Development of a 3-PRR Precision Tracking System with Full Closed-Loop Measurement and Control

Abstract

:1. Introduction

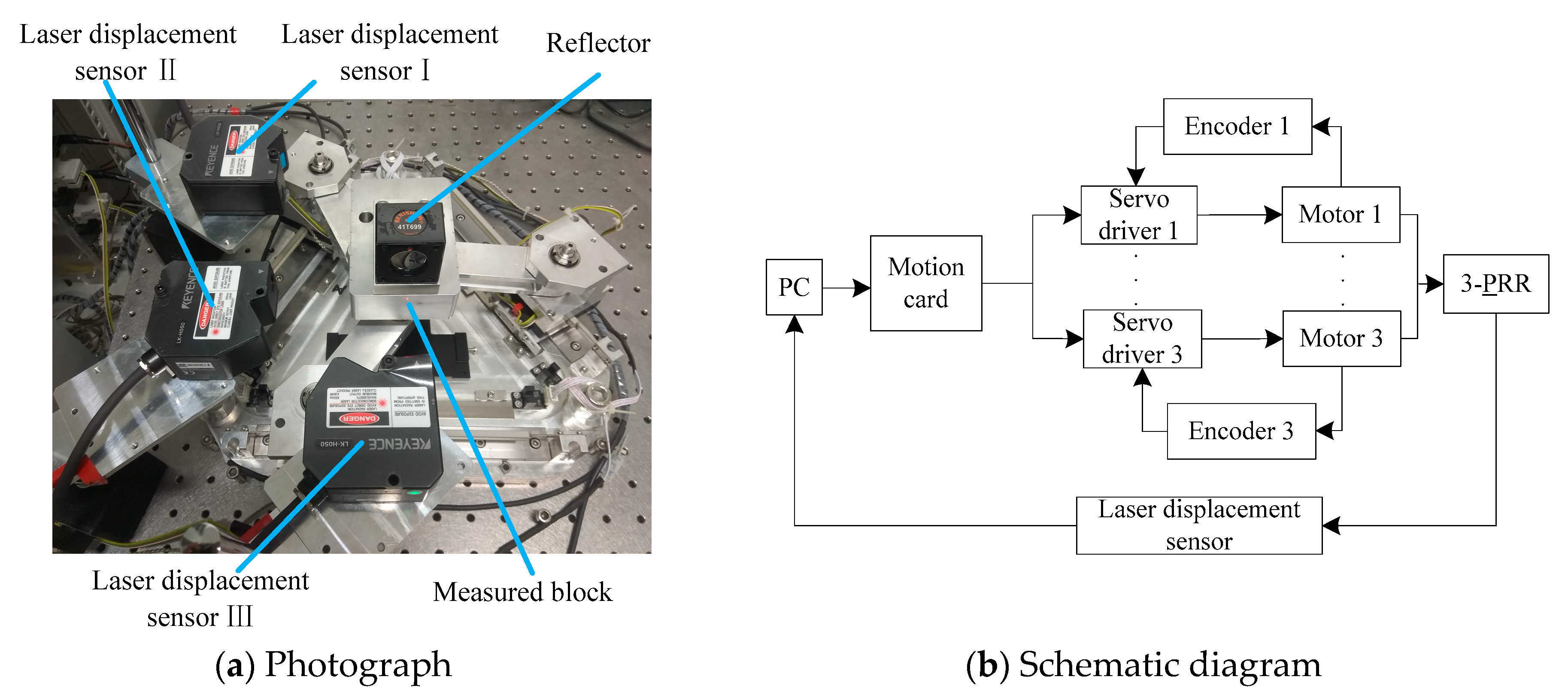

2. Introduction of the Experimental Setup

2.1. Experimental Setup

2.2. Deviation of Installing Angle and Equally-Spaced Sensors

2.3. Measurement Evaluation

3. Feed-Forward Control

3.1. Correlation Analysis of Semi-Closed-Loop Tracking Errors

3.2. Feed-Forward Control Experiment

4. PI Feedback Control

5. RBF Neural Network Control

5.1. RBF Neural Network

5.2. Trajectory Tracking Experiment Based on RBF Neural Network

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zubizarreta, A.; Marcos, M.; Cabanes, I.; Pinto, C.; Portillo, E. Redundant sensor based control of the 3RRR parallel robot. Mech. Mach. Theory 2012, 54, 1–17. [Google Scholar] [CrossRef]

- Choi, S.B.; Han, S.S. Position Control System Using ER Clutch and Piezoactuator. Proc. SPIE 2003, 5056, 424–431. [Google Scholar]

- Liu, X.-J.; Li, J.; Zhou, Y. Kinematic optimal design of a 2-degree-of-freedom 3-parallelogram planar parallel manipulator. Mech. Mach. Theory 2015, 87, 1–17. [Google Scholar] [CrossRef]

- Chetwynd, D.G.; Huang, T.; Li, Z.; Li, M.; Gosselin, C.M. Conceptual design and dimensional synthesis of a novel 2-DOF translational parallel robot for pick-and-place operations. ASME J. Mech. Des. 2004, 126, 449–455. [Google Scholar]

- Payton, O.D.; Champneys, A.R.; Homer, M.E.; Picco, L.; Homer, M.; Miles, M.J.; Raman, A. Experimental observation of contact mode cantilever dynamics with nanosecond resolution. Rev. Sci. Instrum. 2011, 82, 043704. [Google Scholar] [CrossRef]

- Stewart, D. A Platform with Six Degrees of Freedom. Proc. Inst. Mech. Eng. 1965, 180, 371–386. [Google Scholar] [CrossRef]

- Merlet, J.P. Parallel Robots, 2nd ed.; Springer: Cham, The Netherlands, 2006. [Google Scholar]

- Shao, Z.; Tang, X.; Wang, L.; Huang, P. Self-Calibration Method of planar flexible 3-RRR parallel manipulator. Chin. J. Mech. Eng. 2009, 45, 150–155. [Google Scholar] [CrossRef]

- Mo, J.-S.; Qiu, Z.-C.; Zeng, L.; Zhang, X.-M. A New Calibration Method for a Directly Driven 3PRR Positioning System. J. Intell. Robot. Syst. 2017, 85, 613–631. [Google Scholar] [CrossRef]

- Chen, W.H. Disturbance observer based control for nonlinear systems. IEEE/ASME Trans. Mechatron. 2004, 9, 706–710. [Google Scholar] [CrossRef] [Green Version]

- Bokelberg, E.H.; Sommer, H.J., III; Trethewey, M.W. A six-degree-of-freedom laser vibrometer, part I: theoretical development. J. Sound Vib. 1994, 178, 643–654. [Google Scholar] [CrossRef]

- Gao, W.; Kiyono, S.; Satoh, E.; Sata, T. Precision measurement of multi-degree-of-freedom spindle errors using two-dimensional slope sensors. CIRP Ann. 2002, 51, 447–450. [Google Scholar] [CrossRef]

- Giri, P.; Kharkovsky, S. Dual-laser integrated microwave imaging system for nondestructive testing of construction materials and structures. IEEE Trans. Instrum. Meas. 2018, 67, 1329–1337. [Google Scholar] [CrossRef]

- Pradeep, V.; Konolige, K.; Berger, E. Calibrating a Multi-Arm Multi-Sensor Robot: a Bundle Adjustment Approach; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Zhou, L.; Zhang, Q.; Sun, Z. Precision Positioning of a 3-PRR Planar Parallel Manipulator Driven by Linear Ultrasonic Motors Based on Machine Vision. Chin. J. Mech. Eng. 2014, 50, 18–23. [Google Scholar] [CrossRef]

- Fatikow, S.; Stolle, C.; Diederichs, C.; Jasper, D. Auto-configuration and self-calibration in flexible robot-based micro-/nanohandling cells. In Proceedings of the International Federation of Automatic Control, Milano, Italy, 28 August–2 September 2011. [Google Scholar]

- Gan, J.; Zhang, X.; Li, H.; Wu, H. Full closed-loop controls of micro/nano positioning system withnonlinear hysteresis using micro-vision system. Sens. Actuators A 2017, 257, 125–133. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, X. A planar 3-DOF nanopositioning platform with large magnification. Precis. Eng. 2016, 46, 221–231. [Google Scholar] [CrossRef] [Green Version]

- Kuan, Y.; Lu, T.F.; Minase, J. Trajectory following with a three-DOF micro-motion stage. Nucleosides Nucleotides Nucleic Acids 2006, 30, 1272–1275. [Google Scholar]

- Cai, K.; Tian, Y.; Liu, X.; Fatikow, S.; Wang, F.; Cui, L.; Zhang, D.; Shirinzadeh, B. Modeling and controller design of a 6-DOF precision positioning system. Mech. Syst. Signal Process. 2018, 104, 536–555. [Google Scholar] [CrossRef]

- Chen, Q.J.; Chen, H.T.; Wang, Y.J.; Woo, P.Y. Global stability analysis for some trajectory tracking control schemes of robotic manipulators. J. Robot. Syst. 2001, 18, 69–75. [Google Scholar] [CrossRef]

- Ouyang, P.R.; Zhang, W.J.; Gupta, M.M. An Adaptive Switching Learning Control Method for Trajectory Tracking of Robot Manipulators. Mechatronics 2006, 16, 51–61. [Google Scholar] [CrossRef]

- Patel, R.; Kumar, V. Multilayer Neuro PID Controller based on Back Propagation Algorithm. Procedia Comput. Sci. 2015, 54, 207–214. [Google Scholar] [CrossRef] [Green Version]

- Anh, H.P.H. Online tuning gain scheduling MIMO neural PID control of the 2-axes pneumatic artificial muscle (PAM) robot arm. Expert Syst. Appl. 2010, 37, 6547–6560. [Google Scholar] [CrossRef]

- Moody, J.; Darken, C. Fast learning in networks of locally-tuned processing units. Neural Comput. 1989, 1, 281–294. [Google Scholar] [CrossRef]

- Moody, J.; Darken, C. Learning with localized receptive fields. In Proceedings of the 1988 Connectionist Models Summer School, Pittsburg, PA, USA, 17–26 June 1988. [Google Scholar]

| Evaluation Experiment | Ideal Input Displacement (mm) | Laser Sensor Measurement i | Laser Interferometer Measurement j | |

|---|---|---|---|---|

| 1 | 2.000 | 2.016 | 2.014 | 0.002 |

| 2 | 4.000 | 4.030 | 4.022 | 0.008 |

| 3 | 6.000 | 6.037 | 6.035 | 0.002 |

| 4 | 8.000 | 8.041 | 8.044 | 0.003 |

| 5 | 6.000 | 6.037 | 6.035 | 0.002 |

| 6 | 4.000 | 4.029 | 4.022 | 0.007 |

| 7 | 2.000 | 2.014 | 2.014 | 0.000 |

| 8 | 0.000 | 0.002 | 0.000 | 0.002 |

| 9 | −2.000 | −2.015 | −2.014 | 0.001 |

| 10 | −4.000 | −4.027 | −4.027 | 0.000 |

| 11 | −6.000 | −6.039 | −6.039 | 0.000 |

| 12 | −8.000 | −8.053 | −8.054 | 0.001 |

| 13 | −6.000 | −6.039 | −6.039 | 0.000 |

| 14 | −4.000 | −4.029 | −4.028 | 0.001 |

| 15 | −2.000 | −2.017 | −2.015 | 0.002 |

| 16 | 0.000 | −0.004 | −0.002 | 0.002 |

| Symbol | Meaning |

|---|---|

| Gaussian radial basis function | |

| Centric vector of the Gaussian radial basis function | |

| Basis breadth of the Gaussian radial basis function | |

| Weight of the output layer | |

| Output of the RBF neural network | |

| Inertia coefficient | |

| Learning rate | |

| Performance index function | |

| Jacobian function used to adjust the PI parameter |

| Control Algorithm | ||||||

|---|---|---|---|---|---|---|

| Semi-closed-loop control | 0.0220 | 0.0170 | 0.0470 | 0.0120 | 0.0090 | 0.0350 |

| Feed-forward control | 0.0040 | 0.0033 | 0.0170 | 0.0045 | 0.0038 | 0.0210 |

| PI control with | 0.0032 | 0.0026 | 0.0160 | 0.0037 | 0.0031 | 0.0274 |

| RBF neural network control | 0.0025 | 0.0020 | 0.0177 | 0.0026 | 0.0020 | 0.0206 |

| Control Algorithm | Time of First Run (s) | Time of Later Run (s) |

|---|---|---|

| Semi-closed-loop control | 10 | 10 |

| Feed-forward control | 10 | 10 |

| PI control with | 20 | 20 |

| RBF neural network control | 36 | 20 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, L.-b.; Qiu, Z.-c.; Zhang, X.-m. Development of a 3-PRR Precision Tracking System with Full Closed-Loop Measurement and Control. Sensors 2019, 19, 1756. https://doi.org/10.3390/s19081756

Xie L-b, Qiu Z-c, Zhang X-m. Development of a 3-PRR Precision Tracking System with Full Closed-Loop Measurement and Control. Sensors. 2019; 19(8):1756. https://doi.org/10.3390/s19081756

Chicago/Turabian StyleXie, Ling-bo, Zhi-cheng Qiu, and Xian-min Zhang. 2019. "Development of a 3-PRR Precision Tracking System with Full Closed-Loop Measurement and Control" Sensors 19, no. 8: 1756. https://doi.org/10.3390/s19081756