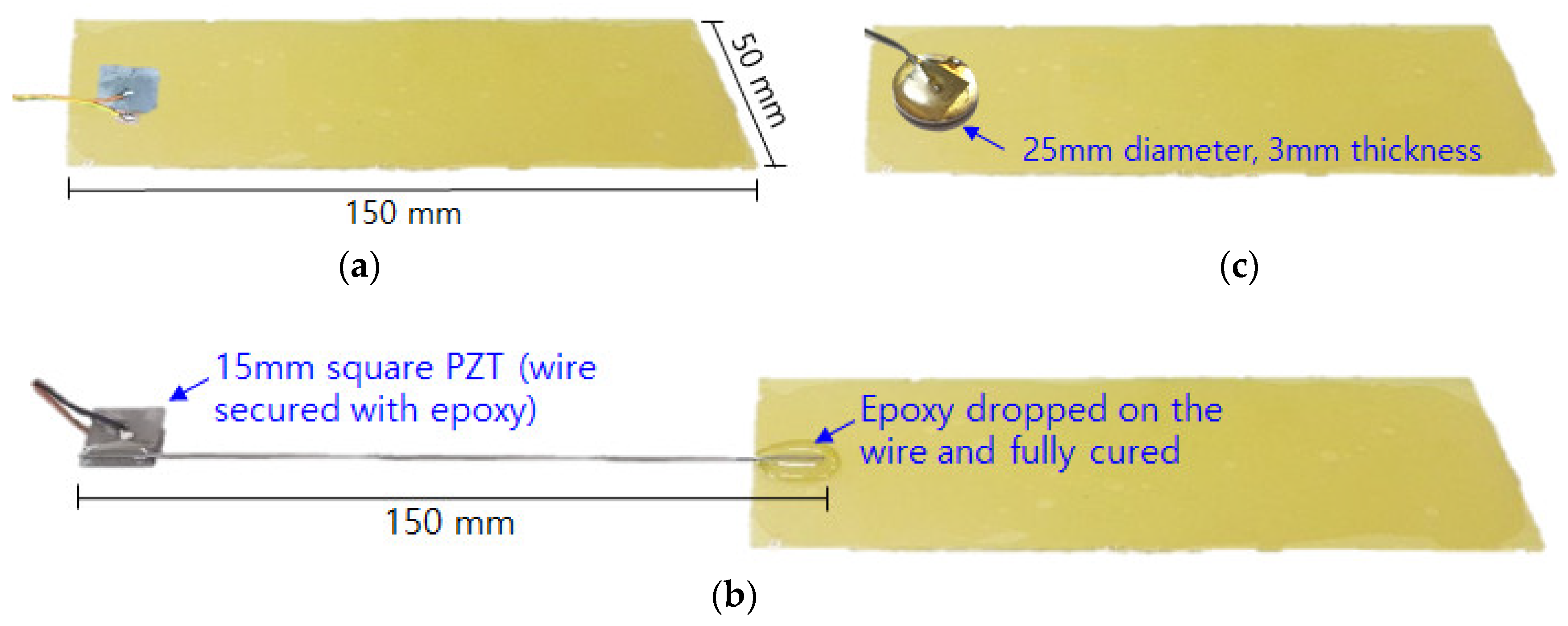

3. Various PZT Attachment Methods

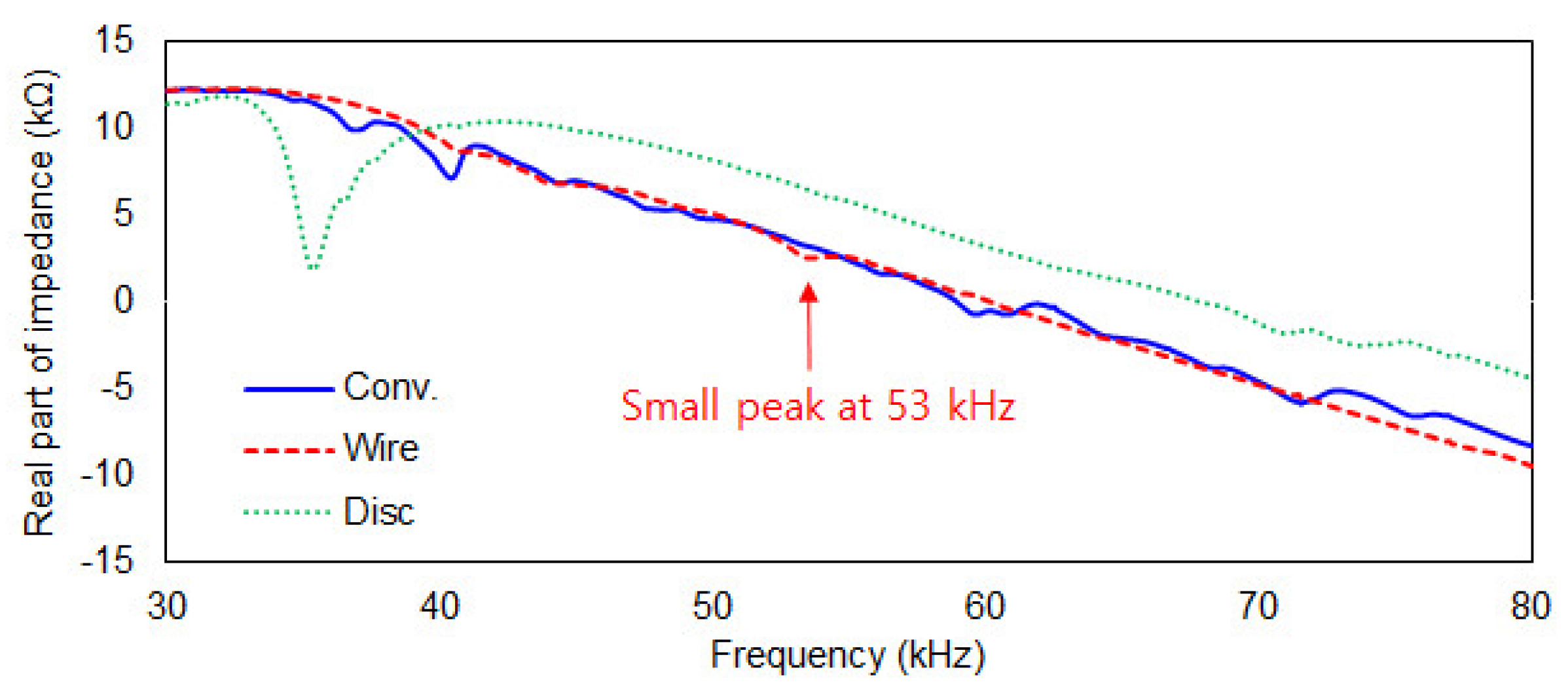

3.1. Conventional PZT Attachment

3.2. Steel Wire-PZT Attachment

3.3. Metal Disc-PZT Attachment

4. Experimental Setup for Damage Detection Performance

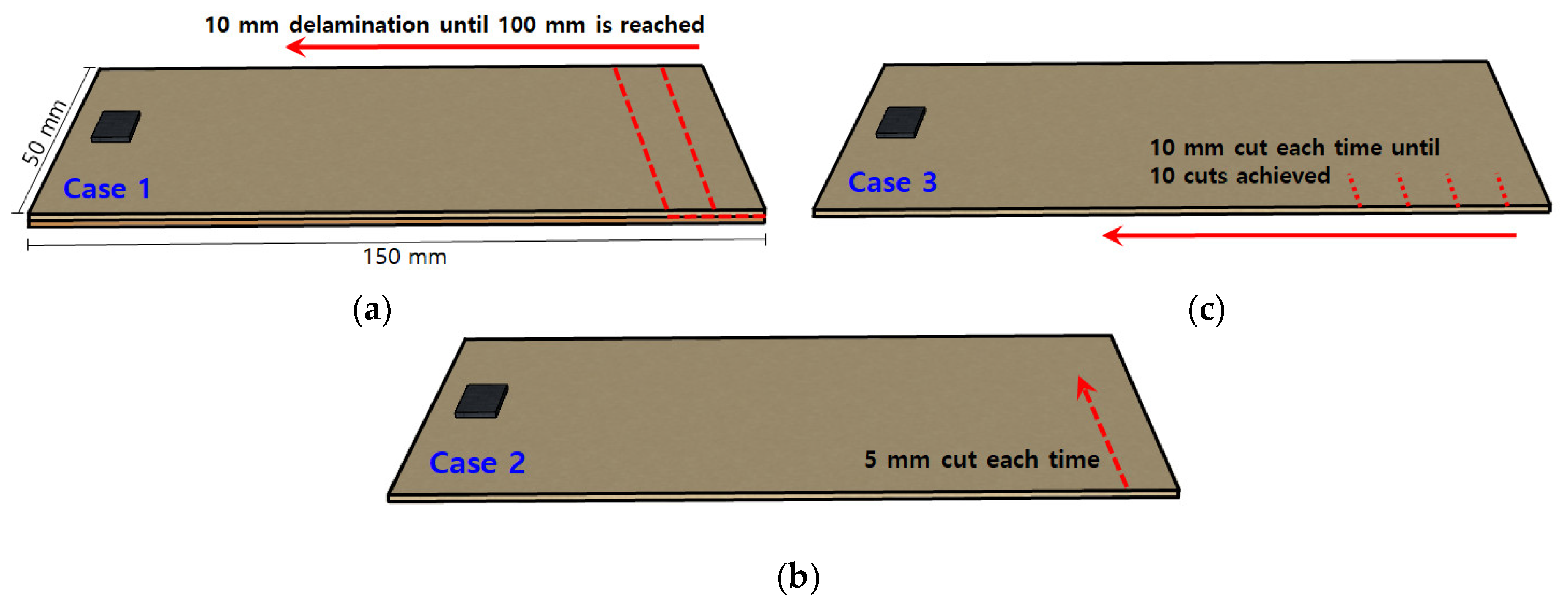

4.1. Delamination Defect between Two Composite Plates

4.2. Increasing Crack Damage at a Fixed Location

4.3. Progressive Crack Damage towards the PZT Patch

5. Discussion and Results

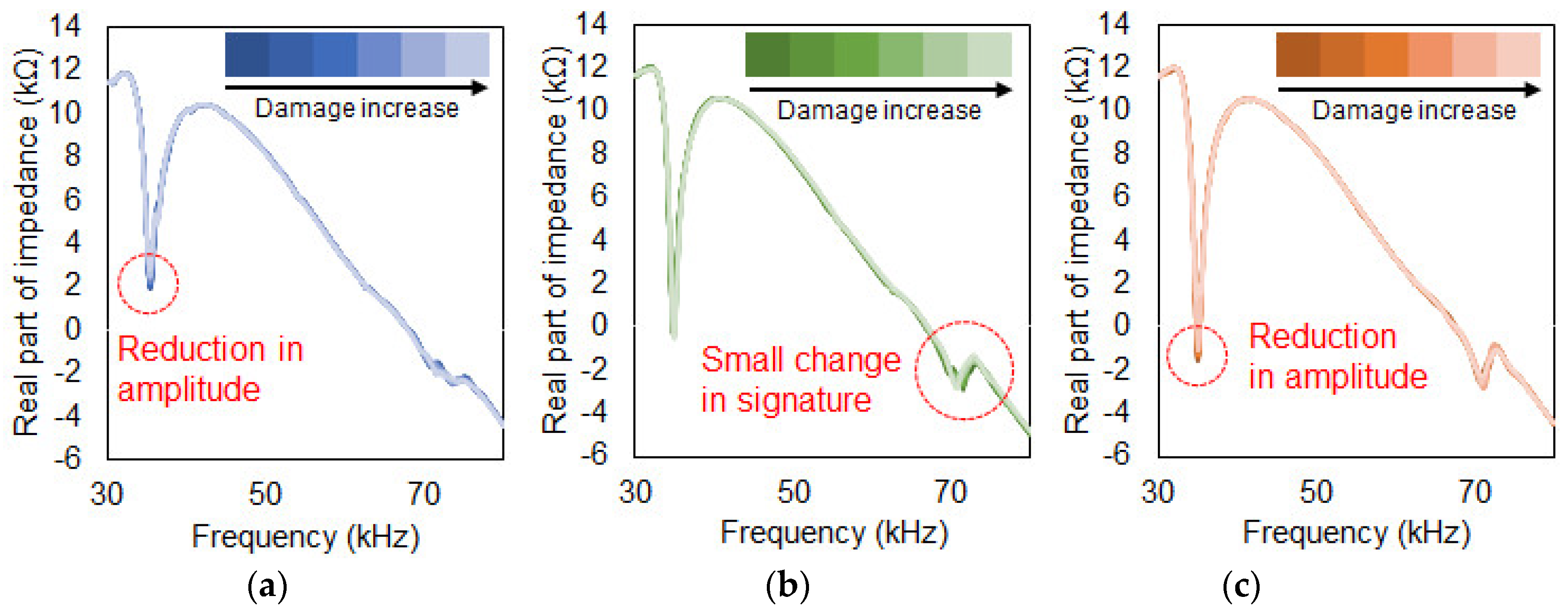

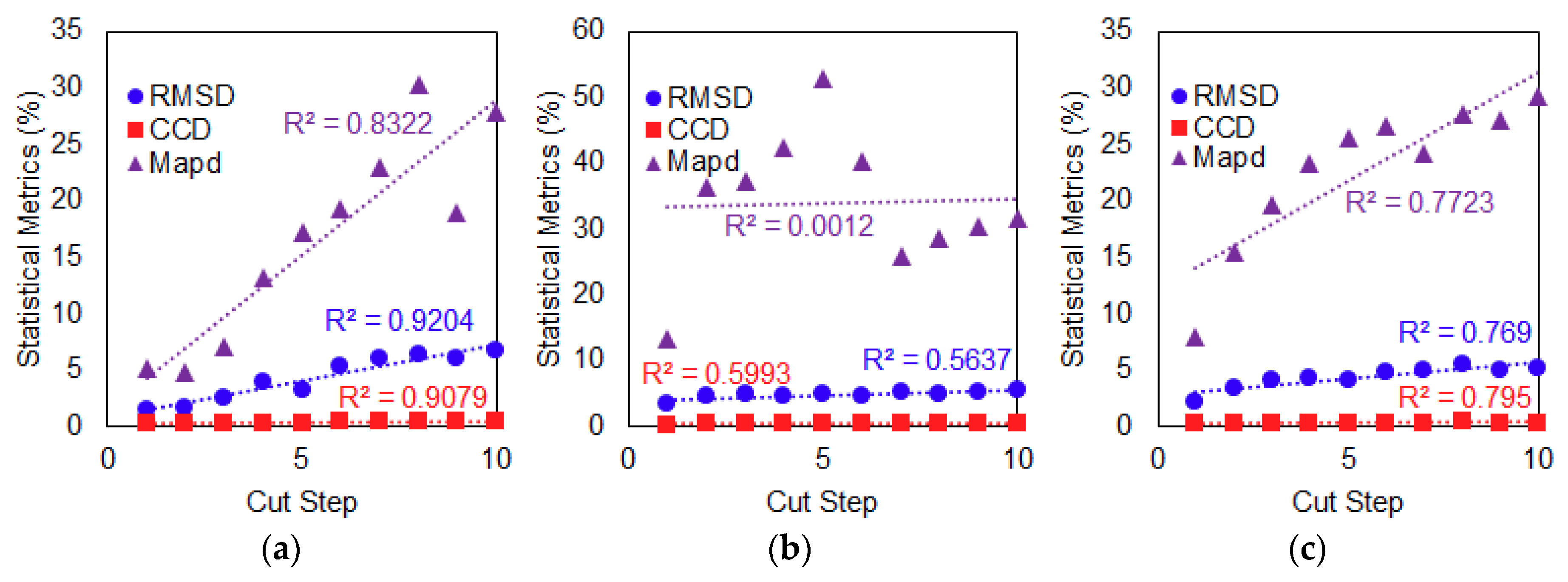

5.1. Damage Detection Performance of Conventional PZT Attachment Method

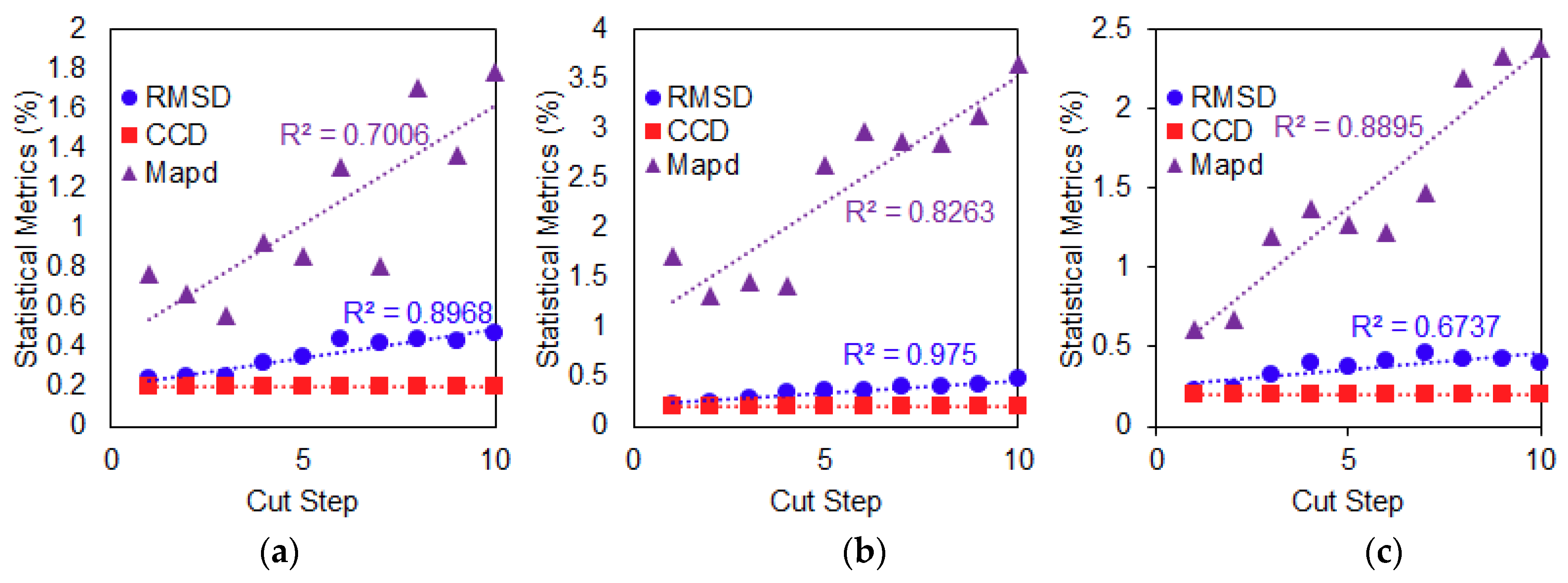

5.2. Damage Detection Performance of the Steel Wire-PZT Attachment Method

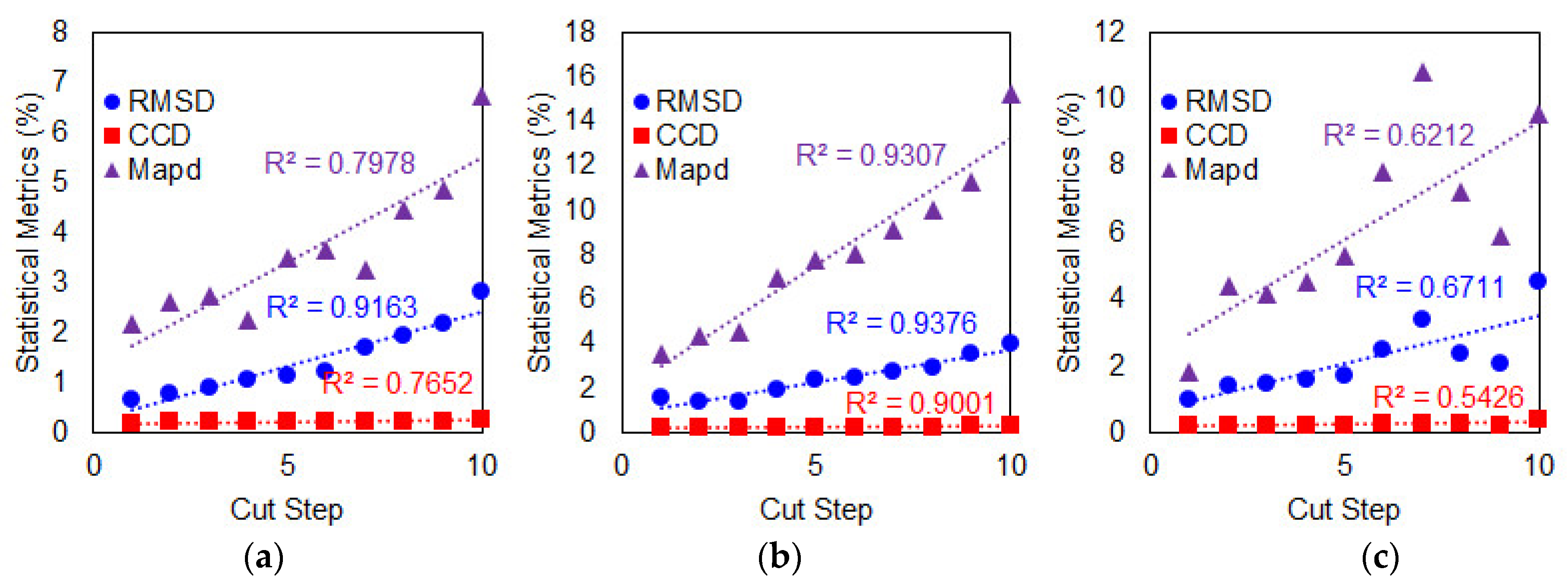

5.3. Damage Detection Performance of Metal Disc-PZT Attachment Method

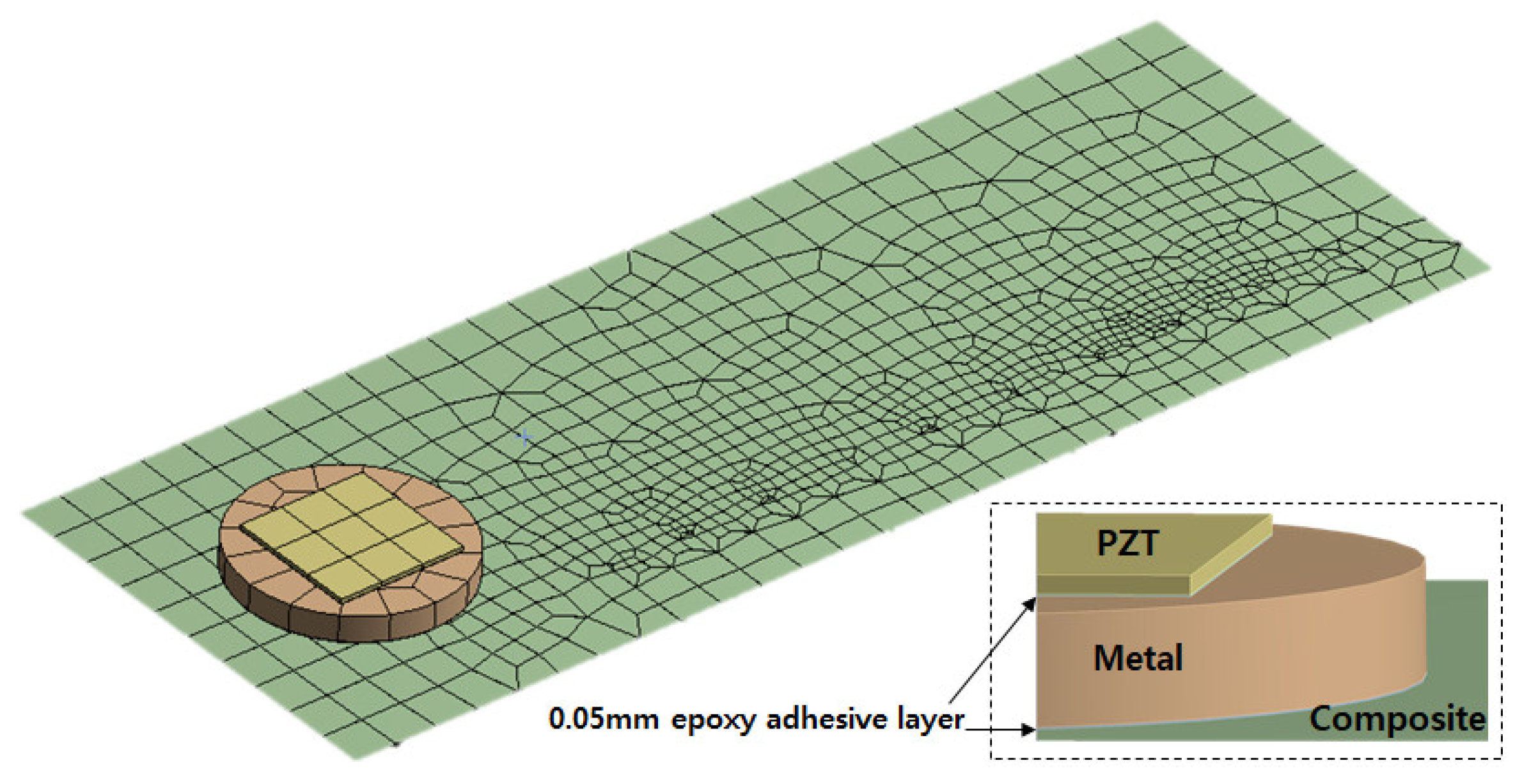

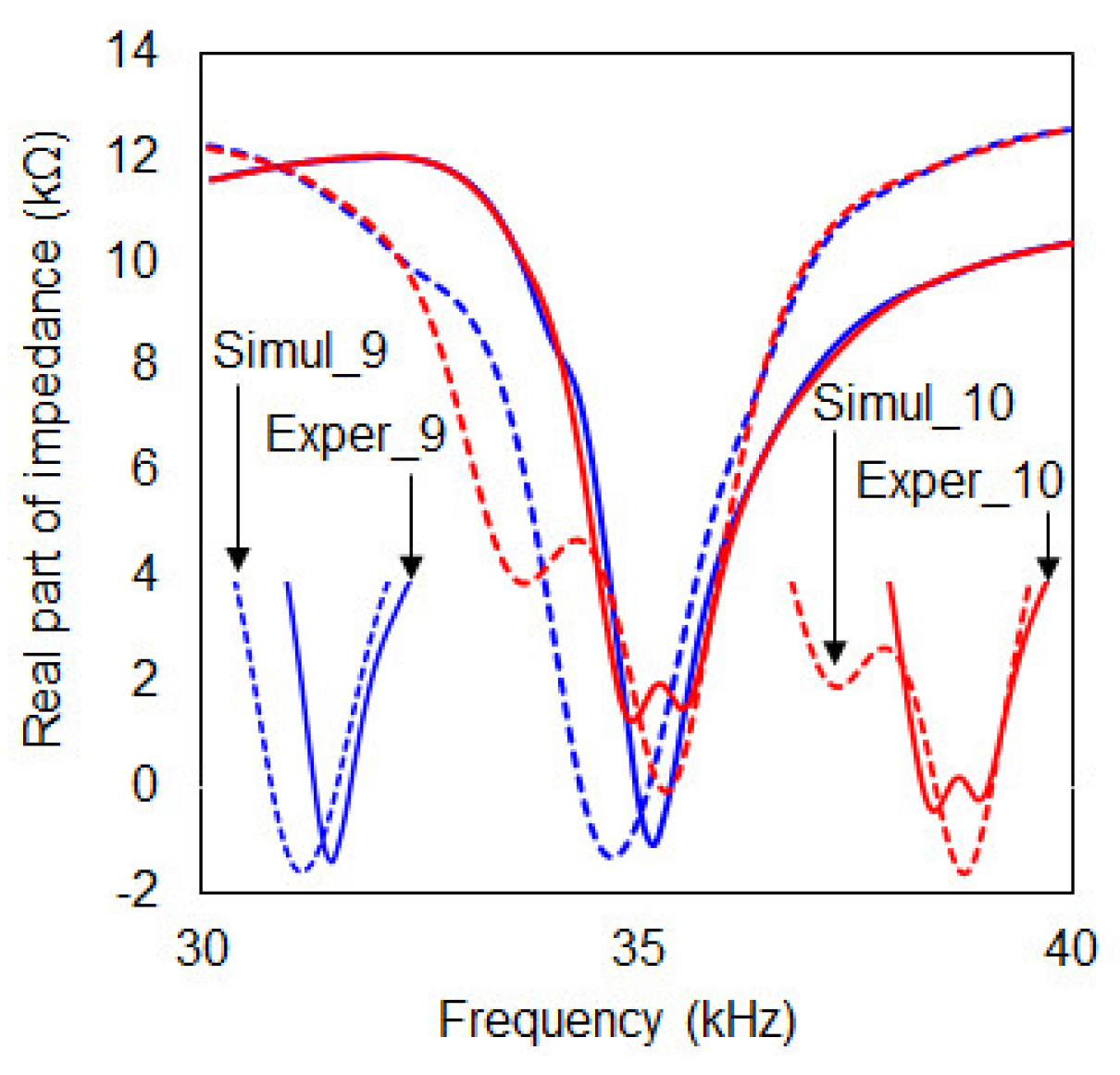

6. Finite Element Modelling and Simulation

7. Conclusions

- -

- From the results, it was confirmed that the use of a thinner plate influences the performance of the conventional attachment method due to existence of multiple peaks in the frequency range of the impedance signatures. The conventional PZT attachment method was reliable for detecting a delamination defect (Case 1) and progressive crack damage (Case 3) when quantified using the three different statistical metrics, namely RMSD, MAPD and CCD.

- -

- Overall, the performance of the steel wire-PZT attachment method was quite good in all three cases of damage types, especially when the damage was quantified using RMSD and MAPD. However, no relationship was found between CCD values and any of the three damage types. The steel wire-PZT attachment method performed better than the conventional PZT attachment method using RMSD and MAPD metrics in detecting increasing crack damage at a fixed location (Case 2).

- -

- Finally, one can conclude that an effective way of monitoring a thin composite structure would be to use both the RMSD and MAPD values as the results showed that the RMSD has best R2 values where MAPD values better indicated the existence of damage.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Jollivet, T.; Peyrac, C.; Lefebvre, F. Damage of composite materials. Procedia Eng. 2013, 66, 746–758. [Google Scholar] [CrossRef]

- Aymerich, F.; Meili, S. Ultrasonic evaluation of matrix damage in impacted composite laminates. Compos. Part B–Eng. 2000, 31, 1–6. [Google Scholar] [CrossRef]

- De Goeje, M.P.; Wapenaar, K.E.D. Non-destructive inspection of carbon fibre-reinforced plastics using eddy current methods. Composites 1992, 23, 147–157. [Google Scholar] [CrossRef]

- Scott, I.G.; Scala, C.M. A review of non-destructive testing of composite materials. NDT Int. 1982, 15, 75–86. [Google Scholar] [CrossRef]

- Avdelidis, N.P.; Moropoulou, A. Applications of infrared thermography for the investigation of historic structures. J. Cult. Herit. 2004, 5, 119–127. [Google Scholar] [CrossRef]

- Cloetens, P.; Pateyron-Salomé, M.; Buffiere, J.Y.; Peix, G.; Baruchel, J.; Peyrin, F.; Schlenker, M. Observation of microstructure and damage in materials by phase sensitive radiography and tomography. J. Appl. Phys. 1997, 81, 5878–5886. [Google Scholar] [CrossRef]

- Wu, D.; Zweschper, T.; Salerno, A.; Busse, G. Lock-in thermography for nondestructive evaluation of aerospace structures. NDT. Net 1998, 3. [Google Scholar]

- Dos Santo, J.A.; Lopes, H.M.R.; Vaz, M.; Soares, C.M.; Soares, C.M.; De Freitas, M.J.M. Damage localization in laminated composite plates using mode shapes measured by pulsed TV holography. Compos. Struct. 2006, 76, 272–281. [Google Scholar] [CrossRef]

- Zou, F.; Aliabadi, M.H. A boundary element method for detection of damages and self-diagnosis of transducers using electro-mechanical impedance. Smart Mater. Struct. 2015, 24, 095015. [Google Scholar] [CrossRef]

- Dugnani, R.; Zhuang, Y.; Kopsaftopoulos, F.; Chang, F.K. Adhesive bond-line degradation detection via a cross-correlation electromechanical impedance–based approach. Struct. Health Monit. 2016, 15, 650–667. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, J.; Guan, W.; Du, G. Damage Detection of Concrete-Filled Square Steel Tube (CFSST) Column Joints under Cyclic Loading Using Piezoceramic Transducers. Sensors 2018, 18, 3266. [Google Scholar] [CrossRef] [PubMed]

- Naidu, A.S.; Pittala, V. Influence of piezoelectric parameters on admittance diagnostic signals for structural health monitoring: A numerical study. Int. J. Mater. Struct. Integr. 2018, 12, 316–338. [Google Scholar] [CrossRef]

- Tinoco, H.; Cardona, C.; Peña, F.; Gomez, J.; Roldan-Restrepo, S.; Velasco-Mejia, M.; Barco, D. Evaluation of a Piezo-Actuated Sensor for Monitoring Elastic Variations of Its Support with Impedance-Based Measurements. Sensors 2019, 19, 184. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Feng, Q.; Li, D.; Cai, S. Loosening Monitoring of a Threaded Pipe Connection Using the Electro-Mechanical Impedance Technique—Experimental and Numerical Studies. Sensors 2018, 18, 3699. [Google Scholar] [CrossRef] [PubMed]

- Na, W.S. Distinguishing crack damage from debonding damage of glass fiber reinforced polymer plate using a piezoelectric transducer based nondestructive testing method. Compos. Struct. 2017, 159, 517–527. [Google Scholar] [CrossRef]

- Na, W.S. Low cost technique for detecting adhesive debonding damage of glass epoxy composite plate using an impedance based non-destructive testing method. Compos. Struct. 2018, 189, 99–106. [Google Scholar] [CrossRef]

- Liang, C.; Sun, F.P.; Rogers, C.A. Coupled electro-mechanical analysis of adaptive material systems—Determination of the actuator power consumption and system energy transfer. J. Intell. Mater. Syst. Struct. 1997, 8, 335–343. [Google Scholar] [CrossRef]

- Panigrahi, R.; Bhalla, S.; Gupta, A. A low cost variant of electro-mechanical impedance (EMI) technique for structural health monitoring. Exp. Tech. 2010, 34, 25–29. [Google Scholar] [CrossRef]

- Na, S.; Lee, H.K. Steel wire electromechanical impedance method using a piezoelectric material for composite structures with complex surfaces. Compos. Struct. 2013, 98, 79–84. [Google Scholar] [CrossRef]

- Na, S.; Lee, H.K. Resonant frequency range utilized electro-mechanical impedance method for damage detection performance enhancement on composite structures. Compos. Struct. 2012, 94, 2383–2389. [Google Scholar] [CrossRef]

| Cut | Case 1 | Case 2 | Case 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Step | RMSD | MAPD | CCD | RMSD | MAPD | CCD | RMSD | MAPD | CCD |

| 1 | 1.53 | 5.13 | 0.21 | 3.31 | 0.26 | 13.20 | 2.09 | 0.22 | 7.87 |

| 2 | 1.63 | 4.80 | 0.21 | 4.77 | 0.32 | 36.27 | 3.36 | 0.26 | 15.47 |

| 3 | 2.50 | 7.03 | 0.24 | 4.85 | 0.33 | 37.18 | 4.08 | 0.29 | 19.64 |

| 4 | 3.87 | 13.18 | 0.28 | 4.77 | 0.32 | 42.35 | 4.34 | 0.30 | 23.38 |

| 5 | 3.21 | 17.13 | 0.26 | 4.97 | 0.33 | 52.92 | 4.17 | 0.29 | 25.50 |

| 6 | 5.26 | 19.22 | 0.36 | 4.55 | 0.31 | 40.36 | 4.77 | 0.32 | 26.68 |

| 7 | 6.02 | 22.96 | 0.40 | 5.26 | 0.35 | 25.85 | 4.93 | 0.33 | 24.25 |

| 8 | 6.43 | 30.24 | 0.43 | 4.93 | 0.33 | 28.66 | 5.52 | 0.37 | 27.62 |

| 9 | 6.06 | 18.90 | 0.40 | 5.31 | 0.35 | 30.50 | 4.92 | 0.33 | 27.06 |

| 10 | 6.64 | 27.85 | 0.43 | 5.45 | 0.36 | 31.59 | 5.12 | 0.34 | 29.18 |

| Cut | Case 1 | Case 2 | Case 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Step | RMSD | MAPD | CCD | RMSD | MAPD | CCD | RMSD | MAPD | CCD |

| 1 | 0.24 | 0.20 | 0.77 | 0.22 | 0.20 | 1.72 | 0.23 | 0.20 | 0.61 |

| 2 | 0.25 | 0.20 | 0.67 | 0.25 | 0.20 | 1.32 | 0.24 | 0.20 | 0.68 |

| 3 | 0.25 | 0.20 | 0.56 | 0.28 | 0.20 | 1.46 | 0.32 | 0.20 | 1.20 |

| 4 | 0.32 | 0.20 | 0.93 | 0.33 | 0.20 | 1.42 | 0.40 | 0.20 | 1.37 |

| 5 | 0.35 | 0.20 | 0.86 | 0.35 | 0.20 | 2.64 | 0.38 | 0.20 | 1.27 |

| 6 | 0.44 | 0.20 | 1.31 | 0.36 | 0.20 | 2.97 | 0.41 | 0.20 | 1.22 |

| 7 | 0.42 | 0.20 | 0.81 | 0.39 | 0.20 | 2.87 | 0.46 | 0.20 | 1.47 |

| 8 | 0.44 | 0.20 | 1.71 | 0.40 | 0.20 | 2.86 | 0.43 | 0.20 | 2.20 |

| 9 | 0.43 | 0.20 | 1.37 | 0.42 | 0.20 | 3.13 | 0.42 | 0.20 | 2.33 |

| 10 | 0.47 | 0.20 | 1.79 | 0.47 | 0.20 | 3.65 | 0.40 | 0.20 | 2.38 |

| Cut | Case 1 | Case 2 | Case 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Step | RMSD | MAPD | CCD | RMSD | MAPD | CCD | RMSD | MAPD | CCD |

| 1 | 0.68 | 0.20 | 2.16 | 1.57 | 0.22 | 3.59 | 0.97 | 0.21 | 1.86 |

| 2 | 0.78 | 0.21 | 2.61 | 1.38 | 0.21 | 4.35 | 1.41 | 0.22 | 4.39 |

| 3 | 0.92 | 0.21 | 2.72 | 1.39 | 0.21 | 4.53 | 1.48 | 0.22 | 4.16 |

| 4 | 1.08 | 0.21 | 2.26 | 1.92 | 0.23 | 7.01 | 1.59 | 0.22 | 4.55 |

| 5 | 1.14 | 0.21 | 3.50 | 2.43 | 0.24 | 7.75 | 1.71 | 0.23 | 5.29 |

| 6 | 1.24 | 0.21 | 3.64 | 2.48 | 0.25 | 8.06 | 2.47 | 0.25 | 7.83 |

| 7 | 1.69 | 0.23 | 3.25 | 2.76 | 0.26 | 9.12 | 3.38 | 0.30 | 10.8 |

| 8 | 1.95 | 0.23 | 4.44 | 2.96 | 0.26 | 10.03 | 2.38 | 0.25 | 7.19 |

| 9 | 2.17 | 0.24 | 4.84 | 3.54 | 0.29 | 11.26 | 2.10 | 0.24 | 5.89 |

| 10 | 2.82 | 0.27 | 6.73 | 3.98 | 0.31 | 15.27 | 4.51 | 0.38 | 9.58 |

| PSI-5A4E | ||

|---|---|---|

| Density | 7800 | |

| Damping Ratio | 0.0125 | |

| Stiffness Matrix [cE] | C11 = C22 | 152 |

| C12 | 102 | |

| C13 = C23 | 100 | |

| C33 | 127 | |

| C44 = C55 | 21 | |

| C66 | 25 | |

| Piezoelectric Stress Matrix [e] | e31 = e32 | –5.5 |

| e33 | 16.4 | |

| e24 = e15 | 12.4 | |

| Electric Permittivity Matrix [εs] | ε11 = ε22 | 950 |

| ε33 | 890 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tawie, R.; Park, H.B.; Baek, J.; Na, W.S. Damage Detection Performance of the Electromechanical Impedance (EMI) Technique with Various Attachment Methods on Glass Fibre Composite Plates. Sensors 2019, 19, 1000. https://doi.org/10.3390/s19051000

Tawie R, Park HB, Baek J, Na WS. Damage Detection Performance of the Electromechanical Impedance (EMI) Technique with Various Attachment Methods on Glass Fibre Composite Plates. Sensors. 2019; 19(5):1000. https://doi.org/10.3390/s19051000

Chicago/Turabian StyleTawie, Rudy, Hee Beom Park, Jongdae Baek, and Wongi S. Na. 2019. "Damage Detection Performance of the Electromechanical Impedance (EMI) Technique with Various Attachment Methods on Glass Fibre Composite Plates" Sensors 19, no. 5: 1000. https://doi.org/10.3390/s19051000

APA StyleTawie, R., Park, H. B., Baek, J., & Na, W. S. (2019). Damage Detection Performance of the Electromechanical Impedance (EMI) Technique with Various Attachment Methods on Glass Fibre Composite Plates. Sensors, 19(5), 1000. https://doi.org/10.3390/s19051000