A Novel Infrared Thermography Sensing Approach for Rapid, Quantitative Assessment of Damage in Aircraft Composites

Abstract

:1. Introduction

2. Experimental Study

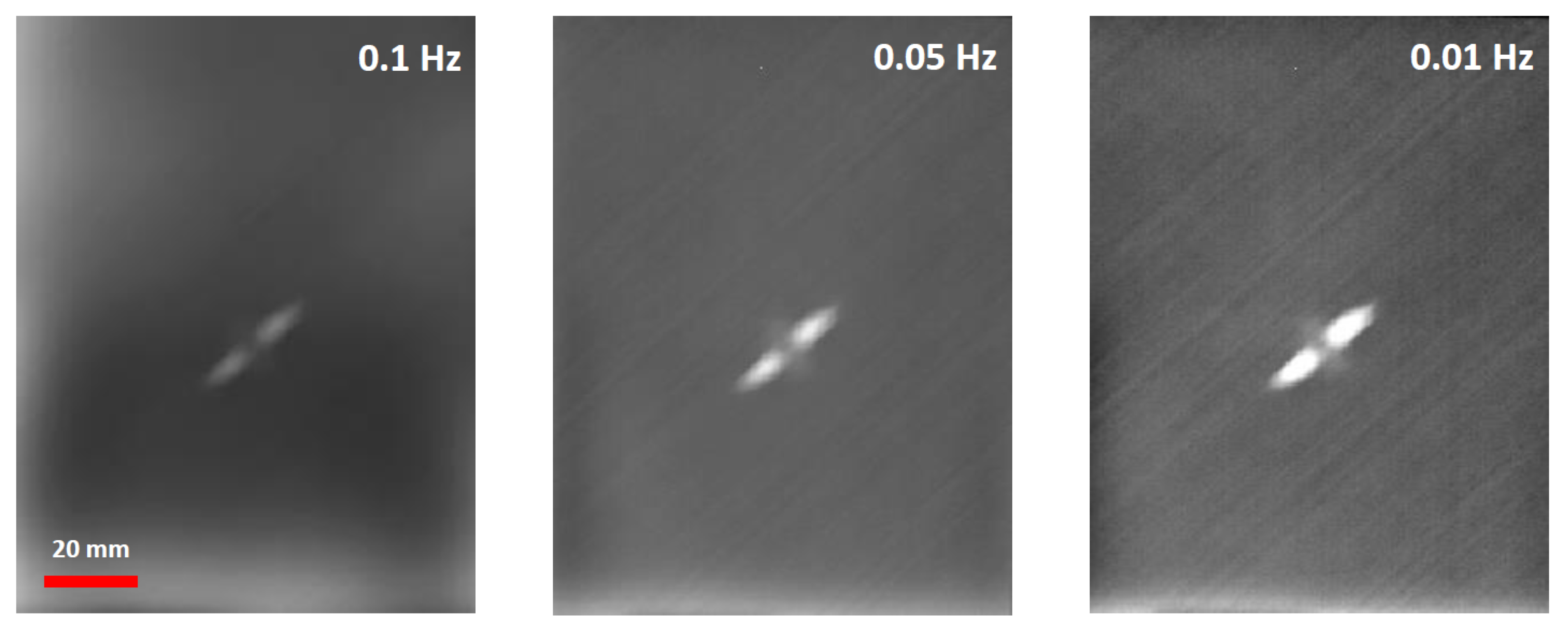

2.1. Pulsed Phase-Informed Lock-in Thermography

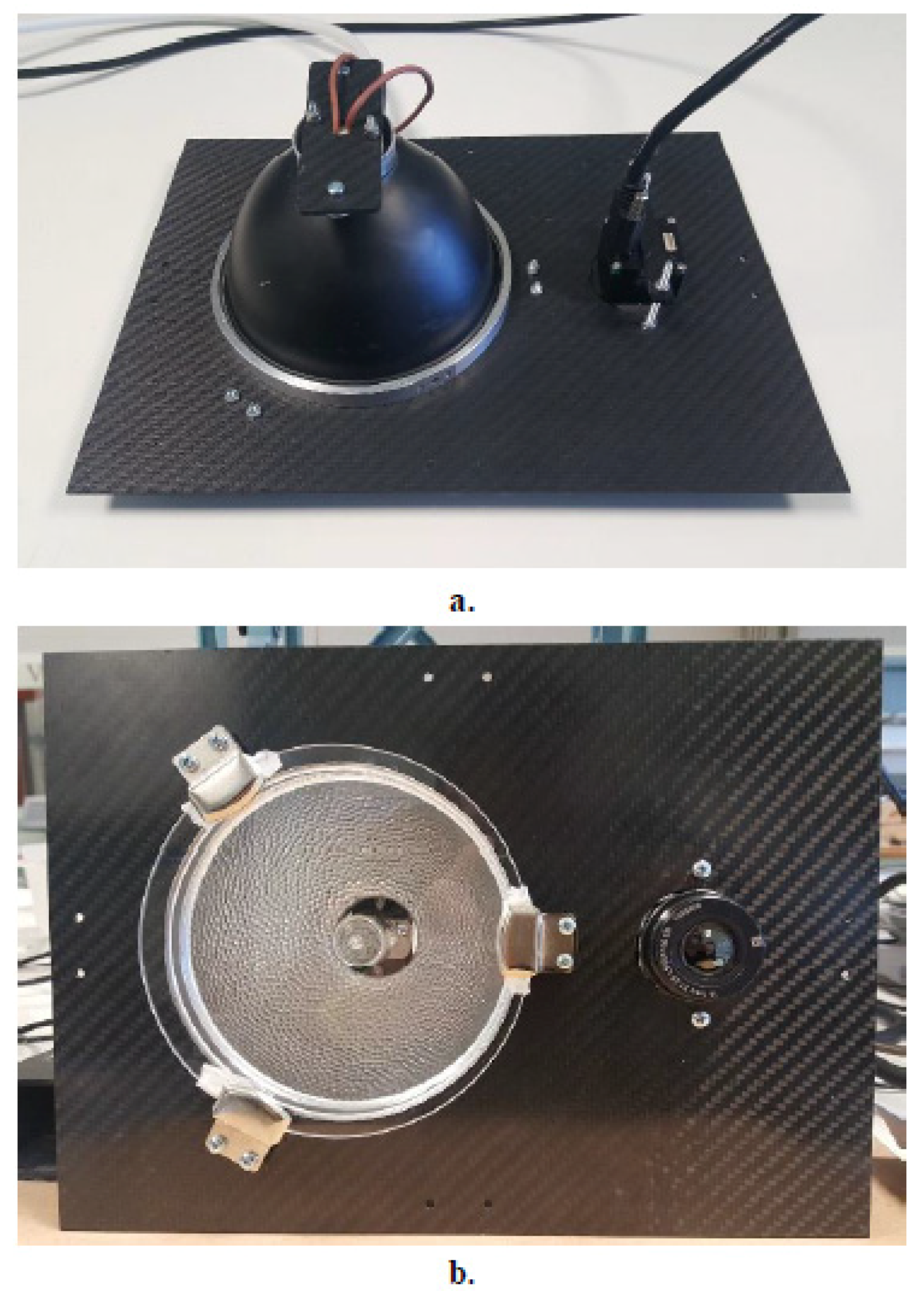

2.2. IR Sensor and Heating Source

2.3. Control and Analysis Interface

2.4. Materials and Specimens

3. Results and Discussion

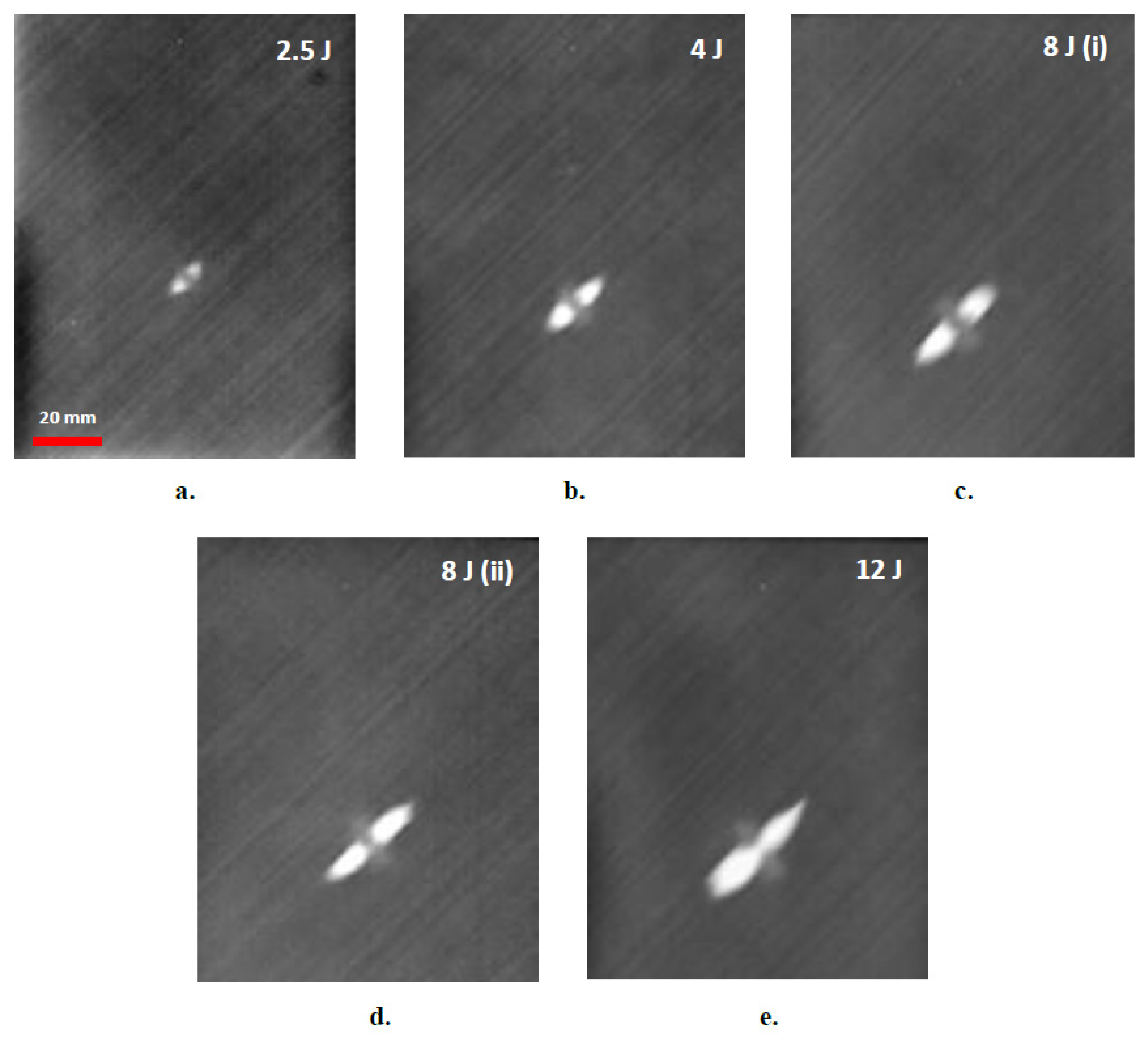

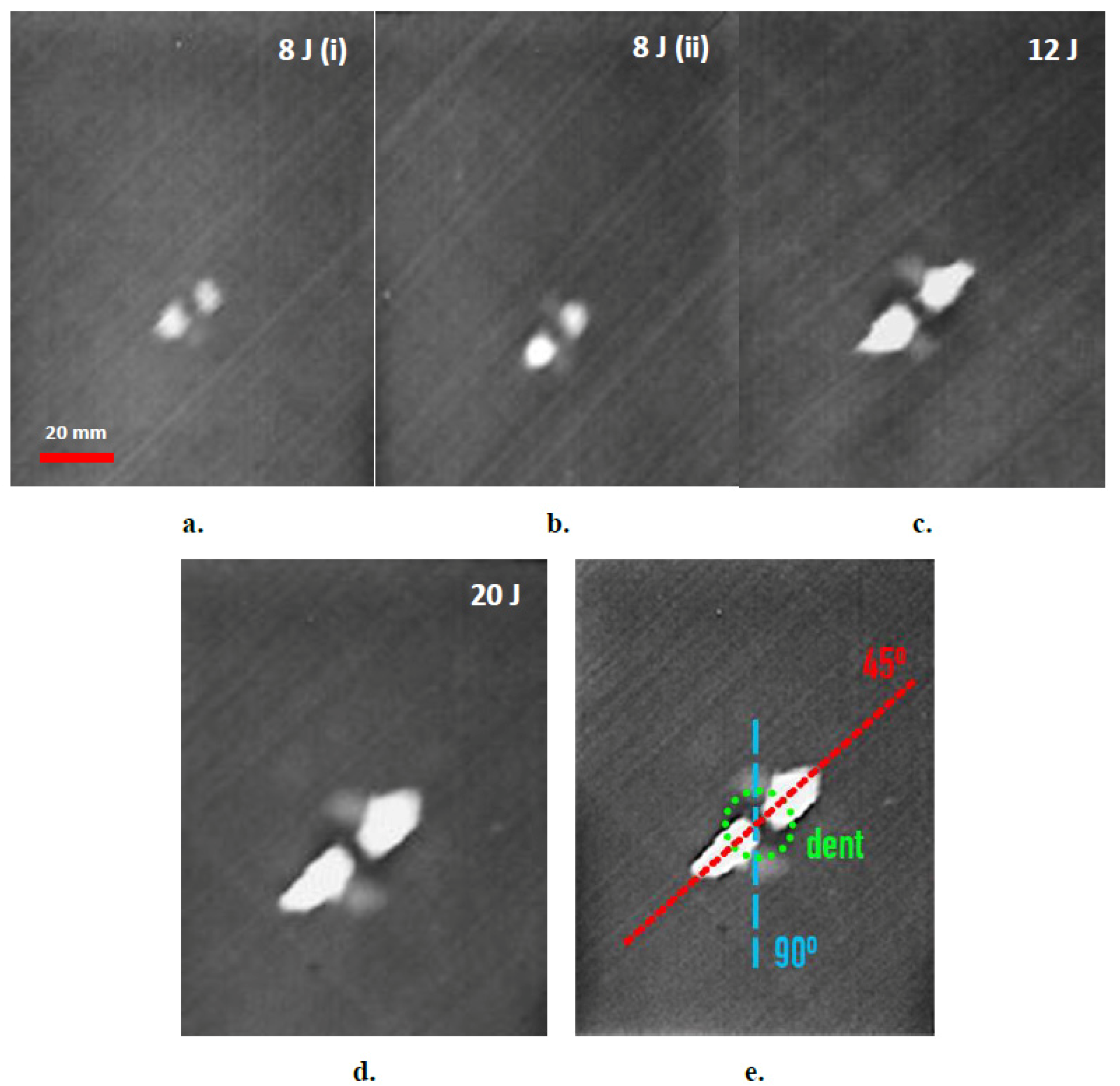

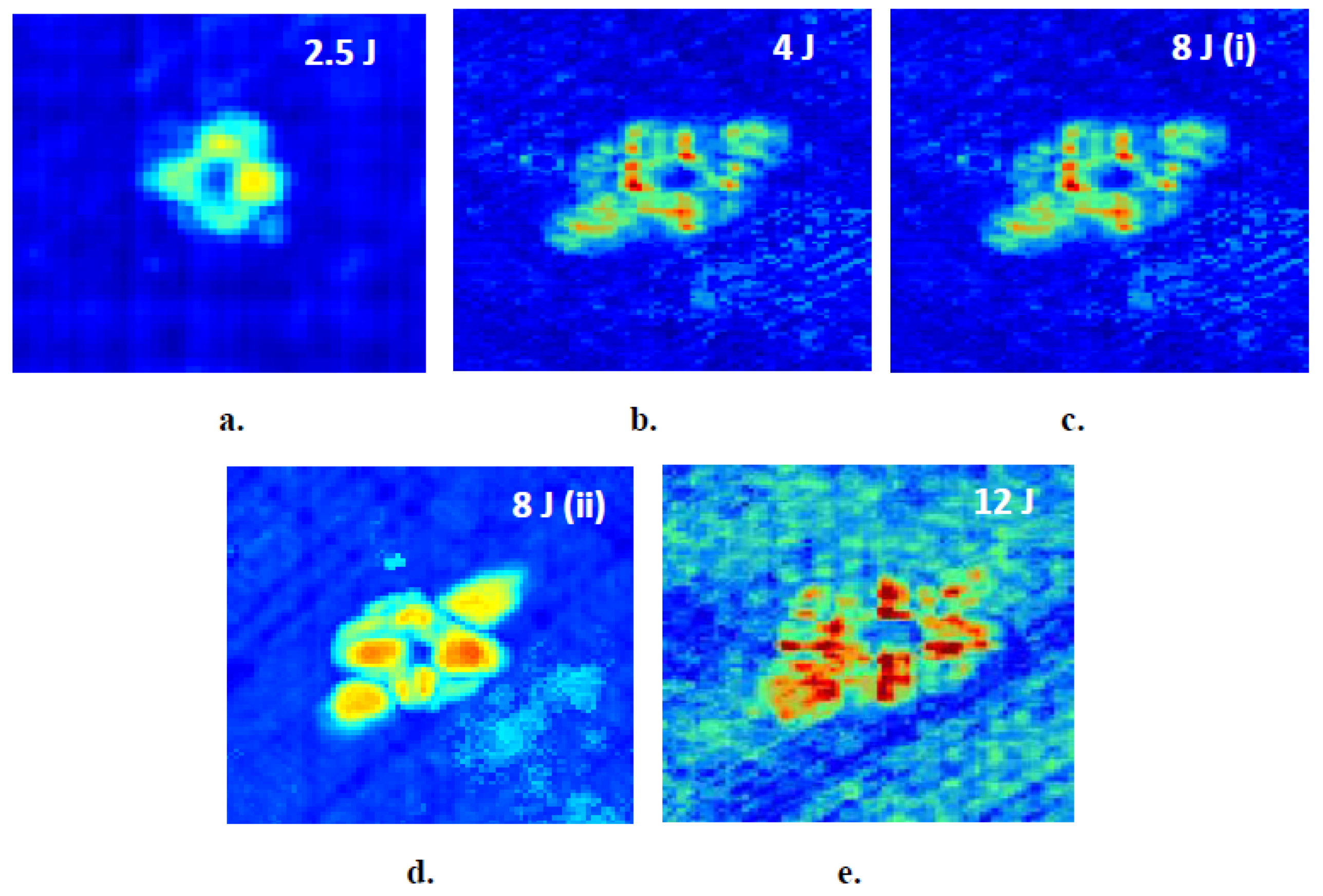

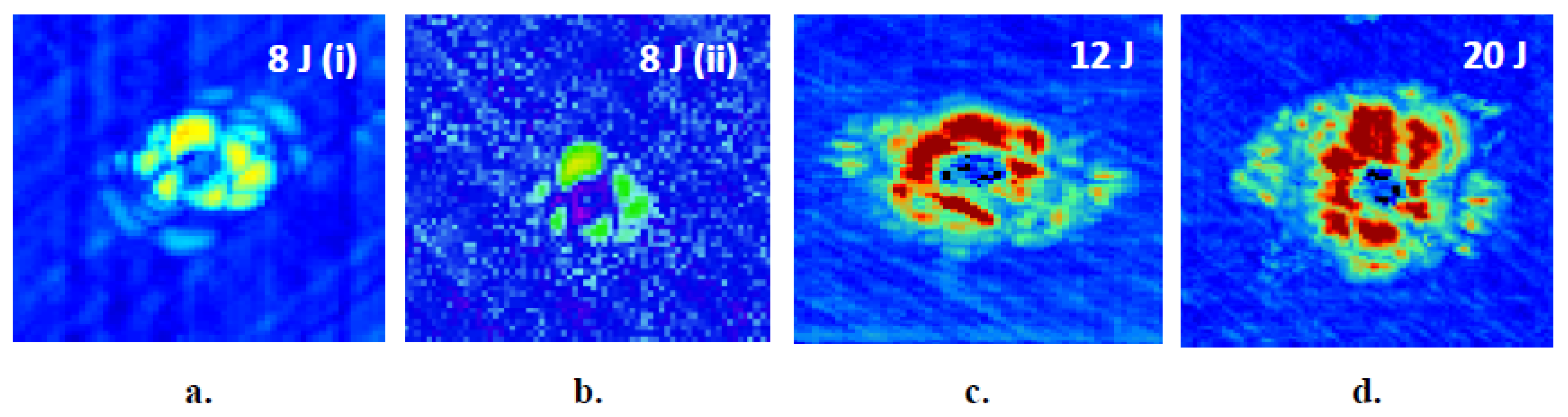

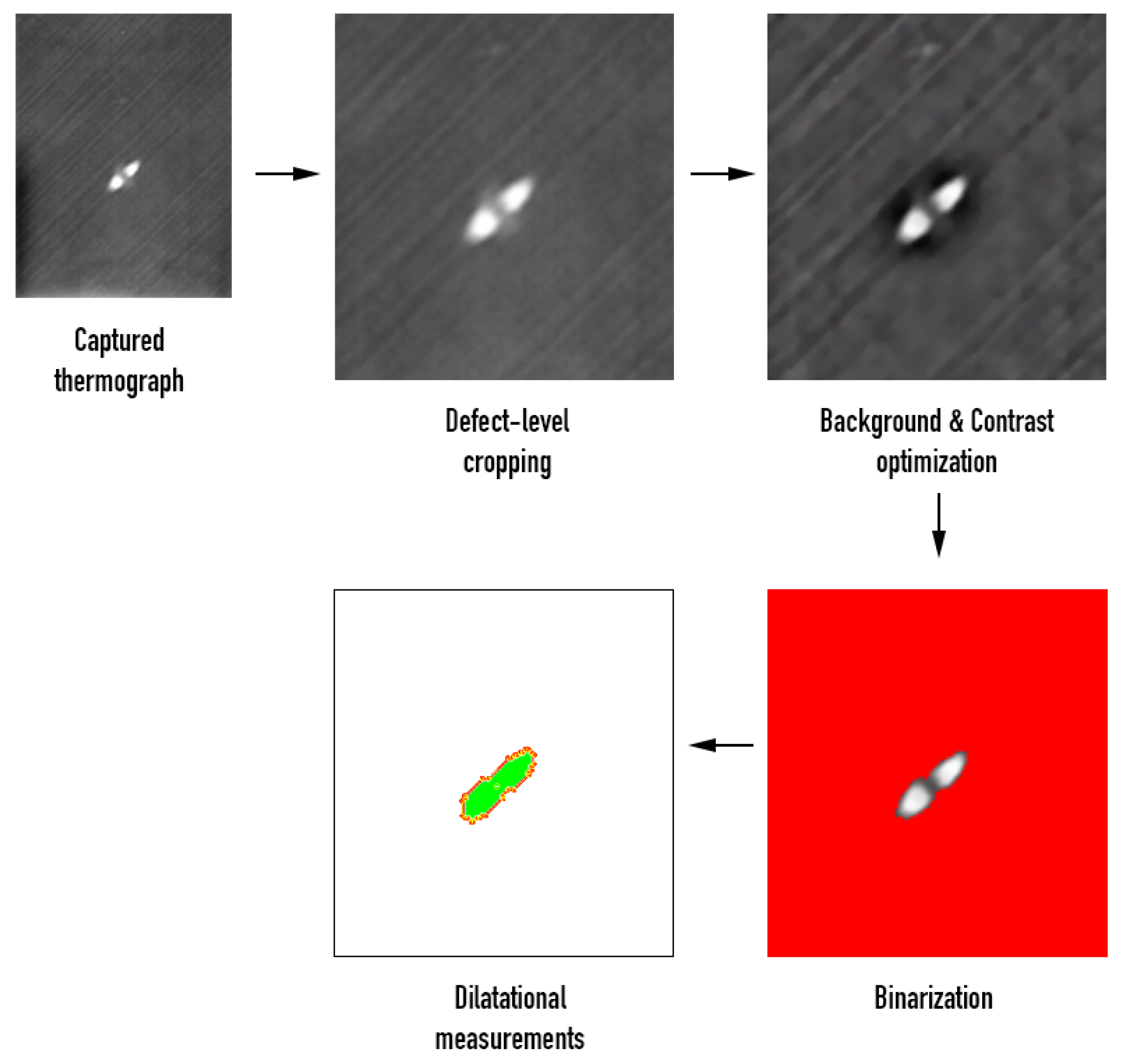

3.1. Aircraft-Grade Specimens

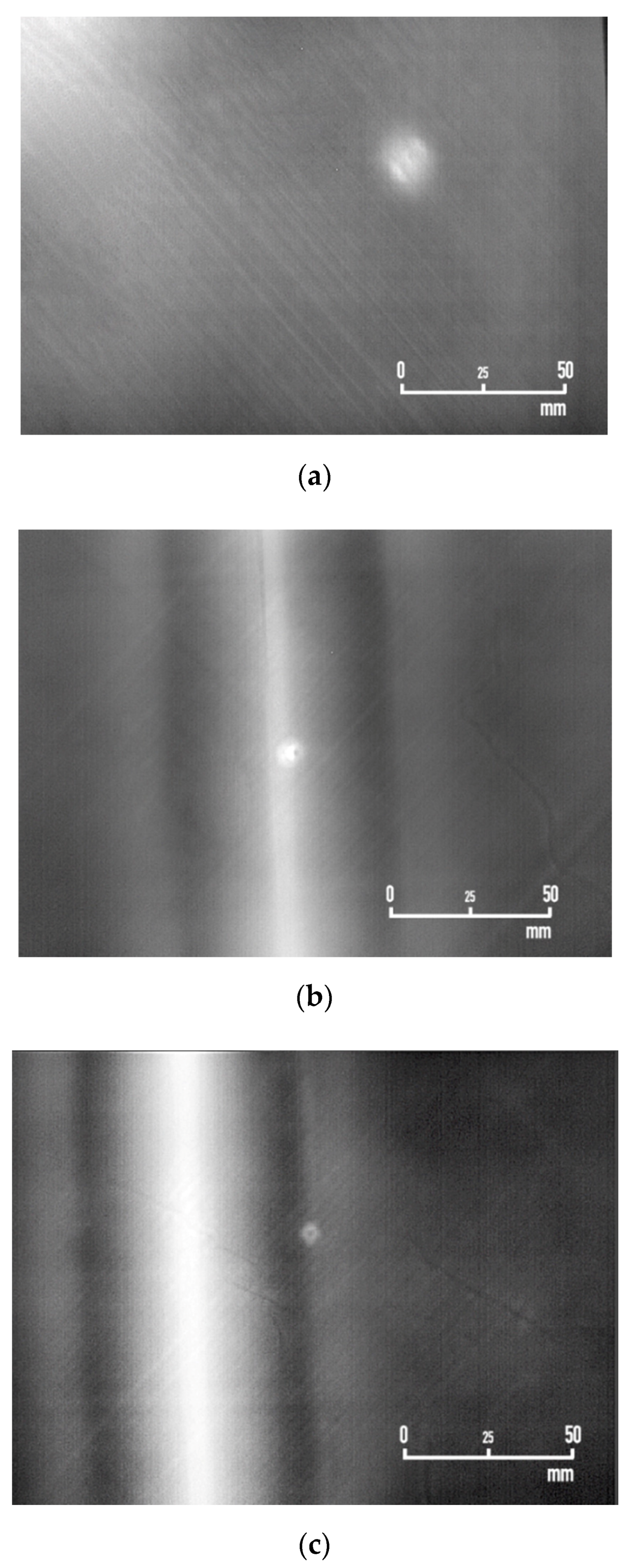

3.2. Full-Scale Fuselage Skin Panel

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- D’Orazio, T.; Guaragnella, C.; Leo, M.; Spagnolo, P. Defect detection in aircraft composites by using a neural approach in the analysis of thermographic images. NDT E Int. 2005, 38, 665–673. [Google Scholar] [CrossRef]

- Avdelidis, N.; Hawtin, B.; Almond, D. Transient thermography in the assessment of defects of aircraft composites. NDT E Int. 2003, 36, 433–439. [Google Scholar] [CrossRef]

- Kordatos, E.; Dassios, K.; Aggelis, D.; Matikas, T.E. Rapid evaluation of the fatigue limit in composites using infrared lock-in thermography and acoustic emission. Mech. Res. Commun. 2013, 54, 14–20. [Google Scholar] [CrossRef]

- Ackert, S.P. Basics of Aircraft Maintenance Programs for Financiers: Evaluation & Insights of Commercial Aircraft Maintenance Programs. Available online: http://www.aircraftmonitor.com/uploads/1/5/9/9/15993320/basics_of_aircraft_maintenance_programs_for_financiers___v1.pdf (accessed on 15 May 2020).

- Eurocontrol. Standard Inputs for Eurocontrol Cost Benefit Analyses 2018. Available online: https://www.eurocontrol.int/sites/default/files/publication/files/standard-input-for-eurocontrol-cost-benefit-analyses-2018-edition-8-version-2.6.pdf (accessed on 15 May 2020).

- Palmer, D. Maintenance Planning and Scheduling Handbook; McGraw-Hill Professional: New York, NY, USA, 1999. [Google Scholar]

- Rantala, J.; Wu, D.; Busse, G. Amplitude-Modulated lock-in vibrothermography for NDE of polymers and composites. Res. Nondestruct. Eval. 1996, 7, 215–228. [Google Scholar] [CrossRef]

- Kelley, L.P. Understanding Maintenance Caused Accidents. In Proceedings of the International Society of Air Safety Investigators, San Diego, CA, USA, 22–24 August 2017. [Google Scholar]

- Hobbs, A. An Overview of Human Factors in Aviation Maintenance; Australian Transport Safety Bureau: Canberra, Australia, 2008. [Google Scholar]

- Dillenz, A.; Busse, G.; Wu, D. Ultrasound lock-in thermography: Feasibilities and limitations. Ind. Lasers Insp. EUROPTO Ser. 1999, 3827, 10–15. [Google Scholar] [CrossRef]

- Kordatos, E.; Aggelis, D.; Matikas, T.E. Monitoring mechanical damage in structural materials using complimentary NDE techniques based on thermography and acoustic emission. Compos. Part B Eng. 2012, 43, 2676–2686. [Google Scholar] [CrossRef]

- Deane, S.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Zhang, H.; Yazdani-Nezhad, H.; Williamson, A.A.; Mackley, T.; Davis, M.J.; Maldague, X.; Tsourdos, A. Application of NDT thermographic imaging of aerospace structures. Infrared Phys. Technol. 2019, 97, 456–466. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Avdelidis, N.P.; Osman, A.; Castanedo, C.I.; Sfarra, S.; Fernandes, H.C.; Matikas, T.E.; Maldague, X.P. Enhanced Infrared Image Processing for Impacted Carbon/Glass Fiber-Reinforced Composite Evaluation. Sensors 2017, 18, 45. [Google Scholar] [CrossRef] [Green Version]

- Wróbel, G.; Rdzawski, Z. Determination of thermal diffusivity of carbon/epoxy composites with different fiber content using transient thermography. J. Achiev. Mater. Manuf. Eng. 2009, 37, 518–525. [Google Scholar]

- Maldague, X.P.V. Introduction to NDT by active infrared thermography. Mater. Eval. 2002, 60, 1060–1073. [Google Scholar]

- Kordatos, E.; Exarchos, D.; Stavrakos, C.; Moropoulou, A.; Matikas, T.E. Infrared thermographic inspection of murals and characterization of degradation in historic monuments. Constr. Build. Mater. 2013, 48, 1261–1265. [Google Scholar] [CrossRef]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent Advances in Active Infrared Thermography for Non-Destructive Testing of Aerospace Components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef] [Green Version]

- Hellard, G. Composites in Airbus—A Long Story of Innovations and Experiences. In Proceedings of the Global Investment Forum, Geneva, Switzerland, 2–3 June 2016; pp. 1–26. [Google Scholar]

- Mrazova, M. Advanced composite materials of the future in aerospace industry. INCAS Bull. 2013, 5, 139–150. [Google Scholar] [CrossRef]

- Shi, Z.; Xu, X.; Ma, J.; Zhen, D.; Zhang, H. Quantitative Detection of Cracks in Steel Using Eddy Current Pulsed Thermography. Sensors 2018, 18, 1070. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahmed, J.; Gao, B.; Tian, G.; Yang, Y.; Fan, Y.C. Sparse ensemble matrix factorization for debond detection in CFRP composites using optical thermography. Infrared Phys. Technol. 2018, 92, 392–401. [Google Scholar] [CrossRef]

- Palumbo, D.; Cavallo, P.; Galietti, U. An investigation of the stepped thermography technique for defects evaluation in GFRP materials. NDT E Int. 2019, 102, 254–263. [Google Scholar] [CrossRef]

- Yi, Q.; Tian, G.; Malekmohammadi, H.; Zhu, J.; Laureti, S.; Ricci, M. New features for delamination depth evaluation in carbon fiber reinforced plastic materials using eddy current pulse-compression thermography. NDT E Int. 2019, 102, 264–273. [Google Scholar] [CrossRef]

- Wang, Q.; Hu, Q.; Qiu, J.; Pei, C.; Li, X.; Zhou, H. Using differential spread laser infrared thermography to detect delamination and impact damage in CFRP. Infrared Phys. Technol. 2020, 106, 103282. [Google Scholar] [CrossRef]

- Swiderski, W. Non-Destructive testing of CFRP by laser excited thermography. Compos. Struct. 2019, 209, 710–714. [Google Scholar] [CrossRef]

- Liang, T.; Ren, W.; Tian, G.; Elradi, M.; Gao, Y. Low energy impact damage detection in CFRP using eddy current pulsed thermography. Compos. Struct. 2016, 143, 352–361. [Google Scholar] [CrossRef] [Green Version]

- Kersemans, M.; Verboven, E.; Segers, J.; Hedayatrasa, S.; Van Paepegem, W. Non-Destructive Testing of Composites by Ultrasound, Local Defect Resonance and Thermography. MDPI Proc. 2018, 2, 5464. [Google Scholar] [CrossRef] [Green Version]

- Wu, J.; Xu, C.; Qi, B.; Hernandez, F.R. Detection of Impact Damage on PVA-ECC Beam Using Infrared Thermography. Appl. Sci. 2018, 8, 839. [Google Scholar] [CrossRef] [Green Version]

- Poelman, G.; Hedayatrasa, S.; Segers, J.; Tellez, J.A.C.; Van Paepegem, W.; Kersemans, M. Optical Infrared Thermography of CFRP with Artificial Defects: Performance of Various Post-Processing Techniques. MDPI Proc. 2018, 2, 5358. [Google Scholar] [CrossRef] [Green Version]

- Dorafshan, S.; Maguire, M.; Collins, W. Infrared Thermography for Weld Inspection: Feasibility and Application. Infrastructures 2018, 3, 45. [Google Scholar] [CrossRef] [Green Version]

- Duan, Y.; Zhang, H.; Maldague, X.P.; Ibarra-Castanedo, C.; Servais, P.; Genest, M.; Sfarra, S.; Meng, J. Reliability assessment of pulsed thermography and ultrasonic testing for impact damage of CFRP panels. NDT E Int. 2019, 102, 77–83. [Google Scholar] [CrossRef]

- Maldague, X. Theory and Practice of Infrared Technology for Nondestructive Testing; Wiley-Interscience: Hoboken, NJ, USA, 2001. [Google Scholar]

- Ibarra-Castanedo, C.; Piau, J.-M.; Guilbert, S.; Avdelidis, N.P.; Genest, M.; Bendada, A.; Maldague, X.P.V. Comparative Study of Active Thermography Techniques for the Nondestructive Evaluation of Honeycomb Structures. Res. Nondestruct. Eval. 2009, 20, 1–31. [Google Scholar] [CrossRef]

- Zalameda, J.; Winfree, W. Detection and Characterization of Damage in Quasi-Static Loaded Composite Structures Using Passive Thermography. Sensors 2018, 18, 3562. [Google Scholar] [CrossRef] [Green Version]

- Kordatos, E.; Exarchos, D.A.; Dassios, K.; Matikas, T.E. Thermo-Electrical lockin thermography for characterization of subsurface defects. SPIE Smart Struct. Mater. Nondestruct. Eval. Health Monit. 2014, 9062, 90620G. [Google Scholar] [CrossRef]

- Myriounis, D.P.; Kordatos, E.; Hasan, S.; Matikas, T.E. Crack-Tip Stress Field and Fatigue Crack Growth Monitoring Using Infrared Lock-In Thermography in A359/SiCp Composites. Strain 2010, 47, e619–e627. [Google Scholar] [CrossRef]

- Mountain, D.S.; Webber, J.M. Stress Pattern Analysis by Thermal Emission. In Proceedings of the Fourth European Electro-Optics Conference, Utrecht, The Netherlands, 10–13 October 1978; pp. 189–196. [Google Scholar]

- Chrysochoos, A.; Dupre, J. An infrared set-up for continuum thermomechanics. Quant. Infrared Thermogr. 1992, 92, 129–134. [Google Scholar] [CrossRef]

- Deane, S.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Zhang, H.; Nezhad, H.Y.; Williamson, A.A.; Mackley, T.; Maldague, X.; Tsourdos, A.; Nooralishahi, P. Comparison of Cooled and Uncooled IR Sensors by Means of Signal-To-Noise Ratio for NDT Diagnostics of Aerospace Grade Composites. Sensors 2020, 20, 3381. [Google Scholar] [CrossRef] [PubMed]

- Maldague, X.; Marinetti, S. Pulse phase infrared thermography. J. Appl. Phys. 1996, 79, 2694–2698. [Google Scholar] [CrossRef]

- Maldague, X.; Galmiche, F.; Ziadi, A. Advances in pulsed phase thermography. Infrared Phys. Technol. 2002, 43, 175–181. [Google Scholar] [CrossRef] [Green Version]

- Guo, X.; Vavilov, V.P. Crack detection in aluminum parts by using ultrasound-excited infrared thermography. Infrared Phys. Technol. 2013, 61, 149–156. [Google Scholar] [CrossRef]

- Dillenz, A.; Zweschper, T.; Busse, G. Progress in ultrasound phase thermography. Aerosp. Def. Sens. Simul. Control. 2001, 4360, 574–580. [Google Scholar] [CrossRef]

- Riegert, G.; Zweschper, T.; Busse, G. Lockin thermography with eddy current excitation. Quant. Infrared Thermogr. J. 2004, 1, 21–32. [Google Scholar] [CrossRef]

- Riegert, G.; Gleiter, A.; Busse, G. Potential and limitations of eddy current lockin-thermography. Def. Secur. Symp. 2006, 6205, 62051. [Google Scholar] [CrossRef]

- Park, H.; Choi, M.; Park, J.; Kim, W. A study on detection of micro-cracks in the dissimilar metal weld through ultrasound infrared thermography. Infrared Phys. Technol. 2014, 62, 124–131. [Google Scholar] [CrossRef]

- Tang, Q.; Junyan, L.; Yang, W.; Hui, L. Subsurface Interfacial Defects of Metal Materials Testing Using Ultrasound Infrared Lock-in Thermography. Procedia Eng. 2011, 16, 499–505. [Google Scholar] [CrossRef] [Green Version]

- Exarchos, D.A.; Dassios, K.; Matikas, T.E. Novel infrared thermography approach for rapid assessment of damage in aerospace structures. Smart Mater. Nondestruct. Eval. Energy Syst. IV 2018, 10601, 106010P. [Google Scholar] [CrossRef]

- Weekes, B.; Almond, D.P.; Cawley, P.; Barden, T. Eddy-Current induced thermography—Probability of detection study of small fatigue cracks in steel, titanium and nickel-based superalloy. NDT E Int. 2012, 49, 47–56. [Google Scholar] [CrossRef]

- Airbus, S.A.S. Airbus Test Method: Determination of Compression Strength after Impact; AITM1-0010; Instron: Norwood, MA, USA, 2005. [Google Scholar]

- Meola, C.; Boccardi, S.; Carlomagno, G.; Boffa, N.; Monaco, E.; Ricci, F. Nondestructive evaluation of carbon fibre reinforced composites with infrared thermography and ultrasonics. Compos. Struct. 2015, 134, 845–853. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.M. A quantitative approach to retrieve delamination extension from thermal images recorded during impact tests. NDT E Int. 2018, 100, 142–152. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.M. Infrared Thermography in the Evaluation of Aerospace Composite Materials: Infrared Thermography to Composites, 1st ed.; Woodhead Publishing: Sawston, UK, 2016. [Google Scholar]

| Feature | Description |

|---|---|

| Resolution | 640 × 480 pixels |

| Material | Resistive amorphous silicon |

| Sensor type | Microbolometer |

| Cooling | Uncooled |

| Pixel pitch | 17 µm |

| Spectral response (LWIR) | 7–14 µm |

| NETD * (f/1; 300 K; 30 Hz) | <50 mK |

| Power consumption | <850 mW |

| Shutter | Shutterless |

| Control | Free run and External sync |

| Time to image | <1 s |

| Frame rate | Adjustable: 9–120 Hz |

| Connection | USB 3.0 |

| Operating temperature range | −20–60 °C |

| Total weight of IR assembly (with lens) | 70 g |

| Impact Energy (J) | Drop Height (mm) | Number of Coupons | Number of Layers | Cured Thickness (mm) |

|---|---|---|---|---|

| 2.5 | 200 | 1 | 9 | 1.65 |

| 4 | 335 | 1 | 9 | 1.65 |

| 8 | 670 | 2 | 9 | 1.65 |

| 8 | 670 | 2 | 18 | 3.80 |

| 12 | 1000 | 1 | 9 | 1.65 |

| 12 | 1000 | 1 | 18 | 3.80 |

| 20 | 918 | 1 | 18 | 3.80 |

| 9-Layer Laminates | 18-Layer Laminates | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Impact Energy, (J) | 2.5 | 4 | 8 | 8 | 12 | 8 | 8 | 12 | 20 |

| Damage Area, (mm2) | 11.60 | 37.72 | 60.55 | 56.21 | 80.08 | 26.15 | 39.89 | 67.97 | 123.09 |

| Damage Perimeter, (mm) | 14.42 | 29.05 | 38.88 | 40.28 | 48.31 | 28.54 | 37.08 | 56.58 | 72.53 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farmaki, S.; Exarchos, D.A.; Tragazikis, I.K.; Matikas, T.E.; Dassios, K.G. A Novel Infrared Thermography Sensing Approach for Rapid, Quantitative Assessment of Damage in Aircraft Composites. Sensors 2020, 20, 4113. https://doi.org/10.3390/s20154113

Farmaki S, Exarchos DA, Tragazikis IK, Matikas TE, Dassios KG. A Novel Infrared Thermography Sensing Approach for Rapid, Quantitative Assessment of Damage in Aircraft Composites. Sensors. 2020; 20(15):4113. https://doi.org/10.3390/s20154113

Chicago/Turabian StyleFarmaki, Spyridoula, Dimitrios A. Exarchos, Ilias K. Tragazikis, Theodore E. Matikas, and Konstantinos G. Dassios. 2020. "A Novel Infrared Thermography Sensing Approach for Rapid, Quantitative Assessment of Damage in Aircraft Composites" Sensors 20, no. 15: 4113. https://doi.org/10.3390/s20154113

APA StyleFarmaki, S., Exarchos, D. A., Tragazikis, I. K., Matikas, T. E., & Dassios, K. G. (2020). A Novel Infrared Thermography Sensing Approach for Rapid, Quantitative Assessment of Damage in Aircraft Composites. Sensors, 20(15), 4113. https://doi.org/10.3390/s20154113