A Novel Mine Cage Safety Monitoring Algorithm Utilizing Visible Light

Abstract

:1. Introduction

- We propose a novel mine cage safety monitoring algorithm. To the best of our knowledge, we are the first to propose the use of visible light technology to count miners with miner’s lamps. Besides, this method can also be applied to miner’s attendance in the future.

- We designed a special safe area monitoring method to minimize the probability of danger in the mine cage. To the best of our knowledge, we are the first to propose the use of visible light technology to perceive the range of human activity in underground mines. It can effectively reduce the probability of hidden risks only through the modulated LED lamp and a small number of PDs.

- We implemented our algorithm with a simulated coal mine cage. We also designed the special transmitter (including Xilinx ZYNQ-7020 FPGA and commercial LED lamps) and receiver (including the PD Honeywell SD5421-002 and AN706 digital-to-analog converter (ADC)). The experimental results show that the accuracy of personnel overload judgment and safe area monitoring of our algorithm can reach 99%, and the accuracy of limb extension monitoring is more than 96%.

2. Algorithm Overview

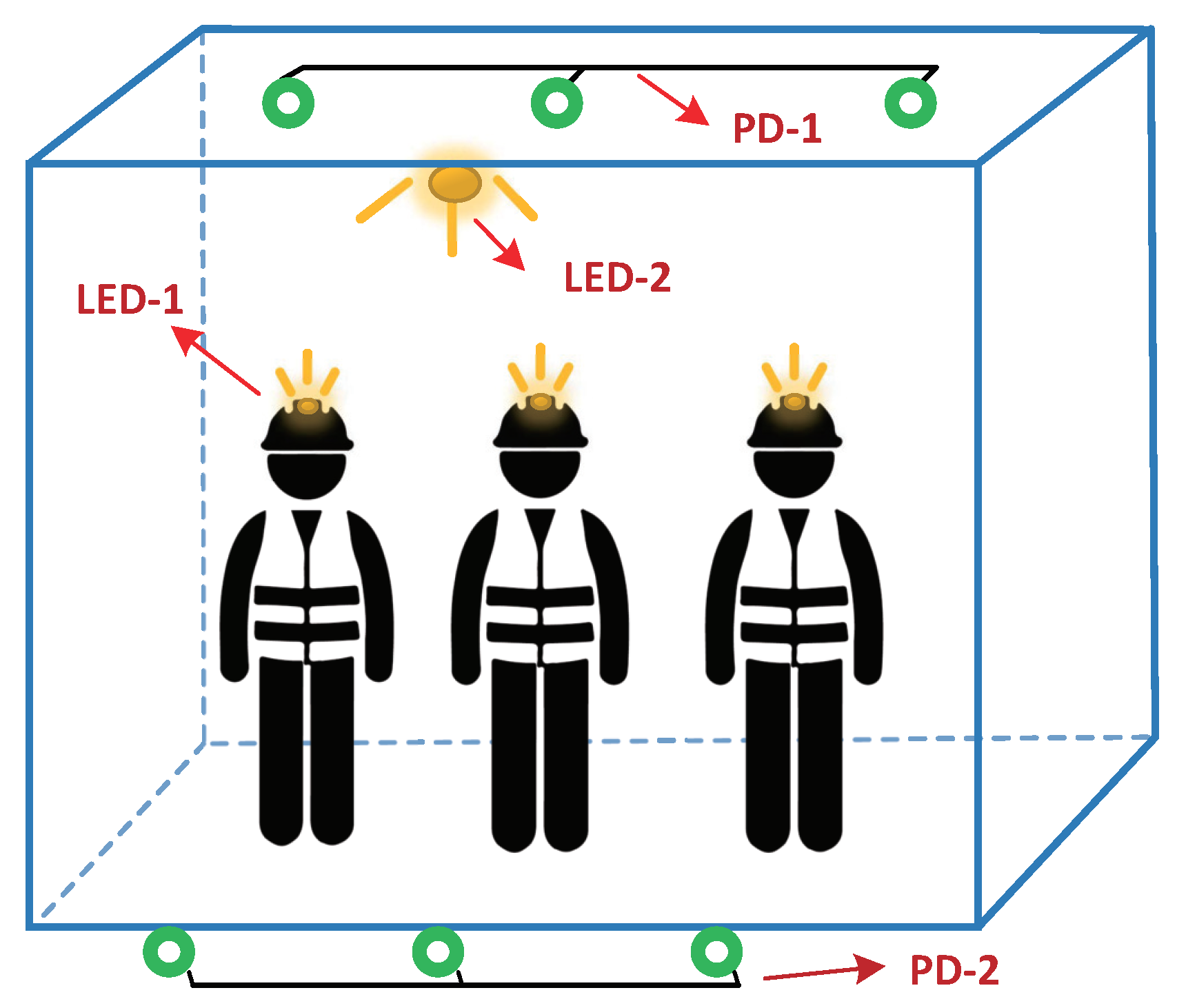

- Step 1: We use pulse width modulation (PWM) to assign unique PWM frequencies to each miner’s headlamp (i.e., LED-1 in Figure 1) as their identity (ID) tags according to the frequency allocation law (Section 3.1.1) and then store the correspondence between miner i and frequency in the preset database.

- Step 2: When the miner enters the mine cage with his/her modulated headlamp on, the j-th PD deployed on the top of the cage (i.e., PD-1 in Figure 1) can perceive the modulated optical signals illuminating within its field of vision (FoV). Next, the data sampling module sends the sampled data of the voltage value of all the PDs to the server for processing.

- Step 3: After receiving the sampled data, the server separates all visible light frequencies of the mixed optical signals perceived by , and the correct light frequencies can be matched by comparing with the preset dataset. Finally, we can accurately calculate the number of people in the mine cage combining all the PDs.

- Step 1: First, we modulate the miner’s lamp deployed on the top of the cage door (i.e., LED-2 in Figure 1) to broadcast the light beacon with unique PWM frequency, and we represent its flashing frequency as .

- Step 2: Then we first collect fingerprints (i.e., the frequency power of perceived by the k-th PD when no limbs extend out of the mine cage) on a series of PDs deployed at the bottom of the cage door (i.e., PD-2 in Figure 1), and store these data into the preset dataset. Meanwhile we represent it as .

- Step 3: Finally, when the mine cage is running, the server calculates the real-time change ratio of the frequency power of obtained by each PD compared with the frequency power of the preset data (i.e., ), and we regard the change ratio of the frequency power as the basis for limb extension monitoring.

3. Specific Process

3.1. Personnel Counting

3.1.1. Frequency Allocation

3.1.2. Frequency Separation and Personnel Counting

3.2. Limb Extension Monitoring

- (1)

- We first collect the frequency power of the miner’s lamp on the cage door as perceived by the k-th PD deployed at the bottom of the cage door without the obstruction of external objects and then store it in the preset dataset.

- (2)

- Assuming that when a person enters the cage, the frequency power of the k-th PD at time t is , then the change ratio of the frequency power of the k-th PD can be expressed as:Since the fluctuation of the light intensity, the inherent noise of the PD, and the incomplete waveform factors generated by the LED, the frequency power fluctuation rate is less than 20% when the light is not blocked [32]. In order to maximize the accuracy of the limb extension monitoring of our algorithm, we think that when any PD receives a frequency power change rate of is greater than 20%, it indicates that the limb has extended out of the cage.

- (3)

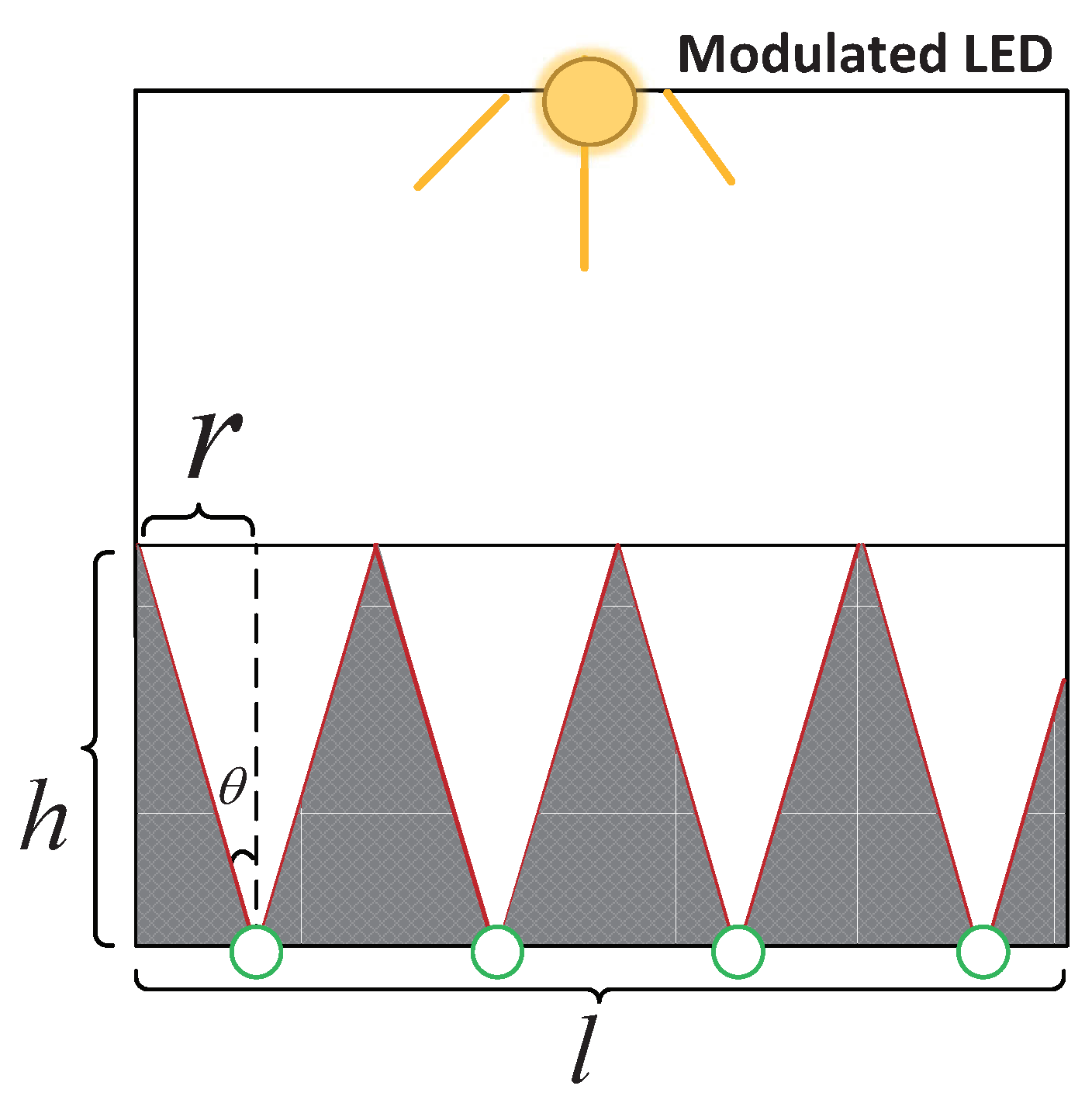

- Due to the limitation of the sensing angle (i.e., FoV) of the PD, in theory, the more PDs are deployed, the higher the accuracy of the limb extension monitoring. On the other hand, it is not practical to deploy a large number of PDs in a harsh mine cage environment. Thus we need to give the best number of deployed PDs according to the actual situation of the mine cage. The conditions for the deployment of PDs are as follows.

- Condition 1: As shown in Figure 7, in the case where the miner’s lamp can fill the bottom of the entire cage door (see Step 3), assume that the minimum height we need to monitor is h, the width is l, and the FoV of the PD is , then the number N of PD we choose is at least:

- Condition 2: The larger the FoV of the PD, the smaller the blind zone for sensing light, so the fewer PDs are needed. Half of the FoV of the PD should be greater than the angle between the connection between the PD and the LED and the plane normal to the LED to ensure the PD’s effective reception of the modulated light signal. We express the height of the mine cage as H, and the distance from the deployed PD to the mine cage as S, therefore we give the selection range:

- Condition 3: Since most of the miner’s lamps are spotlights with a certain spotlight angle, we need to ensure that the illumination range of the LED lamp deployed on the top of the cage door can fully cover the PDs deployed at the bottom of the cage door. We mark the concentration of the LED lamp as , the width of the mine cage is l, and the height of the mine cage as H. Thereby the condition that the range of the LED light irradiating the bottom of the cage door needs to be met is

3.3. Safe Area Delineation

4. Experimental Evaluation

4.1. Experimental Equipment and Environment

4.2. Personnel Counting

4.3. Limb Extension Monitoring

4.4. Safe Area Monitoring

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chandler, C.E. Mine Cage Safety Device. U.S. Patent 2,925,151, 16 February 1960. [Google Scholar]

- Zou, J.; Zhao, Q. Occupancy detection in elevator car by fusing analysis of dual videos. In Proceedings of the 2017 13th IEEE Conference on Automation Science and Engineering (CASE), Xi’an, China, 20–23 August 2017; pp. 906–911. [Google Scholar]

- Fan, H.; Zhu, H.; Yuan, D. People Counting in Elevator Car Based on Computer Vision. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 252, p. 032131. [Google Scholar]

- Tang, Y.P.; Wang, X.J.; Lu, H.F. Intelligent video analysis technology for elevator cage abnormality detection in computer vision. In Proceedings of the 2009 Fourth International Conference on Computer Sciences and Convergence Information Technology, Seoul, Korea, 24–26 November 2009; pp. 1252–1258. [Google Scholar]

- Chen, T.H.; Chen, T.Y.; Chen, Z.X. An intelligent people-flow counting method for passing through a gate. In Proceedings of the 2006 IEEE Conference on Robotics, Automation and Mechatronics, Bangkok, Thailand, 1–3 June 2006; pp. 1–6. [Google Scholar]

- Brooker, G.; Hennessey, R.; Lobsey, C.; Bishop, M.; Widzyk-Capehart, E. Seeing through dust and water vapor: Millimeter wave radar sensors for mining applications. J. Field Robot. 2007, 24, 527–557. [Google Scholar] [CrossRef]

- Bhattacherya, I.; Dunn, P.; Eger, T. Development of a new operator visibility assessment technique for mobile equipment. J. S. Afr. Inst. Min. Metall. 2006, 106, 87–92. [Google Scholar]

- Jing, C. Design of a New Type of Automatic Cage Door with Hydraulic Drive. In Proceedings of the 2018 11th International Conference on Intelligent Computation Technology and Automation (ICICTA), Changsha, China, 22–23 September 2018; IEEE Computer Society: Los Alamitos, CA, USA, 2018; pp. 342–345. [Google Scholar] [CrossRef]

- Yunjiang, M.; Shengwei, Y.; Ting, L.; Feng, W. Design of automatic cage door based on endless rope. In Proceedings of the 2011 Second International Conference on Mechanic Automation and Control Engineering, Hohhot, China, 15–17 July 2011; pp. 1180–1182. [Google Scholar]

- Zhai, L.; Wang, H.; Liu, C. Distributed schemes for crowdsourcing-based sensing task assignment in cognitive radio networks. Wirel. Commun. Mob. Comput. 2017, 2017, 5017653. [Google Scholar] [CrossRef] [Green Version]

- Zhai, L.; Wang, H. Crowdsensing task assignment based on particle swarm optimization in cognitive radio networks. Wirel. Commun. Mob. Comput. 2017, 2017, 4687974. [Google Scholar] [CrossRef] [Green Version]

- Lu, D.; Huang, X.; Zhang, W.; Fan, J. Interference-aware spectrum handover for cognitive radio networks. Wirel. Commun. Mob. Comput. 2014, 14, 1099–1112. [Google Scholar] [CrossRef]

- Hassan, N.U.; Naeem, A.; Pasha, M.A.; Jadoon, T.; Yuen, C. Indoor positioning using visible led lights: A survey. ACM Comput. Surv. (CSUR) 2015, 48, 1–32. [Google Scholar] [CrossRef]

- Saadi, M.; Wattisuttikulkij, L.; Zhao, Y.; Sangwongngam, P. Visible light communication: Opportunities, challenges and channel models. Int. J. Electron. Inform. 2013, 2, 1–11. [Google Scholar]

- Huang, C.; Zhang, X. Impact and feasibility of darklight LED on indoor visible light positioning system. In Proceedings of the 2017 IEEE 17th International Conference on Ubiquitous Wireless Broadband (ICUWB), Salamanca, Spain, 12–15 September 2017; pp. 1–5. [Google Scholar]

- Li, Z.; Yang, A.; Lv, H.; Feng, L.; Song, W. Fusion of visible light indoor positioning and inertial navigation based on particle filter. IEEE Photonics J. 2017, 9, 1–13. [Google Scholar] [CrossRef]

- Chow, C.W.; Yeh, C.; Liu, Y.; Huang, P.; Liu, Y. Adaptive scheme for maintaining the performance of the in-home white-LED visible light wireless communications using OFDM. Opt. Commun. 2013, 292, 49–52. [Google Scholar] [CrossRef]

- Ong, Z.; Rachim, V.P.; Chung, W.Y. Novel electromagnetic-interference-free indoor environment monitoring system by mobile camera-image-sensor-based VLC. IEEE Photonics J. 2017, 9, 1–11. [Google Scholar] [CrossRef]

- Wang, Y.; Tao, L.; Huang, X.; Shi, J.; Chi, N. Enhanced performance of a high-speed WDM CAP64 VLC system employing Volterra series-based nonlinear equalizer. IEEE Photonics J. 2015, 7, 1–7. [Google Scholar] [CrossRef]

- Singh, S.; Kakamanshadi, G.; Gupta, S. Visible Light Communication-an emerging wireless communication technology. In Proceedings of the 2015 2nd International Conference on Recent Advances in Engineering & Computational Sciences (RAECS), Chandigarh, India, 21–22 December 2015; pp. 1–3. [Google Scholar]

- Wang, J.; Al-Kinani, A.; Zhang, W.; Wang, C.X.; Zhou, L. A general channel model for visible light communications in underground mines. China Commun. 2018, 15, 95–105. [Google Scholar] [CrossRef]

- Sammarco, J.J.; Pollard, J.P.; Porter, W.L.; Dempsey, P.G.; Moore, C.T. The effect of cap lamp lighting on postural control and stability. Int. J. Ind. Ergon. 2012, 42, 377–383. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yenchek, M.R.; Sammarco, J.J. The potential impact of light emitting diode lighting on reducing mining injuries during operation and maintenance of lighting systems. Saf. Sci. 2010, 48, 1380–1386. [Google Scholar] [CrossRef]

- Wu, H.; Zhang, H.; Cui, L.; Wang, X. CEPTM: A cross-edge model for diverse personalization service and topic migration in MEC. Wirel. Commun. Mob. Comput. 2018, 2018, 8056195. [Google Scholar] [CrossRef] [Green Version]

- Krommenacker, N.; Vásquez, Ó.C.; Alfaro, M.D.; Soto, I. A self-adaptive cell-ID positioning system based on visible light communications in underground mines. In Proceedings of the 2016 IEEE International Conference on Automatica (ICA-ACCA), Curico, Chile, 19–21 October 2016; pp. 1–7. [Google Scholar]

- Iturralde, D.; Seguel, F.; Soto, I.; Azurdia, C.; Khan, S. A new VLC system for localization in underground mining tunnels. IEEE Lat. Am. Trans. 2017, 15, 581–587. [Google Scholar] [CrossRef]

- Dehghan Firoozabadi, A.; Azurdia-Meza, C.; Soto, I.; Seguel, F.; Krommenacker, N.; Iturralde, D.; Charpentier, P.; Zabala-Blanco, D. A novel frequency domain visible light communication (VLC) three-dimensional trilateration system for localization in underground mining. Appl. Sci. 2019, 9, 1488. [Google Scholar] [CrossRef] [Green Version]

- Sugiyama, H.; Haruyama, S.; Nakagawa, M. Brightness control methods for illumination and visible-light communication systems. In Proceedings of the 2007 Third International Conference on Wireless and Mobile Communications (ICWMC’07), Guadeloupe, France, 4–9 March 2007; p. 78-78. [Google Scholar]

- Marosek, M.W. LED Dimming Control Technique for Increasing the Maximum PWM Dimming Ratio and Avoiding LED Flicker. U.S. Patent 7,321,203, 22 January 2008. [Google Scholar]

- Siddique, A.B.; Tahir, M. Joint brightness control and data transmission for visible light communication systems based on white LEDs. In Proceedings of the 2011 IEEE Consumer Communications and Networking Conference (CCNC), Las Vegas, NV, USA, 9–12 January 2011; pp. 1026–1030. [Google Scholar]

- Wang, Z.; Zhong, W.D.; Yu, C.; Chen, J.; Francois, C.P.S.; Chen, W. Performance of dimming control scheme in visible light communication system. Opt. Express 2012, 20, 18861–18868. [Google Scholar] [CrossRef]

- Li, T.; An, C.; Tian, Z.; Campbell, A.T.; Zhou, X. Human sensing using visible light communication. In Proceedings of the 21st Annual International Conference on Mobile Computing and Networking, Paris, France, 7–11 September 2015; pp. 331–344. [Google Scholar]

- Spiazzi, G.; Buso, S.; Meneghesso, G. Analysis of a high-power-factor electronic ballast for high brightness light emitting diodes. In Proceedings of the 2005 IEEE 36th Power Electronics Specialists Conference, Recife, Brazil, 16 June 2005; pp. 1494–1499. [Google Scholar]

- Kim, K.; Lee, K.; Lee, K. Zero reduction codes for efficient transmission and enhanced brightness in visible light communication. IET Optoelectron. 2016, 11, 108–113. [Google Scholar] [CrossRef]

- Rátosi, M.; Simon, G. Robust VLC Beacon Identification for Indoor Camera-Based Localization Systems. Sensors 2020, 20, 2522. [Google Scholar] [CrossRef] [PubMed]

- Tan, J.; Narendran, N. A driving scheme to reduce AC LED flicker. In LED-Based Illumination Systems; International Society for Optics and Photonics: Bellingham, WA, USA, 2013; Volume 8835, p. 88350O. [Google Scholar]

- Darshith, T.; Bhatt, C. Prototyping of a Li-Fi communication system. In Proceedings of the 2017 International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), Chennai, India, 22–24 March 2017; pp. 1804–1807. [Google Scholar]

- Jerri, A.J. The Shannon sampling theorem—Its various extensions and applications: A tutorial review. Proc. IEEE 1977, 65, 1565–1596. [Google Scholar] [CrossRef]

- Kuo, Y.S.; Pannuto, P.; Hsiao, K.J.; Dutta, P. Luxapose: Indoor positioning with mobile phones and visible light. In Proceedings of the 20th Annual International Conference on Mobile Computing and Networking, Maui, HI, USA, 7–11 September 2014; pp. 447–458. [Google Scholar]

- Li, T.; Xiong, X.; Xie, Y.; Hito, G.; Yang, X.D.; Zhou, X. Reconstructing hand poses using visible light. Proc. ACM Interact. Mob. Wearable Ubiquitous Technol. 2017, 1, 1–20. [Google Scholar] [CrossRef]

- Hsieh, Y.T.; Lin, J.S. Led Lamp Having Ball-Shaped Light Diffusing Modifier. U.S. Patent 6,305,821, 23 October 2001. [Google Scholar]

- Xie, B.; Tan, G.; He, T. Spinlight: A high accuracy and robust light positioning system for indoor applications. In Proceedings of the 13th ACM Conference on Embedded Networked Sensor Systems, Seoul, Korea, 1–4 November 2015; pp. 211–223. [Google Scholar]

| Miner | ||||||

|---|---|---|---|---|---|---|

| Frequency (Hz) | 1770 | 2300 | 2710 | 3125 | 3600 | 4260 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Pang, M.; Li, P.; Chen, P.; Niu, Q. A Novel Mine Cage Safety Monitoring Algorithm Utilizing Visible Light. Sensors 2020, 20, 3920. https://doi.org/10.3390/s20143920

Yang X, Pang M, Li P, Chen P, Niu Q. A Novel Mine Cage Safety Monitoring Algorithm Utilizing Visible Light. Sensors. 2020; 20(14):3920. https://doi.org/10.3390/s20143920

Chicago/Turabian StyleYang, Xu, Mingzhi Pang, Peihao Li, Pengpeng Chen, and Qiang Niu. 2020. "A Novel Mine Cage Safety Monitoring Algorithm Utilizing Visible Light" Sensors 20, no. 14: 3920. https://doi.org/10.3390/s20143920