Sensor Fault-Tolerant Control Design for Magnetic Brake System

Abstract

:1. Introduction

- Proposing a sensor active FTC system for magnetic brakes based on iterative learning control.

- Developing a model of a magnetic brake by means of the mixture of state-space neural network models and gain scheduling.

- Performing fault accommodation analysis for various types of sensor faults.

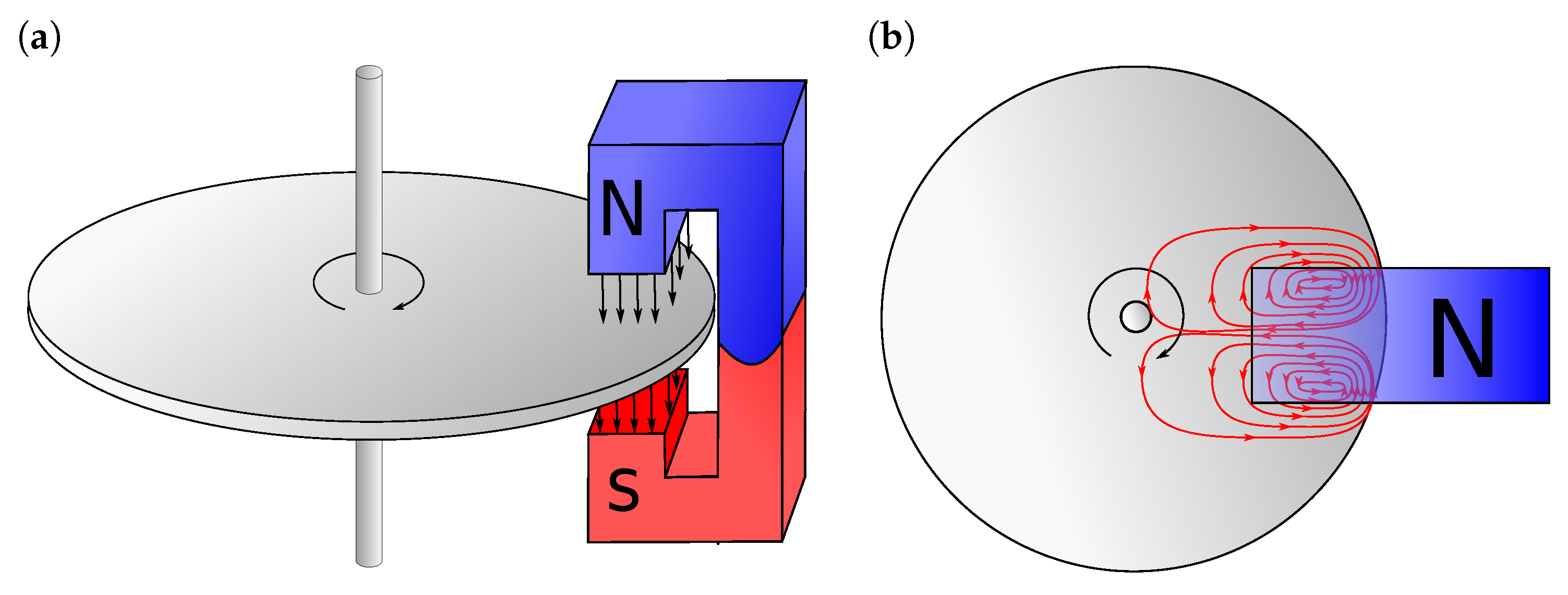

2. Magnetic Brake

3. Iterative Learning Control

4. Model Design

5. Sensor Fault-Tolerant Control

5.1. Fault Detection and Accommodation

5.2. Fault-Tolerant Control

- scenario —abrupt fault, multiplicative type, fault intensity: ;

- scenario —abrupt fault, additive type, fault intensity: ;

- scenario —abrupt fault, additive type, fault intensity: ;

6. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Simeu, E.; Georges, D. Modeling and control of an eddy current brake. Control. Eng. Pract. 1996, 4, 19–26. [Google Scholar] [CrossRef]

- Zamani, A. Design of a controller for rail eddy current brake system. IET Electr. Syst. Transp. 2014, 4, 38–44. [Google Scholar] [CrossRef]

- Yang, J.; Yi, F.; Wang, J. Model-based adaptive control of eddy current retarder. In Proceedings of the 30th Chinese Control and Decision Conference, Shenyang, China, 9–11 June 2018; pp. 1889–1891. [Google Scholar]

- Lee, K.; Park, K. Optimal robust control of a contactless brake system using an eddy current. Mechatronics 1999, 9, 615–631. [Google Scholar] [CrossRef]

- Anwar, S. A torque based sliding model control of an eddy current braking system for automotive applications. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Orlando, FL, USA, 5–11 November 2005; pp. 297–302. [Google Scholar]

- Xu, Y.N.; Deng, W.W. Research of Multiple Sensors Adaptive Fault-Tolerant Control Based on T-S Fuzzy Model for EMB System. Int. J. Eng. Technol. 2015, 7, 65–67. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.; Zhou, C.; Yang, L.; Qinab, Y.; Huang, X.; Huab, B. Fault-tolerant braking control with integerated EMBs and regenerative in-wheel motors. Reliab. Eng. Syst. Saf. 2016, 149, 148–163. [Google Scholar] [CrossRef]

- Kim, S.; Huh, K. Fault-tolerant braking control with integerated EMBs and regenerative in-wheel motors. Int. J. Automot. Technol. 2016, 17, 923–936. [Google Scholar] [CrossRef]

- Bristow, D.A.; Tharayil, M.; Alleyne, A.G. A survey of Iterative Learning Control: A learning-based method for high-performance tracking control. IEEE Control Syst. Mag. 2006, 26, 96–114. [Google Scholar]

- Chien, C.J. A discrete iterative learning control for a class of nonlinear time-varying systems. IEEE Trans. Autom. Control 1998, 43, 748–752. [Google Scholar] [CrossRef]

- Blanke, M.; Kinnaert, M.; Lunze, J.; Staroswiecki, M. Diagnosis and Fault-Tolerant Control; Springer: New York, NY, USA, 2016. [Google Scholar]

- Noura, H.; Theilliol, D.; Ponsart, J.; Chamseddine, A. Fault-Tolerant Control Systems: Design and Practical Applications; Springer: Berlin, Germany, 2003. [Google Scholar]

- Ducard, G.J.J. Fault-Tolerant Flight Control and Guidance Systems: Practical Methods for Small Unmanned Aerial Vehicles; Advances in Industrial Control; Springer: London, UK, 2009. [Google Scholar]

- Mahmoud, M.; Jiang, J.; Zhang, Y. Active Fault Tolerant Control Systems: Stochastic Analysis and Synthesis; Springer: Berlin, Germany, 2003. [Google Scholar]

- Patan, K.; Patan, M. Neural-network-based high-order iterative learning control. In Proceedings of the 2019 American Control Conference (ACC), Philadelphia, PA, USA, 9–11 July 2019; pp. 2873–2878. [Google Scholar] [CrossRef]

- Ponsart, J.C.; Theilliol, D.; Aubrun, C. Virtual sensors design for active fault tolerant control system applied to a winding machine. Control Eng. Pract. 2010, 18, 1037–1044. [Google Scholar] [CrossRef]

- Rotondo, D.; Nejjari, F.; Puig, V. A virtual actuator and sensor approach for fault tolerant control of LPV systems. J. Process. Control. 2014, 24, 203–222. [Google Scholar] [CrossRef]

- Tabbache, B.; Benbouzid, M.E.H.; Kheloui, A.; Bourgeot, J.M. Virtual-sensor-based maximum-likelihood voting approach for fault-tolerant control of electric vehicle powertrains. IEEE Trans. Veh. Technol. 2012, 62, 1075–1083. [Google Scholar] [CrossRef] [Green Version]

- Sami, M.; Patton, R.J. Wind turbine sensor fault tolerant control via a multiple-model approach. In Proceedings of the 2012 UKACC International Conference on Control, IEEE, Cardiff, UK, 3–5 September 2012; pp. 114–119. [Google Scholar]

- Patan, M. Optimal Sensor Networks Scheduling in Identification of Distributed Parameter Systems; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 425. [Google Scholar]

- Ahn, H.S.; Moore, K.L.; Chen, Y. Iterative Learning Control. Robustness and Monotonic Convergence for Interval Systems; Communications and Control Engineering; Springer: London, UK, 2007. [Google Scholar]

- Patan, K.; Patan, M. Design and convergence of iterative learning control based on neural networks. In Proceedings of the European Control Conference, ECC 2018, Limassol, Cyprus, 12–15 June 2018; pp. 3161–3166. [Google Scholar] [CrossRef]

- Patan, K.; Patan, M. Neural-network-based iterative learning control of nonlinear systems. ISA Trans. 2020, 98, 445–453. [Google Scholar] [CrossRef] [PubMed]

- Leith, D.J.; Leithead, W.E. Survey of gain-scheduling analysis and design. Int. J. Control 2000, 73, 1001–1025. [Google Scholar] [CrossRef]

- Sollich, P.; Krogh, A. Learning with ensembles: How over-fitting can be useful. Adv. Neural Inf. Process. Syst. 1996, 9, 190–196. [Google Scholar]

- Patan, K.; Patan, M.; Kowalów, D. Optimal sensor selection for model identification in iterative learning control of spatiotemporal systems. In Proceedings of the 55th IEEE Conference on Decision and Control (CDC), Las Vegas, NV, USA, 12–14 December 2016. [Google Scholar]

- Patan, K.; Patan, M.; Kowalów, D. Neural networks in design of iterative learning control for nonlinear systems. IFAC PapersOnLine 2017, 50, 13402–13407. [Google Scholar] [CrossRef]

| Model no. | v | ||

|---|---|---|---|

| 1 | 2 | 5 | hyperbolic tangent |

| 2 | 2 | 5 | hyperbolic tangent |

| 3 | 3 | 5 | hyperbolic tangent |

| 4 | 3 | 5 | hyperbolic tangent |

| 5 | 3 | 5 | hyperbolic tangent |

| 6 | 3 | 5 | hyperbolic tangent |

| 7 | 3 | 5 | hyperbolic tangent |

| Scenario | Type | Size | Remarks | |

|---|---|---|---|---|

| abrupt/multiplicative | 0.01 | 1 | At some trials the diagnostic signal was below the threshold | |

| abrupt/multiplicative | 0.008 | undetected | Oscillations around threshold | |

| abrupt/multiplicative | 0.006 | undetected | The diagnostic signal was permanently below the threshold | |

| abrupt/additive | 0.01 | undetected | The diagnostic signal was permanently below the threshold | |

| incipient/additive | 0.02 | 5 | — | |

| incipient/additive | 0.01 | 6 | — | |

| incipient/additive | 0.007 | undetected | The diagnostic signal was permanently below the threshold |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patan, K.; Patan, M.; Klimkowicz, K. Sensor Fault-Tolerant Control Design for Magnetic Brake System. Sensors 2020, 20, 4598. https://doi.org/10.3390/s20164598

Patan K, Patan M, Klimkowicz K. Sensor Fault-Tolerant Control Design for Magnetic Brake System. Sensors. 2020; 20(16):4598. https://doi.org/10.3390/s20164598

Chicago/Turabian StylePatan, Krzysztof, Maciej Patan, and Kamil Klimkowicz. 2020. "Sensor Fault-Tolerant Control Design for Magnetic Brake System" Sensors 20, no. 16: 4598. https://doi.org/10.3390/s20164598