2.2. Working Principle

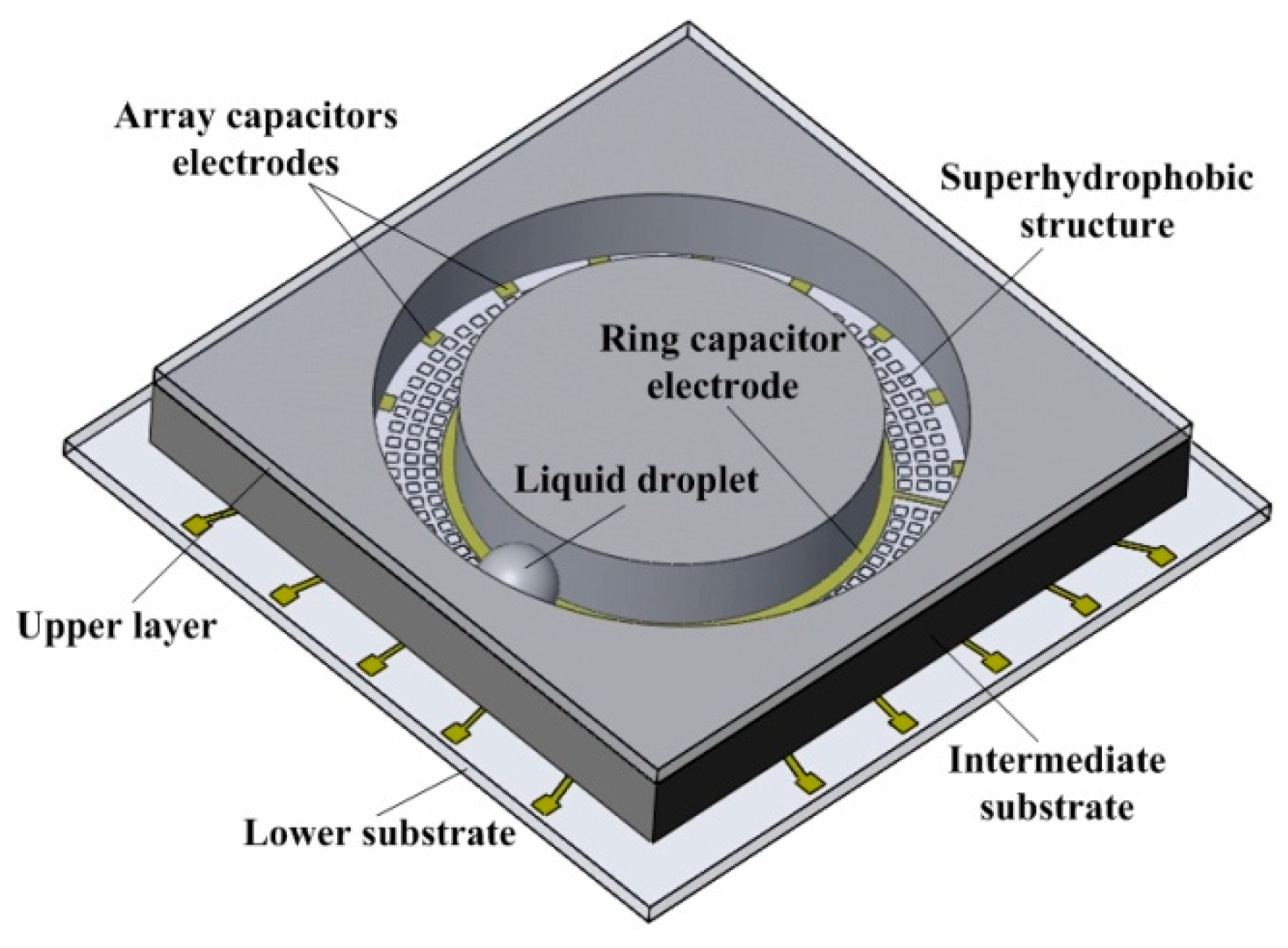

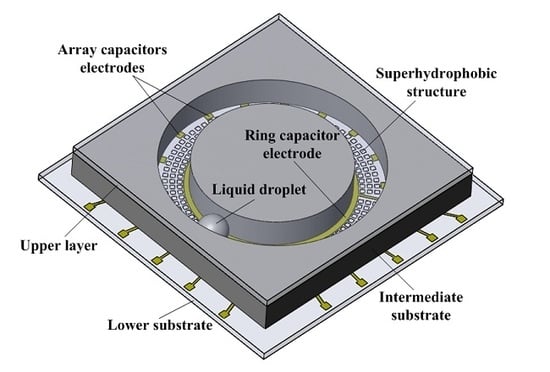

The MEMS liquid inclinometer sensor was proposed based on the principle of changing the mutual capacitance between the ring capacitor and the array capacitors by the sliding of the liquid droplet. The working principle of the sensor is as follows:

Figure 2 shows the distribution of the array capacitor electrodes and the ring capacitor electrode. There were 18 array capacitors was 18 that were evenly distributed inside the large ring of the annular groove, and the angle between two adjacent capacitor electrodes was 20°. Moreover, the ring capacitor was deposited outside the small ring of the annular groove. During the measurement process, the sensor was placed in the initial measurement position, and the angle between the sensor and the horizontal plane was

β. The input angle was provided by rotating the sensor around the horizontal axis and the droplet slid under the action of gravity due to the change in the input angle. The changes in the mutual capacitance between the array capacitor electrodes and the ring capacitor electrode were measured by the new position of the droplet in the annular groove after sliding. Since the sensor was not placed on the horizontal plane, the output angle was not numerically equal to the input angle. The relationship between the input angle and the output angle was analyzed based on the projection of the droplet motion trajectory on the vertical plane [

12].

The movement trajectory of the droplet in the sensor is mainly controlled by the annular groove on the intermediate substrate. Here, the shape of the annular groove was designed as a standard circle with a radius of one to facilitate calculation. In addition, the projection of the circular curve on the vertical plane was an ellipse, which satisfies the standard ellipse equation, as shown in

Figure 3a.

The standard circle equation of the annular groove on the intermediate substrate of the sensor in coordinate system 1 (X−Y) is shown in Equation (1):

Here,

x and

y are the horizontal coordinate and vertical coordinate of the point on the circle equation in coordinate system 1, respectively. Furthermore, the elliptic curve in the coordinate system 2 (X

1–Y

1) is shown in Equation (2):

Here, a1 and b1 are the long axis and short axis of the elliptic curve projected in the coordinate system 2, a1 = 1, b1 = sinβ, x1, y1 are the horizontal and vertical coordinates of the point on the elliptic equation of the coordinate system 2. β is the angle between the horizontal plane and the initial position of the sensor.

With the combined action of gravity and surface tension, the metal droplet stayed at the lowest point A of the circular curve (i.e., the lowest point of annular groove on the intermediate substrate) in the initial state. At the same time, the corresponding position of the droplet on the vertically projected elliptic curve was A

1, as shown in

Figure 3a. With input angle

α, the metal droplet will eventually stop at the lowest point B of the (X

B, Y

B) coordinate system 1. The projection point of point B on the elliptic curve was B

1 (X

B1, Y

B1), as shown in

Figure 3b.

Lb1 is the tangent of point B

1 on the elliptic curve, and the slope of the tangent

Lb1 in the coordinate system is

tanα, as shown in Equation (3).

When the input angle is

α, the angle at which the droplet slides in the annular groove of the intermediate substrate is

α0, and the relationship between

tanα and

tanα0 is shown in Equation (4):

where

α0 is the output angle;

β is the angle between the sensor and horizontal plane; and

α is the input angle.

Figure 4 shows the schematic diagram of the droplet leaving and approaching from the capacitor electrodes. The measured output angle signal was represented by measuring the mutual capacitance between each array capacitor electrode and the ring capacitor electrode. When the mercury liquid droplet was far from the capacitor electrodes, as shown in

Figure 4a, the amount of capacitance tested by the system was the capacitance formed by the array capacitor electrode and the ring capacitor electrode (named

C1). When the droplet is close to the capacitor electrode, as shown in

Figure 4b, the capacitance between the two electrodes will change from

C1 to

C2.

The droplet passing between the two capacitor electrodes is equivalent to reducing the distance between the ring capacitor and the array capacitor, therefore, the mutual capacitance of the ring capacitor and the array capacitors increases as the mercury droplet approaches the capacitor electrodes, and decreases as the mercury droplet moves away from the capacitor electrodes. The mutual capacitance matrix of the sensor is shown in Equation (5):

Here, Cmutual is the mutual capacitance matrix of the sensor; C1~C18 represent the array capacitor electrodes; and C19 represents the ring capacitor electrode. The droplet movement will cause the capacitance values of , …, in the mutual capacitance matrix of the sensor changing. The position of the droplet was determined by detecting the change in mutual capacitance, and then the output angle signal was calculated.

2.3. Design of Sensor Capacitor Electrodes

The measurement of the angle signal by a pair of capacitor electrodes is limited. Therefore, the number of capacitor electrodes needs to be increased to improve the measurement range of the sensor. The design of the sensor capacitor electrodes needs to meet the following principles. First, the capacitor electrodes need to be in the same plane to facilitate MEMS fabrication. Second, the rate change of the mutual capacitance when the droplet passes the capacitor is large, and finally, the number of array capacitor electrodes should be as small as possible. Combining the above principles, two pairs of capacitor electrodes were placed on both sides of the metal droplet movement groove, as shown in

Figure 5. The dimensions of the capacitor electrodes 1, 2, 3, and 4 in

Figure 5 were all 0.5 mm × 0.5 mm, and the diameter of the metal droplet was 1.8 mm. We used COMSOL numerical simulation software to perform the mutual capacitance simulation, calculate the mutual capacitance between capacitor electrodes 1 and 2, and the mutual capacitance between capacitor electrodes 3 and 4 when the mercury droplet moved from point A to point B. Note that Point A and Point B were 10 mm apart).

Capacitor electrodes 1, 3, and capacitor electrodes 2, 4 were 1.5 mm apart as shown in

Figure 5. The mutual capacitance matrix of the capacitor system

Csystem formed by the four capacitor electrodes is shown in Equation (6):

When the metal droplet moves from point A to point B, the droplet will affect the mutual capacitance value between the capacitor electrodes on both sides of the movement direction, and the sensor needs to measure the mutual capacitance between the capacitor electrodes on both sides. Therefore, only the mutual capacitance between capacitor electrodes 1, 3, and 2, 4 is concerned in the model, that is, the values of

C12 and

C34 in the mutual capacitance matrix Equation (6) (

C12 =

C21,

C34 =

C43). Furthermore, the distance between the capacitor electrodes on the same side changed, and the distance between the adjacent capacitor electrodes and the position of the metal droplets were studied. The results are shown in

Figure 6.

Figure 6 is the relationship between the droplet displacement and the mutual capacitance when the distances between the adjacent capacitor electrodes were 1.5 mm, 2 mm, 2.5 mm, and 4 mm, respectively. When the droplet moves from point A to point B, it first approaches the capacitor formed by the 1, 2, capacitor electrodes, so

C12 changes first and increases from 0.95 × 10

−3 pF to 2.1 × 10

−3 pF. As the displacement of the droplet continues to increase, the mercury droplet gradually moves away from capacitor electrodes 1, 2, and close to capacitor electrodes 3, 4. At this time, the mutual capacitance of capacitor electrodes 1 and 2 gradually decreases, while the mutual capacitance

C34 gradually increases. Since the two pairs of capacitor electrodes in the model have the same size, the amount of each mutual capacitance change is the same. Further analysis found that the horizontal distances between the peaks and valleys of curves

C12 and

C34 were the same, both of which were 3.5 mm. This shows that the resolution distance of a pair of capacitor electrodes at this size is 3.5 mm. Therefore, increasing the number of capacitor electrodes and controlling the distance between two adjacent capacitor electrodes can effectively increase the measurement range of the sensor. To facilitate the measurement of the sensor, the distance between capacitor electrodes 1,2 and capacitor electrodes 3,4 should not exceed the period length of the curve (0~3.5 mm).

Combined with the above analysis, the capacitor electrode design of the droplet MEMS inclinometer sensor based on the principle of mutual capacitance was proposed, as shown in

Figure 7. The capacitor system includes a ring capacitor electrode in the inner circle and 18 array capacitor electrodes in the outer circle. The width of the ring capacitor electrode was 0.5 mm. The size of the array capacitor electrodes was 0.5 mm × 0.5 mm, and the angle between two adjacent array capacitor electrodes was 20°. The inner circle radius of the ring capacitor electrode was 5 mm, and the inner circle radius of the array capacitor electrode was 6.5 mm.

COMSOL numerical simulation software was used to perform an analysis of the mutual capacitance changes in the designed capacitor system. A mercury droplet with a diameter of 1.8 mm moved from point A to point B, as shown in

Figure 7, which represented the sensor rotated 180° clockwise in the horizontal plane. In the numerical simulation, the mercury droplet was spherical and tangent to the lower plane of the substrate, so that it was not in contact with the capacitor electrodes.

Table 1 shows the properties of the material:

The initial boundary conduction of the model was as follows:

The potential of the terminal array capacitor was 1 V.

The potential of the terminal ring capacitor was 0 V.

Metal droplet was the terminal with charge 0 C.

The lower surface of the lower substrate was grounded.

The special mesh refinement process is required for the region of the mercury droplet. A mesh consisting of 36,630 elements was generated using the free tetrahedral meshing method and the average cell quality of the mesh reached 0.62.

Table 2 shows the mutual capacitance between the ring capacitor electrode (No. 11) and array capacitor electrodes (No. 1 to No. 10) in the sensor when the droplet stays at point A.

It can be seen from

Table 2 that when the droplet stayed at point A, the mutual capacitance between the No. 1 array capacitor electrode and the No. 11 ring capacitor electrode was the largest, and the amount of mutual capacitance was 7.26 × 10

−3 pF. Furthermore, the mutual capacitance between the array capacitor electrodes (No. 2 to No. 10) and the ring capacitor electrode gradually decreased and approached a fixed value of 3.5 × 10

−3 pF.

Table 3 shows the relationship between the angle and the mutual capacitance of the No. 1 ring capacitor electrodes. (the input angle was from 0° to 15°)

Figure 8 shows the amount of mutual capacitance between the array capacitor electrodes (No. 1 to No. 10) and the ring capacitor electrode (No. 11) when the position of the droplet changes from point A to point B (calculating the mutual capacitance every 5°). The mutual capacitance between the array capacitor electrodes and the ring capacitor electrode will increase when the droplet is close to the array capacitor electrode, and the amount of mutual capacitance can be increased from 3.4 × 10

−3 pF to 7.3 × 10

−3 pF. After that, the mutual capacitance reduces to 3.4 × 10

−3 pF again as the mercury droplet gradually moves away from the array capacitor electrode. Additionally, with this geometry, the change rate of the mutual capacitance of the sensor can reach or even exceed 100%, which can greatly promote signal acquisition and resolution during testing.

2.4. Design of the Superhydrophobic Structure on Lower Structure

The minimum measurement angle of the MEMS liquid inclinometer sensor is mainly determined by the sliding angle of the metal droplet [

12]. In order to further reduce the sliding angle of the droplet, researchers have proposed a method for growing microstructures on the surface of the substrate, which has increased the surface roughness of the substrate and reduced the contact area of the droplet and the surface [

21,

22]. Lv manufactured an array of micro-cubes to create a super hydrophobic surface when predicting the sliding angle of a droplet on a micro-structured surface. The sliding process proposed consisted of three steps using a high-speed camera to observe the movement of the droplet [

23].

When the plate is inclined, the rear contact line of the droplet is detached from the microstructure first. At this time, the front contact line of the droplet does not change significantly. With the increase of the tilt angle

α, the front contact line of the droplet contacts the micro-structure of the front end. However, the rear contact line does not change. As the inclination of the microstructure substrate further increases, the droplet will repeat the entire sliding process described above, as shown in

Figure 9a. During the sliding process of the droplet, the contact line moves in only one direction at the same time. Therefore, the movement of the droplet on the surface of the micro-cube microstructure is considered to be quasi-static and the energy is conserved, as shown in

Figure 9b. When the tilt angle of plate is

α, the area where the rear contact line moves is Δ

S and the amount of change in droplet surface energy Δ

E at this time is shown in Equation (7):

where

γlv is the surface tension of droplet;

θ is the contact angle of surface and droplet; and Δ

S is the area of liquid surface movement when rear contact line moves. The value of the Δ

S is:

where Δ

x is the displacement of the rear contact line movement;

R is the radius of the contact surface of the droplet with the surface;

l is the side length of the micro-cubes; and

d is the distance between two adjacent micro-cubes.

When the inclination angle is

a, the droplet slides from the super hydrophobic surface with the micro-cube structure, and the displacement of the rear contact line of the droplet is Δ

x. At this time, the gravity center of the droplet is moved by Δ

x/2, and the gravitational potential energy is:

According to the law of the conservation of energy, the relationship between the sliding angle and the characteristic size of the micro-structure is as follows:

Based on the above prediction model for the sliding angle, the micro-cube structure on the lower surface was designed (that is, the surface between array capacitor electrodes and ring capacitor electrode on the lower substrate) to reduce the sliding angle of the mercury droplet. As shown in

Figure 10, the size of the micro cubes was 30 × 30 um, and the distance between each adjacent cube was 20 um.

In order to measure the sliding angle of a mercury droplet on the micro-cube structure, a layer of silica array micro-cubes with a size of 30 um × 30 um and a pitch of 20 um was deposited on the glass through the MEMS process. Next, a 1.8 mm diameter mercury droplet was dropped on the glass and the whole substrate was placed on the tilted platform, as shown in

Figure 11. The tilted platform could rotate around the horizontal axis. The high-speed camera observed that when the tilt angle was 2.12°, the droplet started to slide, which shows that the minimum measurement angle of the sensor is 2.12° and the measurement range is from ±2.12° to ±360°.