Smart Pack: Online Autonomous Object-Packing System Using RGB-D Sensor Data

Abstract

:1. Introduction

2. Related Works

3. Real-Time Object Measurement

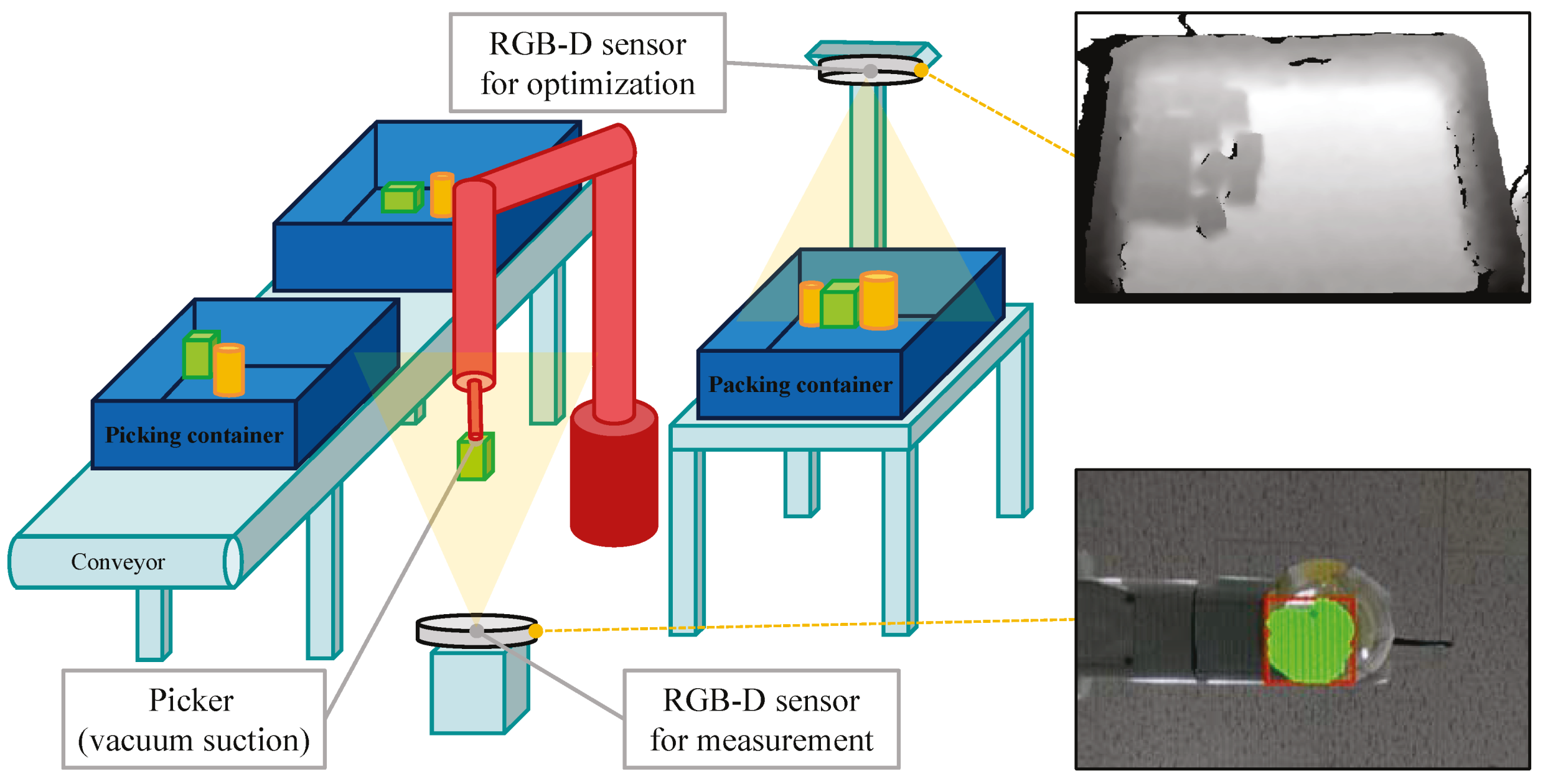

3.1. The Configuration of the Picker and the RGB-D Sensor

3.2. The Object Measurement Procedure

| Algorithm 1 Object Measurement |

| : The lowest position of the picker from the lens in z-axis |

| : The maximum depth of objects |

| , : The rows and columns in the 2D pixel coordinate system |

| : The depth value at |

| : The minimum area of object cross section |

| C: The contour of the object |

| : The width, height, depth and orientation of the object |

| : The width and height of the depth frame |

| : The picked position in -axes on the object |

| (1) Acquire sensor data. |

| Capture a depth frame from D435 |

| if the depth frame is not successfully captured then |

| return the error code of ’’ |

| end if |

| Calculate point clouds from the depth frame |

| (2) Extract object area. |

| Separate the pixels where |

| Find the contours of the separated pixels whose area is larger than |

| if no contour is found then |

| return the error code of ’’ |

| end if |

| Select the largest contour as C |

| if C is out of the depth frame bound then |

| return the error code of ’’ |

| end if |

| (3) Calculate d, w, h and . |

| Accumulate the point clouds in C |

| = average of the z-axis values of the point clouds |

| d = |

| Find a rotated rectangle of the minimum area enclosing C |

| Calculate the scaling factor S from the point clouds |

| w = width pixels of the rectangle |

| h = height pixels of the rectangle |

| = rotation of the rectangle |

| (4) Calculate and . |

| = average of the four corner positions of the rectangle in pixels |

| = ( − , − ) |

| (5) Return w, h, d, , and |

3.2.1. Acquire Sensor Data

3.2.2. Extract Object Area

3.2.3. Calculate d, w, h, and

3.2.4. Calculate and

3.2.5. Return and

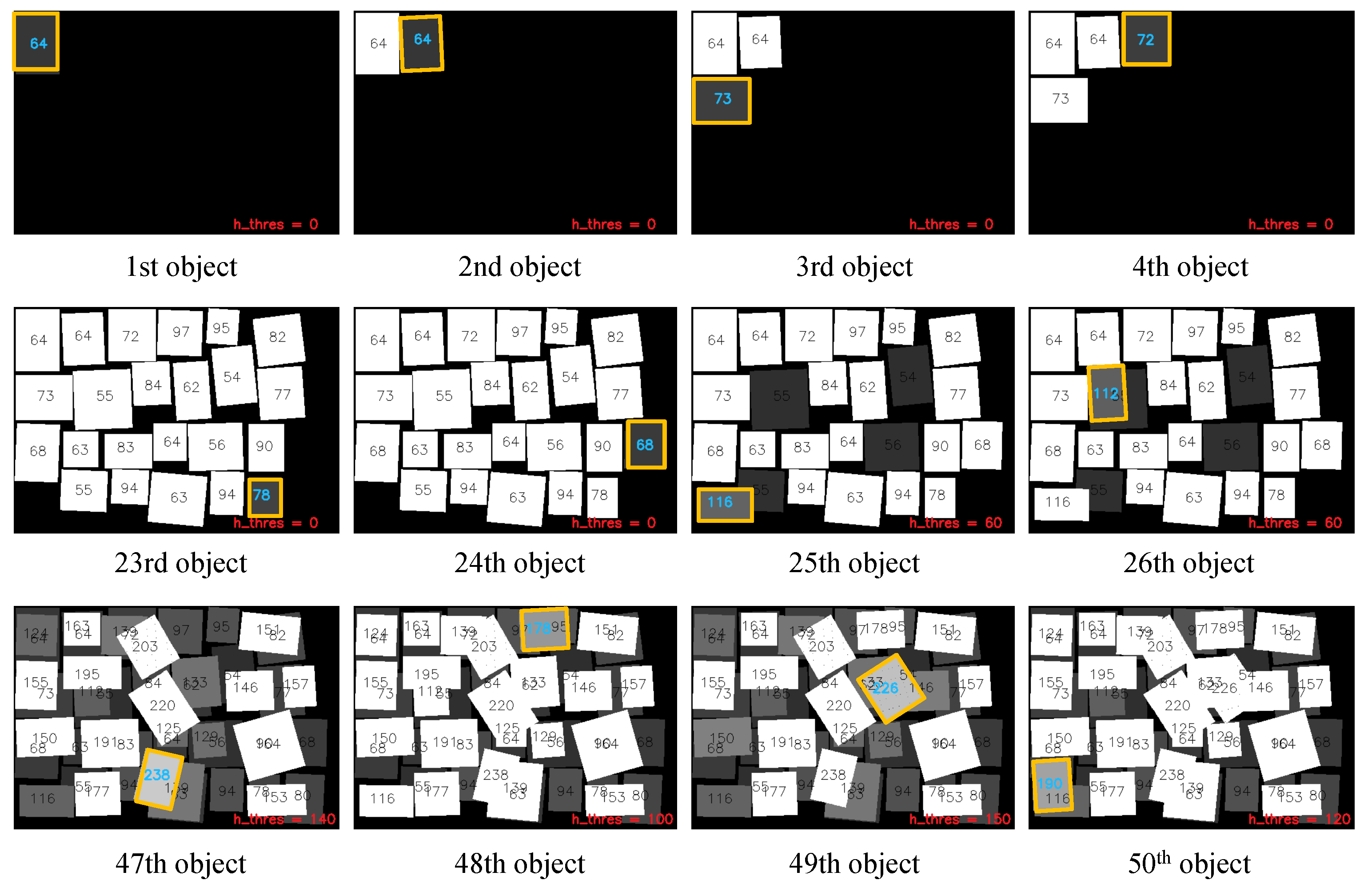

4. Online Object Placement Optimization

4.1. The Optimization Criteria

4.2. The Overall Process of the Optimization Algorithm

4.2.1. Acquire Sensor Data

4.2.2. Generate 2D Depth Map

4.2.3. Run Differential Evolution (DE) Algorithm

| Algorithm 2 Optimization algorithm |

| : The sensor coordinate system |

| : The container(global) coordinate system |

| (1) Acquire sensor data. |

| Capture a depth frame from D435 |

| if the depth frame is not successfully captured then |

| return the error code of ’’ |

| end if |

| Calculate point clouds from the depth frame |

| (2) Generate 2D depth map. |

| Transform the 3D point clouds from SCS to CCS |

| Project every point cloud () into 2D depth map by setting the value at (, ) to |

| Occupy the empty pixels of the map image by linear interpolation with the adjacent pixels |

| Apply sized mean filter to reduce noises |

| (3) Run differential evolution (DE) algorithm. |

| Initialize the DE algorithm |

| Set input bounds of and |

| Select appropriate configuration parameters |

| while the termination condition is not met do |

| for each solution candidate do |

| Perform (1) and (2) |

| Obtain with respect to using the generated depth image |

| Calculate the cost function |

| end for |

| Update solution candidates using DE update process |

| end while |

| Store the final solution along with its cost function value |

| (4) Return and . |

| Repeat (3) three times |

| Return the solution (, ) with the smallest cost function value |

4.2.4. Return the Optimal and

5. Experiments

5.1. Real-Time Object Measurement

5.2. Online Object Placement Optimization

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Matsumoto, E.; Saito, M.; Kume, A.; Tan, J. End-to-end learning of object grasp poses in the Amazon Robotics Challenge. In Advances on Robotic Item Picking; Springer: Berlin, Germany, 2020; pp. 63–72. [Google Scholar]

- Le, T.; Chyi-Yeu, L. Bin-Picking for Planar Objects Based on a Deep Learning Network: A Case Study of USB Packs. Sensors 2019, 19, 3602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, P.; Ishihara, Y.; Sugiyama, N.; Oaki, J.; Tokura, S. Depth image-based deep learning of grasp planning for textureless planar-faced objects in vision-guided robotic bin-picking. Sensors 2020, 20, 706. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Christensen, H.I.; Khan, A.; Pokutta, S.; Tetali, P. Multidimensional Bin Packing and Other Related Problems: A Survey. 2016. Available online: http://people.math.gatech.edu/~tetali/PUBLIS/CKPT.pdf (accessed on 8 August 2020).

- Techasarntikul, N.; Ratsamee, P.; Orlosky, J.; Mashita, T.; Uranishi, Y.; Kiyokawa, K.; Takemura, H. Guidance and Visualization of Optimized Packing Solutions. J. Inf. Process. 2020, 28, 193–202. [Google Scholar] [CrossRef] [Green Version]

- Man, E.C., Jr.; Garey, M.R.; Johnson, D.S. Approximation algorithms for bin packing: A survey. In Approximation Algorithms for NP-Hard Problems; PWS Publishing Company: Boston, MA, USA, 1996; pp. 46–93. [Google Scholar]

- Bortfeldt, A.; Gerhard, W. Constraints in container loading-A state-of-the-art review. Eur. J. Oper. Res. 2013, 229, 1–20. [Google Scholar] [CrossRef]

- Levin, M.S. Towards bin packing (preliminary problem survey, models with multiset estimates). arXiv 2016, arXiv:1605.07574. [Google Scholar]

- Elhedhli, S.; Gzara, F.; Yildiz, B. Three-Dimensional Bin Packing and Mixed-Case Palletization. Informs J. Optim. 2019, 1, 323–352. [Google Scholar] [CrossRef]

- Christensen, H.I.; Khan, A.; Pokutta, S.; Tetali, P. Approximation and online algorithms for multidimensional bin packing: A survey. Comput. Sci. Rev. 2017, 24, 63–79. [Google Scholar] [CrossRef]

- Kundu, O.; Dutta, S.; Kumar, S. Deep-Pack: A Vision-Based 2D Online Bin Packing Algorithm with Deep Reinforcement Learning. In Proceedings of the 2019 28th IEEE International Conference on Robot and Human Interactive Communication (RO-MAN), New Delhi, India, 14–18 October 2019; pp. 1–7. [Google Scholar]

- Hu, H.; Zhang, X.; Yan, X.; Wang, L.; Xu, Y. Solving a new 3d bin packing problem with deep reinforcement learning method. arXiv 2017, arXiv:1708.05930. [Google Scholar]

- Li, H.; Wang, Y.; Ma, D.; Fang, Y.; Lei, Z. Quasi-Monte-Carlo Tree Search for 3D Bin Packing. In Proceedings of the Chinese Conference on Pattern Recognition and Computer Vision, Guangzhou, China, 23–26 November 2018; pp. 384–396. [Google Scholar]

- Christensen, H.I.; Khan, A.; Pokutta, S.; Tetali, P. Smart Packing Simulator for 3D Packing Problem Using Genetic Algorithm. J. Phys. 2020, 1447, 012041. [Google Scholar]

- Araya, I.; Moyano, M.; Sanchez, C. A beam search algorithm for the biobjective container loading problem. Eur. J. Oper. Res. 2020, 286, 417–431. [Google Scholar] [CrossRef]

- Kanna, S.R.; Udaiyakumar, K.C. A complete framework for multi-constrained 3D bin packing optimization using firefly algorithm. Int. J. Pure Appl. Math. 2017, 114, 267–282. [Google Scholar]

- Ha, C.T.; Nguyen, T.T.; Bui, L.T.; Wang, R. An online packing heuristic for the three-dimensional container loading problem in dynamic environments and the Physical Internet. In Proceedings of the European Conference on the Applications of Evolutionary Computation, Amsterdam, The Netherlands, 19–21 April 2017; pp. 140–155. [Google Scholar]

- Shome, R. Towards robust product packing with a minimalistic end-effector. In Proceedings of the International Conference on Robotics and Automation, Montreal, QC, Canada, 20–24 May 2019. [Google Scholar]

- Duan, L.; Hu, H.; Qian, Y.; Gong, Y.; Zhang, X.; Xu, Y.; Wei, J. A multi-task selected learning approach for solving 3D flexible bin packing problem. arXiv 2018, arXiv:1804.06896. [Google Scholar]

- Verma, R.; Singhal, A.; Khadilkar, H.; Basumatary, A.; Nayak, S.; Singh, H.V.; Sinha, R. A Generalized Reinforcement Learning Algorithm for Online 3D Bin-Packing. arXiv 2007, arXiv:2007.00463. [Google Scholar]

- Zhao, H.; She, Q.; Zhu, C.; Yang, Y.; Xu, K. Online 3D Bin Packing with Constrained Deep Reinforcement Learning. arXiv 2006, arXiv:2006.14978. [Google Scholar]

- Liu, Z.; Zhao, C.; Wu, X.; Chen, W. An effective 3D shape descriptor for object recognition with RGB-D sensors. Sensors 2017, 17, 451. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, Y.P.; Kobbelt, L.; Hu, S.M. Real-time High-accuracy Three-Dimensional Reconstruction with Consumer RGB-D Cameras. ACM Trans. Graph. 2018, 37. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Li, D.; Zhang, C.; Wan, J.; Xie, M. RGB-D Image Processing Algorithm for Target Recognition and Pose Estimation of Visual Servo System. Sensors 2020, 20, 430. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Storn, R.; Price, K. Differential Evolution - a Simple and Efficient Heuristic for Global Optimization over Continuous Spaces. J. Glob. Optim. 1997, 11, 341–359. [Google Scholar] [CrossRef]

- Wormington, M.; Panaccione, C.; Matney, K.M.; Bowen, D.K. Characterization of structures from X-ray scattering data using genetic algorithms. Philos. Trans. R. Soc. Lond. A 1999, 357, 2827–2848. [Google Scholar] [CrossRef]

- Lampinen, J. A constraint handling approach for the differential evolution algorithm. In Proceedings of the International Congress on Evolutionary Computation, Honolulu, HI, USA, 12–17 May 2002. [Google Scholar]

| Computation Time (ms) | Error | ||||||

|---|---|---|---|---|---|---|---|

| w (mm) | h (mm) | d (mm) | (deg) | (mm) | (mm) | ||

| Min | 20.6 | 2.6 | 1.8 | 0.1 | 0.0 | 0.6 | 0.7 |

| Max | 35.4 | 7.6 | 7.7 | 4.8 | 5.9 | 7.5 | 7.4 |

| Average | 27.6 | 5.0 | 5.1 | 2.4 | 3.2 | 4.3 | 4.1 |

| STD | 4.4 | 1.4 | 1.6 | 1.4 | 1.9 | 2.3 | 2.1 |

| Computation | Container Occupancy | |

|---|---|---|

| Time (ms) | Ratio (%) | |

| Min | 227.1 | 52.2 |

| Max | 346.7 | 79.2 |

| Average | 293.5 | 63.2 |

| STD | 33.1 | 9.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, Y.-D.; Kim, Y.-J.; Lee, K.-B. Smart Pack: Online Autonomous Object-Packing System Using RGB-D Sensor Data. Sensors 2020, 20, 4448. https://doi.org/10.3390/s20164448

Hong Y-D, Kim Y-J, Lee K-B. Smart Pack: Online Autonomous Object-Packing System Using RGB-D Sensor Data. Sensors. 2020; 20(16):4448. https://doi.org/10.3390/s20164448

Chicago/Turabian StyleHong, Young-Dae, Young-Joo Kim, and Ki-Baek Lee. 2020. "Smart Pack: Online Autonomous Object-Packing System Using RGB-D Sensor Data" Sensors 20, no. 16: 4448. https://doi.org/10.3390/s20164448