Conical Microstructure Flexible High-Sensitivity Sensing Unit Adopting Chemical Corrosion

Abstract

:1. Introduction

2. Theoretical Research and Structural Design

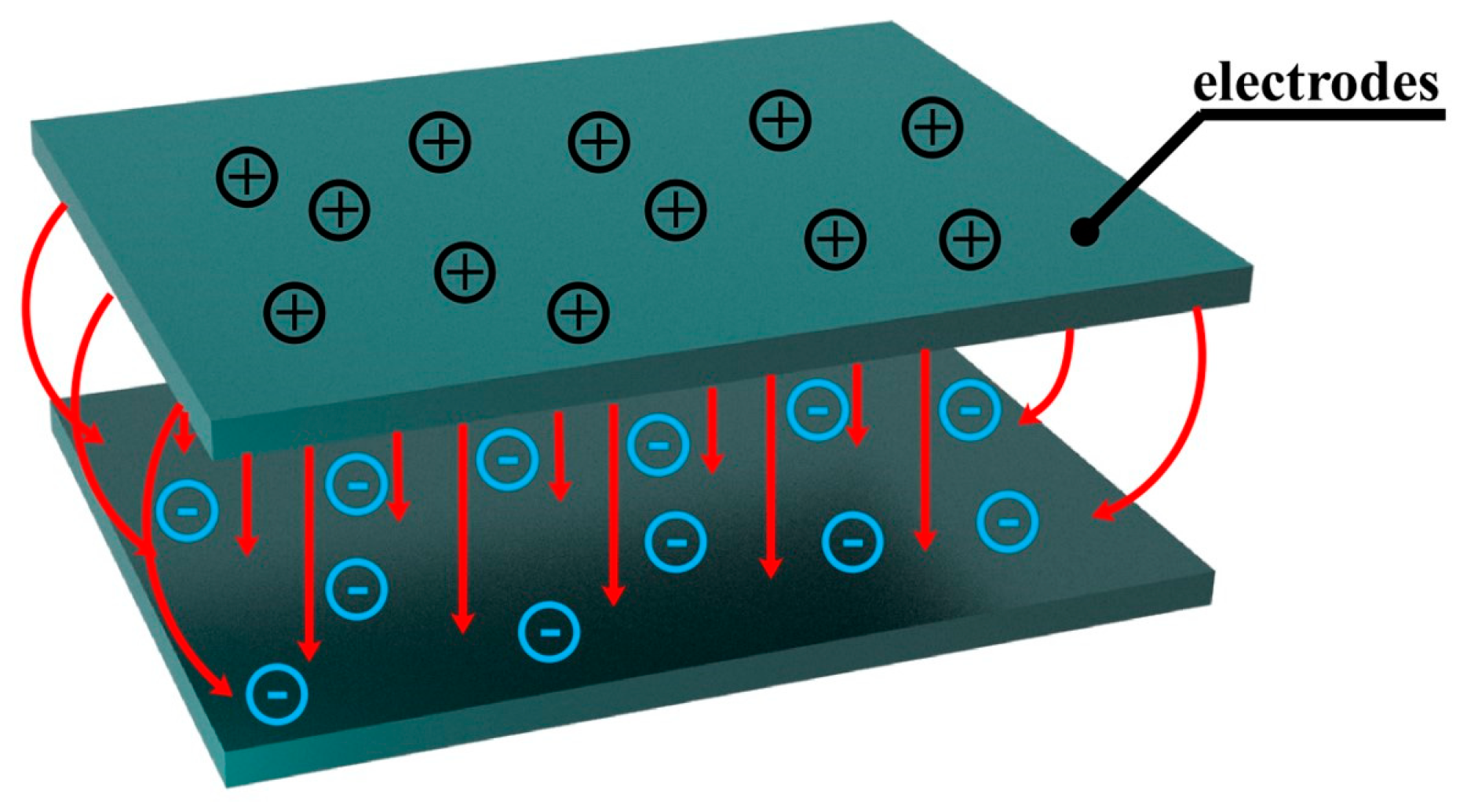

2.1. The Definition of Capacitive Sensor

2.2. Selection of Flexible Substrates

2.3. Selection of the Microstructure

3. Preparation

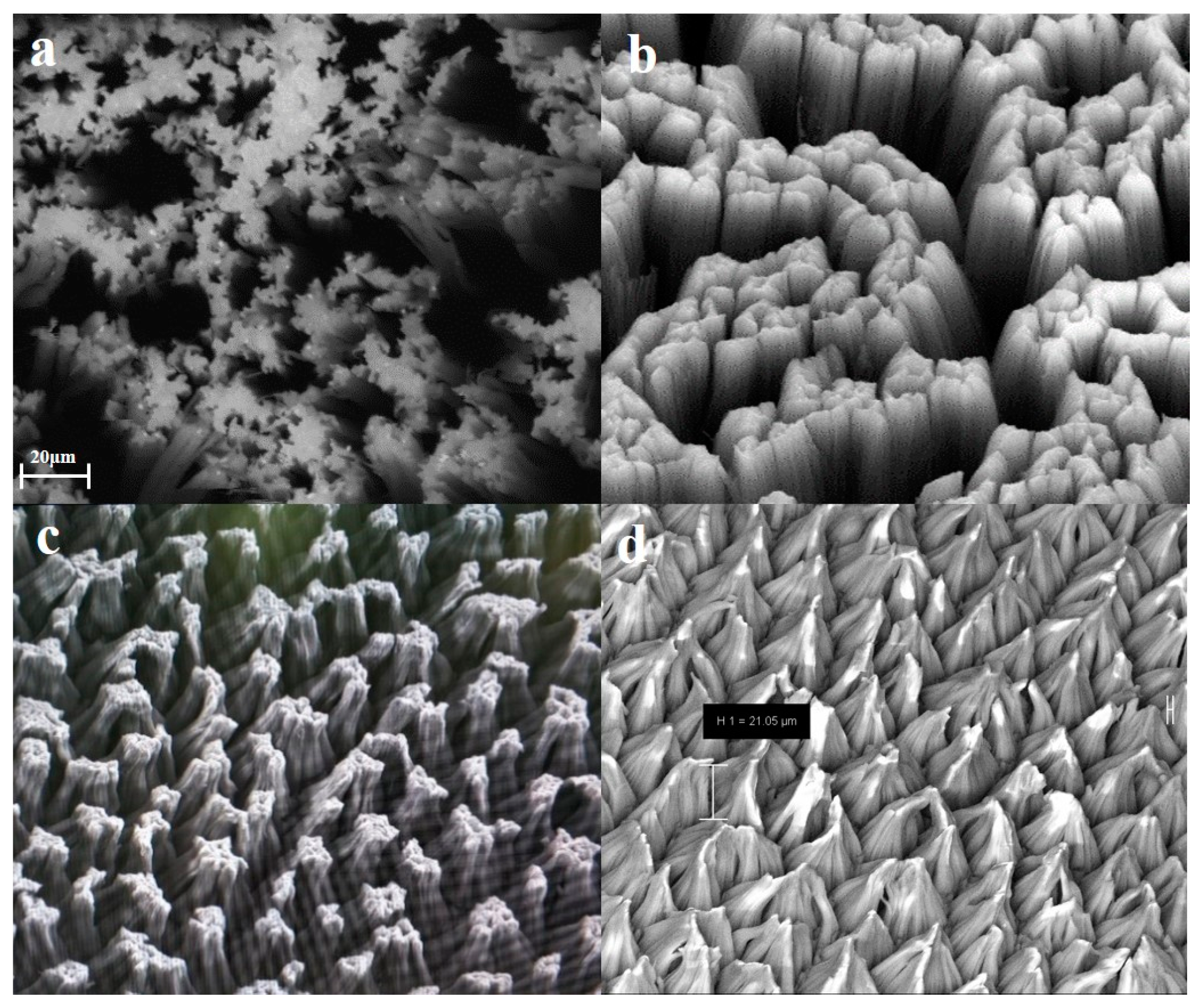

3.1. Fabrication of Dielectric Layer Cone Microstructure

3.2. Fabrication and Analysis of Flexible Electrode

3.2.1. Metal Electrode Surface Treatment

3.2.2. Electrode Performance Test

- Initial resistance test:First, the basic performance of the flexible electrode plate was tested. Flexible electrode structures with different diameters were prepared, which were 300, 800, 1200, and 2000 μm respectively, but their lengths were all 1 cm. Take ten groups of diameters for each category and calculate their average. Through the test, the resistance of the electrode was about 6 ± 0.2 Ω. It was proved that the flexible electrode plate made by the above method has very high stability.

- Repeatability test:In order to verify the flexible electrodes in long-term repeated use of the situation, the process of selecting the initial resistance value was 6 Ω flexible electrodes and 400 reciprocating tensile experiments. The simulation device is used to record the electrode resistance value of each stretch back to the initial state at 5% in real time, as shown in Figure 5a. Compared with the initial resistance value, the maximum change after 400 times is 0.8 Ω, and the electrode can remain stable. The performance testing and optimization of each component were carried out, and the final packaging process was completed. The package flexible sensor structure is shown in the Figure 5b–d.

4. Measurement of Piezoelectric Sensing Effect of Cone Array Structure

4.1. Effect Test of Flexible Pressure Sensing Unit

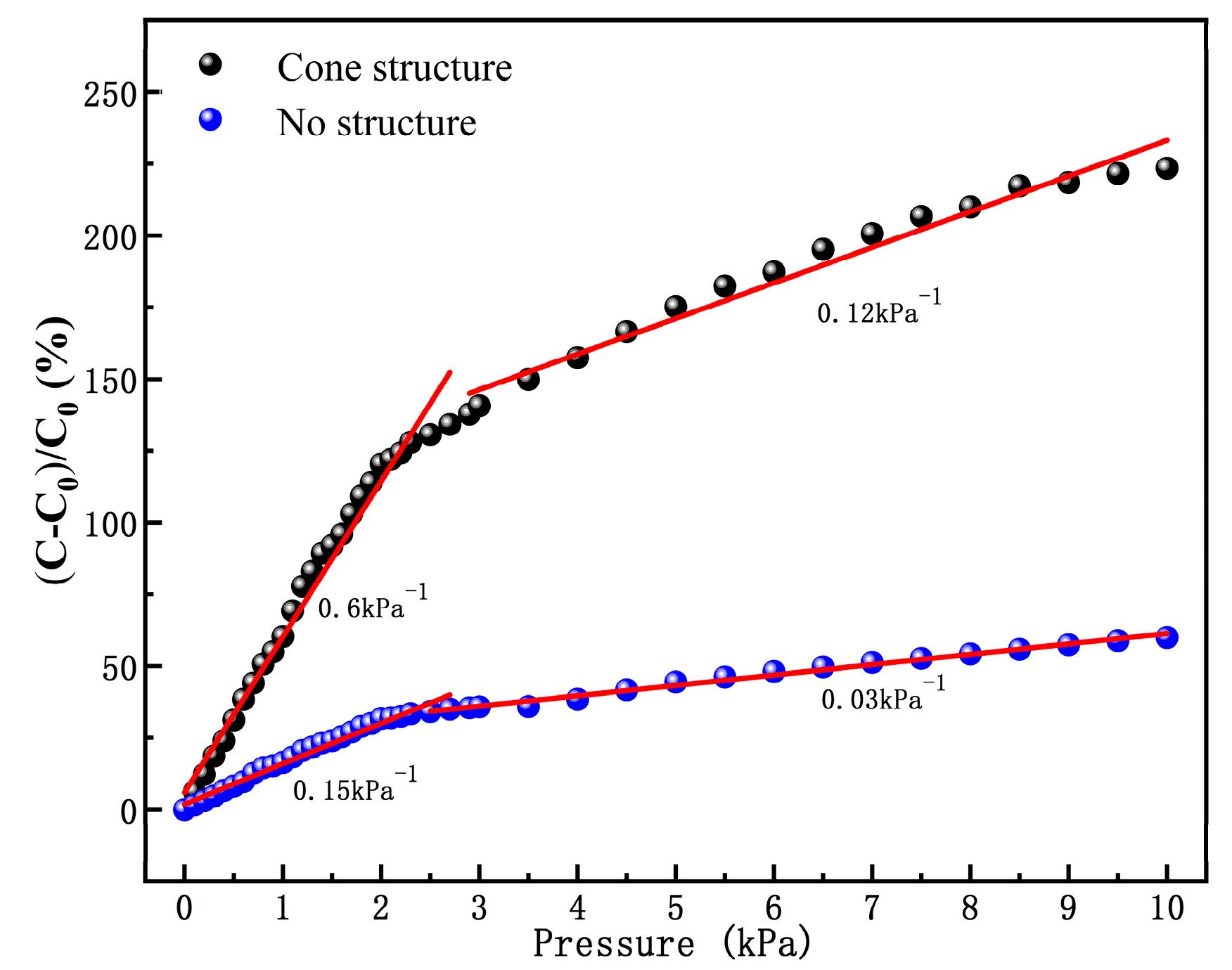

4.1.1. Sensitivity

4.1.2. Low Detection and Instantaneous Response Tests

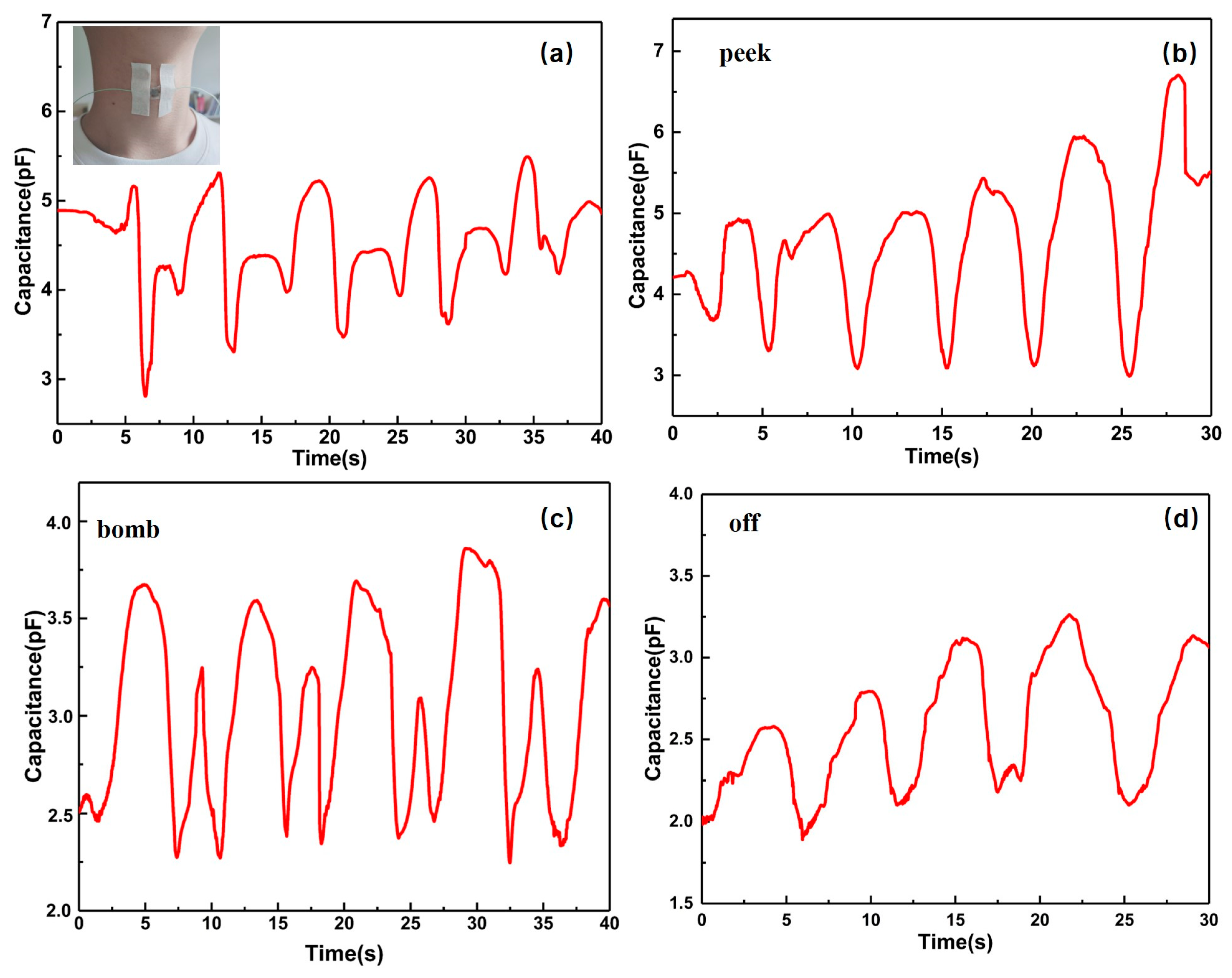

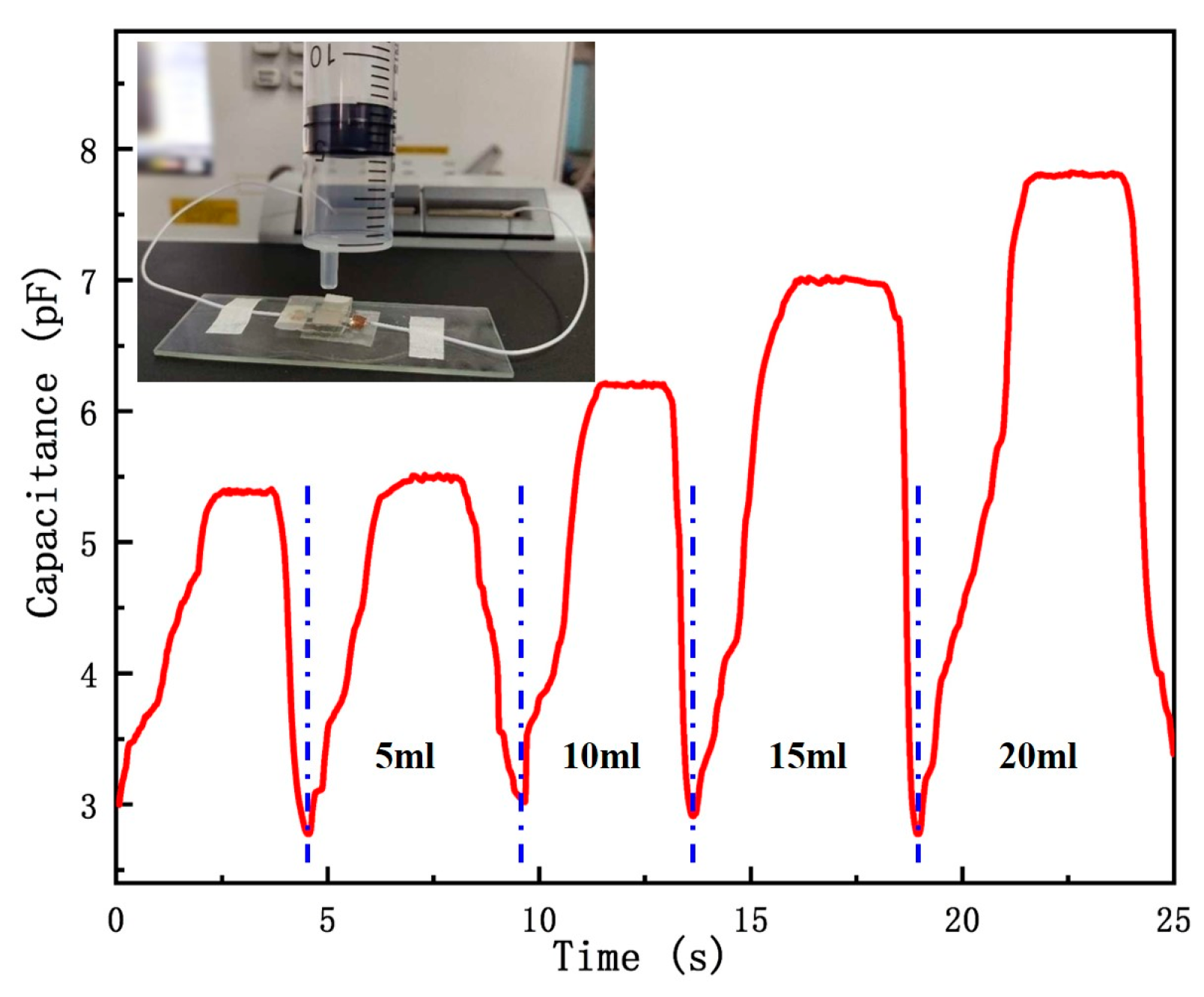

4.2. Study on the Application of Flexible Pressure Sensing Unit

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Lee, Y.; Park, J.; Cho, S.; Shin, Y.E.; Lee, H. Flexible Ferroelectric Sensors with Ultrahigh Pressure Sensitivity and Linear Response over Exceptionally Broad Pressure Range. ACS Nano 2018, 12, 4045–4054. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.K.; Murphy, R.K.; Hwang, S.W.; Lee, S.M.; Harburg, D.V.; Krueger, N.A.; Shin, J.; Gamble, P.; Cheng, H.; Yu, S.; et al. Bioresorbable silicon electronic sensors for the brain. Nature 2016, 530, 71–76. [Google Scholar] [CrossRef] [PubMed]

- Park, S.; Heo, S.W.; Lee, W.; Inoue, D.; Jiang, Z.; Yu, K.; Jinno, H.; Hashizume, D.; Sekino, M.; Yokota, T.; et al. Self-powered ultra-flexible electronics via nano-grating-patterned organic photovoltaics. Nature 2018, 561, 516–521. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.; Helo, P. The role of wearable devices in meeting the needs of cloud manufacturing: A case study. Rob. Comput. Integr. Manuf. 2017, 45, 168–179. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef] [Green Version]

- Ha, M.; Lee, S.; Ko, H. Wearable and flexible sensors for user-interactive health-monitoring devices. J. Mater. Chem. B 2018. [Google Scholar] [CrossRef]

- Hossain, D.; Haider, I.M.; Edward, S. Comparison of Wearable Sensors for Estimation of Chewing Strength. IEEE Sens. J. 2020, 20, 5379–5388. [Google Scholar] [CrossRef]

- Lee, J.; Kwon, H.; Seo, J.; Shin, S.; Koo, J.H.; Pang, C.; Son, S.; Kim, J.H.; Jang, Y.H.; Kim, D.E.; et al. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics. Adv. Mater. 2015, 27, 2433–2439. [Google Scholar] [CrossRef]

- Bahk, J.-H.; Fang, H.; Yazawa, K.; Shakouri, A. Flexible thermoelectric materials and device optimization for wearable energy harvesting. J. Mater. Chem. C 2015, 3, 10362–10374. [Google Scholar] [CrossRef]

- Meyer, J.; Arnrich, B. Design and modeling of a textile pressure sensor for sitting posture classification. IEEE Sens. J. 2010, 10, 1391–1396. [Google Scholar] [CrossRef]

- Lipomi, D.J.; Vosgueritchian, M.; Tee, B.C.; Hellstrom, S.L.; Lee, J.A.; Fox, C.H.; Bao, Z. Skin-like pressure and strain sensors based on transparent elastic films of carbon nanotubes. Nat. Nanotechnol. 2011, 6, 788–792. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Zhang, B.; Duan, J.; Guo, H.; Tang, J. Flexible Pressure Sensor with Ag Wrinkled Electrodes Based on PDMS Substrate. Sensors 2016, 16, 2131. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sharma, S.; Chhetry, A.; Sharifuzzaman, M.; Yoon, H.; Park, J.Y. Wearable Capacitive Pressure Sensor Based on MXene Composite Nanofibrous Scaffolds for Reliable Human Physiological Signal Acquisition. ACS Appl. Mater. Interfaces 2020, 12, 22212–22224. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Liang, J.; Wang, X.; Zhang, M. Ultra-Sensitive Flexible Pressure Sensor Based on Microstructured Electrode. Sensors 2020, 20, 371. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gong, S.; Schwalb, W.; Wang, Y.; Chen, Y.; Tang, Y.; Si, J.; Shirinzadeh, B.; Cheng, W. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun. 2014, 5, 3132. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Niu, D.; Jiang, W.; Ye, G.; Wang, K.; Yin, L. Graphene-elastomer nanocomposites based flexible piezoresistive sensors for strain and pressure detection. Mater. Res. Bull. 2018, 102, 92–99. [Google Scholar] [CrossRef]

- Guan, X.; Wang, Z.; Zhao, W.; Huang, H.; Wang, S.; Zhang, Q.; Zhong, D.; Lin, W.; Ding, N.; Peng, Z. Flexible Piezoresistive Sensors with Wide-Range Pressure Measurements Based on a Graded Nest-like Architecture. ACS Appl. Mater. Interfaces 2020. [Google Scholar] [CrossRef]

- Tian, W.; Zhang, C.; Zhai, T.; Li, S.L.; Wang, X.; Liu, J.; Jie, X.; Liu, D.; Liao, M.; Koide, Y.; et al. Flexible ultraviolet photodetectors with broad photoresponse based on branched ZnS-ZnO heterostructure nanofilms. Adv. Mater. 2014, 26, 3088–3093. [Google Scholar] [CrossRef]

- Mannsfeld, S.C.B.; Tee, C.K.; Stoltenberg, R.M. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater. 2010, 9, 859–864. [Google Scholar] [CrossRef]

- Zhang, L.; Hu, F.; Zhu, S.; Lin, Y.; Meng, Z.; Yu, R.; Liu, X.Y. Meso-Reconstruction of Wool Keratin 3D "Molecular Springs" for Tunable Ultra-Sensitive and Highly Recovery Strain Sensors. Small 2020. [Google Scholar] [CrossRef]

- Ding, L.; Wang, Y.; Sun, C.; Shu, Q.; Hu, T.; Xuan, S.; Gong, X. Three-Dimensional Structured Dual-Mode Flexible Sensors for Highly Sensitive Tactile Perception and Noncontact Sensing. ACS Appl. Mater. Interfaces 2020, 12, 20955–20964. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Han, F.; Hu, Y.; Xiong, Y.; Gu, H.; Zhang, G.; Zhu, P.L.; Sun, R. Flexible and Highly Sensitive Pressure Sensors with Surface Discrete Microdomes Made from Self-Assembled Polymer Microspheres Array. Macromol. Chem. Phys. 2020, 221, 2000073. [Google Scholar] [CrossRef]

- Yu, S.; Li, L.; Wang, J.; Liu, E.; Zhao, J.; Xu, F.; Lu, C. Light-Boosting Highly Sensitive Pressure Sensors Based on Bioinspired Multiscale Surface Structures. Adv. Funct. Mater. 2020, 30, 1907091. [Google Scholar] [CrossRef]

- Wan, Y.; Qiu, Z.; Hong, Y.; Wang, Y.; Zhang, J.; Liu, Q.; Wu, Z.; Guo, C.F. A Highly Sensitive Flexible Capacitive Tactile Sensor with Sparse and High-Aspect-Ratio Microstructures. Adv. Electron. Mater. 2018, 4, 1700586. [Google Scholar] [CrossRef]

- Trang, N.T.; Ngoc, H.V.; Lingappan, N.; Kang, D.J. A comparative study of supercapacitive performances of nickel cobalt layered double hydroxides coated on ZnO nanostructured arrays on textile fibre as electrodes for wearable energy storage devices. Nanoscale 2014, 6, 2434–2439. [Google Scholar] [CrossRef] [PubMed]

- Tien, N.T.; Jeon, S.; Kim, D.I.; Trung, T.Q.; Jang, M.; Hwang, B.U.; Byun, K.E.; Bae, J.; Lee, E.; Tok, J.B.; et al. A flexible bimodal sensor array for simultaneous sensing of pressure and temperature. Adv. Mater. 2014, 26, 796–804. [Google Scholar] [CrossRef]

- Dagdeviren, C.; Su, Y.; Joe, P.; Yona, R.; Liu, Y.; Kim, Y.S.; Huang, Y.; Damadoran, A.R.; Xia, J.; Martin, L.W.; et al. Conformable amplified lead zirconate titanate sensors with enhanced piezoelectric response for cutaneous pressure monitoring. Nat. Commun. 2014, 5, 4496. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Luo, H.; Qin, L.; Wang, X.; Xiong, Z.; Ding, H.; Gu, Y.; Liu, Z.; Zhang, T. Flexible Capacitive Tactile Sensor Based on Micropatterned Dielectric Layer. Small 2016, 12, 5042–5048. [Google Scholar] [CrossRef]

- Zheng, T.; Yu, Z.; Wang, J.; Lu, G. A New Automatic Foot Arch Index Measurement Method Based on a Flexible Membrane Pressure Sensor. Sensors 2020, 20, 2892. [Google Scholar] [CrossRef]

- Yao, S.; Zhu, Y. Wearable multifunctional sensors using printed stretchable conductors made of silver nanowires. Nanoscale 2014, 6, 2345–2352. [Google Scholar] [CrossRef]

| Microstructural | Hemisphere | Cube | Cuboid | Tri-Pyramid | Circular Cone | No Microstructure |

|---|---|---|---|---|---|---|

| Size (μm) | R = 20 | a = 20 | A = 20 | h = 20 | H = 20 | -- |

| Maximum Shape Variable (μm) | 71.874 | 70.564 | 70.392 | 72.513 | 72.924 | 67.352 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Deng, J.; Duan, J.; Zhang, B. Conical Microstructure Flexible High-Sensitivity Sensing Unit Adopting Chemical Corrosion. Sensors 2020, 20, 4613. https://doi.org/10.3390/s20164613

Wang Y, Deng J, Duan J, Zhang B. Conical Microstructure Flexible High-Sensitivity Sensing Unit Adopting Chemical Corrosion. Sensors. 2020; 20(16):4613. https://doi.org/10.3390/s20164613

Chicago/Turabian StyleWang, Yangyang, Jiangyu Deng, Junping Duan, and Binzhen Zhang. 2020. "Conical Microstructure Flexible High-Sensitivity Sensing Unit Adopting Chemical Corrosion" Sensors 20, no. 16: 4613. https://doi.org/10.3390/s20164613