A Guided Wave Transducer with Sprayed Magnetostrictive Powder Coating for Monitoring of Aluminum Conductor Steel-Reinforced Cables

Abstract

:1. Introduction

2. Theory of Ultrasonic Guided Waves (UGW)

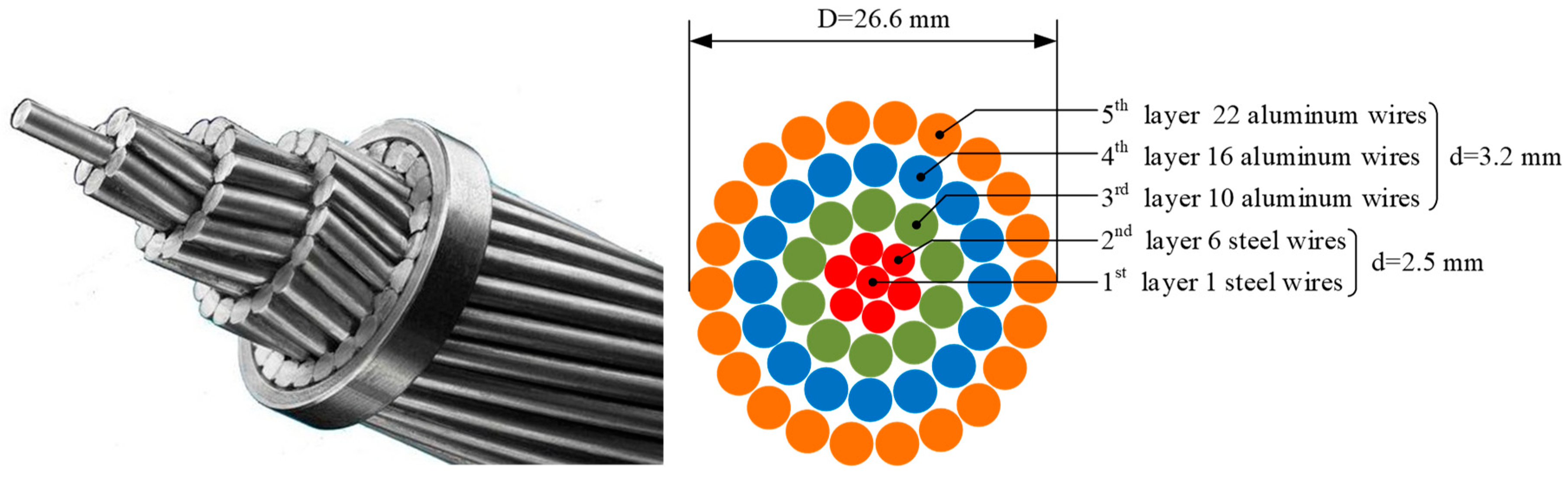

2.1. Aluminum Conductor Steel-Reinforced (ACSR) Cable Information

2.2. Dispersion Curves of Guided Waves

3. Sprayed Magnetostrictive Powder Coating (SMPC) Transducer

3.1. Magnetostrictive Powder Spraying System

3.2. Working Mechanism

4. Experimental Setup

5. Results and Discussion

5.1. ACSR Cable End Detection

5.2. ACSR Cable Defect Detection

6. Conclusion

Author Contributions

Funding

Conflicts of Interest

References

- Yang, L.; Hao, Y.P.; Li, W.-G.; Li, Z.-T. Relationships Among Transmission Line Icing, Conductor Temperature and Local Meteorology Using Grey Relational Analysis. High Volt. Eng. 2010, 36, 775–781. [Google Scholar]

- Paluch, M.; Cappellari, T.; Riera, J. Experimental and numerical assessment of EPS wind action on long span transmission line conductors. J. Wind. Eng. Ind. Aerodyn. 2007, 95, 473–492. [Google Scholar] [CrossRef]

- He, J.; Tu, Y.; Zeng, R.; Lee, J.; Chang, S.; Guan, Z. Numeral Analysis Model for Shielding Failure of Transmission Line Under Lightning Stroke. IEEE Trans. Power Deliv. 2005, 20, 815–822. [Google Scholar] [CrossRef]

- Zhao, C.; Chen, J.; Gu, S.; Ruan, J.; Li, X. Analysis On the Lightning Trip-Out Failure of Transmission Line Under Conditions of Complex Landscape in a Mountainous Area. Power Syst. Technol. 2011, 12, 135–141. [Google Scholar]

- Chen, J.; Hu, J.; Xie, Y.; Li, M.; Liu, F. Corrosion Failure of Fittings in Electric Power Transmission Line in Typical Industrial Areas. Corros. Sci. Protect. Technol. 2013, 25, 508–513. [Google Scholar]

- Wang, J.; Xiong, X.; Li, Z.; Liang, Y.; Weng, S. Time Distribution of Weather-Related Transmission Line Failure and its Fitting. Electric Power Autom. Equip. 2016, 3, 109–123. [Google Scholar]

- Shull, P.J. Nondestructive Evaluation: Theory, Techniques, and Applications; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Zhang, J.; Guo, Z.; Jiao, T.; Wang, M. Defect Detection of Aluminum Alloy Wheels in Radiography Images Using Adaptive Threshold and Morphological Reconstruction. Appl. Sci. 2018, 8, 2365. [Google Scholar] [CrossRef]

- Omidi, P.; Zafar, M.; Mozaffarzadeh, M.; Hariri, A.; Haung, X.; Orooji, M.; Nasiriavanaki, M. A Novel Dictionary-Based Image Reconstruction for Photoacoustic Computed Tomography. Appl. Sci. 2018, 8, 1570. [Google Scholar] [CrossRef]

- Qin, L.; Ren, H.; Dong, B.; Xing, F. Development of technique capable of identifying different corrosion stages in reinforced concrete. Appl. Acoust. 2015, 94, 53–56. [Google Scholar] [CrossRef]

- Cao, Y.-J.; Wang, J.-D.; Liu, W.; Yang, Y.-R. Wall sheeting diagnosis in fluidized beds based on chaos analysis of acoustic emission signals. J. Zhejiang Univ. Sci. A 2009, 10, 1341–1349. [Google Scholar] [CrossRef]

- Jian, J.; Xiao-Jun, Z.; Tian-Tai, G.; Si-Yuan, W. Research on ultrasonic detection of complex surfaces. J. Zhejiang Univ. Sci. A 2005, 6, 1146–1151. [Google Scholar] [CrossRef]

- Shin, E.-J.; Kang, B.; Chang, J.H. Real-Time HIFU Treatment Monitoring Using Pulse Inversion Ultrasonic Imaging. Appl. Sci. 2018, 8, 2219. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, X.; Zheng, P.; Passaro, V.M.N. Non-Destructive Detection of Wire Rope Discontinuities from Residual Magnetic Field Images Using the Hilbert-Huang Transform and Compressed Sensing. Sensors 2017, 17, 608. [Google Scholar] [CrossRef] [PubMed]

- Huang, P.-j.; Wu, Z.-t. Inversion of Thicknesses of Multi-Layered Structures from Eddy Current Testing Measurements. J. Zhejiang Univ. Sci. A 2004, 5, 86–91. [Google Scholar] [CrossRef]

- Rose, J.L. Ultrasonic Guided Waves in Solid Media; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Yao, Z.-J.; Yu, G.-L.; Wang, Y.-S.; Shi, Z.-F.; Li, J.-B. Propagation of flexural waves in phononic crystal thin plates with linear defects. J. Zhejiang Univ. Sci. A 2010, 11, 827–834. [Google Scholar] [CrossRef]

- Zhang, X.-W.; Tang, Z.-F.; Lv, F.-Z.; Pan, X.-H. Excitation of axisymmetric and non-axisymmetric guided waves in elastic hollow cylinders by magnetostrictive transducers. J. Zhejiang Univ. Sci. A 2016, 17, 215–229. [Google Scholar] [CrossRef]

- Kwun, H.; Hanley, J.J.; Bartels, K.A. Recent developments in nondestructive evaluation of steel strands and cables using magnetostrictive sensors. In Proceedings of the OCEANS 96 MTS/IEEE Conference, The Coastal Ocean—Prospects for the 21st Century, Fort Lauderdale, FL, USA, 23–26 September 1996; pp. 144–148. [Google Scholar]

- Raisutis, R.; Kazys, R.; Mazeika, L.; Zukauskas, E.; Samaitis, V.; Jankauskas, A. Ultrasonic guided wave-based testing technique for inspection of multi-wire rope structures. NDT E Int. 2014, 62, 40–49. [Google Scholar] [CrossRef]

- Schaal, C.; Bischoff, S.; Gaul, L. Energy-based models for guided ultrasonic wave propagation in multi-wire cables. Int. J. Solids Struct. 2015, 64, 22–29. [Google Scholar] [CrossRef]

- Raisutis, R.; Kazys, R.; Mazeika, L.; Samaitis, V.; Zukauskas, E. Propagation of Ultrasonic Guided Waves in Composite Multi-Wire Ropes. Materials 2016, 9, 451. [Google Scholar] [CrossRef] [PubMed]

- Treyssède, F. Dispersion curve veering of longitudinal guided waves propagating inside prestressed seven-wire strands. J. Sound Vib. 2016, 367, 56–68. [Google Scholar] [CrossRef]

- Gaul, L.; Bischoff, S.; Sprenger, H.; Haag, T. Numerical and experimental investigation of wave propagation in rod-systems with cracks. Eng. Fract. Mech. 2010, 77, 3532–3540. [Google Scholar] [CrossRef]

- Ke, W.; Peng, X.; Chen, R.; Chen, H.; Guo, X. Unmanned Aerial Vehicle Platform Selection for Overhead Transmission Line Inspection. Electric. Power Sci. Eng. 2014, 6, 46–53. [Google Scholar]

- Peungsungwal, S.; Pungsiri, B.; Chamnongthai, K.; Okuda, M. Autonomous Robot for a Power Transmission Line Inspection. IEEE Int. Symp. Circuits Syst. 2001, 3, 121–124. [Google Scholar]

- Hernandez-Salazar, C.D.; Baltazar, A.; Mijarez, R.; Solis, L.; Thompson, D.O.; Chimenti, D.E. Structural Damage Monitoring On Overhead Transmission Lines Using Guided Waves and Signal Processing. Rev. Quant. Nondestruc. Eval. 2010, 1211, 1721–1728. [Google Scholar]

- Baltazar, A.; Hernandez-Salazar, C.D.; Manzanares-Martinez, B. Study of wave propagation in a multiwire cable to determine structural damage. NDT E Int. 2010, 43, 726–732. [Google Scholar] [CrossRef]

- Legg, M.; Yücel, M.K.; Kappatos, V.; Selcuk, C.; Gan, T.-H. Increased range of ultrasonic guided wave testing of overhead transmission line cables using dispersion compensation. Ultrasonics 2015, 62, 35–45. [Google Scholar] [CrossRef]

- Qiu, J.; Ji, H.; Wang, E.; Takagi, T.; Uchimoto, T.; Cheng, J. High precision ultrasonic guided wave technique for inspection of power transmission line. Chin. J. Mech. Eng. 2016, 30, 170–179. [Google Scholar]

- Cho, S.H.; Lee, J.S.; Kim, Y.Y. Guided wave transduction experiment using a circular magnetostrictive patch and a figure-of-eight coil in nonferromagnetic plates. Appl. Phys. Lett. 2006, 88, 224101. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Kwon, Y.E. Review of magnetostrictive patch transducers and applications in ultrasonic nondestructive testing of waveguides. Ultrasonics 2015, 62, 3–19. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bartels, K.A.; Kwun, H.; Hanley, J.J. Magnetostrictive sensors for the characterization of corrosion in rebars and prestressing strands. Proc. SPIE 1996, 2946, 40–50. [Google Scholar] [CrossRef]

- Haag, T.; Beadle, B.M.; Sprenger, H.; Gaul, L. Wave-based defect detection and interwire friction modeling for overhead transmission lines. Arch. Appl. Mech. 2009, 79, 517–528. [Google Scholar] [CrossRef]

- Lin, B.; Giurgiutiu, V. Modeling and testing of PZT and PVDF piezoelectric wafer active sensors. Smart Mater. Struct. 2006, 15, 1085–1093. [Google Scholar] [CrossRef]

- Gao, H.; Ali, S.; López, B. Efficient detection of delamination in multilayered structures using ultrasonic guided wave EMATs. NDT E Int. 2010, 43, 316–322. [Google Scholar] [CrossRef]

- Wilcox, P.; Lowe, M.; Cawley, P. Omnidirectional guided wave inspection of large metallic plate structures using an EMAT array. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2005, 52, 653–665. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Glorieux, C.; Thoen, J. Laser ultrasonic study of Lamb waves: Determination of the thickness and velocities of a thin plate. Int. J. Eng. Sci. 2003, 41, 219–228. [Google Scholar] [CrossRef]

- An, Y.-K.; Park, B.; Sohn, H. Complete noncontact laser ultrasonic imaging for automated crack visualization in a plate. Smart Mater. Struct. 2013, 22, 25022. [Google Scholar] [CrossRef]

- Seung, H.M.; Park, C.I.; Kim, Y.Y. An omnidirectional shear-horizontal guided wave EMAT for a metallic plate. Ultrasonics 2016, 69, 58–66. [Google Scholar] [CrossRef] [PubMed]

- Hernandez-Valle, F.; Dixon, S. Initial tests for designing a high temperature EMAT with pulsed electromagnet. NDT E Int. 2010, 43, 171–175. [Google Scholar] [CrossRef]

- Monchalin, J. Laser-Ultrasonics: From the Laboratory to Industry. AIP Conf. Proc. 2004, 700, 3–31. [Google Scholar]

- McCallum, R.W. Composite magnetostrictive materials for advanced automotive magnetomechanical sensors. Low Temp. Phys. 2001, 27, 266–274. [Google Scholar] [CrossRef] [Green Version]

- Gambino, R.; Raja, M.; Sampath, S.; Greenlaw, R. Plasma-Sprayed Thick-Film Anisotropic Magnetoresistive (AMR) Sensors. IEEE Sens. J. 2004, 4, 764–767. [Google Scholar] [CrossRef]

- Glass, S.W.; Lareau, J.P.; Ross, K.S.; Ali, S.; Hernandez, F.; Lopez, B. Magnetostrictive Cold Spray Sensor for Harsh Environment and Long-Term Condition Monitoring. In Proceedings of the 45th Annual Review of Progress in Quantitative Nondestructive Evaluation, Burlington, Vermont, 15–19 July 2018. [Google Scholar]

- Glass, S.W., III; Lareau, J.P.; Ross, K.A. Magnetostrictive cold spray coating for enhanced ultrasonic inspection. U.S. Patent Application No. 15/831,624, 18 January 2018. [Google Scholar]

- Gazis, D.C. Three-Dimensional Investigation of the Propagation of Waves in Hollow Circular Cylinders. I. Analytical Foundation. J. Acoust. Soc. Am. 1959, 31, 568–573. [Google Scholar] [CrossRef]

- Marzani, A.; Viola, E.; Bartoli, I.; Di Scalea, F.L.; Rizzo, P. A semi-analytical finite element formulation for modeling stress wave propagation in axisymmetric damped waveguides. J. Sound Vib. 2008, 318, 488–505. [Google Scholar] [CrossRef]

- Treyssède, F.; Laguerre, L. Investigation of elastic modes propagating in multi-wire helical waveguides. J. Sound Vib. 2010, 329, 1702–1716. [Google Scholar] [CrossRef] [Green Version]

- Laguerre, L.; Treyssède, F. Non destructive evaluation of seven-wire strands using ultrasonic guided waves. Eur. J. Environ. Civ. Eng. 2011, 15, 487–500. [Google Scholar] [CrossRef]

- Treyssède, F. Elastic waves in helical waveguides. Wave Motion 2008, 45, 457–470. [Google Scholar] [CrossRef]

- Seco, F.; Martín, J.M.; Jiménez, A.; Pons, J.L.; Calderón, L.; Ceres, R. Pcdisp: A Tool for the Simulation of Wave Propagation in Cylindrical Waveguides. In Proceedings of the 9th International Congress on Sound and Vibration, Orlando, FL, USA, 8–11 July 2002. [Google Scholar]

- Seco, F.; Jiménez, A.R. Modelling the Generation and Propagation of Ultrasonic Signals in Cylindrical Waveguides. Ultrasonic Waves 2012. [Google Scholar] [CrossRef] [Green Version]

- Ditri, J.J.; Rose, J.L. Excitation of guided elastic wave modes in hollow cylinders by applied surface tractions. J. Appl. Phys. 1992, 72, 2589–2597. [Google Scholar] [CrossRef]

- Hirao, M.; Ogi, H. Emats for Science and Industry: Noncontacting Ultrasonic Measurements; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Lee, E.W. Magnetostriction and Magnetomechanical Effects. Rep. Prog. Phys. 1955, 18, 184–229. [Google Scholar] [CrossRef]

- Laguerre, L.; Aime, J.-C.; Brissaud, M. Magnetostrictive pulse-echo device for non-destructive evaluation of cylindrical steel materials using longitudinal guided waves. Ultrasonics 2002, 39, 503–514. [Google Scholar] [CrossRef]

- Zhang, P.; Tang, Z.; Duan, Y.; Yun, C.B.; Lv, F. Ultrasonic Guided Wave Approach Incorporating Safe for Detecting Wire Breakage in Bridge Cable. Smart Struct. Syst. 2018, 22, 481–493. [Google Scholar] [CrossRef]

| Material | Diameter | Density | Young Modulus | Poisson Ratio |

|---|---|---|---|---|

| Steel | 2.5 mm | 7800 kg/m3 | 209 GPa | 0.3 |

| Aluminum | 3.2 mm | 2700 kg/m3 | 72 GPa | 0.35 |

| Transducer Frequency (kHz) | 50 kHz | 100 kHz | ||||||

| Wave packet | 1st | 2nd | 3rd | 4th | 1st | 2nd | 3rd | 4th |

| Exact distance (m) | 3.0 | 3.2 | 6.2 | 6.4 | 3.0 | 3.2 | 6.2 | 6.4 |

| ToF (ms) | 0.632 | 1.291 | 0.597 | 0.662 | 1.215 | 1.282 | ||

| Group velocity (m/s) | 5065 | 5065 | 5065 | 5065 | 5065 | 5065 | ||

| Estimated distance (m) | 3.201 | 6.539 | 3.024 | 3.353 | 6.154 | 6.493 | ||

| Errors (%) | / | / | 0.8% | 4.8% | 0.7% | 1.5% | ||

| Without SMPC amplitude (V) | N/A | N/A | N/A | N/A | N/A | N/A | ||

| With SMPC amplitude (V) | 0.442 | 0.449 | 1.161 | 1.28 | 0.261 | 0.302 | ||

| Experimental Stage | Stage 0 | Stage I | Stage II | ||

|---|---|---|---|---|---|

| Wave packet | Cable End | Defect-1 | Cable End | Defect-2 | Cable End |

| Exact position (m) | 1.5 | 1.0 | 1.5 | 0.7 | 1.5 |

| Exact distance (m) | 3.0 | 2.0 | 3.0 | 1.4 | 3.0 |

| ToF (ms) | 0.573 | 0.391 | 0.573 | 0.279 | 0.573 |

| Group velocity (m/s) | 5065 | 5065 | 5065 | 5065 | 5065 |

| Travel distance (m) | 2.902 | 1.980 | 2.902 | 1.413 | 2.902 |

| Estimated location (m) | 1.451 | 0.990 | 1.451 | 0.707 | 1.451 |

| Amplitude (V) | 1.054 | 0.243 | 0.791↓ | 0.251 | 0.793↓ |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, F.; Zhang, P.; Tang, Z.; Yue, Y.; Yang, K. A Guided Wave Transducer with Sprayed Magnetostrictive Powder Coating for Monitoring of Aluminum Conductor Steel-Reinforced Cables. Sensors 2019, 19, 1550. https://doi.org/10.3390/s19071550

Lv F, Zhang P, Tang Z, Yue Y, Yang K. A Guided Wave Transducer with Sprayed Magnetostrictive Powder Coating for Monitoring of Aluminum Conductor Steel-Reinforced Cables. Sensors. 2019; 19(7):1550. https://doi.org/10.3390/s19071550

Chicago/Turabian StyleLv, Fuzai, Pengfei Zhang, Zhifeng Tang, Yonggang Yue, and Keji Yang. 2019. "A Guided Wave Transducer with Sprayed Magnetostrictive Powder Coating for Monitoring of Aluminum Conductor Steel-Reinforced Cables" Sensors 19, no. 7: 1550. https://doi.org/10.3390/s19071550