A Highly Integrated BOTDA/XFG Sensor on a Single Fiber for Simultaneous Multi-Parameter Monitoring of Slopes

Abstract

:1. Introduction

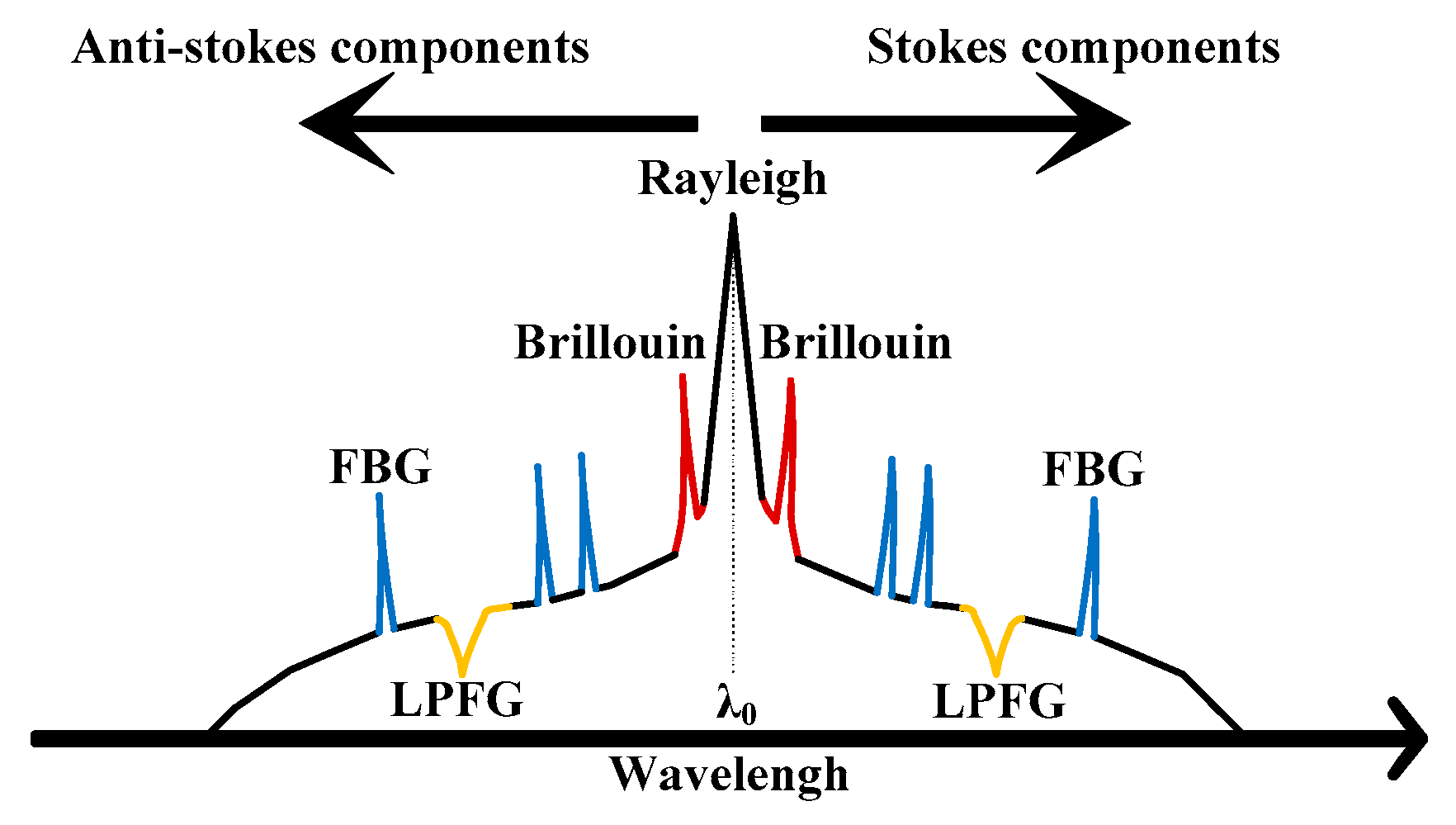

2. The Hybrid BOTDA/XFG Sensing Technology

2.1. XFG Sensor

2.2. Distributed Optical Fiber Sensor

2.3. The Hybrid BOTDA/XFG Sensing Technology

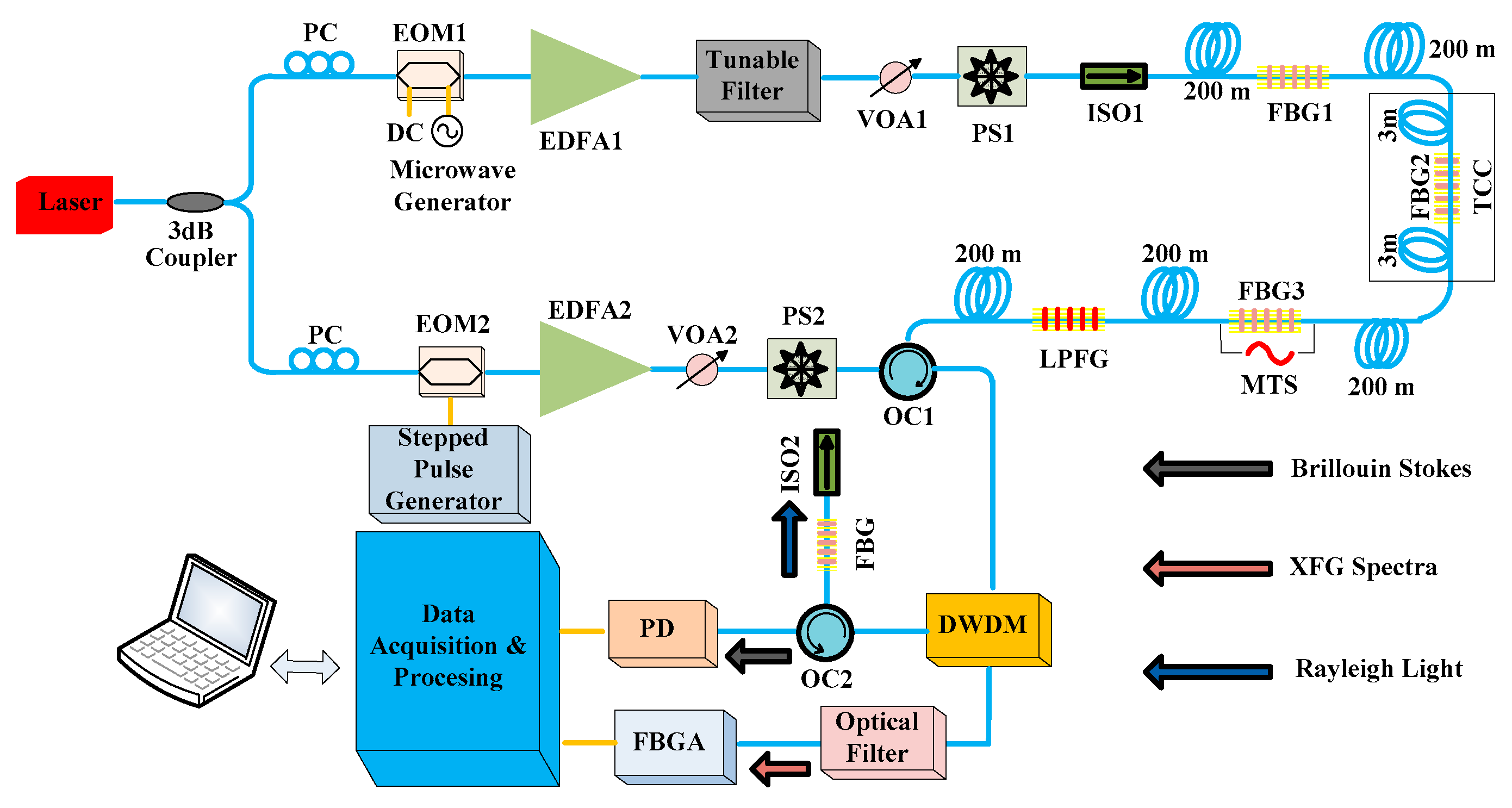

3. Experimental Setup

4. Experimental Results and Discussion

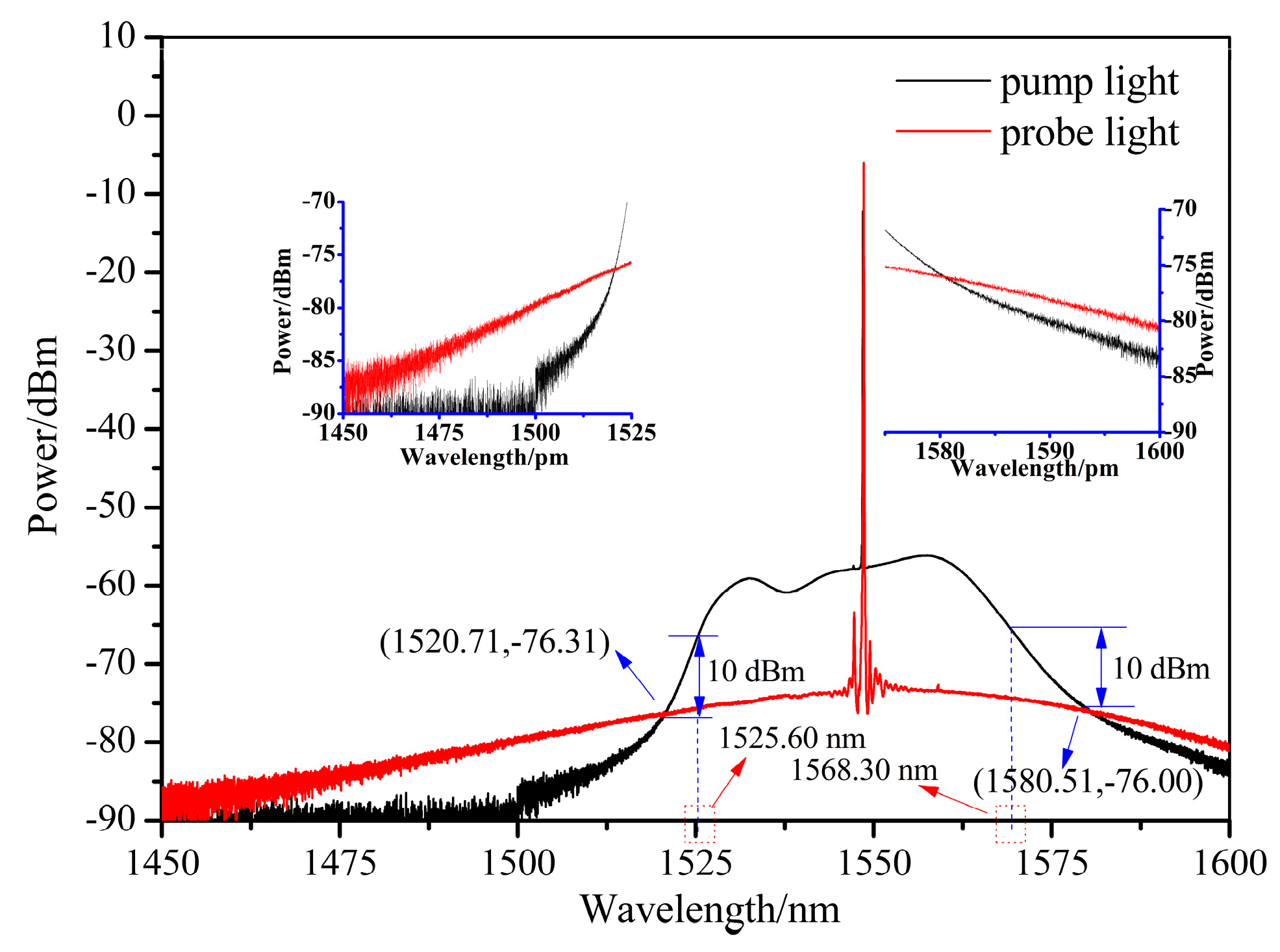

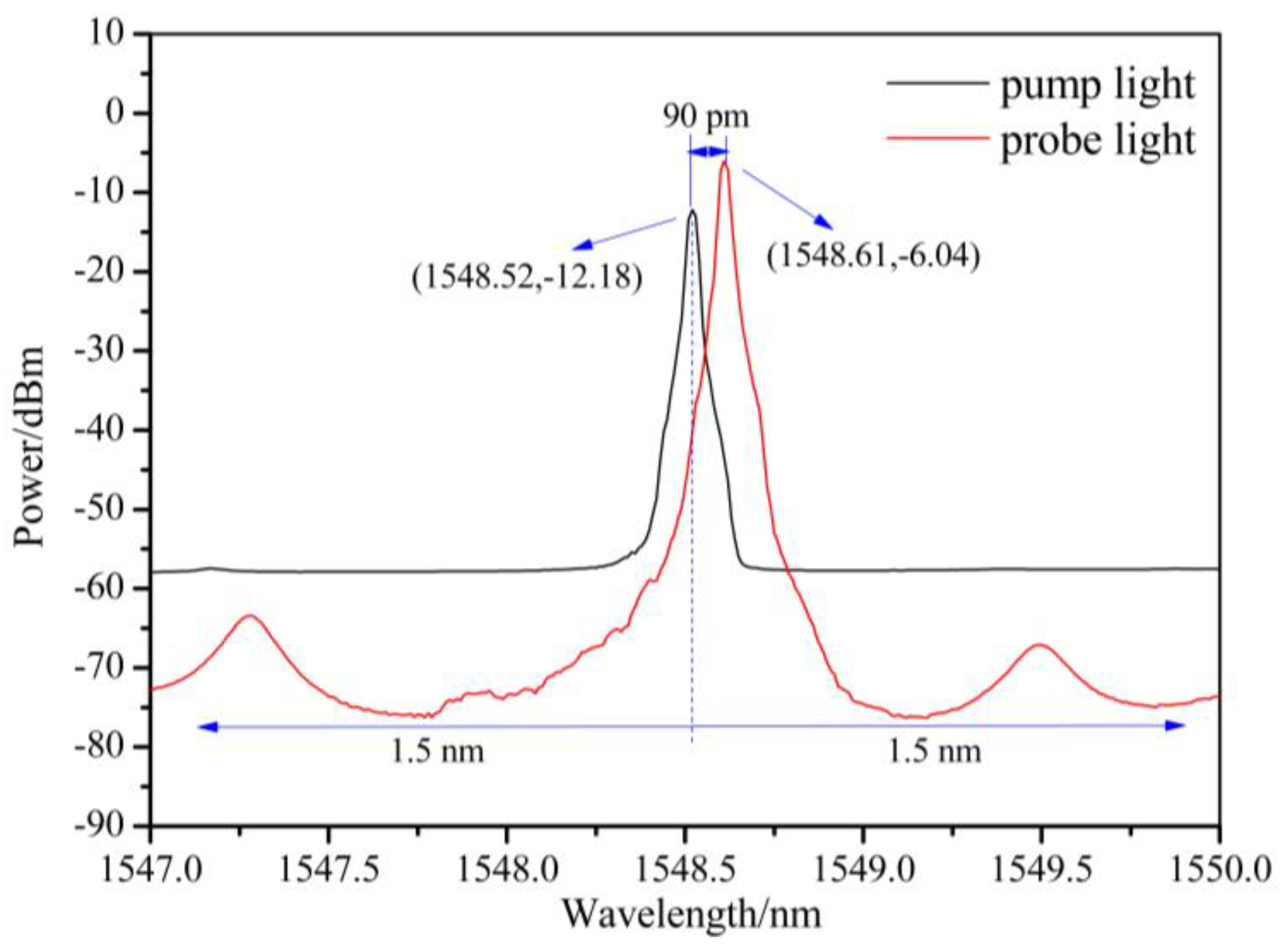

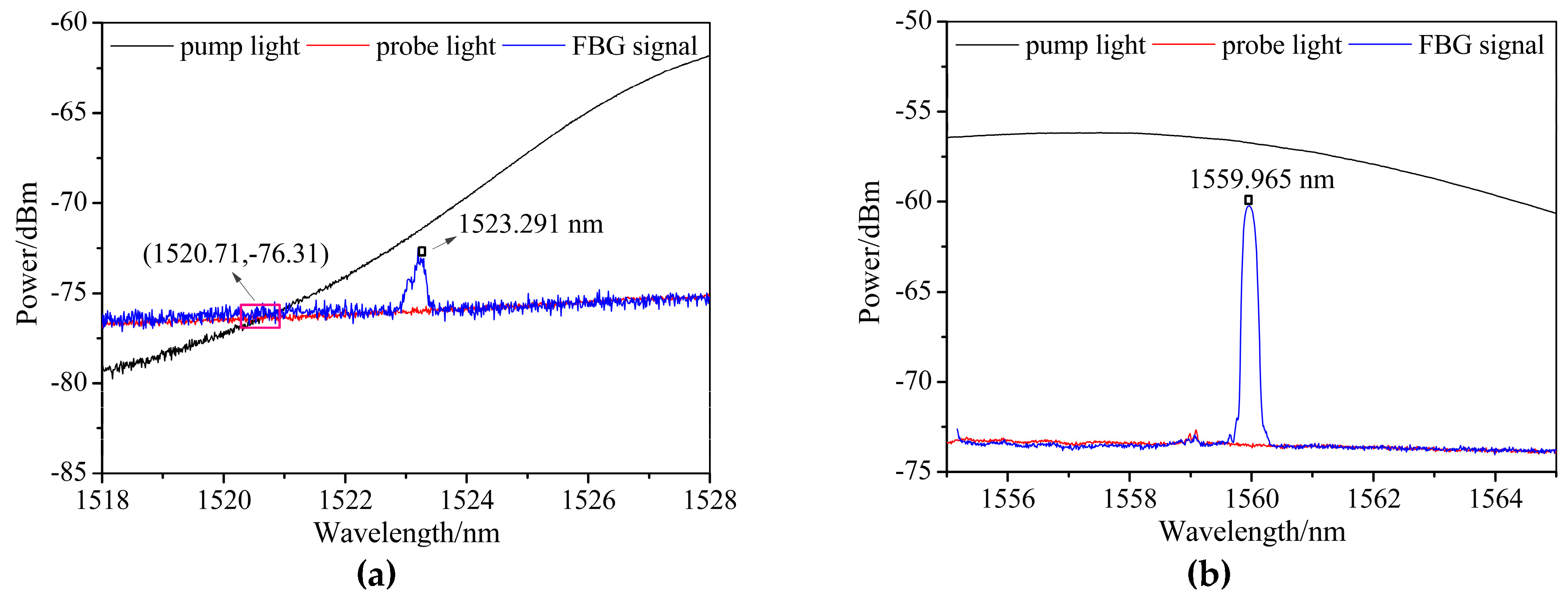

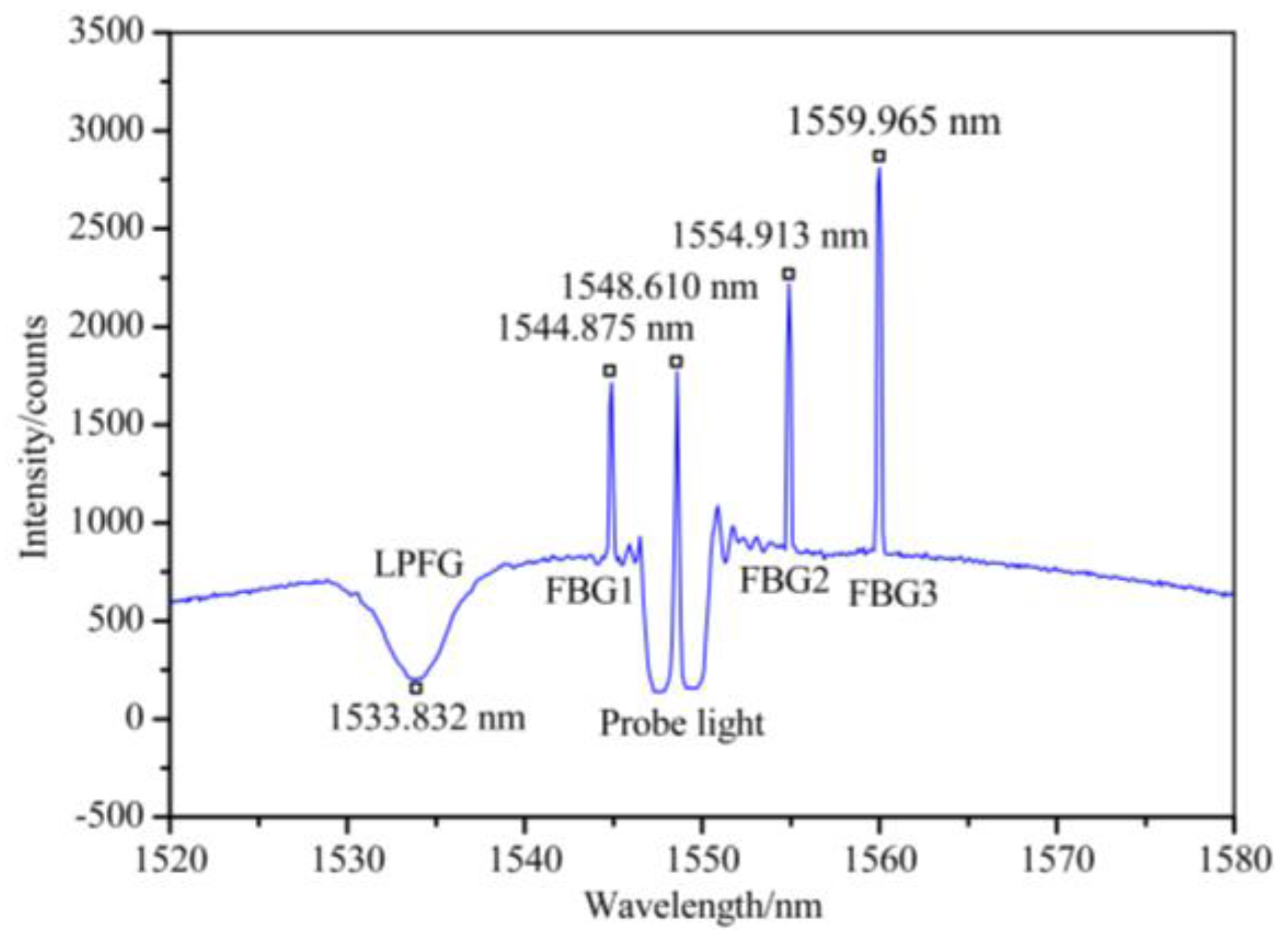

4.1. Spectral Characteristics and Capacity Of the Hybrid System

4.2. BOTDA-Based Distributed Measurement

4.3. FBG-Based Pointed Measurement

5. Multiparameter Monitoring of a Slope Based on the Hybrid System

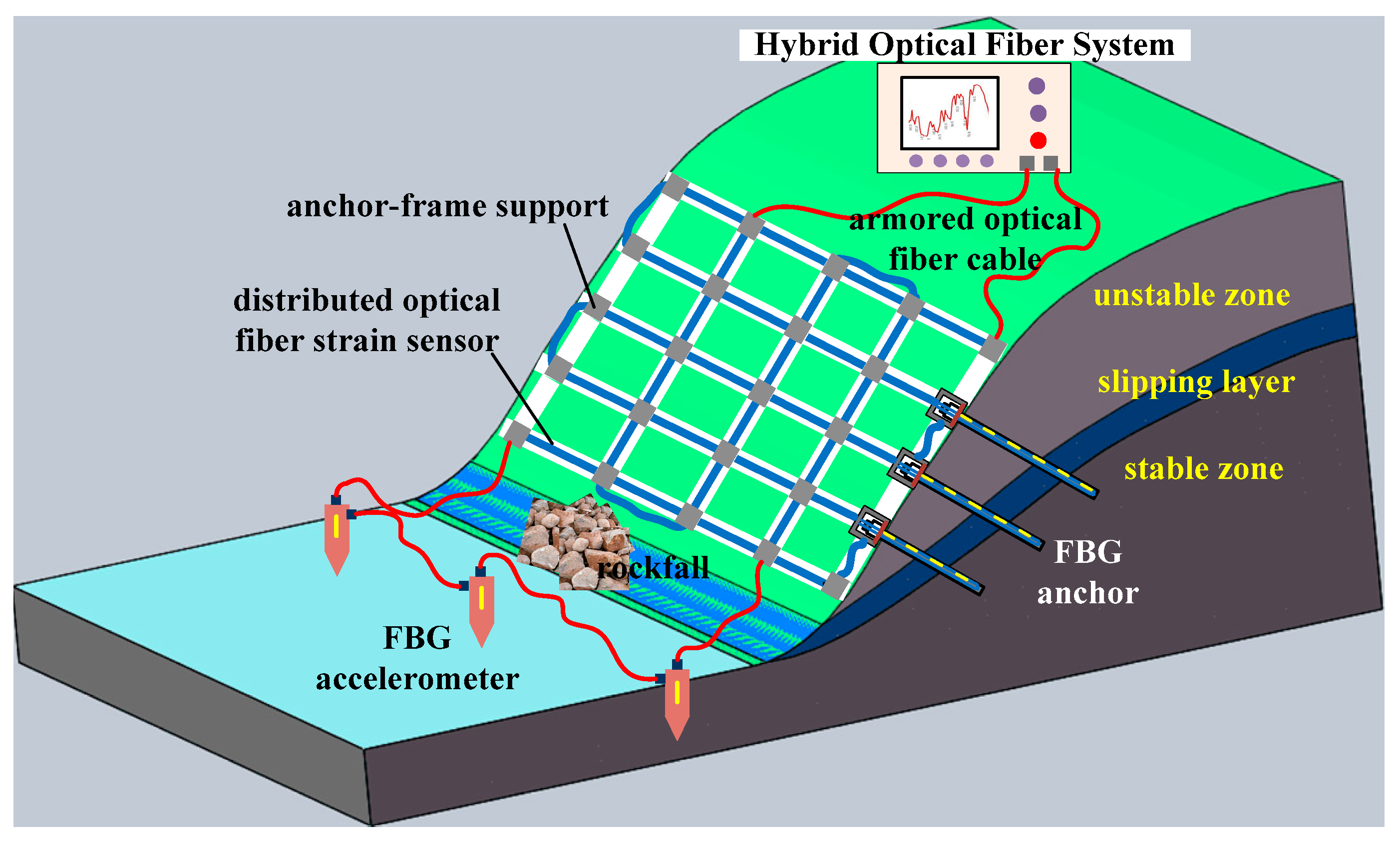

5.1. The Hybrid BOTDA/XFG-Based Multiparameter Monitoring System

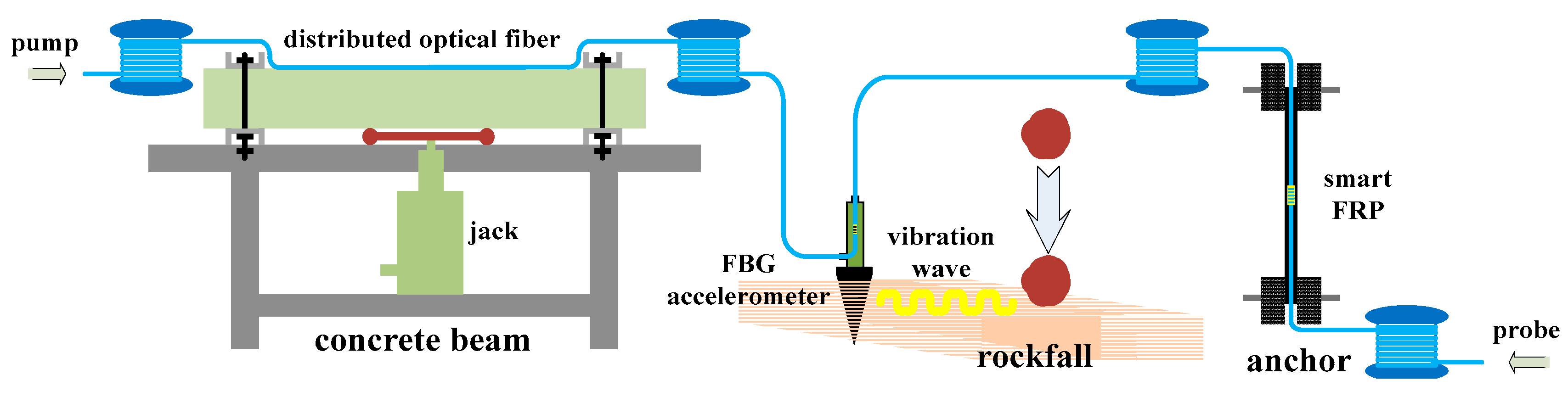

5.2. Measurement of Distributed Static Strain on a Frame Beam

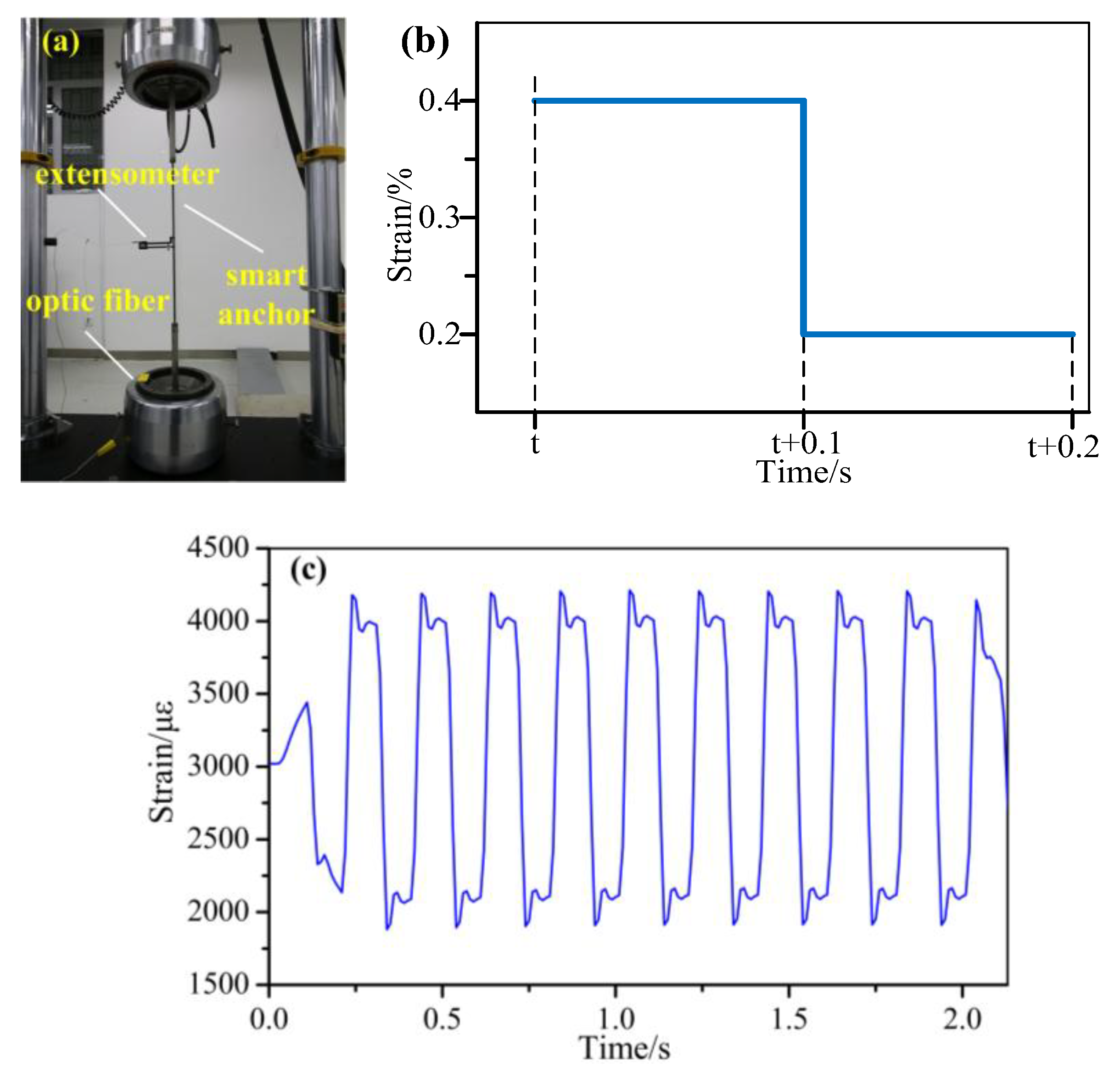

5.3. Measurement of Dynamic Strain on an Anchor

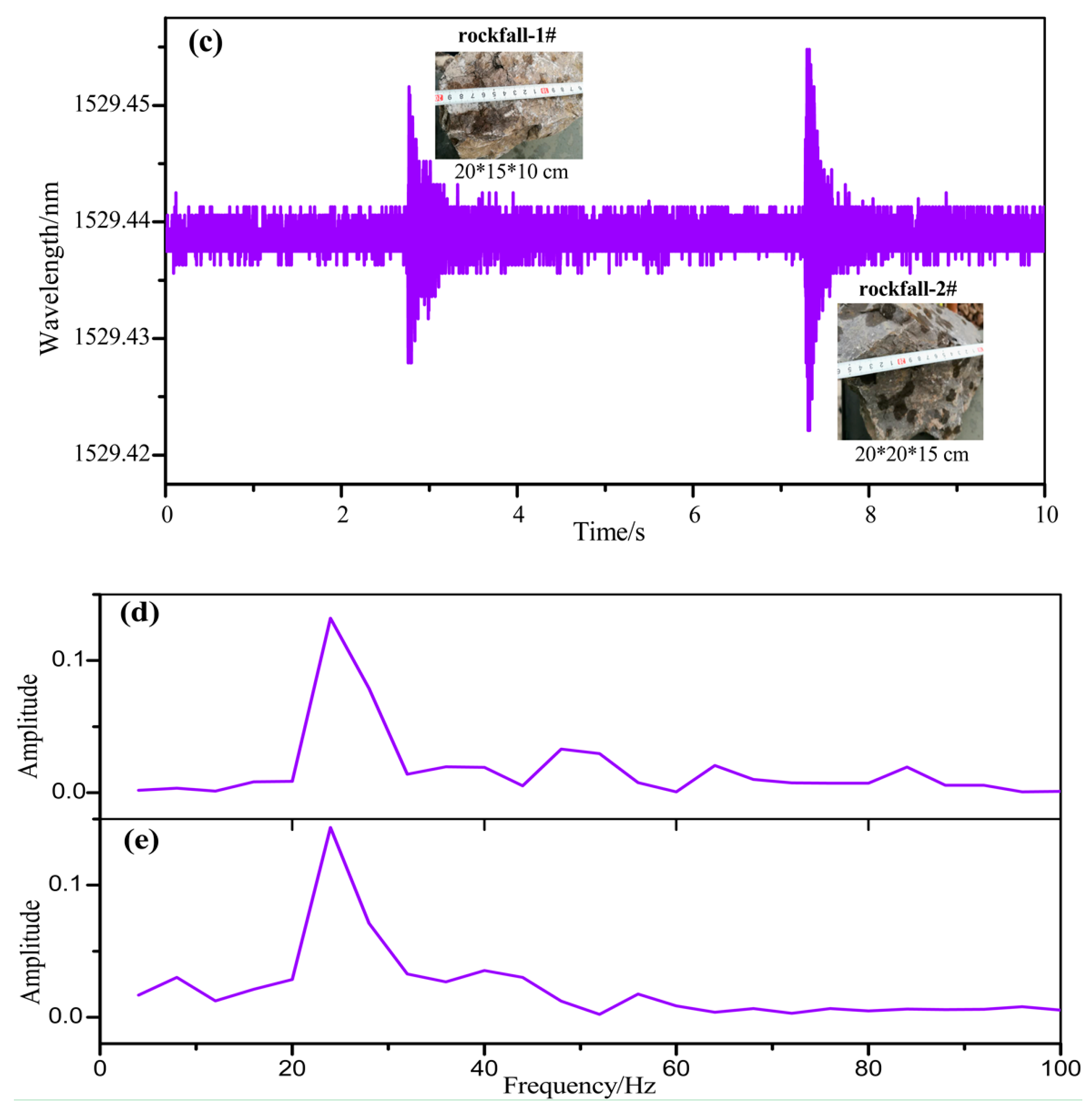

5.4. Measurement of Rockfall Vibration

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gili, J.A.; Corominas, J.; Rius, J. Using Global Positioning System techniques in landslide monitoring. Eng. Geol. 2000, 55, 167–192. [Google Scholar] [CrossRef]

- Wang, G.Q. Kinematics of the Cerca del Cielo, Puerto Rico landslide derived from GPS observations. Landslides 2012, 9, 117–130. [Google Scholar] [CrossRef]

- Booth, A.M.; Lamb, M.P.; Avouac, J.P.; Delacourt, C. Landslide velocity, thickness, and rheology from remote sensing: La Clapière landslide, France. Geophys. Res. Lett. 2013, 40, 4299–4304. [Google Scholar] [CrossRef] [Green Version]

- Yin, Y.; Zheng, W.; Liu, Y.; Zhang, J.; Li, X. Integration of GPS with InSAR to monitoring of the Jiaju landslide in Sichuan, China. Landslides 2010, 7, 359–365. [Google Scholar] [CrossRef]

- Atzeni, C.; Barla, M.; Pieraccini, M.; Antolini, F. Early warning monitoring of natural and engineered slopes with ground-based synthetic-aperture radar. Rock. Mech. Rock. Eng. 2015, 48, 235–246. [Google Scholar] [CrossRef]

- Su, M.B.; Chen, I.H.; Liao, C.H. Using TDR Cables and GPS for Landslide Monitoring in High Mountain Area. J. Geotech. Geoenviron. Eng. 2009, 135, 1113–1121. [Google Scholar] [CrossRef]

- Green, G.E.; Mickkelsen, P.E. Deformation Measurements with Inclinometers. Transp. Res. Record 1988, 1169, 1–15. [Google Scholar]

- Stark, T.D.; Choi, H. Slope inclinometers for landslides. Landslides 2008, 5, 339–350. [Google Scholar] [CrossRef]

- Xie, P.; Wen, H.; Xiao, P.; Zhang, Y. Evaluation of ground-penetrating radar (GPR) and geology survey for slope stability study in mantled karst region. Environ. Earth Sci. 2018, 77, 122. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, W. Curvelet transform-based identification of void diseases in ballastless track by ground-penetrating radar. Struct Control Health Monit. 2019, 26, e2322. [Google Scholar] [CrossRef]

- Schenato, L. A Review of Distributed Fibre Optic Sensors for Geo-Hydrological Applications. Appl. Sci. 2017, 7, 896. [Google Scholar] [CrossRef]

- Zhu, H.H.; Shi, B.; Zhang, C.C. FBG-based monitoring of geohazards: current status and trends. Sensors 2017, 17, 452. [Google Scholar] [CrossRef] [PubMed]

- Hong, C.Y.; Zhang, Y.F.; Zhang, M.X.; Leung, L.M.G.; Liu, L.Q. Application of FBG sensors for geotechnical health monitoring, a review of sensor design, implementation methods and packaging technique. Sens. Actuators A Phys. 2016, 244, 184–197. [Google Scholar] [CrossRef]

- Hong, C.Y.; Zhang, Y.F.; Li, G.W.; Zhang, M.X.; Liu, Z.X. Recent progress of using Brillouin distributed fiber optic sensors for geotechnical health monitoring. Sens. Actuators A Phys. 2017, 258, 131–145. [Google Scholar] [CrossRef]

- Xu, G.; Xiong, D.; Yun, D.; Cao, X. Open pit slope deformation monitoring by fiber Bragg grating sensors. Opt. Eng. 2014, 54, 011003. [Google Scholar] [CrossRef]

- Fujihashi, K.; Miyamoto, M.; Okutsu, K. Activities in the Area of Disaster Prevention Using Optical Fiber Sensing Technology. NTT Tech. Rev. 2007, 5, 1–7. [Google Scholar]

- Ho, Y.T.; Huang, A.B.; Lee, J.T. Development of a fibre Bragg grating sensored ground movement monitoring system. Meas. Sci. Technol. 2006, 17, 1733–1740. [Google Scholar] [CrossRef]

- Zhang, C.C.; Zhu, H.H.; Shi, B.; She, J.K. Interfacial characterization of soil embedded optical fiber for ground deformation measurement. Smart Mater. Struct. 2014, 23, 95022. [Google Scholar] [CrossRef]

- Zheng, Y.; Huang, D.; Shi, L. A new deflection solution and application of a fiber Bragg grating-based inclinometer for monitoring internal displacements in slopes. Meas. Sci. Technol. 2018, 29, 055008. [Google Scholar] [CrossRef] [Green Version]

- Minardo, A.; Picarelli, L.; Avolio, B.; Coscetta, A.; Papa, R.; Zeni, G. Fiber optic based inclinometer for remote monitoring of landslides: on site comparison with traditional inclinometers. In Proceedings of the 2014 IEEE Geoscience and Remote Sensing Symposium, Quebec City, QC, Canada, 13–18 July 2014. [Google Scholar]

- Pei, H.F.; Li, C.; Zhu, H.H.; Wang, Y.J. Slope stability analysis based on measured strains along soil nails using FBG sensing technology. Math. Probl. Eng. 2013, 2013, 561360. [Google Scholar] [CrossRef]

- Hong, C.Y.; Yin, J.H.; Zhang, Y.F. Deformation monitoring of long GFRP bar soil nails using distributed optical fiber sensing technology. Smart Mater. Struct. 2016, 25, 85044–85051. [Google Scholar] [CrossRef]

- Kim, Y.S.; Sung, H.J.; Kim, H.W.; Kim, J.M. Monitoring of tension force and load transfer of ground anchor by using optical FBG sensors embedded tendon. Smart Struct. Syst. 2011, 7, 303–317. [Google Scholar] [CrossRef]

- Ho, S.C.M.; Li, W.; Wang, B.; Song, G. A load measuring anchor plate for rock bolt using fiber optic sensor. Smart Mater. Struct. 2017, 26, 057003. [Google Scholar] [CrossRef]

- Su, Y.J.; Xu, H.Z.; Gu, P.; Hu, W.J. Application of FBG sensing technology in stability analysis of geogrid-reinforced slope. Sensors 2017, 17, 597. [Google Scholar]

- Schenato, L.; Palmieri, L.; Camporese, M.; Bersan, S.; Cola, S.; Pasuto, A. Distributed optical fibre sensing for early detection of shallow landslides triggering. Sci. Rep. 2017, 7, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.J.; Li, K.; Shi, B.; Wei, G.Q. Test on application of distributed fiber optic sensing technique into soil slope monitoring. Landslides 2009, 6, 61–68. [Google Scholar] [CrossRef]

- Zhu, H.H.; Shi, B.; Yan, J.F.; Zhang, J.; Zhang, C.C.; Wang, B.J. Fiber Bragg grating-based performance monitoring of a slope model subjected to seepage. Smart Mater. Struct. 2014, 23, 095027. [Google Scholar] [CrossRef]

- Damiano, E.; Avolio, B.; Minardo, A.; Olivares, L.; Picarelli, L.; Zeni, L. A Laboratory Study on the Use of Optical Fibers for Early Detection of Pre-Failure Slope Movements in Shallow Granular Soil Deposits. Geotech. Test. J. 2017, 40, 529–541. [Google Scholar] [CrossRef]

- Ho, Y.T.; Huang, A.B.; Lee, J. Development of a chirped/differential optical fiber Bragg grating pressure sensor. Meas. Sci. Technol. 2008, 19, 88–91. [Google Scholar] [CrossRef]

- Li, F.; Du, Y.; Zhang, W.; Li, F. Fiber Bragg grating soil-pressure sensor based on dual l-shaped levers. Opt. Eng. 2013, 52, 014403. [Google Scholar] [CrossRef]

- Huang, C.J.; Chu, C.R.; Tien, T.M.; Yin, H.Y.; Chen, P.S. Calibration and deployment of a fiber-optic sensing system for monitoring debris flows. Sensors 2012, 12, 5835–5849. [Google Scholar] [CrossRef]

- Schenato, L.; Aneesh, R.; Palmieri, L.; Galtarossa, A.; Pasuto, A. Fiber optic sensor for hydrostatic pressure and temperature measurement in riverbanks monitoring. Opt. Laser Technol. 2016, 82, 57–62. [Google Scholar] [CrossRef]

- Leone, M.; Principe, S.; Consales, M.; Parente, R.; Laudati, A.; Caliro, S. Fiber optic thermo-hygrometers for soil moisture monitoring. Sensors 2017, 17, 1451. [Google Scholar] [CrossRef]

- Huang, A.B.; Lee, J.T.; Ho, Y.T.; Chiu, Y.F.; Cheng, S.Y. Stability monitoring of rainfall-induced deep landslides through pore pressure profile measurements. Soils Found. 2012, 52, 737–747. [Google Scholar] [CrossRef] [Green Version]

- Macciotta, R.; Hendry, M.; Martin, C.D. Developing an early warning system for a very slow landslide based on displacement monitoring. Nat. Hazard. 2015, 81, 1–21. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, D.; Shi, B.; Tong, H.; Wei, G.; Wang, X. Distributed acquisition, characterization and process analysis of multi-field information in slopes. Eng. Geol. 2014, 182, 49–62. [Google Scholar] [CrossRef]

- Huntley, D.; Bobrowsky, P.; Zhang, Q.; Sladen, W.; Bunce, C.; Edwards, T. Fiber Optic Strain Monitoring and Evaluation of a Slow-Moving Landslide Near Ashcroft, British Columbia, Canada. In Landslide Science for a Safer Geoenvironment; Springer: Cham, Switzerland, 2014. [Google Scholar]

- Zhu, H.H.; Shi, B.; Yan, J.F.; Zhang, J.; Wang, J. Investigation of the evolutionary process of a reinforced model slope using a fiber-optic monitoring network. Eng. Geol. 2015, 186, 34–43. [Google Scholar] [CrossRef]

- Lan, C.; Zhi, Z.; Ou, J. Monitoring of structural prestress loss in rc beams by inner distributed Brillouin and fiber Bragg grating sensors on a single optical fiber. Struct. Control Health Monit. 2014, 21, 317–330. [Google Scholar] [CrossRef]

- He, J.; Zhou, Z.; Ou, J. Simultaneous measurement of strain and temperature using a hybrid local and distributed optical fiber sensing system. Measurement 2014, 47, 698–706. [Google Scholar] [CrossRef]

- Luo, J.; Hao, Y.; Ye, Q.; Hao, Y.; Li, L. Development of optical fiber sensors based on Brillouin scattering and FBG for on-line monitoring in overhead transmission lines. J. Lightwave Technol. 2013, 31, 1559–1565. [Google Scholar] [CrossRef]

- Mao, J.; Chen, J.; Cui, L.; Jin, W.; Xu, C.; He, Y. Monitoring the corrosion process of reinforced concrete using BOTDA and FBG sensors. Sensors 2015, 15, 8866–8883. [Google Scholar] [CrossRef]

- Hill, K.; Meltz, G. Fiber Bragg grating technology fundamentals and overview. J. Lightwave Technol. 1997, 15, 1263–1276. [Google Scholar] [CrossRef]

- Venugopalan, T.; Sun, T.; Grattan, K.T.V. Long period grating-based humidity sensor for potential structural health monitoring. Sens. Actuators A Phys. 2008, 148, 57–62. [Google Scholar] [CrossRef]

- Horiguchi, T.; Kurashima, T.; Tateda, M. Tensile strain dependence of Brillouin frequency shift in silica optical fibers. IEEE Photonic. Technol. Lett. 1989, 1, 107–108. [Google Scholar] [CrossRef]

- Kishida, K.; Li, C.H.; Nishiguchi, K. Pulse pre-pump method for cm-order spatial resolution of BOTDA. Proc. SPIE 2005, 5855, 559–562. [Google Scholar]

- Kishida, K.; Li, C.H. Pulse pre-pump-BOTDA technology for new generation of distributed strain measuring system. In Structural Health Monitoring and Intelligent Infrastructure; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Li, F.; Du, Y.L.; Sun, X.; Zhao, W.G. Sensing performance assessment of twisted CFRP with embedded fiber Bragg grating sensors subjected to monotonic and fatigue loading. Sens. Actuators A Phys. 2018, 271, 153–161. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, W.; Du, Y.; Sun, B.; Ma, H.; Li, F. Detection of rail corrugation based on fiber laser accelerometers. Meas. Sci. Technol. 2013, 24, 094014. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, F.; Zhao, W.; Xu, H.; Wang, S.; Du, Y. A Highly Integrated BOTDA/XFG Sensor on a Single Fiber for Simultaneous Multi-Parameter Monitoring of Slopes. Sensors 2019, 19, 2132. https://doi.org/10.3390/s19092132

Li F, Zhao W, Xu H, Wang S, Du Y. A Highly Integrated BOTDA/XFG Sensor on a Single Fiber for Simultaneous Multi-Parameter Monitoring of Slopes. Sensors. 2019; 19(9):2132. https://doi.org/10.3390/s19092132

Chicago/Turabian StyleLi, Feng, Weigang Zhao, Hongbin Xu, Shupeng Wang, and Yanliang Du. 2019. "A Highly Integrated BOTDA/XFG Sensor on a Single Fiber for Simultaneous Multi-Parameter Monitoring of Slopes" Sensors 19, no. 9: 2132. https://doi.org/10.3390/s19092132

APA StyleLi, F., Zhao, W., Xu, H., Wang, S., & Du, Y. (2019). A Highly Integrated BOTDA/XFG Sensor on a Single Fiber for Simultaneous Multi-Parameter Monitoring of Slopes. Sensors, 19(9), 2132. https://doi.org/10.3390/s19092132