Forensic Analysis of Commercial Inks by Laser-Induced Breakdown Spectroscopy (LIBS)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Samples

2.2. LIBS Set-Up

3. Results and Discussions

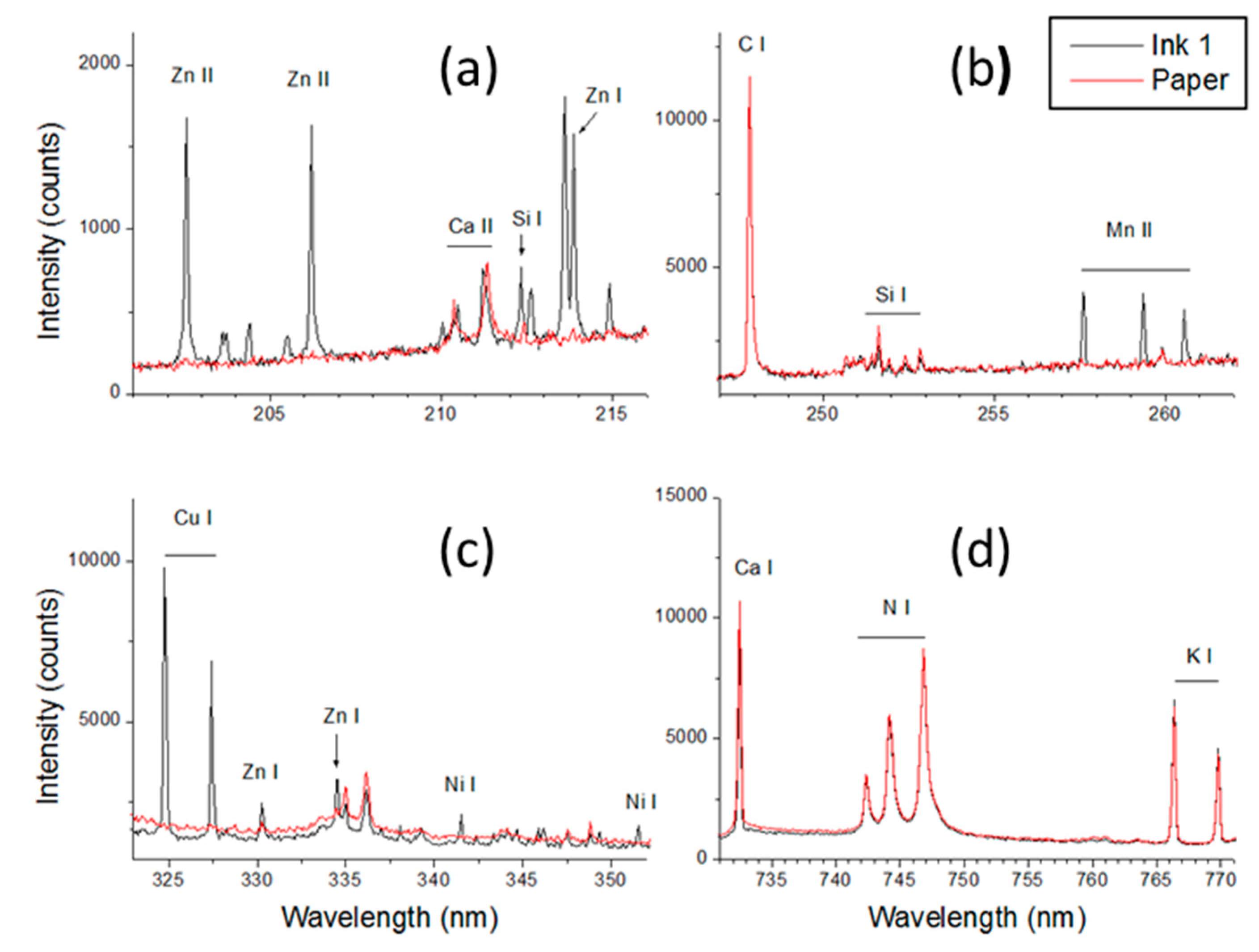

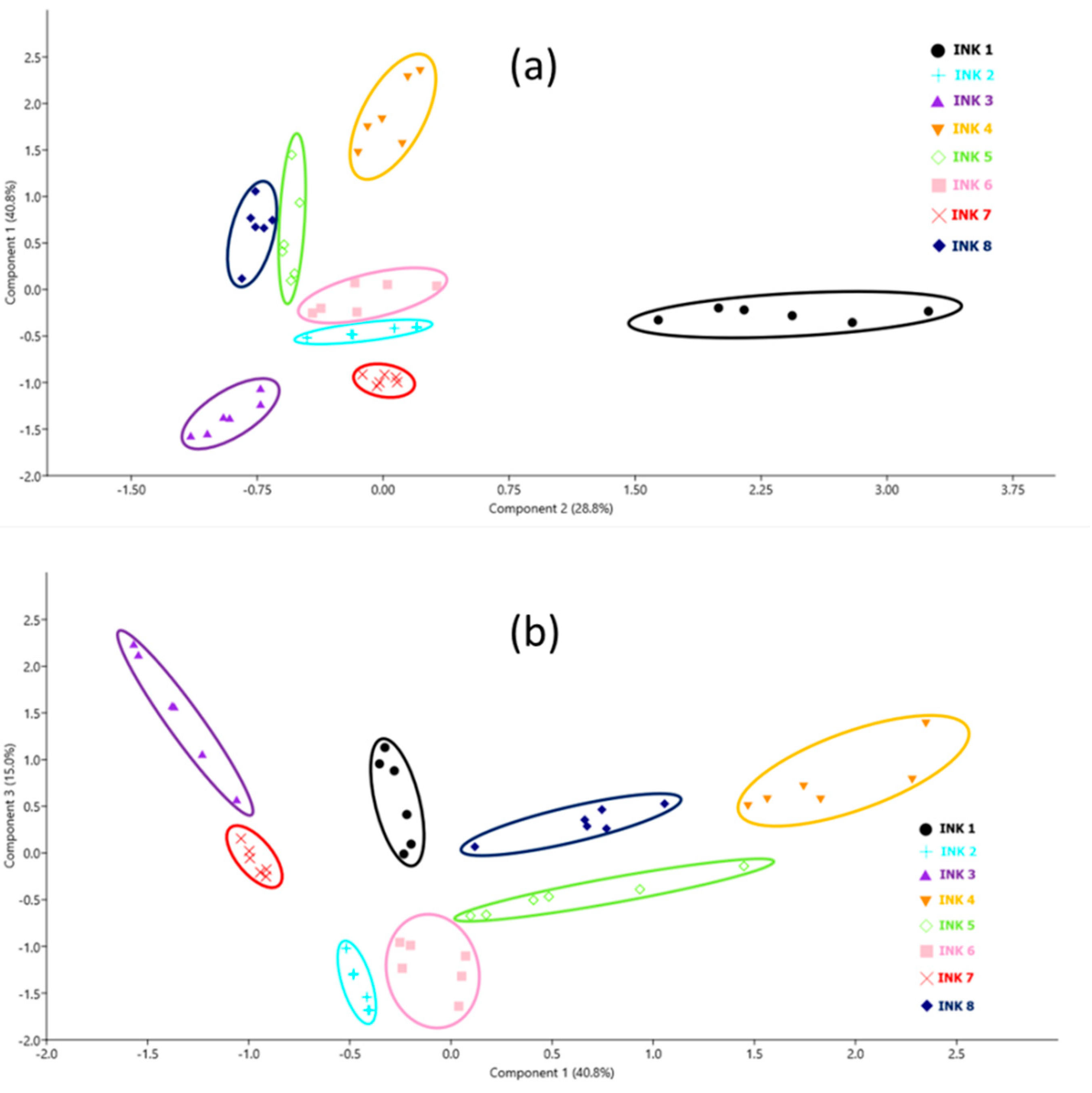

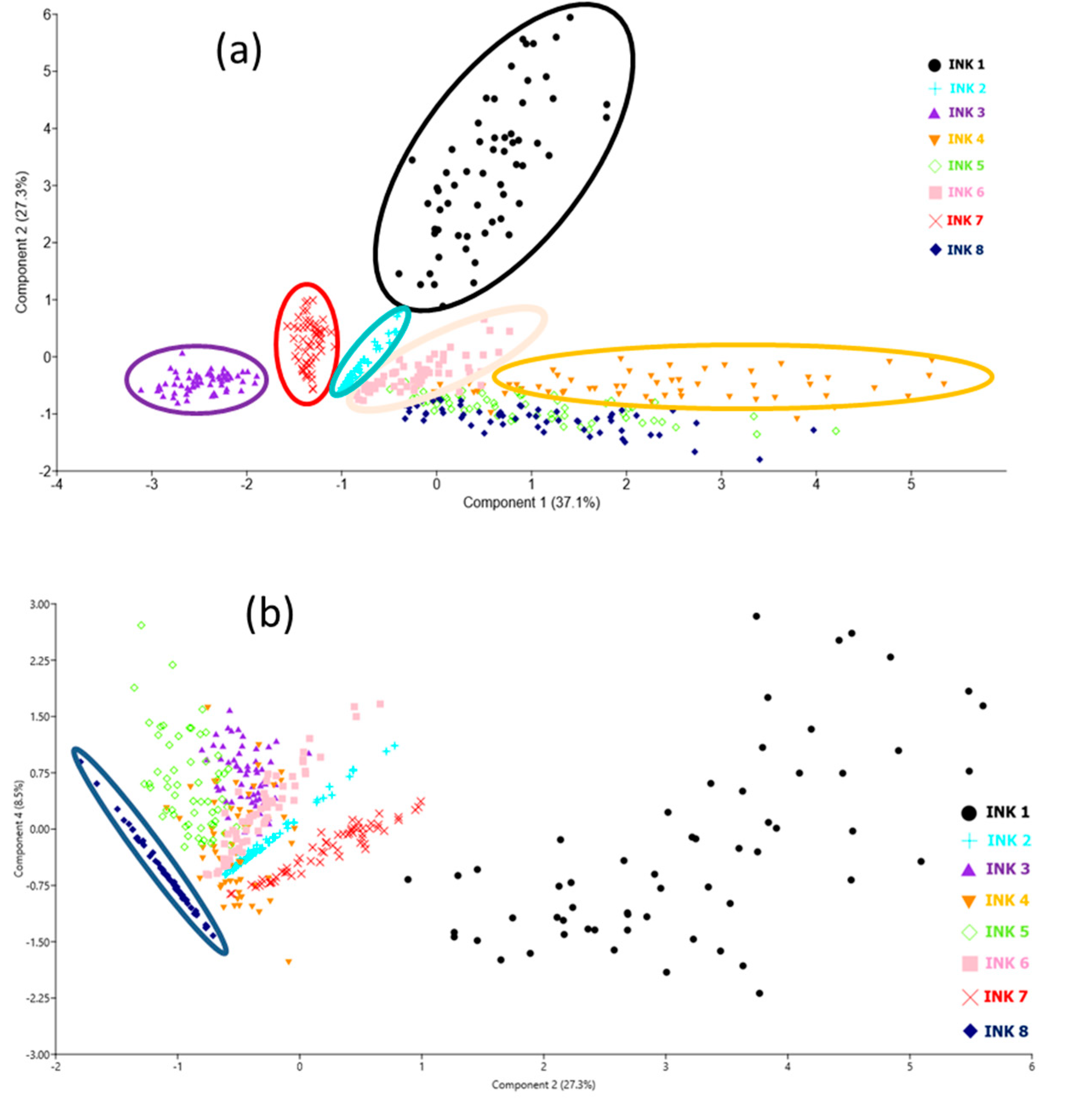

3.1. Analysis of Commercial Inks on One Paper Sheet

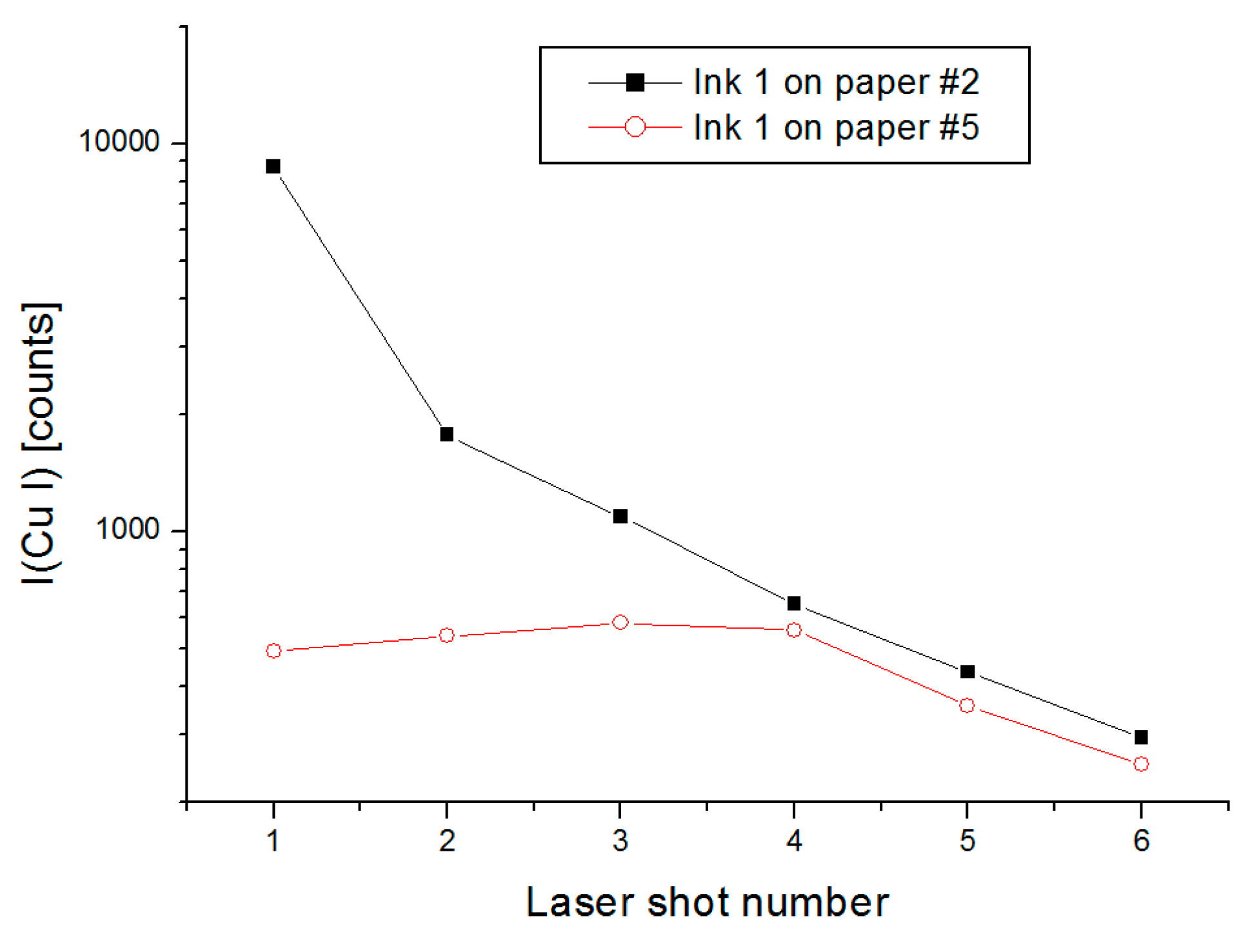

3.2. Analysis of Commercial Black Inks on Different Papers

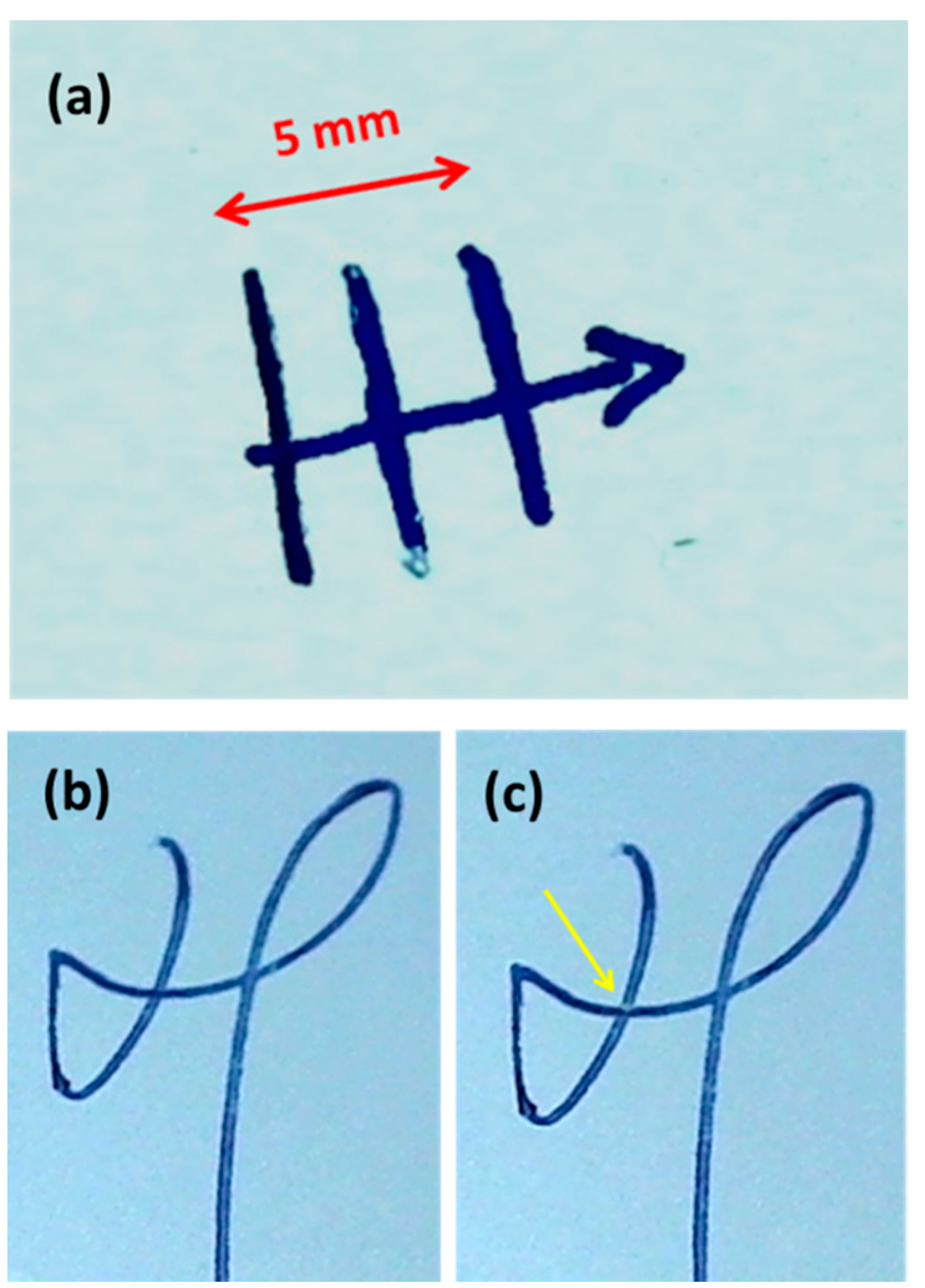

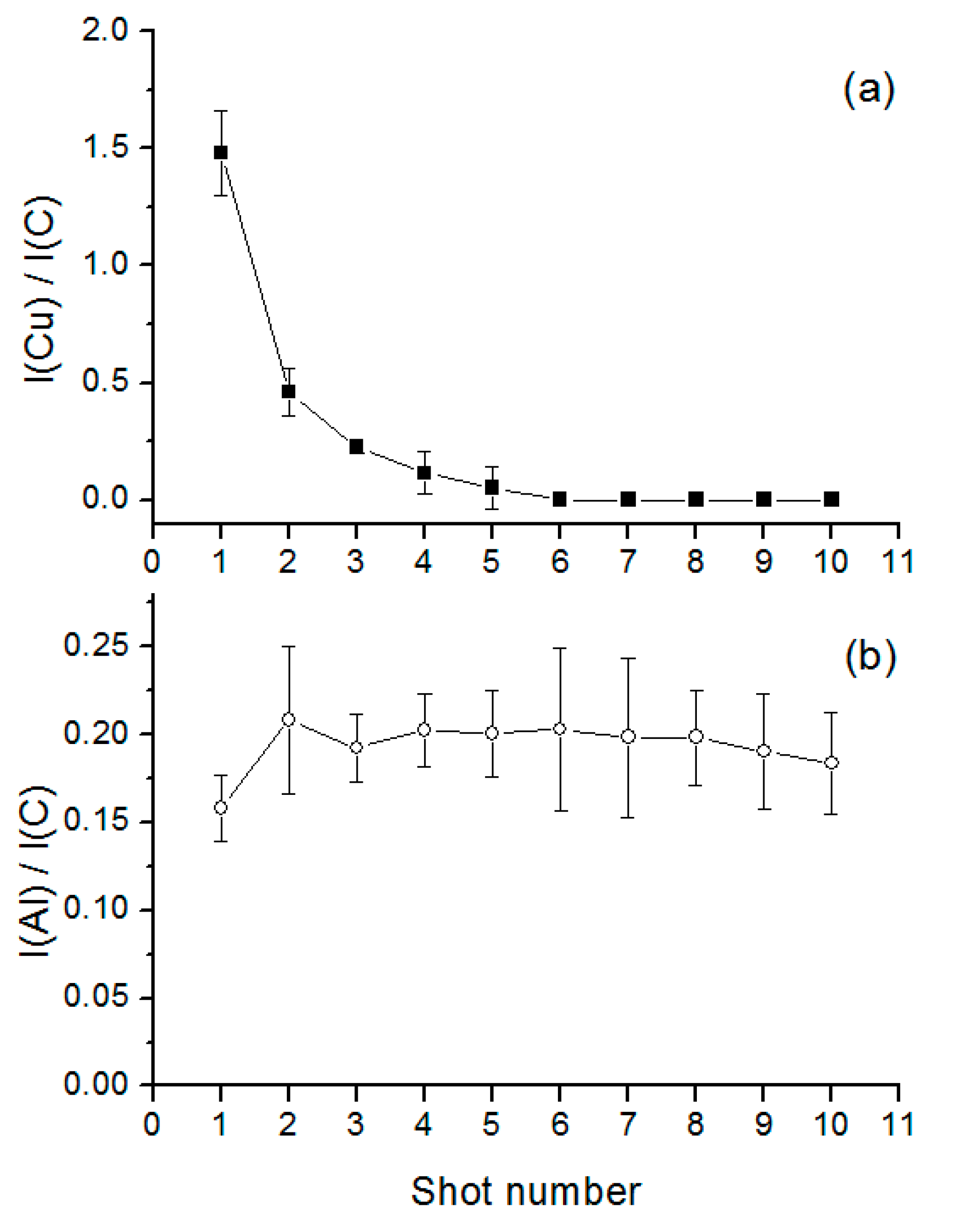

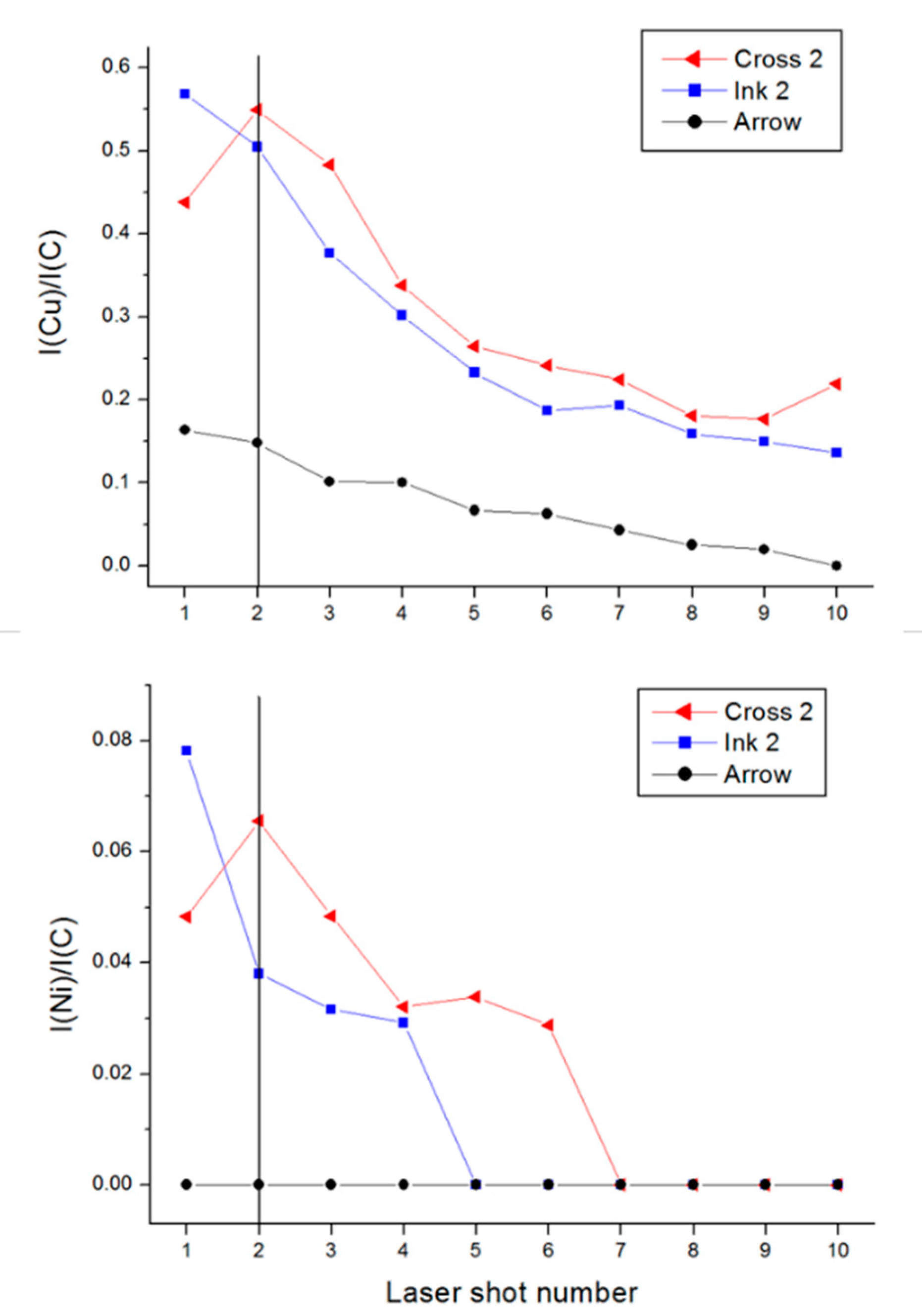

3.3. Characterization of Inks on Cross Points

3.4. Characterization of Inks and Toners on an Questioned Document

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Calcerrada, M.; García-Ruiz, C. Analysis of questioned documents: A review. Anal. Chim. Acta 2015, 853, 143–166. [Google Scholar] [CrossRef] [PubMed]

- Denman, J.A.; Skinner, W.M.; Kirkbride, K.P.; Kempson, I.M. Organic and inorganic discrimination of ballpoint pen inks by ToF-SIMS and multivariate statistics. Appl. Surf. Sci. 2010, 256, 2155–2163. [Google Scholar] [CrossRef]

- Ezcurra, M.; Góngora, J.M.G.; Maguregui, I.; Alonso, R. Analytical methods for dating modern writing instrument inks on paper. Forensic Sci. Int. 2010, 197, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Gorziza, R.P.; Bello de Carvalho, C.M.; González, M.; Leal, L.B.; Korndörfer, T.; Ortiz, R.S.; Trejos, T.; Limberger, R.P. Blue and black ballpoint pen inks: A systematic review for ink characterization and dating analysis. Braz. J. Forensic Sci. Med. Law Bioeth. 2019, 8, 113–138. [Google Scholar] [CrossRef] [Green Version]

- Neumann, C.; Ramotowski, R.; Genessay, T. Forensic examination of ink by high-performance thin layer chromatography, The United States Secret Service Digital Ink Library. J. Chromatogr. A 2011, 1218, 2793–2811. [Google Scholar] [CrossRef]

- Saini, K.; Rathore, R. Differentiation of Red and Black Ballpoint Pen Inks using High Performance Thin Layer Chromatography and Gas Chromatography-Mass Spectrometry. Arab J. Forensic Sci. Forensic Med. 2018, 1, 829–841. [Google Scholar] [CrossRef] [Green Version]

- Alamilla, F.; Calcerrada, M.; García-Ruiz, C.; Torre, M. Forensic discrimination of blue ballpoint pens on documents by laser ablation inductively coupled plasma mass spectrometry and multivariate analysis. Forensic Sci. Int. 2013, 228, 1–7. [Google Scholar] [CrossRef]

- Trejos, T.; Flores, A.; Almirall, J.R. Micro-spectrochemical analysis of document paper and gel inks by laser ablation inductively coupled plasma mass spectrometry and laser induced breakdown spectroscopy. Spectrochim. Acta Part B 2010, 65, 884–895. [Google Scholar] [CrossRef]

- Agarwal, A.; Sharma, N.; Negi, Y.S. Review: Techniques for the characterization of inks. IOSR J. Appl. Chem. 2016, 9, 76–96. [Google Scholar]

- Braz, A.; López-López, M.; Garcì-Ruiz, C. Raman spectroscopy for forensic analysis of inks in questioned documents. Forensic Sci. Int. 2013, 232, 206–212. [Google Scholar] [CrossRef]

- Silva, C.S.; Braz, A.; Pimentel, M.F. Vibrational Spectroscopy and Chemometrics in Forensic Chemistry: Critical Review, Current Trends and Challenges. J. Braz. Chem. Soc. 2019, 30, 2259–2290. [Google Scholar] [CrossRef]

- Zieba-Palus, J.; Borusiewicz, R.; Kunicki, M. PRAXIS--combined μRaman and μXRF spectrometers in the examination of forensic samples. Forensic Sci. Int. 2008, 175, 1–10. [Google Scholar] [CrossRef]

- Claybourn, M.; Ansell, M. Using Raman spectroscopy to solve crimes: Inks questioned documents and fraud. Sci. Justice 2000, 40, 261–271. [Google Scholar] [CrossRef]

- Mazzella, W.; Khanmy-Vital, A. A study to investigate the evidential value of blue gel pens inks. J. Forensic Sci. 2003, 48, 419–424. [Google Scholar] [CrossRef]

- Buzzini, P.; Polston, C.; Schackmuth, M. On the criteria for the discrimination of inkjet printer inks using micro-Raman spectroscopy. J. Raman Spectrosc. 2018, 49, 1791–1801. [Google Scholar] [CrossRef]

- Braz, A.; López-López, M.; García-Ruiz, C. Studying the variability in the Raman signature of writing pen inks. Forensic Sci. Int. 2014, 245, 38–44. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.S.; Borba, F.S.L.; Pimentel, M.F.; Pontes, M.J.C.; Honorato, R.S.; Pasquini, C. Classification of blue pen ink using infrared spectroscopy and linear discriminant analysis. Microchem. J. 2013, 109, 122–127. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, R. Fourier transform infrared spectroscopy and high-performance thin layer chromatography for characterization and multivariate discrimination of blue ballpoint pen ink for forensic applications. Vib. Spectrosc. 2017, 92, 96–101. [Google Scholar] [CrossRef]

- Sharif, M.; Batool, M.; Chand, S.; Farooqi, Z.H.; Tirmazi, S.A.A.S.; Athar, M. Forensic discrimination potential of Blue, Black, Green, and Red colored fountain pen inks commercially used in Pakistan, by UV/Visible spectroscopy, thin layer chromatography, and Fourier transform infrared spectroscopy. Int. J. Anal. Chem. 2019, 2019, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, C.; Brown, J.F.; Mackenzie, M.J.; Randall, L.; Smith, H.G.B. The Printing Ink Manual, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 154–196. [Google Scholar]

- Materazzi, S.; Risoluti, R.; Pinci, S.; Romolo, F.S. New insights in forensic chemistry: NIR/Chemometrics analysis of toners for questioned documents examination. Talanta 2017, 174, 673–678. [Google Scholar] [CrossRef]

- Król, M.; Karoly, A.; Kóscielniak, P. Raman spectroscopy and capillary electrophoresis applied to forensic colour inkjet printer inks analysis. Forensic Sci. Int. 2014, 242, 142–149. [Google Scholar] [CrossRef] [PubMed]

- Johnson, C.E.; Martin, P.; Roberts, K.A.; Trejos, T.; Corzo, R.; Almirall, J.R.; Safer, A.M. The capability of Raman microspectroscopy to differentiate printing inks. J. Forensic Sci. 2018, 63, 66–79. [Google Scholar] [CrossRef] [PubMed]

- Almeida Assis, A.C.; Barbosa, M.F.; Valente Nabais, J.M.; Custódio, A.F.; Tropecelo, P. Diamond cell Fourier transform infrared spectroscopy transmittance analysis of black toners on questioned documents. Forensic Sci. Int. 2012, 214, 59–66. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lennard, C.; El-Deftar, M.M.; Robertson, J. Forensic application of laser-induced breakdown spectroscopy for the discrimination of questioned documents. Forensic Sci. Int. 2015, 254, 68–79. [Google Scholar] [CrossRef]

- Hoehse, M.; Paul, A.; Gornushkin, I.; Panne, U. Multivariate classification of pigments and inks using combined Raman spectroscopy and LIBS. Anal. Bioanal. Chem. 2012, 402, 1443–1450. [Google Scholar] [CrossRef]

- Kula, A.; Wietecha-Posłuszny, R.; Pasionek, K.; Król, M.; Woźniakiewicz, M.; Kościelniak, P. Application of laser induced breakdown spectroscopy to examination of writing inks for forensic purposes. Sci. Justice 2014, 54, 118–125. [Google Scholar] [CrossRef]

- Elsherbiny, N.; Nassef, O.A. Wavelength dependence of laser induced breakdown spectroscopy (LIBS) on questioned document investigation. Sci. Justice 2015, 55, 254–263. [Google Scholar] [CrossRef]

- Rzecki, K.; Sośnicki, T.; Baran, M.; Niedźwiecki, M.; Król, M.; Łojewski, T.; Acharya, U.R.; Yildirim, Ö.; Pławiak, P. Application of computational intelligence methods for the automated identification of Paper-Ink samples based on LIBS. Sensors 2018, 18, 3670. [Google Scholar] [CrossRef] [Green Version]

- Subedi, K.; Trejos, T.; Almirall, J. Forensic analysis of printing inks using tandem Laser Induced Breakdown Spectroscopy and Laser Ablation Inductively Coupled Plasma Mass Spectrometry. Spectrochim. Acta Part B 2015, 103–104, 76–83. [Google Scholar] [CrossRef]

- Metzinger, A.; Rajkó, R.; Galbács, G. Discrimination of paper and print types based on their laser induced breakdown spectra. Spectrochim. Acta Part B 2014, 94–95, 48–57. [Google Scholar] [CrossRef]

- Hui, Y.W.; Mahat, N.A.; Ismail, D.; Ibrahim, R.K.R. Laser-induced breakdown spectroscopy (LIBS) for printing ink analysis coupled with principle component analysis (PCA). AIP Conf. Proc 2019, 2155, 020010. [Google Scholar]

- Oujja, M.; Vila, A.; Rebollar, E.; Garcìa, J.F.; Castillejo, M. Identification of inks and structural characterization of contemporary artistic prints by laser-induced breakdown spectroscopy. Spectrochim. Acta Part B 2005, 60, 1140–1148. [Google Scholar] [CrossRef]

- Brito, L.R.; Martins, A.R.; Braz, A.; Chaves, A.B.; Braga, J.W.; Pimentel, M.F. Critical review and trends in forensic investigations of crossing ink lines. Trends Analyt. Chem. 2017, 94, 54–69. [Google Scholar]

- Goacher, R.E.; DiFonzo, L.G.; Lesko, K.C. Challenges determining the correct deposition order of different intersecting black inks by Time-of-Flight secondary ion mass spectrometry. Anal. Chem 2017, 89, 759–766. [Google Scholar] [CrossRef]

- Li, B.; Ouyang, G.; Zhao, P. Preliminary study on determining the sequence of intersecting lines by fluorescence technique. J. Forensic Sci. 2018, 63, 577–582. [Google Scholar] [CrossRef] [PubMed]

- Malloy, M.; Bogdanović Radović, I.; Siketić, Z.; Jakšić, M. Determination of deposition order of blue ballpoint pen lines by MeV SIMS. Forensic Chem. 2018, 7, 75–80. [Google Scholar] [CrossRef]

- Brito, L.R.; Chaves, A.B.; Braz, A.; Pimentel, M.F. Raman hyperspectral imaging and a novel approach for objective determination of the order of crossing ink lines. Spectrochim. Acta Part A 2019, 223, 117287. [Google Scholar] [CrossRef]

- Lazic, V.; De Ninno, A. Calibration approach for extremely variable laser induced plasmas and a strategy to reduce the matrix effect in general. Spectrochim. Acta Part B 2017, 137, 28–38. [Google Scholar] [CrossRef]

- Amador, V.S.; Pereira, H.V.; Sena, M.M.; Augusti, R.; Piccin, E. Paper spray mass spectrometry for the forensic analysis of black ballpoint pen inks. J. Am. Soc. Mass Spectrom 2017, 28, 1965–1976. [Google Scholar] [CrossRef]

- Williams, M.R.; Moody, C.; Arceneaux, L.A.; Rinke, C.; White, K.; Sigman, M.E. Analysis of black writing ink by electrospray ionization mass spectrometry. Forensic Sci. Int. 2009, 191, 97–103. [Google Scholar] [CrossRef]

| N° | Brand/Producer | Type/Model | Ink Color |

|---|---|---|---|

| 1 | Papermate | Flexgrip Ultra 1M | Black |

| 2 | Tratto | Uno 1 | Black |

| 3 | Pilot | BP-S Matic Fine | Black |

| 4 | Bic | Soft Feel Med | Black |

| 5 | Staedtler | Noris Stick | Black |

| 6 | Papermate | Inkjoy 300 RT 1M | Black |

| 7 | Pilot | G-1 Grip | Black |

| 8 | Faber Castell | Lux 300 | Black |

| 9 | Papermate | Flexgrip Ultra 1M | Blue |

| 10 | Tratto | Uno 1 | Blue |

| 11 | Pilot | G-1 Grip | Blue |

| 12 | Bic | Cristal | Blue |

| 13 | Bic | Cristal | Red |

| 14 | Bic | Cristal | Green |

| Lease Agreement | ||

|---|---|---|

| Pages 1 and 3 | Page 2 | |

| Paper | Inacópia office 80 g/m2, 100 µm | Staples 80 g/m2, 100 µm |

| Printer | Konica Minolta model bizhub | OKI Model ES8453 MFP223 |

| Wrinting inks | Signature of the first grantor | |

| Blue Gel pen Mitsubishi uni.ball Signo | Blue Gel pen Mitsubishi uni.ball Signo 0.7 | |

| Signature of the second grantor | ||

| Black ballpoint pen BIC | Black ballpoint pen Pentel SUPERB | |

| Signature of the third grantor | ||

| Blue ballpoint pen “white label” | Blue ballpoint pen OfficeCover Astro 1.0 | |

| Element | State * | Wavelength (nm) | Paper |

|---|---|---|---|

| Al | I | 309.271 | + |

| Ba | II | 455.403 | - |

| C | I | 247.856 | + |

| Ca | I | 452.69 | + |

| Cr | I | 425.222 | - |

| Cu | I | 324.754 | - |

| Fe | II | 238.204 | - |

| H | I | 656.279 | + |

| K | I | 769.896 | + |

| Li | I | 670.776 | + |

| Mg | I | 285.213 | + |

| Mn | II | 257.610 | - |

| Na | I | 589.592 | + |

| Ni | I | 352.454 | - |

| Pb | I | 405.781 | - |

| Si | I | 288.158 | + |

| Sr | II | 407.771 | + |

| Ti | I | 498.173 | - |

| Zn | II | 202.548 | - |

| No | Cu/C | Zn/C | Mn/C | Ni/C | Pb/C | Fe/C | Cr/C |

|---|---|---|---|---|---|---|---|

| 1 | 0.92 ± 0.22 | 0.16 ± 0.09 | 0.27 ± 0.11 | 0.11 ± 0.02 | 0.033 ± 0.006 | 0.017 ± 0.004 | 0 |

| 2 | 0.056 ± 0.009 | 0 | 0 | 0.051 ± 0.011 | 0 | 0 | 0 |

| 3 | 0 | 0 | 0.078 ± 0.013 | 0 | 0 | 0 | 0.50 ± 0.24 |

| 4 | 2.86 ± 0.78 | 0.41 ± 0.07 | 0 | 0.0304 ± 0.009 | 0.078 ± 0.035 | 0 | 0 |

| 5 | 1.56 ± 0.60 | 0.20 ± 0.08 | 0 | 0.033 ± 0.003 | 0.028 ± 0.005 | 0 | 0 |

| 6 | 0.39 ± 0.04 | 0.089 ± 0.013 | 0 | 0.061 ± 0.013 | 0 | 0 | 0 |

| 7 | 0 | 0 | 0.064 ± 0.015 | 0 | 0 | 0 | 0 |

| 8 | 1.00 ± 0.33 | 0.20 ± 0.07 | 0 | 0 | 0.028 ± 0.011 | 0 | 0.029 ± 0.005 |

| 9 | 0.75 ± 0.31 | 0.13 ± 0.05 | 0.22 ± 0.09 | 0.098 ± 0.044 | 0.041 ± 0.014 | 0.023 ± 0.012 | 0 |

| 10 | 0.28 ± 0.02 | 0.046 ± 0.001 | 0.10 ± 0.02 | 0.059 ± 0.03 | 0.017 ± 0.006 | 0.019 ± 0.008 | 0 |

| 11 | 0.043 ± 0.002 | 0 | 0.078 ± 0.007 | 0 | 0 | 0.012 ± 0.005 | 0 |

| 12 | 3.5 ± 1.0 | 0.36 ± 0.10 | 0 | 0.053 ± 0.02 | 0.058 ± 0.004 | 0 | 0 |

| 13 | 3.0 ± 1.0 | 0.29 ± 0.09 | 0 | 0.042 ± 0.007 | 0.091 ± 0.020 | 0.022 ± 0.010 | 0 |

| 14 | 2.7 ± 1.2 | 0.29 ± 0.07 | 0 | 0.046 ± 0.011 | 0.039 ± 0.009 | 0.013 ± 0.005 | 0 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | Total | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 60 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 60 |

| 2 | 0 | 60 | 0 | 0 | 0 | 0 | 0 | 0 | 60 |

| 3 | 0 | 0 | 60 | 0 | 0 | 0 | 0 | 0 | 60 |

| 4 | 0 | 0 | 0 | 48 | 4 | 2 | 0 | 6 | 60 |

| 5 | 0 | 0 | 0 | 0 | 50 | 10 | 0 | 0 | 60 |

| 6 | 0 | 20 | 0 | 0 | 1 | 39 | 0 | 0 | 60 |

| 7 | 0 | 0 | 0 | 0 | 0 | 0 | 60 | 0 | 60 |

| 8 | 0 | 0 | 0 | 4 | 2 | 0 | 0 | 54 | 60 |

| Total | 60 | 80 | 60 | 52 | 57 | 51 | 60 | 60 | 480 |

| Ink | Cu/C | Zn/C | Mn/C | Ni/C | Pb/C |

|---|---|---|---|---|---|

| ARROW | 0.157 ± 0.038 | 0.072 ± 0.014 | 0 | 0 | 0.035 ± 0.008 |

| INK 1 | 0.788 ± 0.162 | 0.105 ± 0.014 | 0 | 0 | 0.078 ± 0.005 |

| INK 2 | 0.606 ± 0.119 | 0.054 ± 0.009 | 0.054 ± 0.009 | 0.086 ± 0.025 | 0.046 ± 0.005 |

| INK 3 | 0.572 ± 0.105 | 0.073 ± 0.008 | 0.145 ± 0.011 | 0.077 ± 0.016 | 0.042 ± 0.009 |

| Sample | R(Cu) | R(Pb) | R(Ni) | PCA |

|---|---|---|---|---|

| Ink 1 | 1.22 ± 0.19 | 1.50 ± 0.27 | - | |

| Ink 2 | 1.15 ± 0.15 | 1.37 ± 0.23 | 1.47 ± 0.38 | |

| Ink 3 | 1.15 ± 0.18 | 1.50 ± 0.31 | 2.12 ± 0.61 | |

| Arrow | 1.09 ± 0.07 | 1.31 ± 0.13 | - | |

| Cross 1-m1 | 0.97 | 1.06 | Mixed layers | |

| Cross 1-m2 | 1.02 | 0.86 + | Arrow → Ink 1 | |

| Cross 2-m1 | 0.90 + | 0.74 + | Arrow → Ink 2 | |

| Cross 2-m2 | 1.05 | 1.01 | Arrow → Ink 2 | |

| Cross 3-m1 | 0.85 + | 1.06 | Arrow → Ink 3 | |

| Cross 3-m2 | 0.81 + | 0.92 | Arrow → Ink 3 |

| Line Peak Ratio | Sample | Page 1 | Page 2 | Page 3 |

|---|---|---|---|---|

| Cu/C | Ink | 0.45 | 0.54 | 0.33 |

| Paper | 0 | 0 | 0 | |

| Zn/C | Ink | 0.012 | 0.026 | 0.013 |

| Paper | 0 | 0 | 0 | |

| Fe/C | Ink | 0 | 0.018 | 0 |

| Paper | 0 | 0 | 0 | |

| Li/C | Ink | 0.020 | 0.11 | 0.018 |

| Paper | 0.025 ± 0.016 | 0.052 ± 0.020 | 0.025 ± 0.028 | |

| K/C | Ink | 0.088 | 0.51 | 0.17 |

| Paper | 0.11 ± 0.02 | 0.19 ± 0.11 | 0.12 ± 0.04 |

| Page | Si/C | Ti/C | Ca/C | Mg/C | K/C |

|---|---|---|---|---|---|

| 1 | 0.12 ± 0.03 | 0.43 ± 0.07 | 0.05 ± 0.03 | 0.22 ± 0.12 | 0.27 ± 0.05 |

| 2 | 0.47 ± 0.09 | 0 | 0 | 0 | 0.27 ± 0.13 |

| 3 | 0.11 ± 0.02 | 0.38 ± 0.05 | 0.06 ± 0.02 | 0.18 ± 0.10 | 0.37 ± 0.14 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cicconi, F.; Lazic, V.; Palucci, A.; Almeida Assis, A.C.; Saverio Romolo, F. Forensic Analysis of Commercial Inks by Laser-Induced Breakdown Spectroscopy (LIBS). Sensors 2020, 20, 3744. https://doi.org/10.3390/s20133744

Cicconi F, Lazic V, Palucci A, Almeida Assis AC, Saverio Romolo F. Forensic Analysis of Commercial Inks by Laser-Induced Breakdown Spectroscopy (LIBS). Sensors. 2020; 20(13):3744. https://doi.org/10.3390/s20133744

Chicago/Turabian StyleCicconi, Flavio, Violeta Lazic, Antonio Palucci, Ana Cristina Almeida Assis, and Francesco Saverio Romolo. 2020. "Forensic Analysis of Commercial Inks by Laser-Induced Breakdown Spectroscopy (LIBS)" Sensors 20, no. 13: 3744. https://doi.org/10.3390/s20133744