Tacsac: A Wearable Haptic Device with Capacitive Touch-Sensing Capability for Tactile Display

Abstract

:1. Introduction

2. Materials and Methods

2.1. Device Structure and Operating Principle

2.2. Device Fabrication

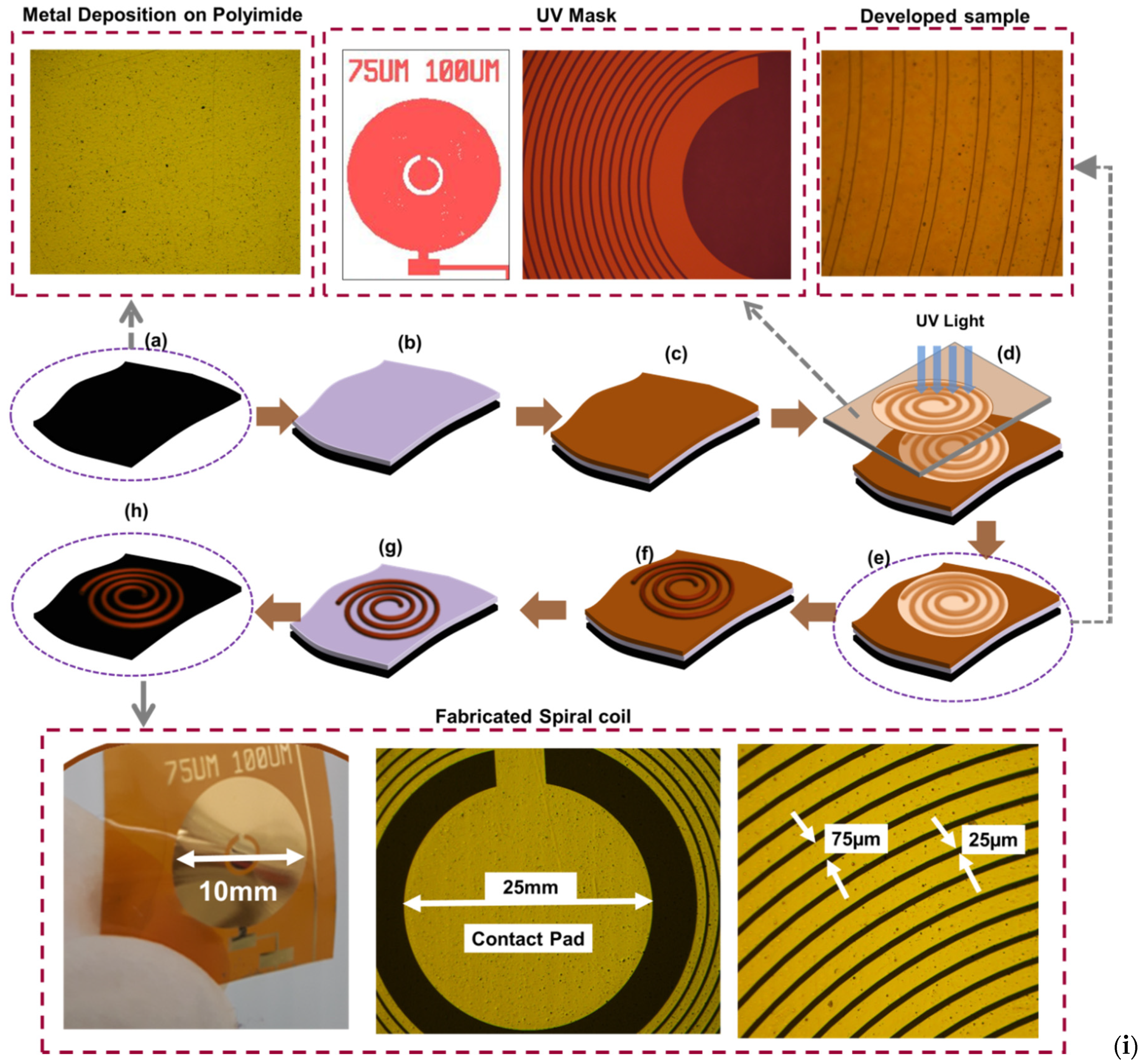

2.2.1. Fabrication of the Spiral Coil

2.2.2. Fabrication of the Capacitive Sensing Layer

2.2.3. Device Integration

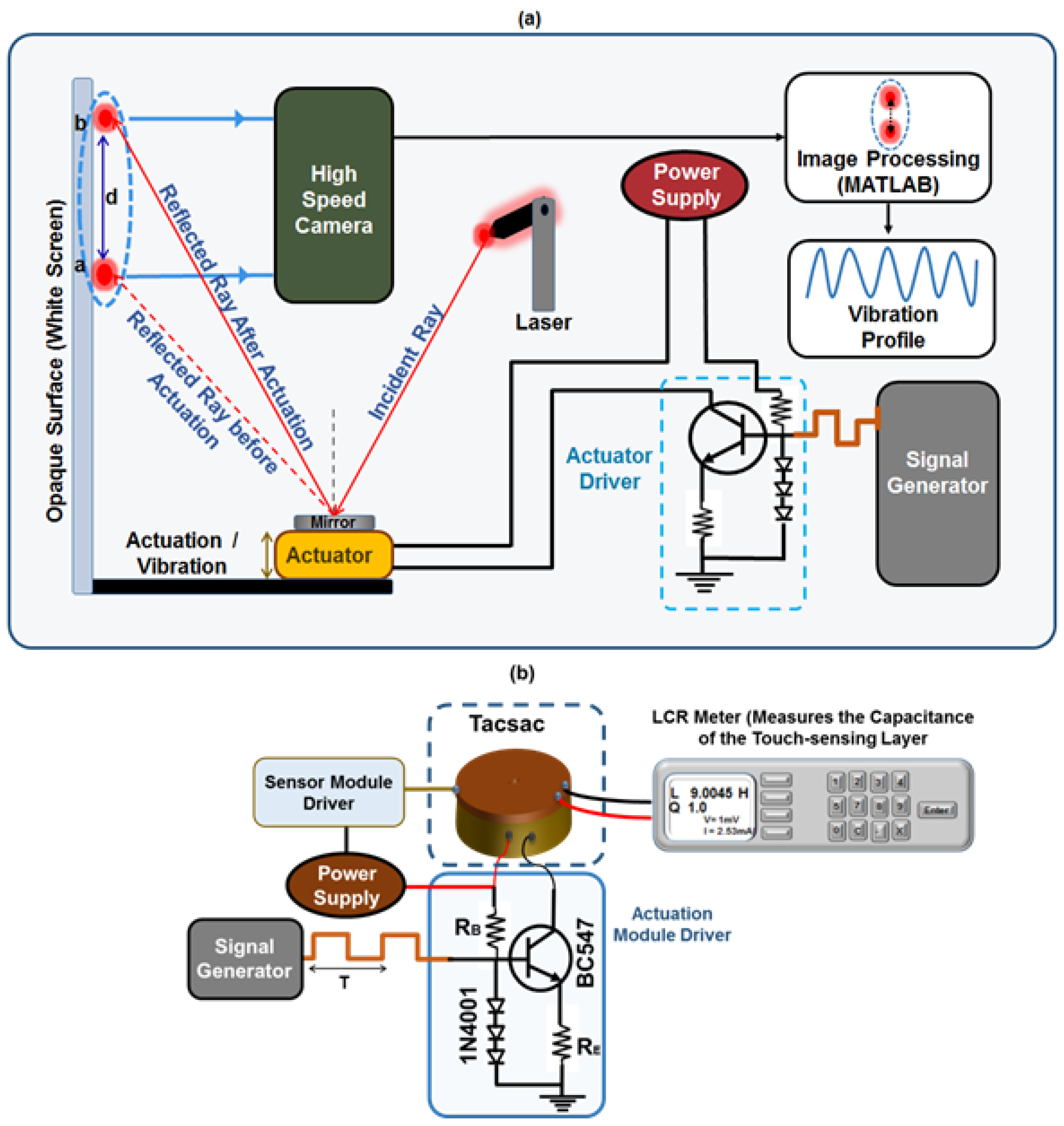

2.3. Device Characterization

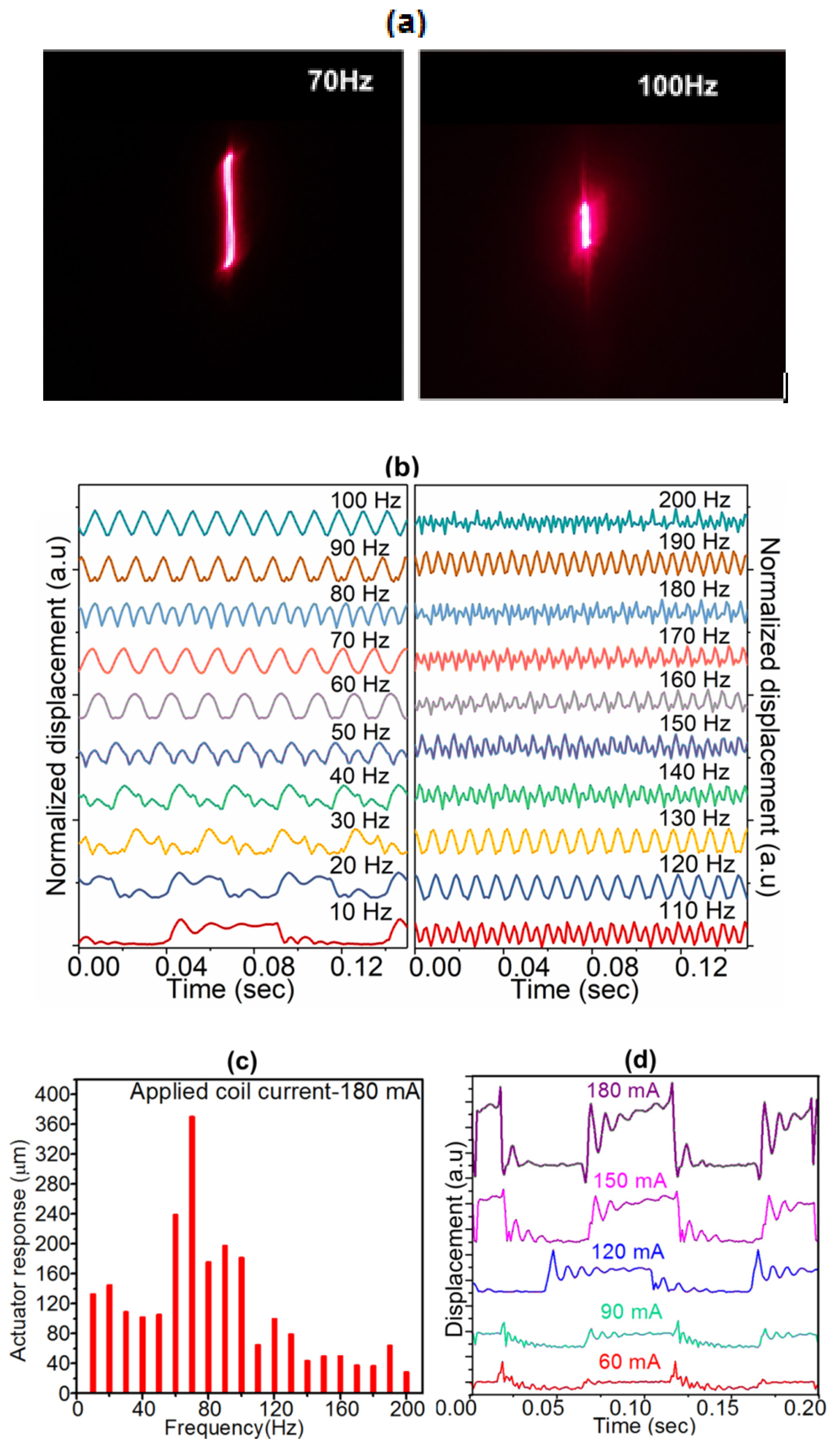

3. Results and Discussion

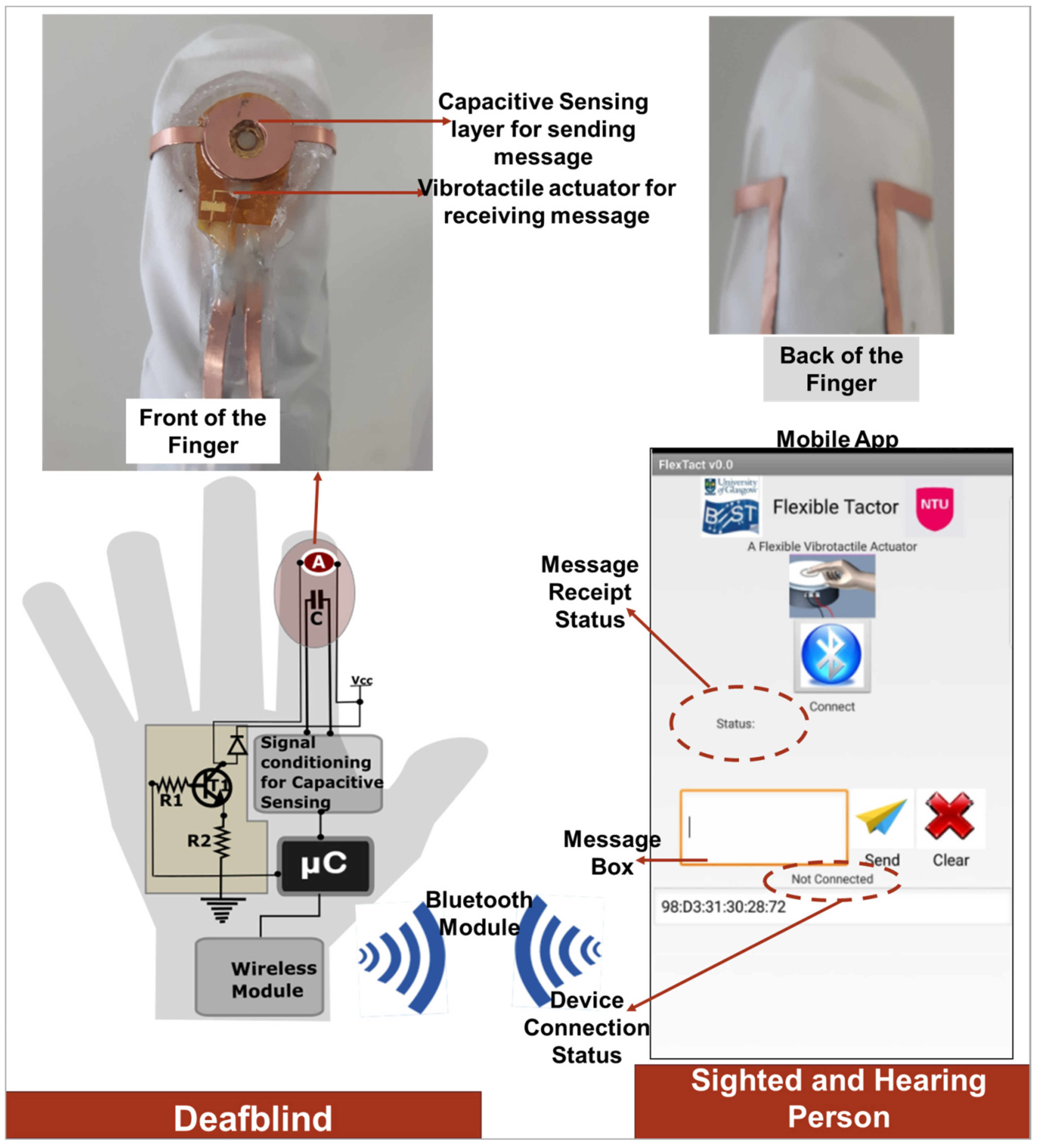

4. Application

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Culbertson, H.; Schorr, S.B.; Okamura, A.M. Haptics: The Present and Future of Artificial Touch Sensation. Annu. Rev. Control Robot. Auton. Syst. 2018, 1, 385–409. [Google Scholar] [CrossRef]

- Abiri, A.; Pensa, J.; Tao, A.; Ma, J.; Juo, Y.-Y.; Askari, S.J.; Bisley, J.; Rosen, J.; Dutson, E.P.; Grundfest, W.S. Multi-Modal Haptic Feedback for Grip Force Reduction in Robotic Surgery. Sci. Rep. 2019, 9, 5016. [Google Scholar] [CrossRef] [Green Version]

- Dahiya, R.; Yogeswaran, N.; Liu, F.; Manjakkal, L.; Burdet, E.; Hayward, V.; Jörntell, H. Large-Area Soft e-Skin: The Challenges Beyond Sensor Designs. Proc. IEEE 2019, 107, 2016–2033. [Google Scholar] [CrossRef] [Green Version]

- Ozioko, O.; Karipoth, P.; Hersh, M.; Dahiya, R. Wearable Assistive Tactile Communication Interface Based on Integrated Touch Sensors and Actuators. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 1344–1352. [Google Scholar] [CrossRef]

- Okamura, A.M. Haptic Feedback in Robot-Assisted Minimally Invasive Surgery. Curr. Opin. Urol. 2009, 19, 102–107. [Google Scholar] [CrossRef]

- Sreelakshmi, M.; Subash, T.D. Haptic Technology: A comprehensive review on its applications and future prospects. Mater. Today Proc. 2017, 4, 4182–4187. [Google Scholar] [CrossRef]

- Srinivasan, M.A.; Basdogan, C. Haptics in virtual environments: Taxonomy, research status, and challenges. Comput. Graph. 1997, 21, 393–404. [Google Scholar] [CrossRef]

- Goethals, P. Tactile Feedback for Robot Assisted Minimally Invasive Surgery: An Overview; Department of Mechanical Engineering KU Leuven: Leuven, Belgium, 2008. [Google Scholar]

- Hale, K.S.; Stanney, K.M. Deriving haptic design guidelines from human physiological, psychophysical, and neurological foundations. IEEE Comput. Graph. Appl. 2004, 24, 33–39. [Google Scholar] [CrossRef]

- Gescheider, G.A.; Verrillo, R.T.; McCann, J.T.; Aldrich, E.M. Effects of the menstrual cycle on vibrotactile sensitivity. Percept. Psychophys. 1984, 36, 586–592. [Google Scholar] [CrossRef]

- Verrillo, R.T. Effects of aging on the suprathreshold responses to vibration. Percept. Psychophys. 1982, 32, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Venkatesan, L.; Barlow, S.M.; Kieweg, D. Age- and sex-related changes in vibrotactile sensitivity of hand and face in neurotypical adults. Somatosens. Mot. Res. 2015, 32, 44–50. [Google Scholar] [CrossRef]

- Wang, Y.; Millet, B.; Smith, J.L. Designing wearable vibrotactile notifications for information communication. Int. J. Hum. Comput. Stud. 2016, 89, 24–34. [Google Scholar] [CrossRef]

- Jones, L.A.; Lederman, S.J. Human Hand Function; Oxford University Press: New York, NY, USA, 2006. [Google Scholar]

- Lederman, S.J.; Browse, R.A. The Physiology and Psychophysics of Touch. In Sensors and Sensory Systems for Advanced Robots; Dario, P., Ed.; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Tiwana, M.I.; Redmond, S.J.; Lovell, N.H. A review of tactile sensing technologies with applications in biomedical engineering. Sens. Actuators A Phys. 2012, 179, 17–31. [Google Scholar] [CrossRef]

- Wan, Y.; Wang, Y.; Guo, C.F. Recent progresses on flexible tactile sensors. Mater. Today Phys. 2017, 1, 61–73. [Google Scholar] [CrossRef]

- Dahiya, R. E-Skin: From Humanoids to Humans. In Proceedings of the IEEE; IEEE: Piscataway Township, NJ, USA, 2019; Volume 107, pp. 247–252. [Google Scholar]

- Taube Navaraj, W.; García Núñez, C.; Shakthivel, D.; Vinciguerra, V.; Labeau, F.; Gregory, D.H.; Dahiya, R. Nanowire FET Based Neural Element for Robotic Tactile Sensing Skin. Front. Neurosci. 2017, 11. [Google Scholar] [CrossRef]

- Soni, M.; Dahiya, R. Soft eSkin: Distributed touch sensing with harmonized energy and computing. Philos. Trans. R. Soc. A 2020, 378, 20190156. [Google Scholar] [CrossRef] [Green Version]

- Dahiya, R.S. Epidermal electronics—flexible electronics for biomedical applications. In Handbook of Bioelectronics: Directly Interfacing Electronics and Biological Systems; Iniewski, K., Carrara, S., Eds.; Cambridge University Press: Cambridge, UK, 2015; pp. 245–255. [Google Scholar]

- Dahiya, R.S.; Valle, M. Robotic Tactile Sensing: Technologies and System; Springer: New York, NY, USA, 2013. [Google Scholar]

- Hersh, M. Mobility technologies for blind, partially sighted and deafblind people: Design issues. In Mobility of Visually Impaired People; Springer: Berlin/Heidelberg, Germany, 2018; pp. 377–409. [Google Scholar]

- Hersh, M.A. Mobility Technologies for Blind, Partially Sighted and Deafblind People: Design Issues. In Mobility of Visually Impaired People: Fundamentals and ICT Assistive Technologies; Pissaloux, E., Velazquez, R., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 377–409. [Google Scholar]

- Ogrinc, M.; Farkhatdinov, I.; Walker, R.; Burdet, E. Horseback riding therapy for a deafblind individual enabled by a haptic interface. Assist. Technol. 2017, 30, 1–8. [Google Scholar]

- Dammeyer, J. Deafblindness: A Review of the Literature. Scand. J. Public Health 2014, 554–562. [Google Scholar] [CrossRef]

- Sorgini, F.; Caliò, R.; Carrozza, M.C.; Oddo, C.M. Haptic-assistive technologies for audition and vision sensory disabilities. Disabil. Rehabil. Assist. Technol. 2018, 13, 394–421. [Google Scholar] [CrossRef]

- Aggravi, M.; Pausé, F.; Giordano, P.R.; Pacchierotti, C. Design and evaluation of a wearable haptic device for skin stretch, pressure, and vibrotactile stimuli. IEEE Robot. Autom. Lett. 2018, 3, 2166–2173. [Google Scholar] [CrossRef] [Green Version]

- Schorr, S.B.; Quek, Z.F.; Romano, R.Y.; Nisky, I.; Provancher, W.R.; Okamura, A.M. Sensory substitution via cutaneous skin stretch feedback. In Proceedings of the 2013 IEEE International Conference on Robotics and Automation, Karlsruhe, Germany, 6–10 May 2013; pp. 2341–2346. [Google Scholar]

- Caporusso, N.; Biasi, L.; Cinquepalmi, G.; Trotta, G.F.; Brunetti, A.; Bevilacqua, V. A wearable device supporting multiple touch-and gesture-based languages for the deaf-blind. In Proceedings of the International Conference on Applied Human Factors and Ergonomics, Los Angeles, CA, USA, 17–21 July 2017; pp. 32–41. [Google Scholar]

- Srinivasan, M.; Cutkosky, M.; Howe, R.; Salisbury, J. Human and Machine Haptics. RLE Prog. Rep. 1999, 147, 1–39. [Google Scholar]

- Navaraj, W.; Dahiya, R. Fingerprint-Enhanced Capacitive-Piezoelectric Flexible Sensing Skin to Discriminate Static and Dynamic Tactile Stimuli. In Advanced Intelligent Systems; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2019. [Google Scholar]

- Chen, X.; Hu, J. A review of haptic simulator for oral and maxillofacial surgery based on virtual reality. Expert Rev. Med. Devices 2018, 15, 435–444. [Google Scholar] [CrossRef] [PubMed]

- Ge, J.; Wang, X.; Drack, M.; Volkov, O.; Liang, M.; Cañón Bermúdez, G.S.; Illing, R.; Wang, C.; Zhou, S.; Fassbender, J.; et al. A bimodal soft electronic skin for tactile and touchless interaction in real time. Nat. Commun. 2019, 10, 4405. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dahiya, R.; Navaraj, W.T.; Khan, S.; Polat, E.O. Developing Electronic Skin with the Sense of Touch. Inf. Disp. 2015, 31, 6–10. [Google Scholar] [CrossRef]

- Dahiya, R.; Akinwande, D.; Chang, J.S. Flexible Electronic Skin: From Humanoids to Humans [Scanning the Issue]. In Proceedings of the IEEE; IEEE: Piscataway Township, NJ, USA, 2019; Volume 107, pp. 2011–2015. [Google Scholar]

- Seo, D.G.; Cho, Y.-H. Resonating tactile stimulators based on piezoelectric polymer films. J. Mech. Sci. Technol. 2018, 32, 631–636. [Google Scholar] [CrossRef]

- Noguchi, T.; Nagai, S.; Kawamura, A. Electromagnetic Linear Actuator providing High Force Density per Unit Area without Position Sensor as a Tactile Cell. IEEJ J. Ind. Appl. 2018, 7, 259–265. [Google Scholar] [CrossRef] [Green Version]

- Zárate, J.J.; Shea, H. Using Pot-Magnets to Enable Stable and Scalable Electromagnetic Tactile Displays. In IEEE Transactions on Haptics; IEEE: Piscataway Township, NJ, USA, 2017; Volume 10, pp. 106–112. [Google Scholar]

- Hyun, U.K.; Hyun Chan, K.; Jaehwan, K.; Sang-Youn, K. Miniaturized 3 × 3 array film vibrotactile actuator made with cellulose acetate for virtual reality simulators. Smart Mater. Struct. 2015, 24, 055018. [Google Scholar] [CrossRef]

- Phung, H.; Nguyen, C.T.; Jung, H.; Nguyen, T.D.; Choi, H.R. Bidirectional tactile display driven by electrostatic dielectric elastomer actuator. Smart Mater. Struct. 2020, 29, 035007. [Google Scholar] [CrossRef]

- Mitsuhiro, S.; Tsubasa, I.; Shinji, U.; Takaaki, M.; Kazuo, S. Fabrication of a bubble-driven arrayed actuator for a tactile display. J. Micromechanics Microengineering 2008, 18, 065012. [Google Scholar] [CrossRef]

- Kitamura, N.; Chim, J.; Miki, N. Electrotactile display using microfabricated micro-needle array. J. Micromechanics Microengineering 2015, 25, 025016. [Google Scholar] [CrossRef]

- Ozioko, O.; Taube, W.; Hersh, M.; Dahiya, R. SmartFingerBraille: A tactile sensing and actuation based communication glove for deafblind people. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; pp. 2014–2018. [Google Scholar]

- Gollner, U.; Bieling, T.; Joost, G. Mobile Lorm Glove—Introducing a Communication Device for Deaf-Blind People. In TEI 2012; Association for Computing Machinery: New York, NY, USA, 2012; pp. 127–130. [Google Scholar]

- Sapra, P.; Parsurampuria, A.K.; Muralikrishnan, S.; Gupta, V.; Karthikeyan, H.; Bhagavatheesh, K.; Venkatesan, A.; Valiyaveetil, S.; Balakrishnan, M.; Rao, P.V.M. Refreshable Braille Display Using Shape Memory Alloy With Latch Mechanism. In Proceedings of the 13th ASME/IEEE International Conference on Mechatronic and Embedded Systems and Applications, Cleveland, OH, USA, 6–9 August 2017; p. V009T07A040. [Google Scholar] [CrossRef]

- Matsunaga, T.; Totsu, K.; Esashi, M.; Haga, Y. Tactile display using shape memory alloy micro-coil actuator and magnetic latch mechanism. Displays 2013, 34, 89–94. [Google Scholar] [CrossRef]

- Wu, X.; Kim, S.H.; Zhu, H.; Ji, C.H.; Allen, M.G. A Refreshable Braille Cell Based on Pneumatic Microbubble Actuators. IEEE J. Microelectromechanical Syst. 2012, 21, 908–916. [Google Scholar] [CrossRef]

- Mazursky, A.; Koo, J.-H.; Yang, T.-H. Design, modeling, and evaluation of a slim haptic actuator based on electrorheological fluid. J. Intell. Mater. Syst. Struct. 2019, 30, 2521–2533. [Google Scholar] [CrossRef]

- Hathazi, A. Developing and implementing a curriculum for children with deafblindness/multisensory impairment. Educatia 2010, 21, 145–150. [Google Scholar]

- Do, T.N.; Phan, H.; Nguyen, T.Q.; Visell, Y. Soft Electromagnetic Actuators: Miniature Soft Electromagnetic Actuators for Robotic Applications. Adv. Funct. Mater. 2018, 28, 1800244. [Google Scholar] [CrossRef]

- Caporusso, N.; Trizio, M.; Perrone, G. Pervasive assistive technology for the deaf-blind need, emergency and assistance through the sense of touch. In Pervasive Health; Springer: Berlin/Heidelberg, Germany, 2014; pp. 289–316. [Google Scholar]

- Ozioko, O.; Hersh, M.A. Development of a Portable Two-way Communication and Information Device for Deafblind People. In Proceedings of the 13th AAATE International Conference, Budapest, Hungary, 9–12 September 2015; pp. 518–525. [Google Scholar]

- Busch-Vishniac, I.J. The case for magnetically driven microactuators. Sens. Actuators A Phys. 1992, 33, 207–220. [Google Scholar] [CrossRef]

- Genolet, G.; Lorenz, H. UV-LIGA: From development to commercialization. Micromachines 2014, 5, 486–495. [Google Scholar] [CrossRef]

- Schlesinger, M.; Paunovic, M. Modern Electroplating; John Wiley & Sons: Hoboken, NJ, USA, 2011; Volume 55. [Google Scholar]

| Technology | Tactile Sensing | Disp. (µm) | Type | Current Req. (mA) | Voltage Req. | Freq (Hz) | Ref. |

|---|---|---|---|---|---|---|---|

| Piezoelectric | No | 0.257 | ET | <250 | 80 Vpk | 250 | [41] |

| Electromagnetic | 1000 | ET | 0.250 | 5 V | N/A | [42,43] | |

| Electrostatic | No | N/A | ET | <200 | 2000 Vp–p | 100–400 | [44] |

| Electroactive Polymer | No | 680 | LST | N/A | 5 kV/mm | 0.1–300 | [45] |

| Thermal | 61 | ET | N/A | 28.7 V | N/A | [46] | |

| Electrotactile | No | N/A | ET | N/A | 9.3–63.4 V | 20 | [47] |

| ERM Motor | No | NA | LST | 72 | 5 V | 208 | [39,48] |

| SMA | No | up to 2000 | ET | N/A | 120 mA | 2 | [49,50] |

| Pneumatic | No | 560 | ET | N/A | N/A | 0.2–20 | [51] |

| Electrorheological Fluid | No | 700 | LST | N/A | 4 kV | 10 | [52] |

| Electromagnetic | Capacitive | 377 | LST | 100 mA | 3–5 V | 10–200 | This Work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozioko, O.; Navaraj, W.; Hersh, M.; Dahiya, R. Tacsac: A Wearable Haptic Device with Capacitive Touch-Sensing Capability for Tactile Display. Sensors 2020, 20, 4780. https://doi.org/10.3390/s20174780

Ozioko O, Navaraj W, Hersh M, Dahiya R. Tacsac: A Wearable Haptic Device with Capacitive Touch-Sensing Capability for Tactile Display. Sensors. 2020; 20(17):4780. https://doi.org/10.3390/s20174780

Chicago/Turabian StyleOzioko, Oliver, William Navaraj, Marion Hersh, and Ravinder Dahiya. 2020. "Tacsac: A Wearable Haptic Device with Capacitive Touch-Sensing Capability for Tactile Display" Sensors 20, no. 17: 4780. https://doi.org/10.3390/s20174780

APA StyleOzioko, O., Navaraj, W., Hersh, M., & Dahiya, R. (2020). Tacsac: A Wearable Haptic Device with Capacitive Touch-Sensing Capability for Tactile Display. Sensors, 20(17), 4780. https://doi.org/10.3390/s20174780